Patents

Literature

53results about How to "Variable speed realization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

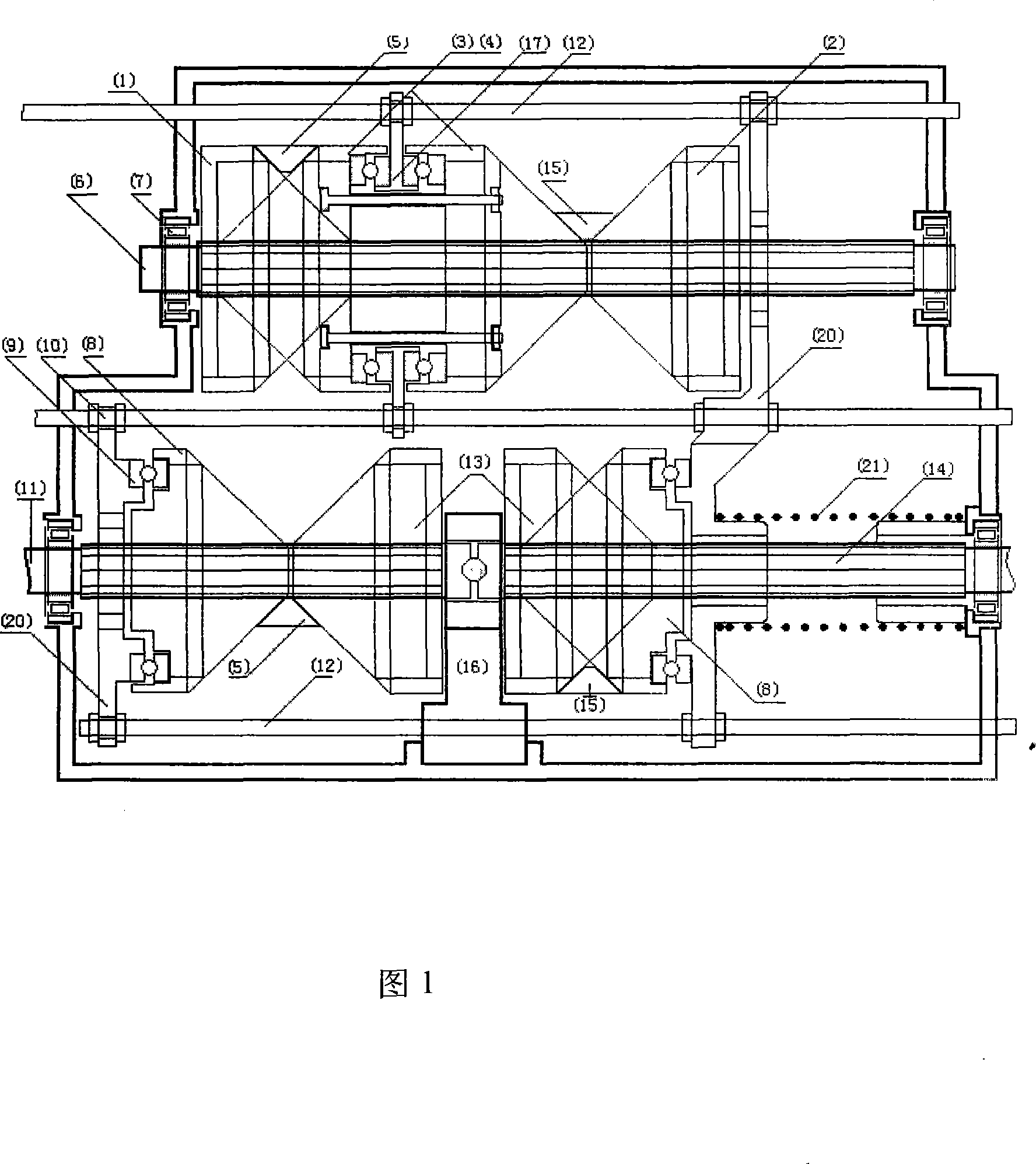

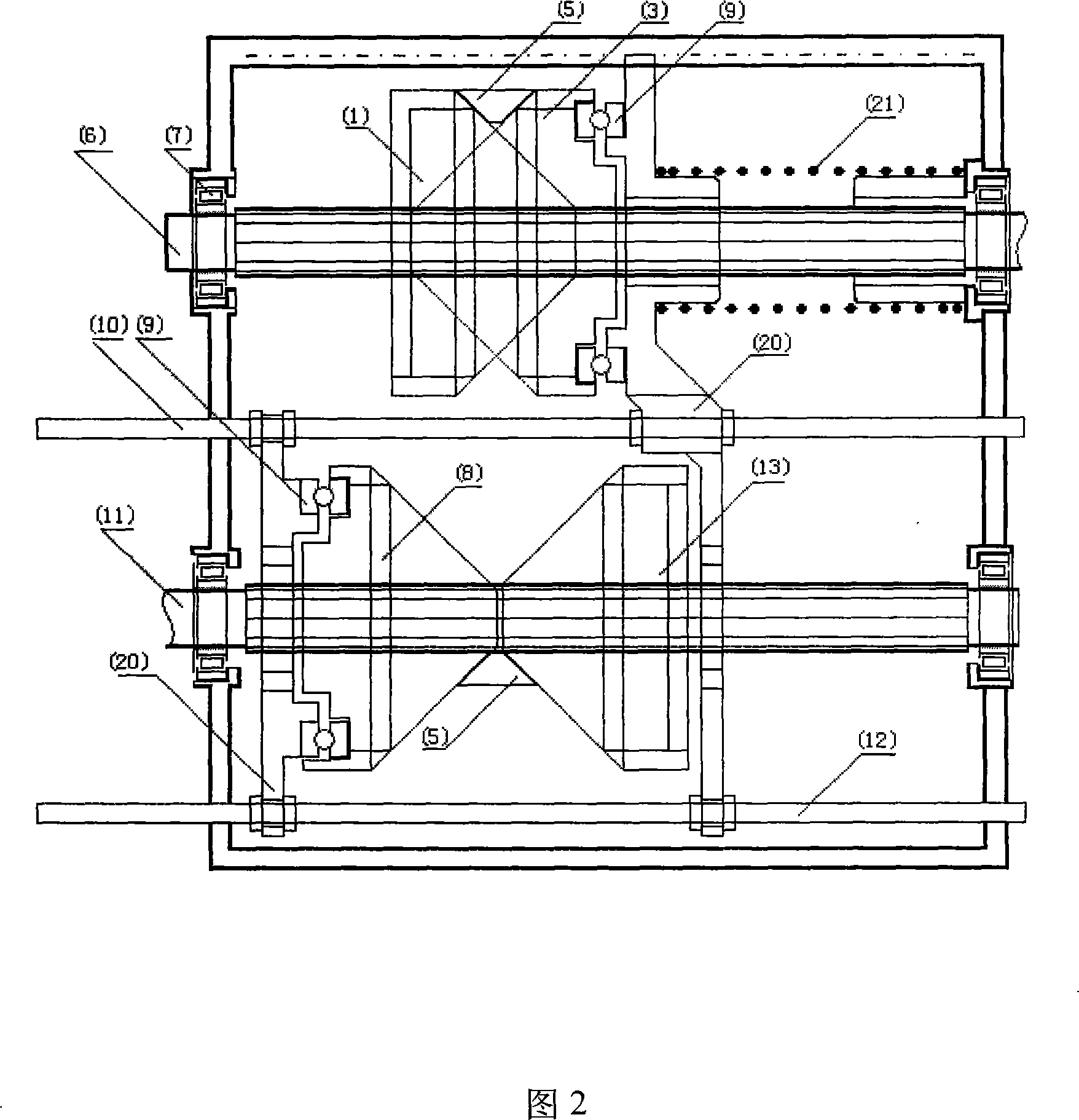

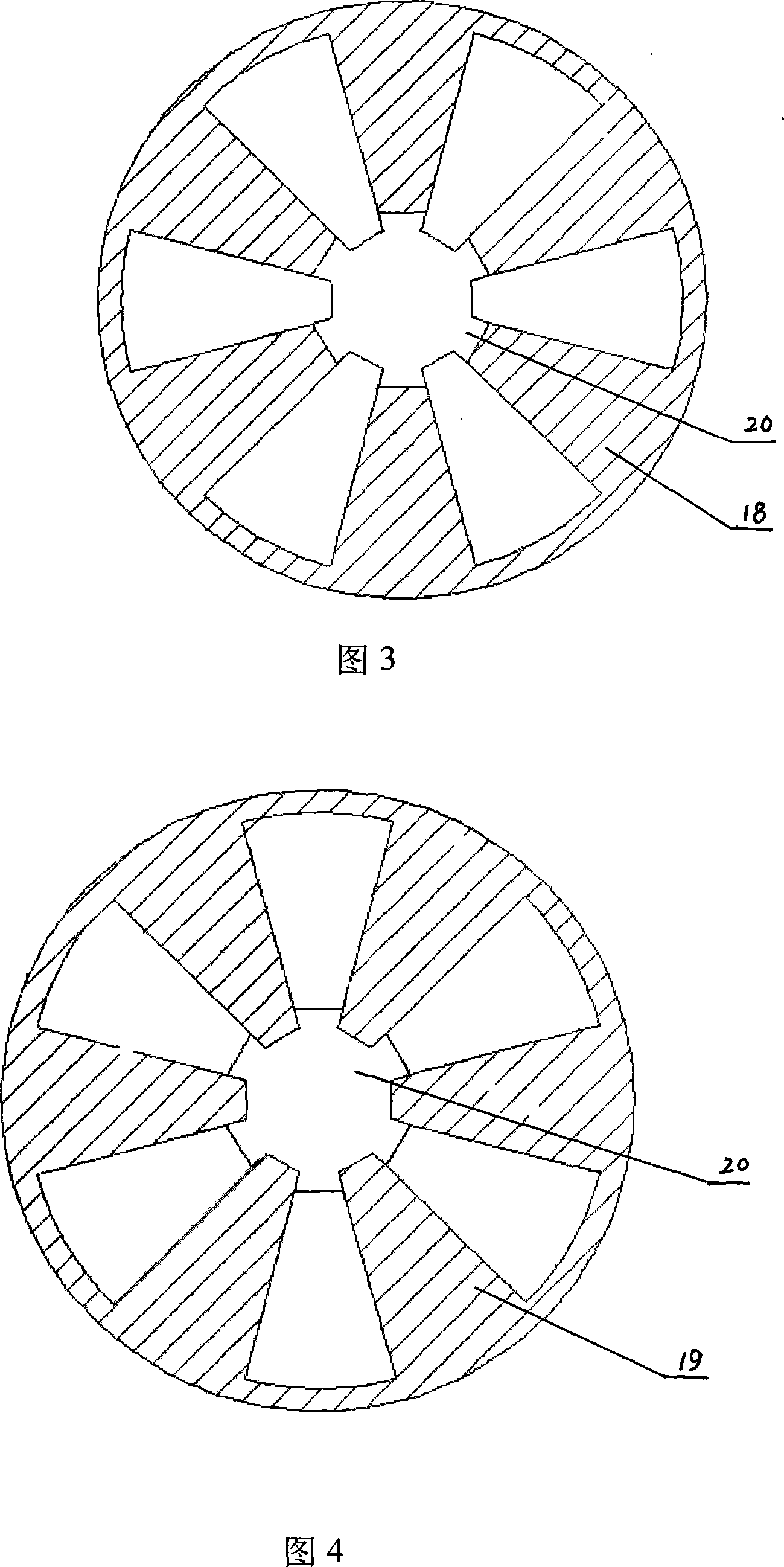

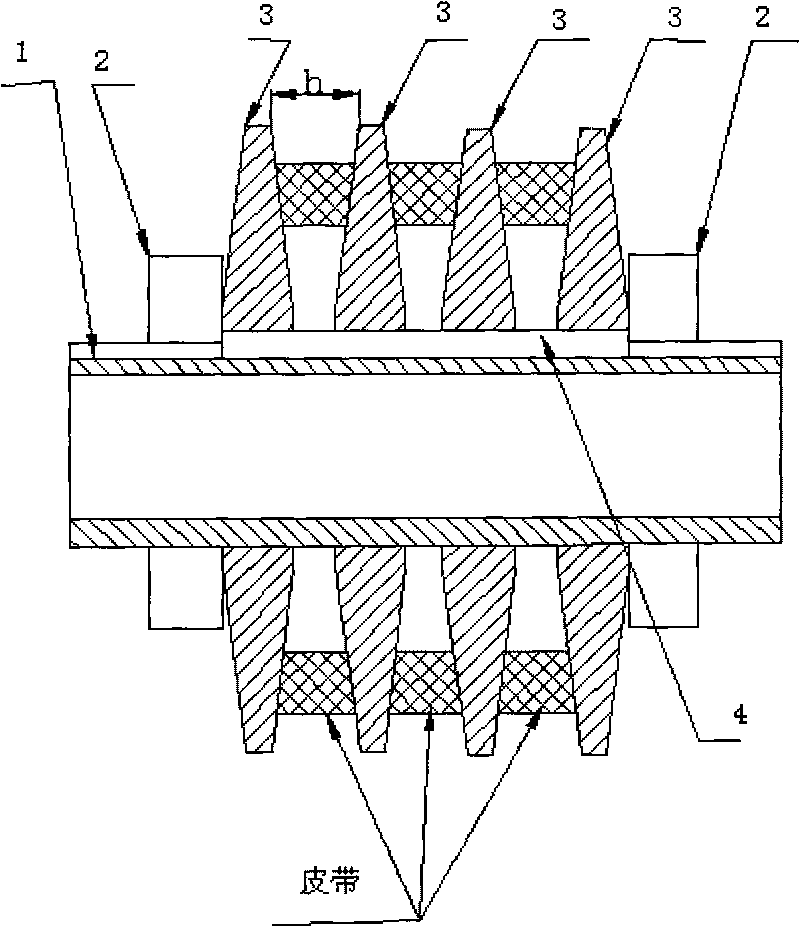

Complementary wheels balancing stepless speed changer

InactiveCN101235885ATo achieve the purpose of speed regulationNot easy to slipGearingFriction forceBalanced line

The invention belongs to the technical field of mechanical transmission, in particular improved stepless transmission with balanced male and female wheels of mechanical transmission, which comprises an active input unit and a primary slave output unit, wherein the active input unit and the primary slave output unit are connected by driving belts, the active input unit is provided with a pair of female wheel and male wheel which are capable of interlacing, the female wheel and the male wheel are equipped with interlacing conical faces which are complementary, the female wheel is fixed on an active output shaft, the male wheel sleeves the active output shaft and can slide left and right, the composition of the primary slave output unit is the same with the active input unit, additionally a regulating mechanism is included, and the regulating mechanism simultaneously drives the main input unit and the male wheel in the primary slave output unit to slide left and right on respective shaft. Because of the specific composition, male and female interlacing complementary structure is formed on the surfaces of the female wheel and the male wheel, the driving belts are attached to the intercrossing surface of the female wheel and the male wheel, have a big stress face and are pushed against by a sliding block inclined surface, the driving belts is radially formed into an S shape for bearing force, thereby increasing the friction, enabling the driving belts to be not easy to slip, and meeting the specific requirement of conventional CTV structure to driving belts.

Owner:寸亚西

Vehicle two-stage transmission main reducer assembly

InactiveCN104455232AVariable speed realizationRealize differential operationGearboxesToothed gearingsLow speedReduction drive

The invention provides a vehicle two-stage transmission main reducer assembly. The vehicle two-stage transmission main reducer assembly comprises an input shaft, wherein the input shaft passes through a box and extends into the box; a bevel gear is arranged at the end, extending into the box, of the input shaft; the bevel gear is meshed with a main driven gear; the main driven gear is fixedly arranged on a driven shaft; a gear hub and a gear sleeve are fixedly arranged on the driven shaft; the gear sleeve can be driven by a shifting fork to move left and right; a high-speed driving gear and a low-speed driving gear are respectively arranged on two sides of the gear sleeve; the gear sleeve is respectively meshed with the end faces of the high-speed driving gear and the low-speed driving gear; the driven shaft is sleeved by the high-speed driving gear and the low-speed driving gear idly; the high-speed driving gear is meshed with a high-speed driven gear; the low-speed driving gear is meshed with a low-speed driven gear; the high-speed driving gear and the low-speed driven gear are respectively connected with a differential mechanism; two independent half shafts are arranged on the two sides of the differential mechanism respectively. The vehicle two-stage transmission main reducer assembly implements the deceleration function through the bevel gear and the main driven gear, and implements the transmission function of the reducer through the high-speed gear and the low-speed gear.

Owner:CHONGQING XIANYOU TECH DEV

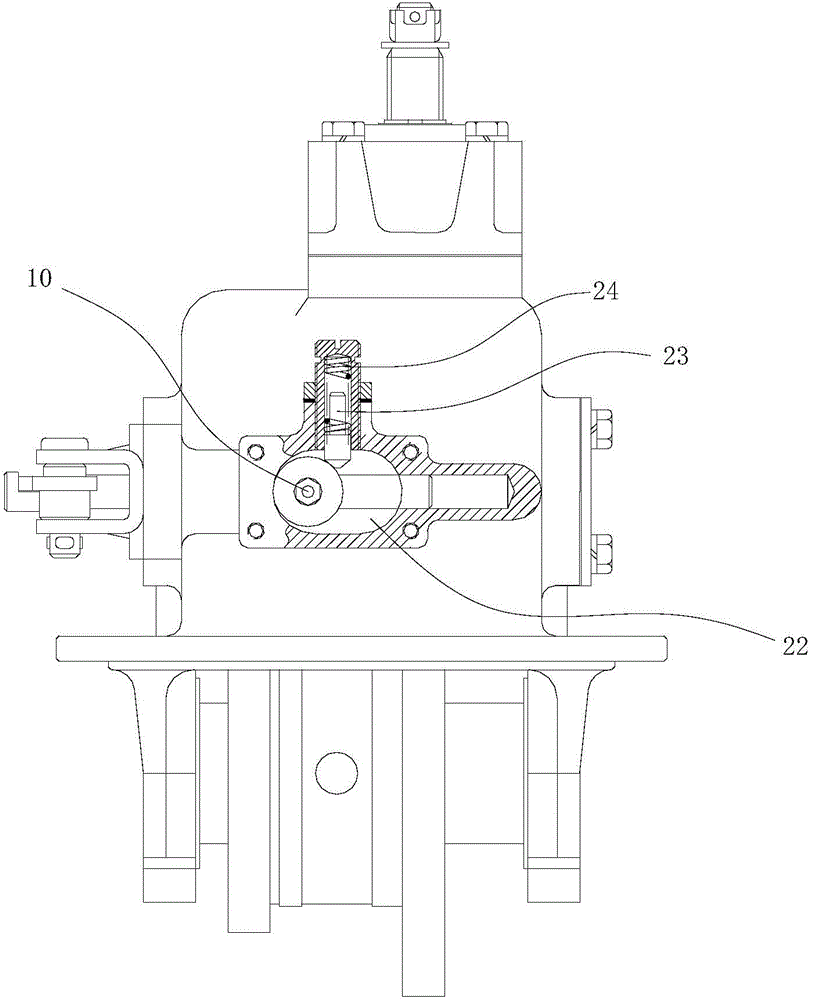

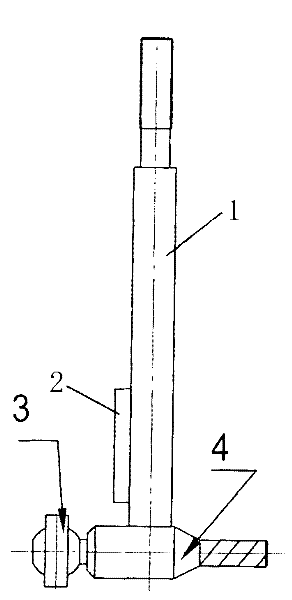

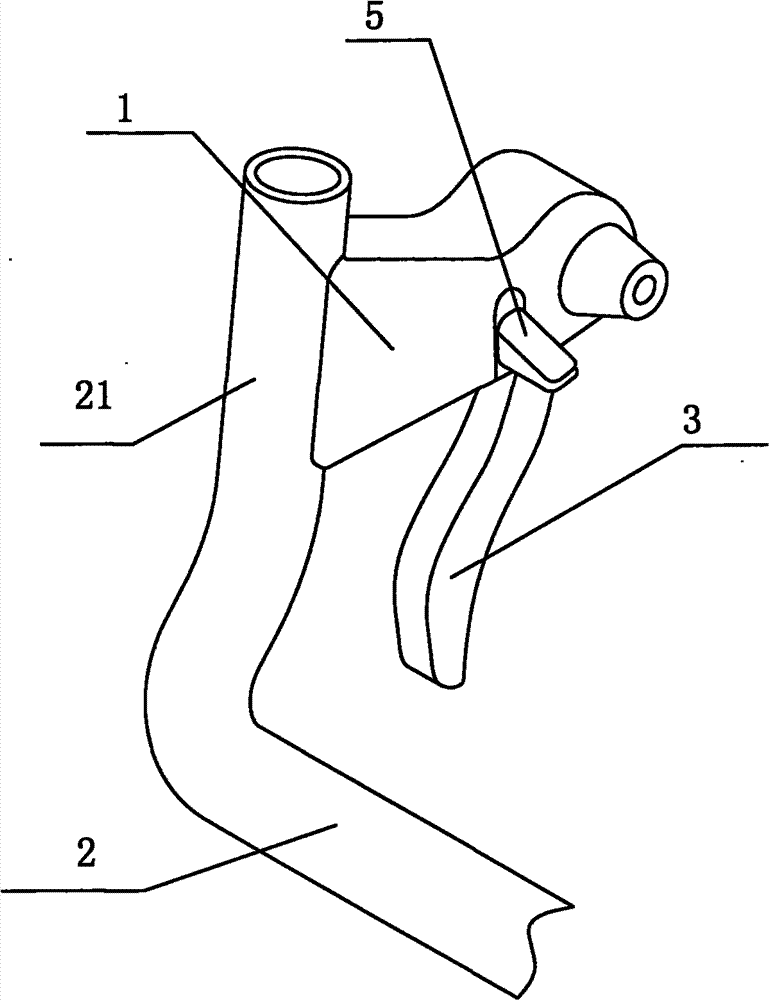

Fork-limited two-stage speed change main reducer assembly

InactiveCN104405829AVariable speed realizationRealize differential operationControlled membersToothed gearingsReduction driveDrive shaft

The invention provides a fork-limited two-stage speed change main reducer assembly. The assembly comprises an input shaft, wherein the inner end, penetrating through a box body, of the input shaft is provided with a bevel gear; the bevel gear is engaged with a main driven gear; the main driven gear is fixedly arranged on a driven shaft; the driven shaft is also fixedly provided with a gear hub and a gear sleeve; the gear sleeve can move left and right through driving of a fork; the tail end of the fork pulls the gear sleeve to move; the other end of the fork is fixed to a fork shaft through a pin; the fork shaft penetrates through the box body; the tail end of the fork shaft is hinged to a shift arm; the middle position of the shift arm is hinged to a shift arm bracket; the fork is arranged in a fork hole; the fork hole is an elliptical hole; the side edge of the fork hole is provided with a positioning hole; a positioning pin is arranged in the positioning hole; the root part of the positioning pin is provided with a spring. The shift arm is pulled to rotate around the hinge point of the bracket, and the fork shaft is driven to move left and right, and the gear sleeve is pulled to move.

Owner:CHONGQING XIANYOU TECH DEV

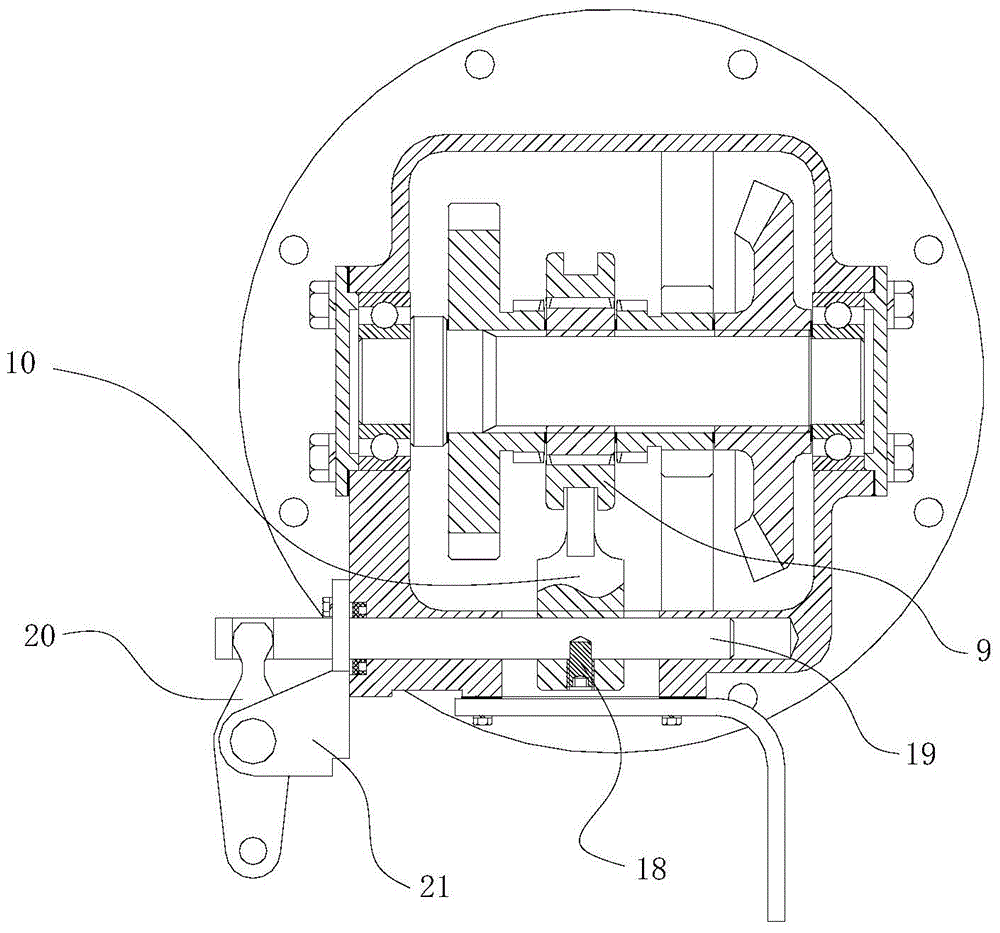

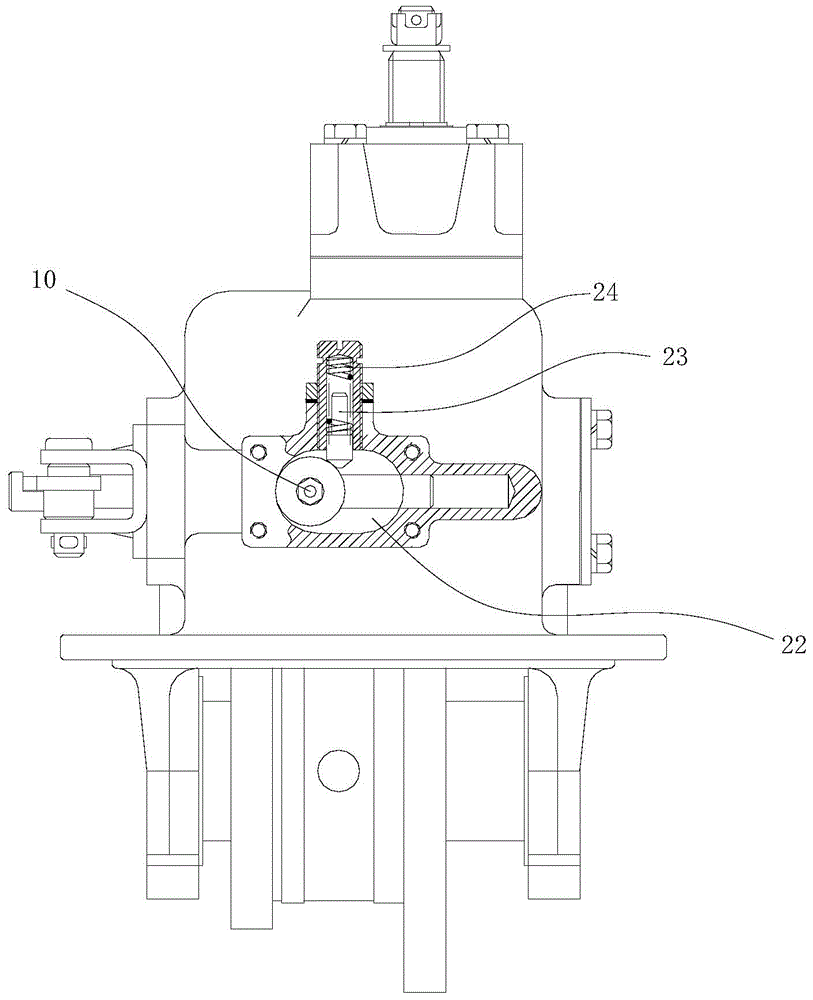

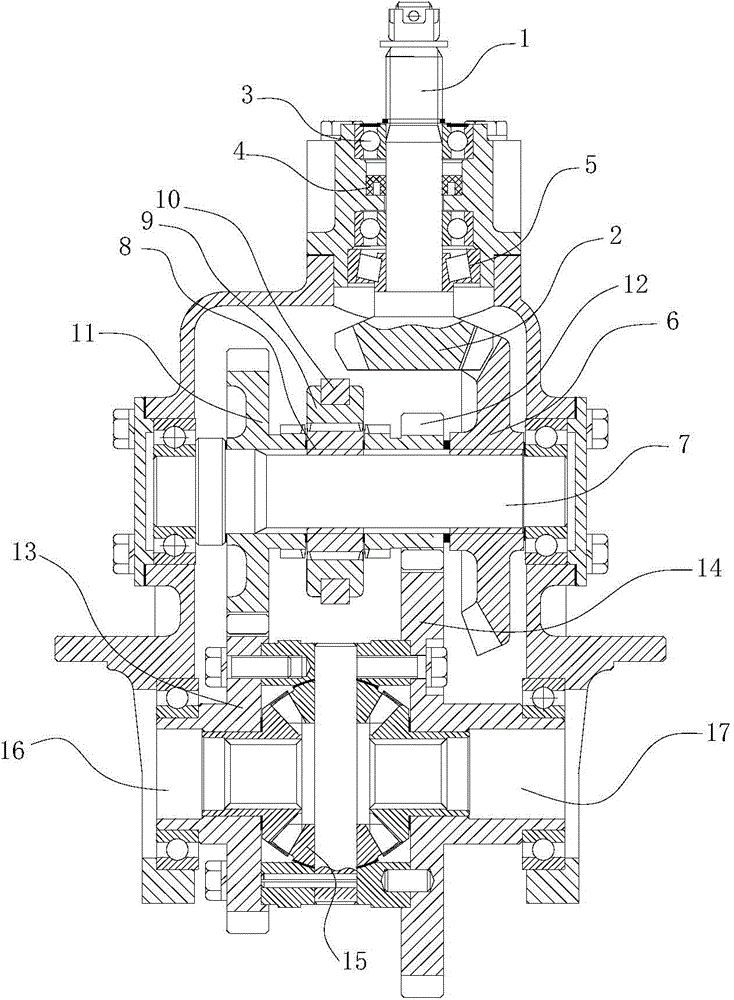

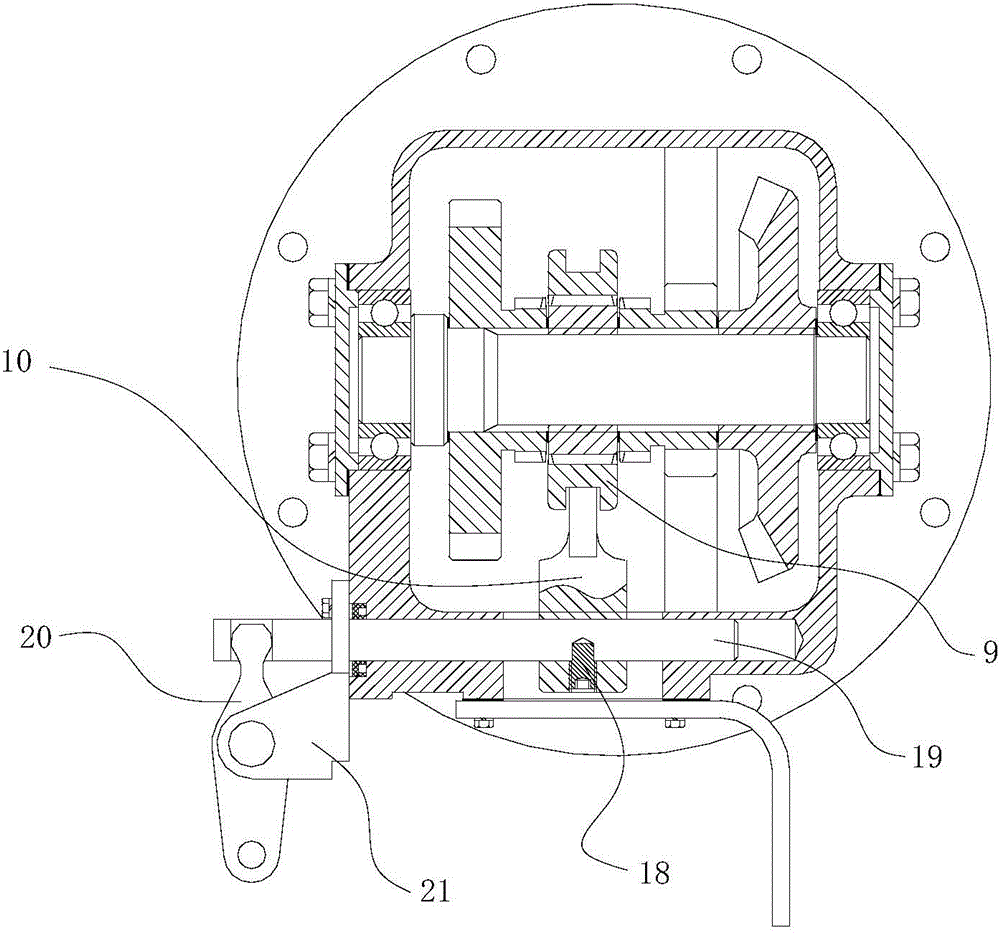

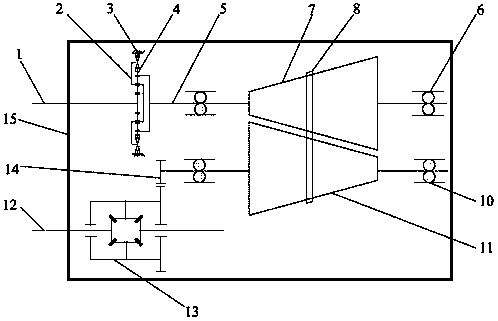

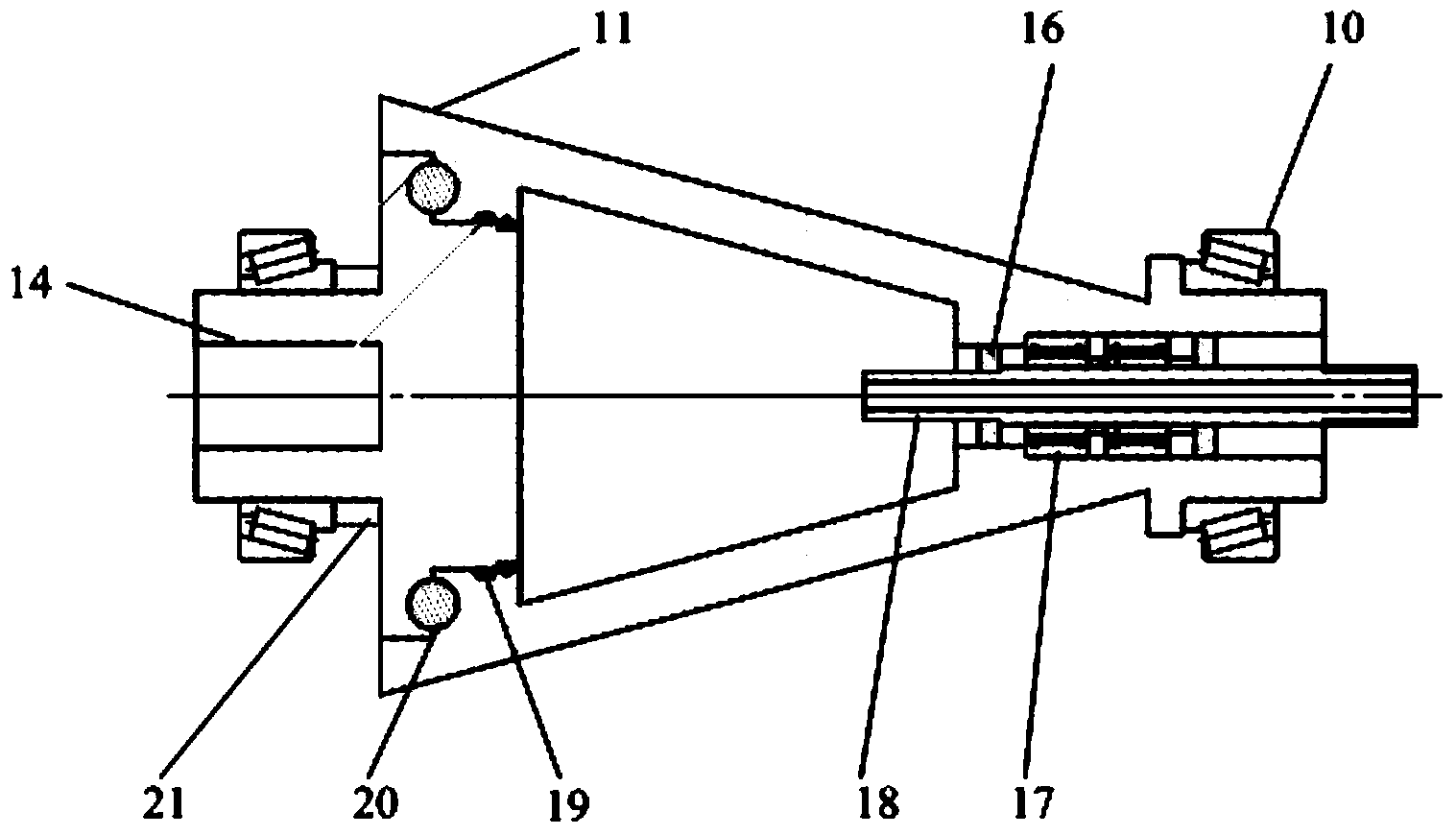

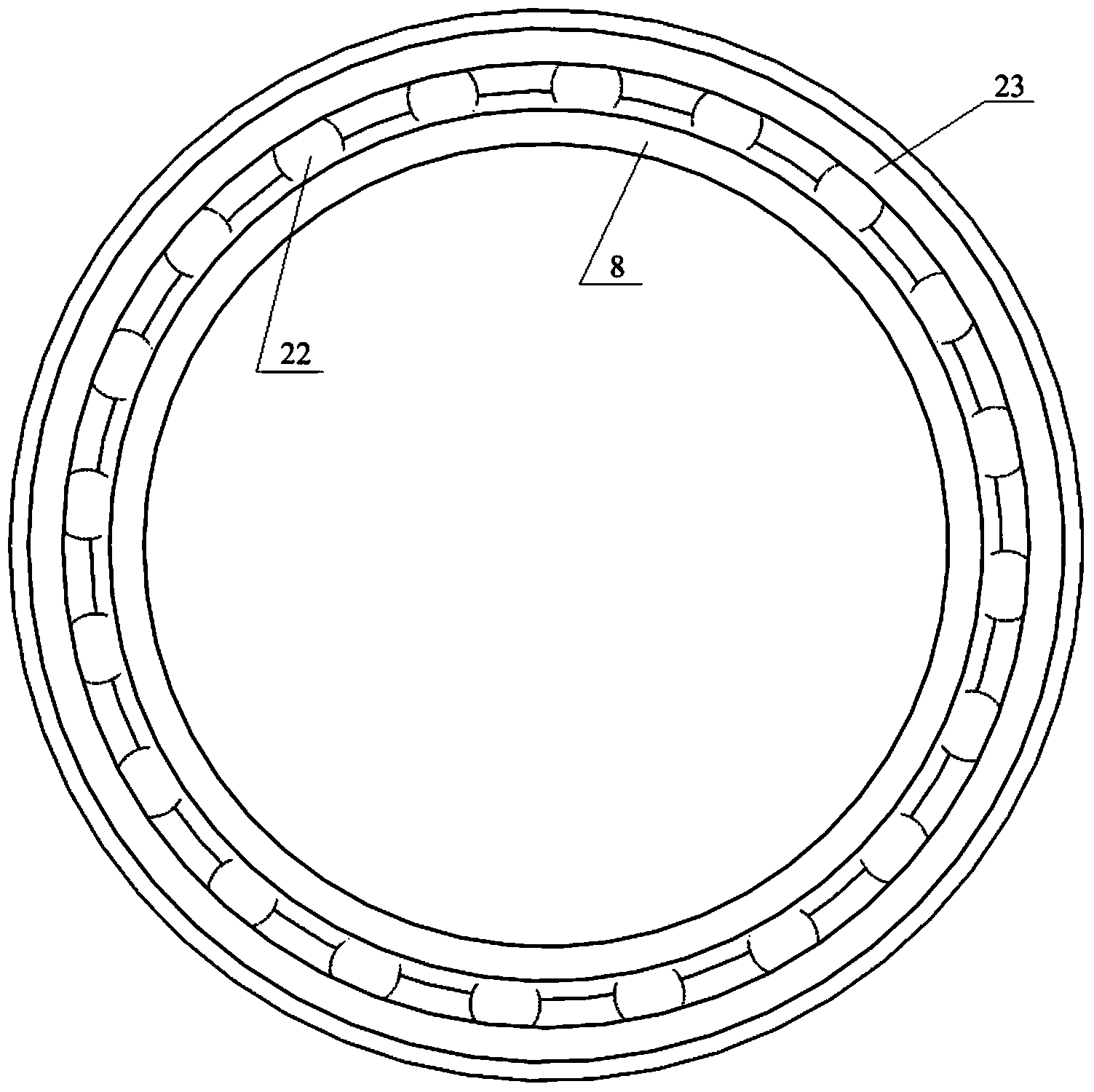

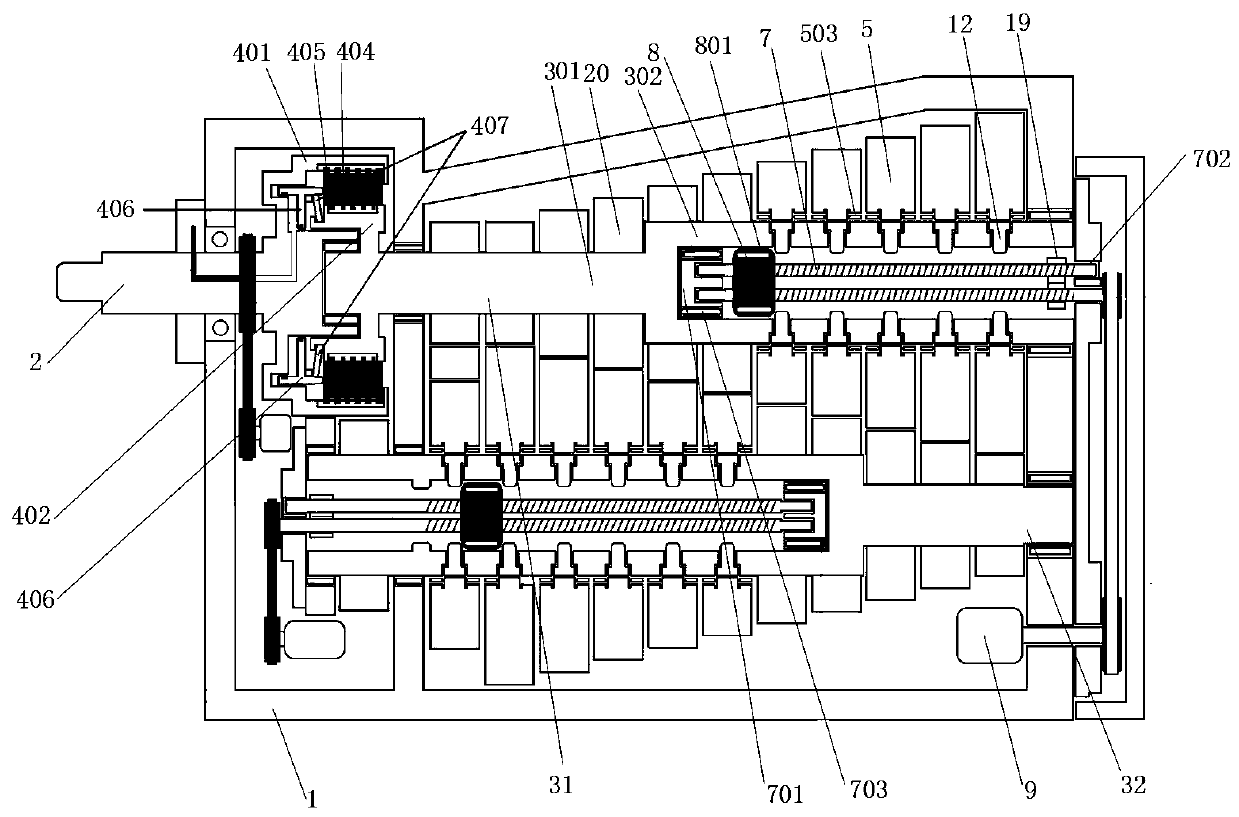

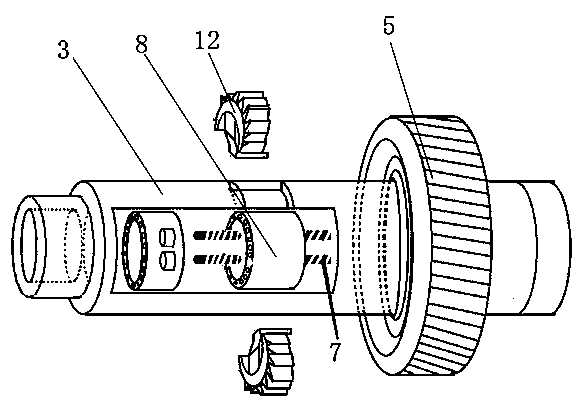

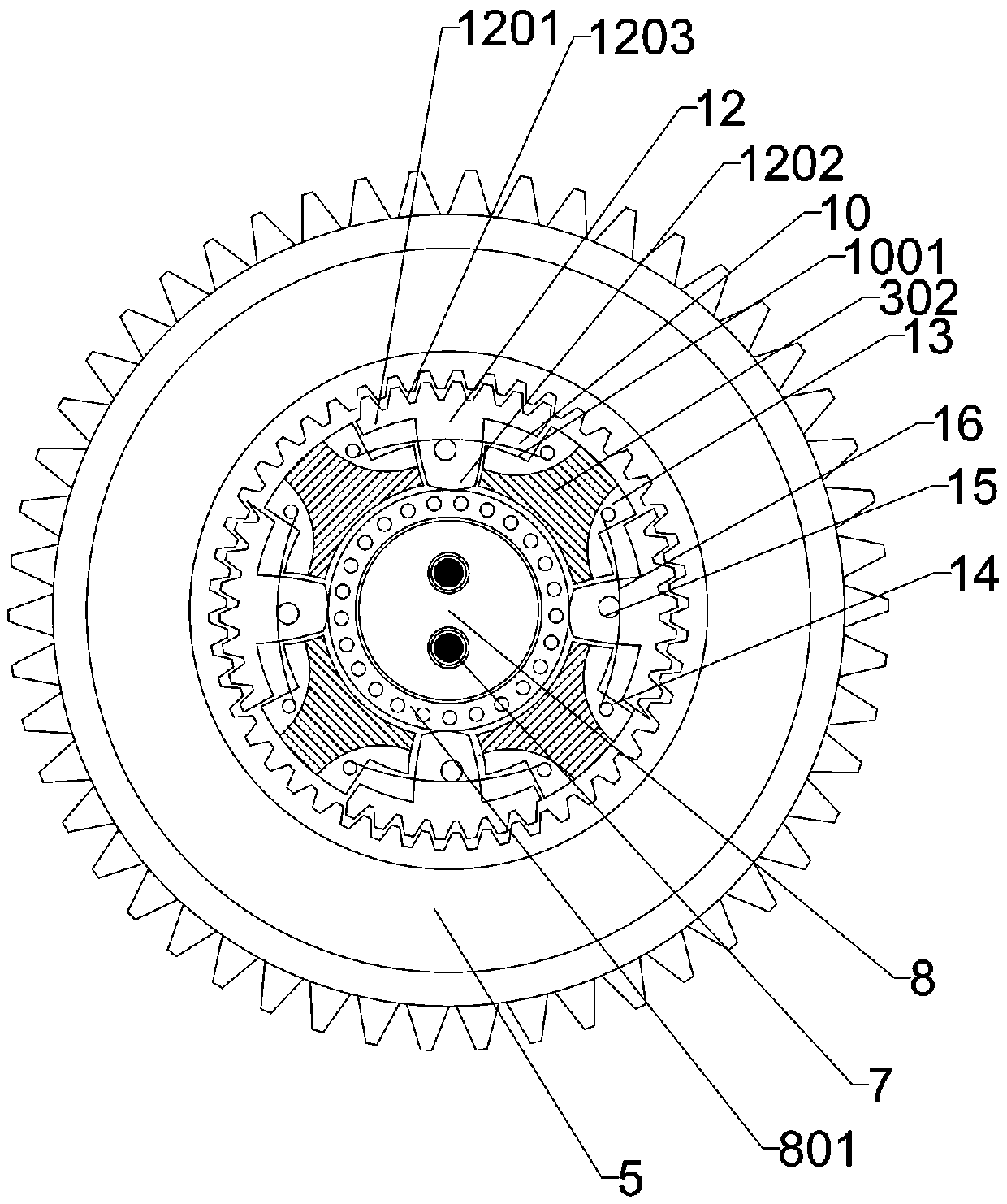

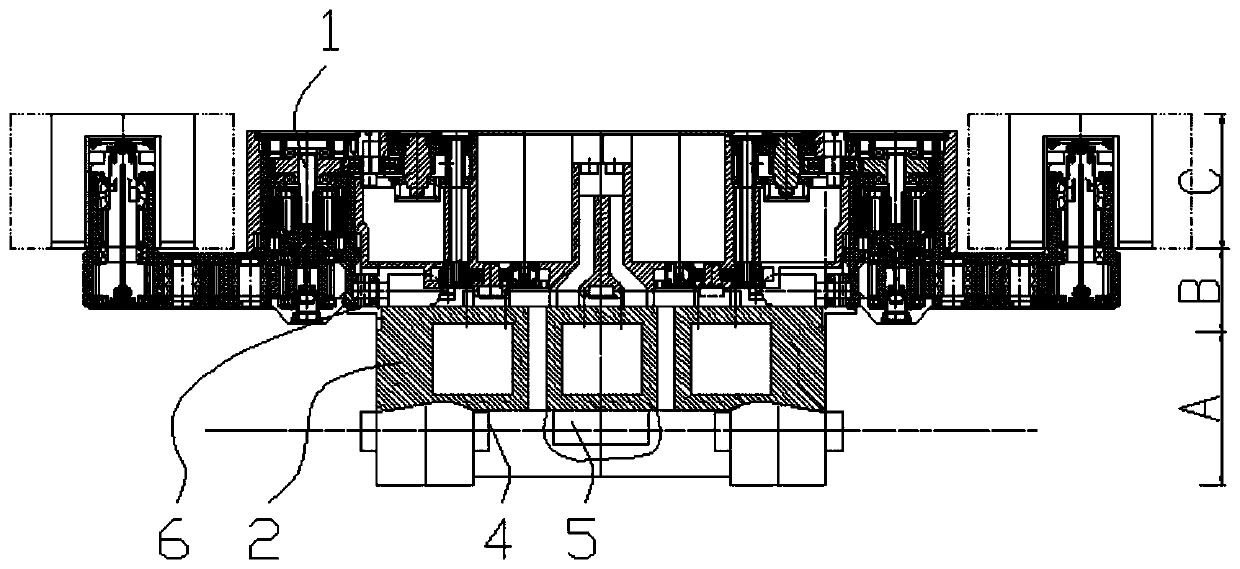

Internal contact conical ring type continuously-variable transmission

ActiveCN103807394AReduce stressExtended service lifeGearing controlGearing detailsGear wheelEngineering

The invention discloses an internal contact conical ring type continuously-variable transmission. Two conical wheels are in internal contact with two conical rings respectively, the stress of a contact area is small, and the service life can be improved. Meanwhile, the reliability is high and the power transmission efficiency is high. The continuously-variable transmission comprises a shell, an input shaft, a planetary line, the input conical wheel, the conical rings, the output conical wheel, an output shaft, a differential mechanism, an output gear, a loading mechanism and a speed changing mechanism, wherein the input shaft, the planetary line, the input conical wheel, the conical rings, the output conical wheel, the output shaft, the differential mechanism, the output gear, the loading mechanism and the speed changing mechanism are located in the shell. Power is transmitted between the output conical wheel and the input conical wheel through the conical rings which are arranged outside the two conical wheels in a sleeved mode. The loading mechanism is a hydraulic-mechanical loading mechanism formed by coupling a hydraulic part and a mechanical part. The speed changing mechanism is of a structure similar to a bearing, and speed changing is realized by pushing an outer ring to drive the conical rings.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

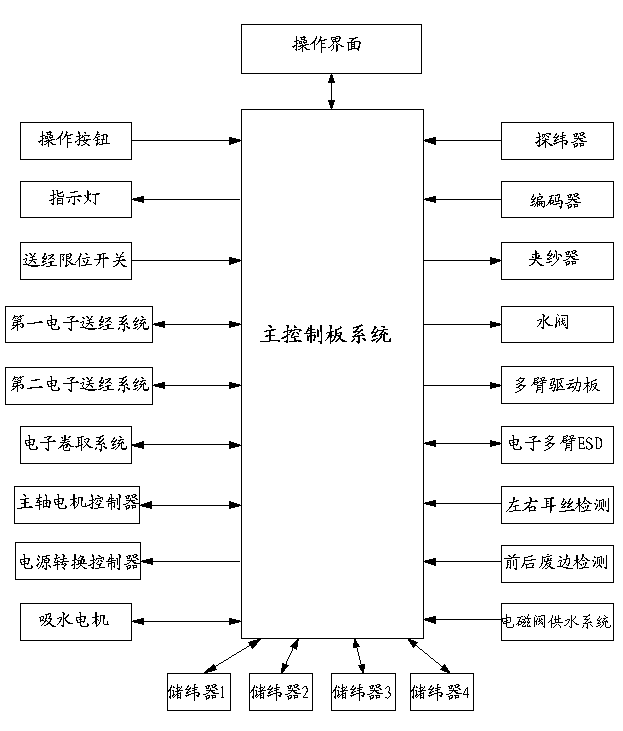

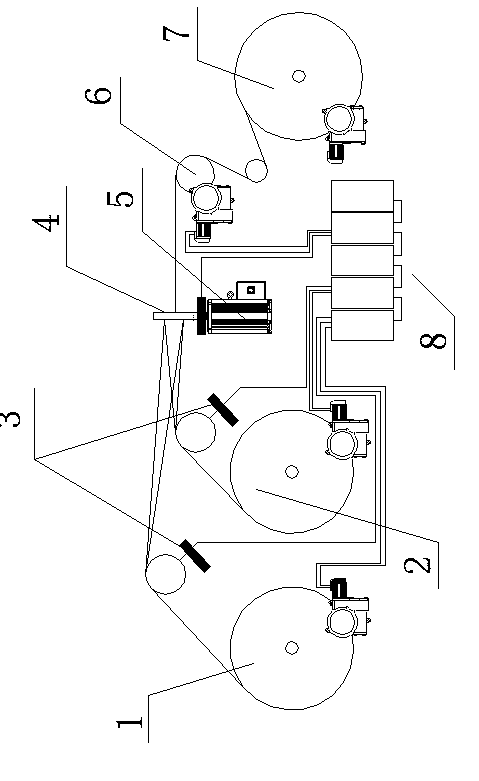

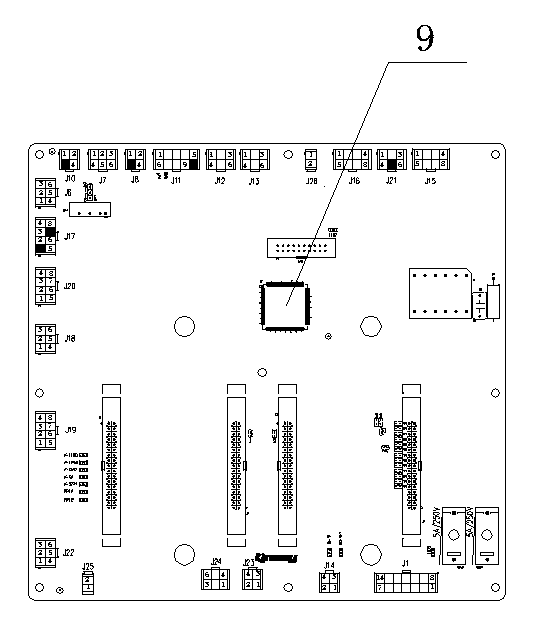

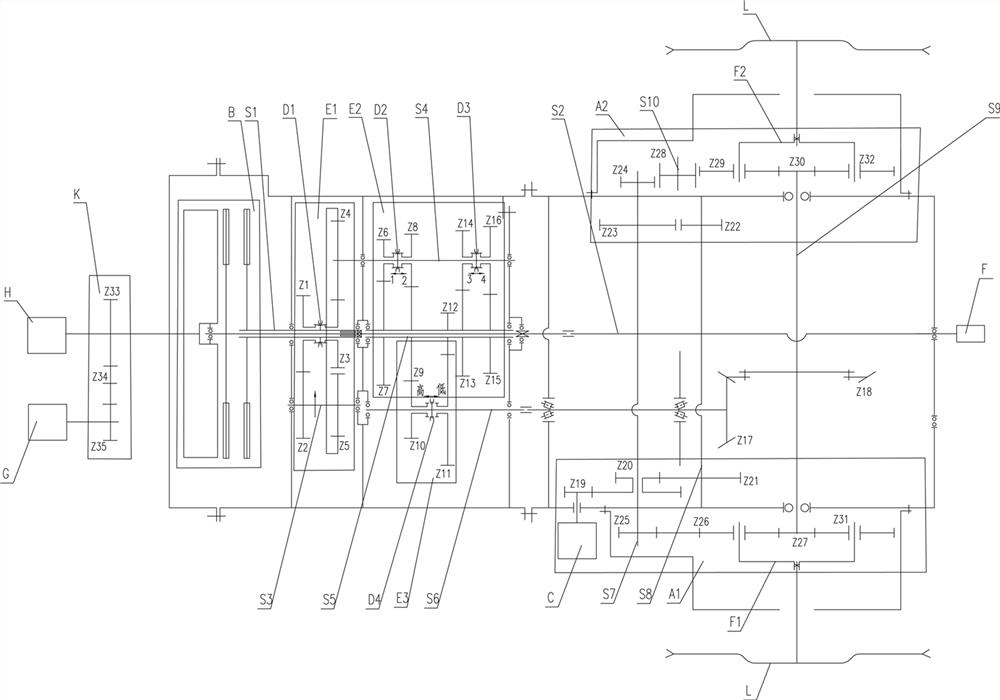

Variable-speed weaving control system, a running method of variable-speed weaving control system and water-jet loom with variable-speed weaving control system

The invention discloses a variable-speed weaving control system which comprises a main control panel system, a motor controller and a peripheral water-jet loom auxiliary device. The main control panel system comprises a core main control panel, an interface circuit switching plate and a power source driving plate. The motor controller comprises a weft accumulator, an electronic take-up system, an electronic warp let-off system and a main shaft motor controller. The peripheral water-jet loom auxiliary device comprises a water valve, a yarn gripper and a weft feeler. The variable-speed weaving control system further comprises a multi-arm driving plate electrically connected with the main control panel system, a brake driving plate and an operating interface. A main shaft motor is electrically connected to the main shaft motor controller. The main shaft motor is a servo motor. Due to the fact that the servo motor is adopted as the main shaft motor, the rotating speed of a water-jet loom can be freely adjusted, a belt pulley does not need to be replaced, workloads are reduced, working efficiency is improved, device faults are avoided, the maintenance cost and the use cost are reduced, variable speeds of an electric control portion are achieved, the weft density can be adjusted as needed, and the application range is wide.

Owner:SHANGHAI INVT INDUSTRY TECHNOLOGY CO LTD

Three-gear speed changing wheel based on electromagnetic gear shift

PendingCN105501044AReduce usageVariable speed realizationGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingGear wheelDrive shaft

The invention belongs to the technical field of speed changing, and particularly relates to a three-gear speed changing wheel based on electromagnetic gear shift. The three-gear speed changing wheel comprises a three-gear wheel hub, three-gear wheel transmission gears, three-gear wheel driving gears, three-gear wheel driving gear clutch mechanisms, three-gear wheel driving shaft circular sections and three-gear wheel driving shaft non-circular sections, the three driving gears are mounted on a driving shaft and meshed with the three transmission gears which are meshed with inner teeth of the inner surface of the hub, the driving gears and the transmission gears are meshed respectively to form three transmission ratios, and one driving gear clutch mechanism is mounted on each of the three driving gears; the driving gear clutch mechanisms can engage and disengage a transmission relation between the driving shaft and the driving gears to enable the driving shaft to selectively drive one driving gear, a driving ratio is determined at the same time, and in this way, the wheel is driven through meshing between the transmission gears and the inner teeth of the hub. Speed changing of the wheel itself is realized through three-gear driving, so that a transmission is omitted and the three-gear speed changing wheel has good actual effect.

Owner:FUZHOU MAILIAO AUTOMATION EQUIP CO LTD

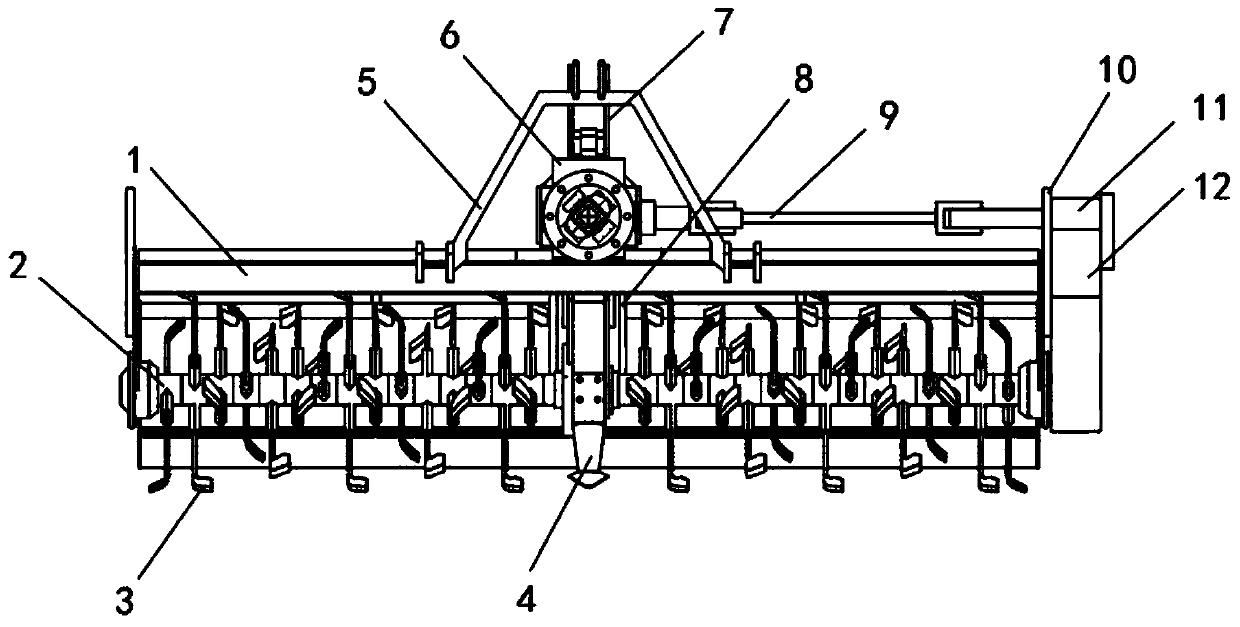

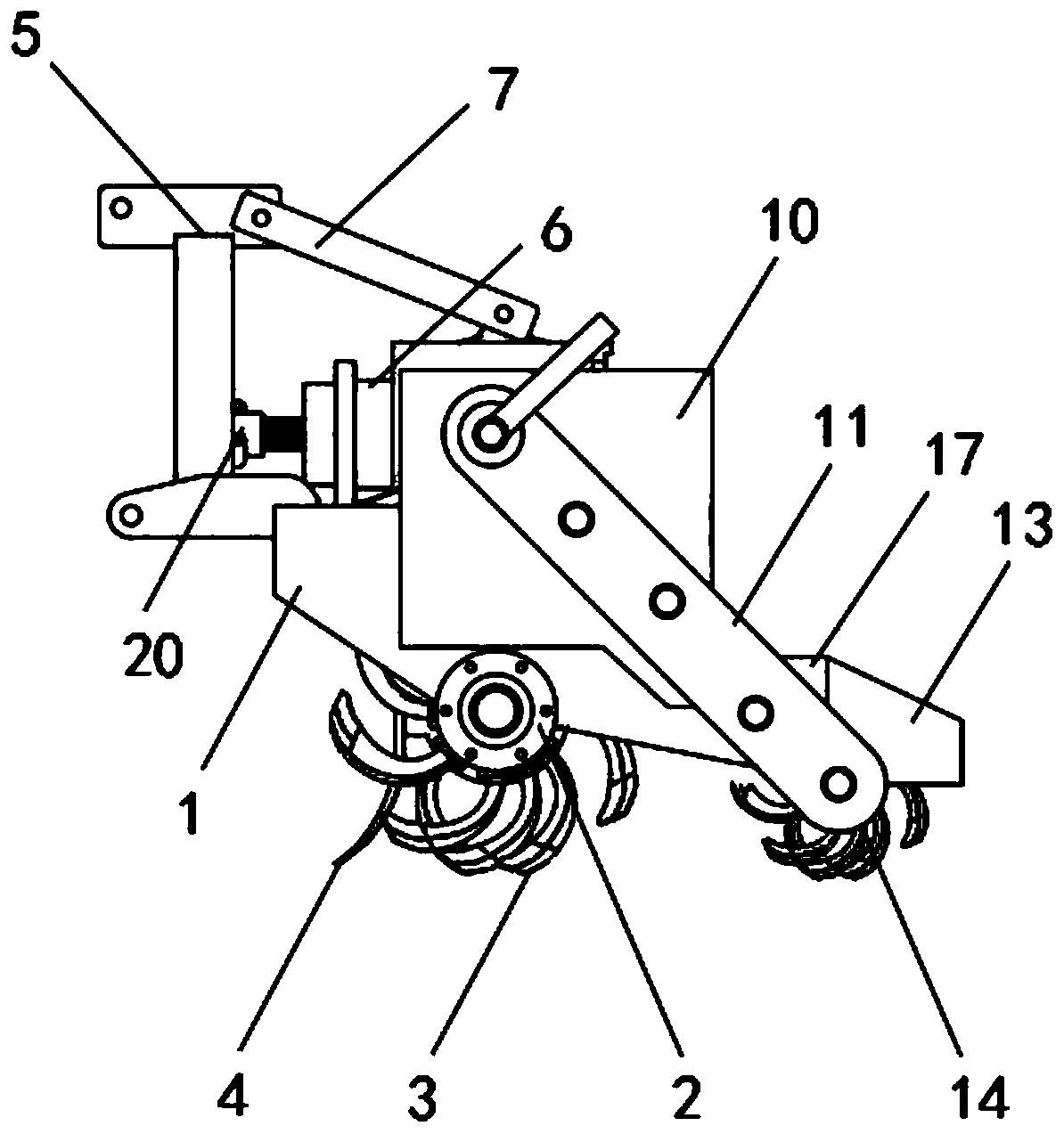

Double-shaft rotary cultivator

InactiveCN110583118AReduce manufacturing costRotary tillage thoroughlySpadesAgricultural machinesAgricultureEngineering

The invention discloses a double-shaft rotary cultivator which comprises a main frame and a rear supporting plate. The back side of the main frame is connected with the rear supporting plate, a main cutter shaft is arranged in the main frame, a plurality of uniformly distributed rotary tillage blades are arranged on the main cutter shaft, and a main gear box is arranged in the middle of the main frame. A front beam of the main frame is provided with a portal frame, left and right suspension plates are arranged on two sides of the lower portion of the portal frame and form three-point suspension with the portal frame, the upper portion of a side gear box is provided with a shift lever for adjusting the speed of rotation, and two lengthened shafts of the main gear box and an upper spline shaft of the side gear box are connected through universal joints to transmit power. By adopting the double-shaft rotary cultivator, the defect can be overcome that traditional rotary cultivators are divided into single-shaft rotary cultivators and double-shaft rotary cultivators, single shafts only utilize rotary tillage blades on the shafts for rotary tillage in use, and accordingly the rotary tillage effect is poor and rotary tillage is unthorough; although each traditional double-shaft rotary cultivator is provided with two shafts with rotary tillage blades, the side gear box of the transmitted double-shaft rotary cultivator is single in rotation speed, an auxiliary shaft is also constant in rotation speed, and different agriculture demands cannot be met.

Owner:泗县伟达农机具有限公司

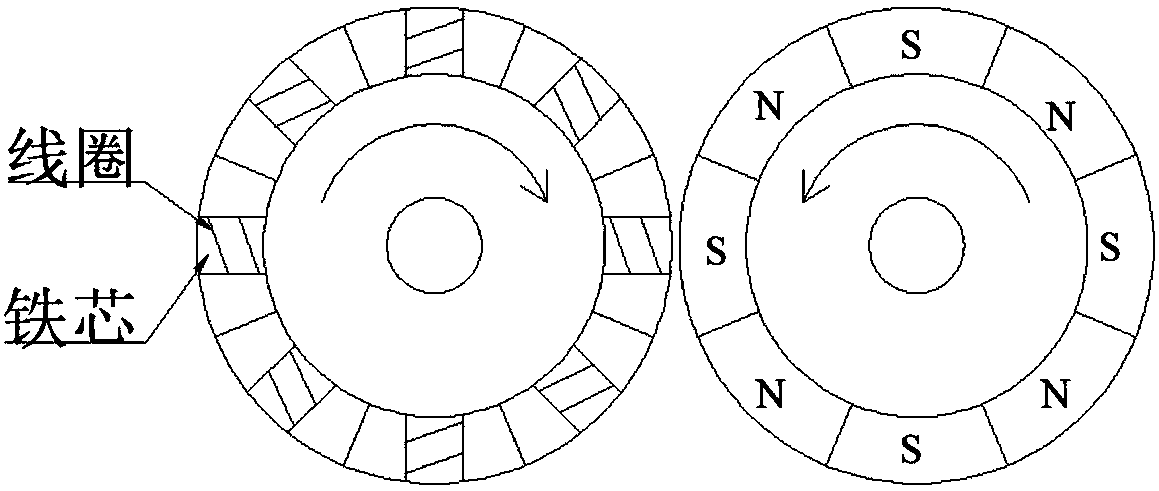

Electromagnetic mixed toothless ring planetary gear shifting system

InactiveCN108206622AAvoid errorsAchieve movementPermanent-magnet clutches/brakesGear wheelElectrical and Electronics engineering

The invention discloses an electromagnetic mixing toothless ring planetary gear shifting system, which comprises an input shaft, an input planet carrier and a plurality of electromagnetic gears are arranged on the input shaft, and the electromagnetic gears are respectively controlled to work by four switches, each electromagnetic gear and the multiple evenly arranged output magnetic gears form a group, the centers of the multiple output magnetic gears which are in different groups but the in the same direction are on the same straight line and are connected with a same planetary rotating shaftI which is connected with an output planet carrier, the input planet carrier is connected with a planetary rotating shaft II which is eccentrically connected with a plurality of output magnetic gearswhich are in different groups but in the same direction.

Owner:SHANDONG UNIV

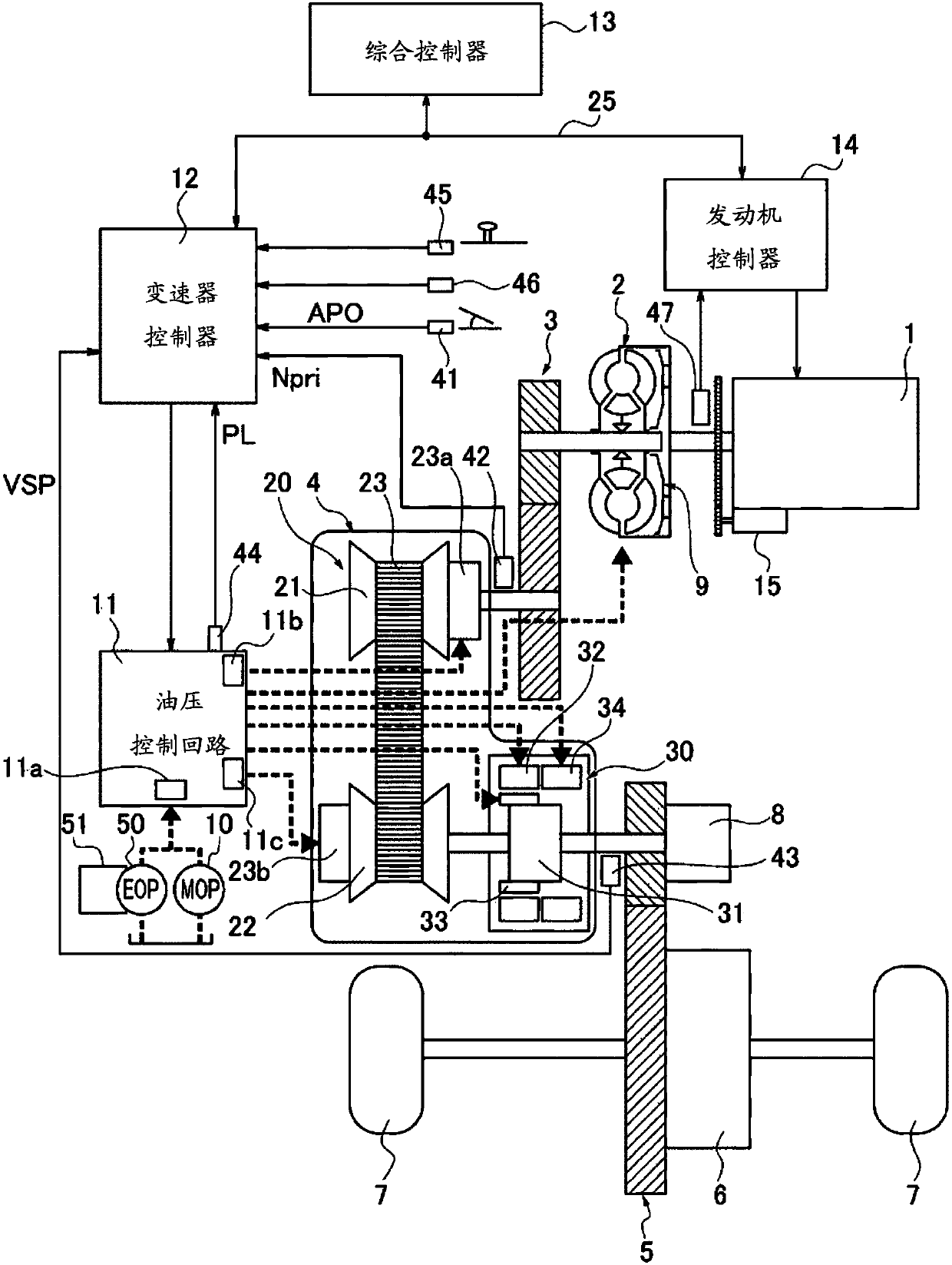

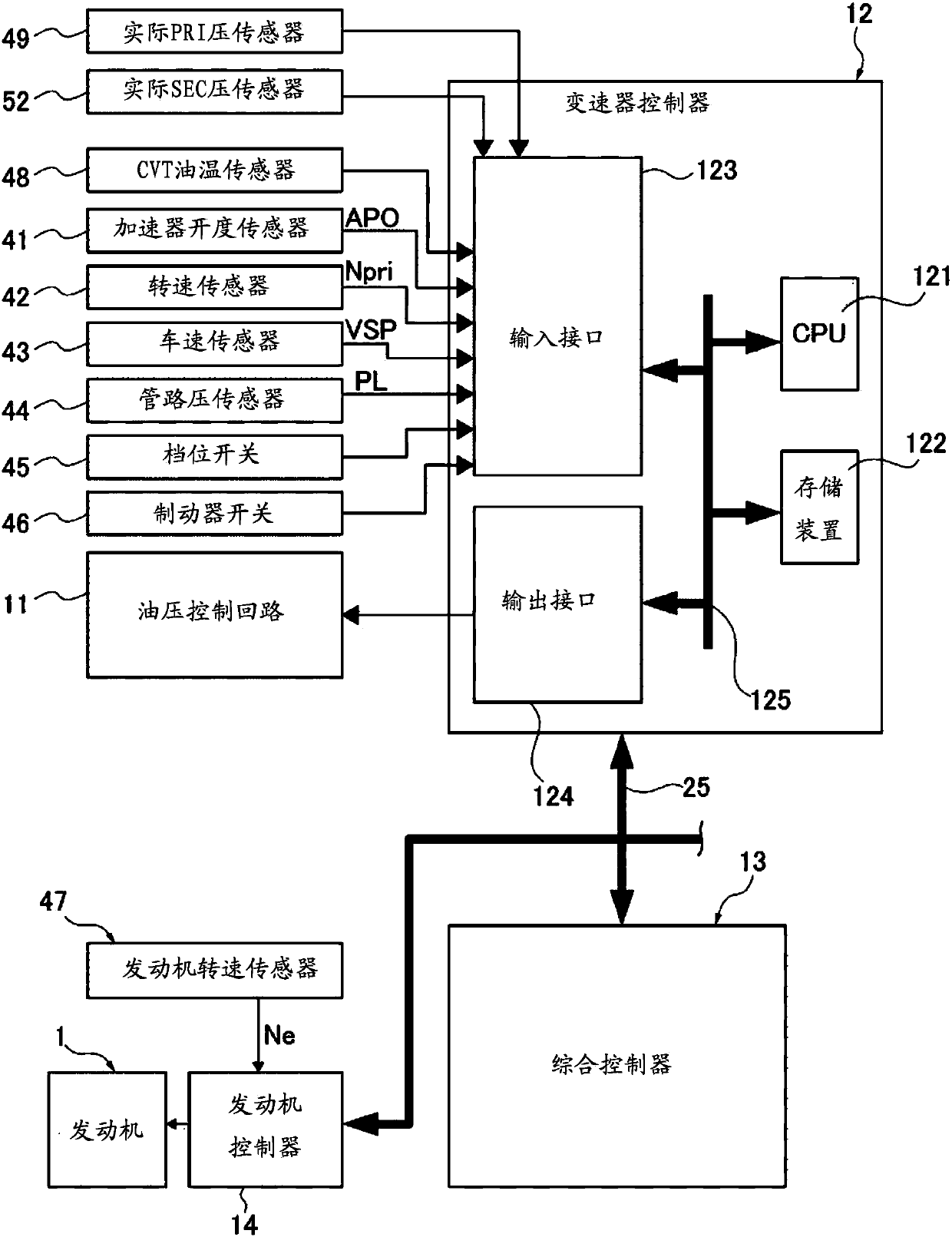

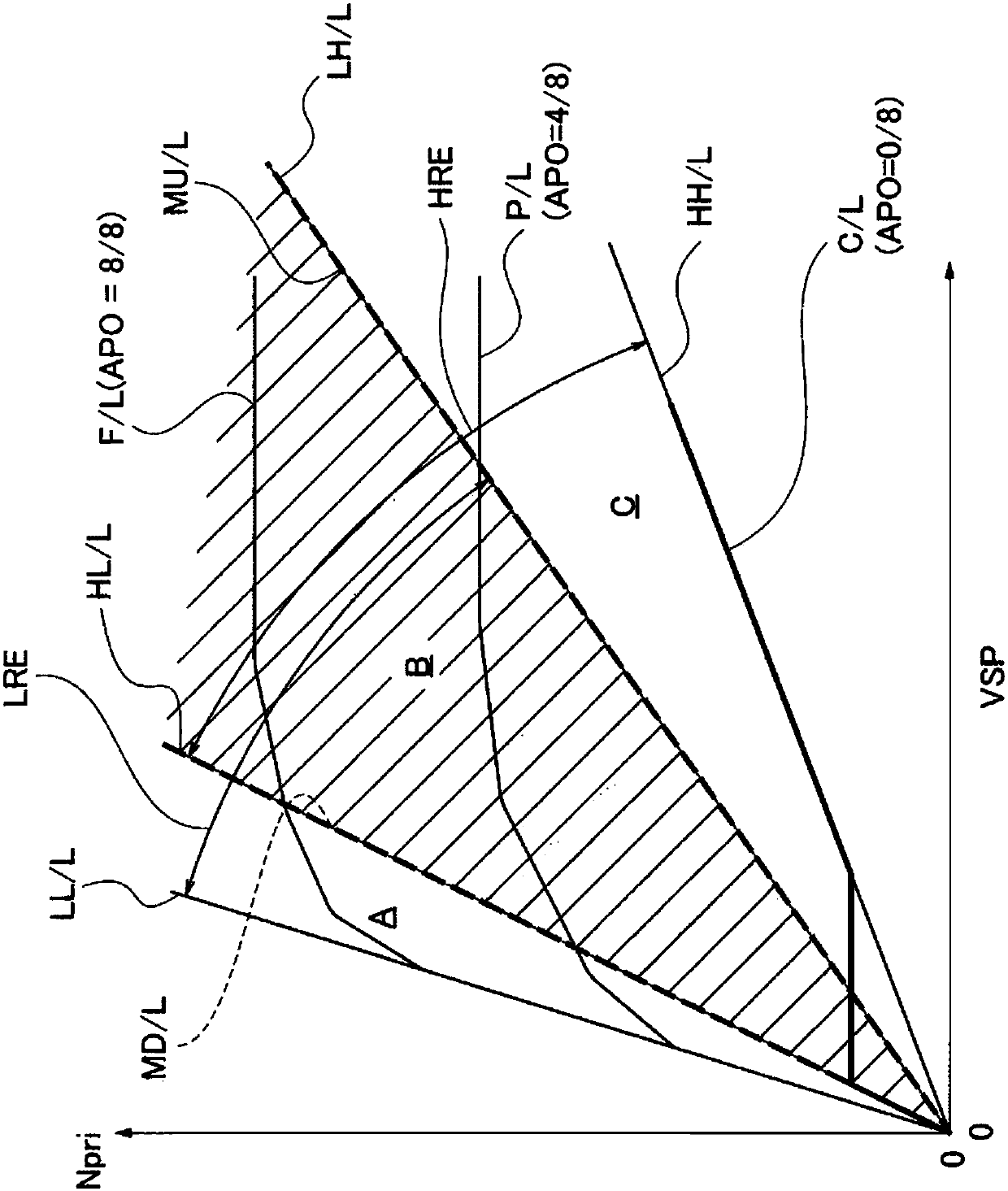

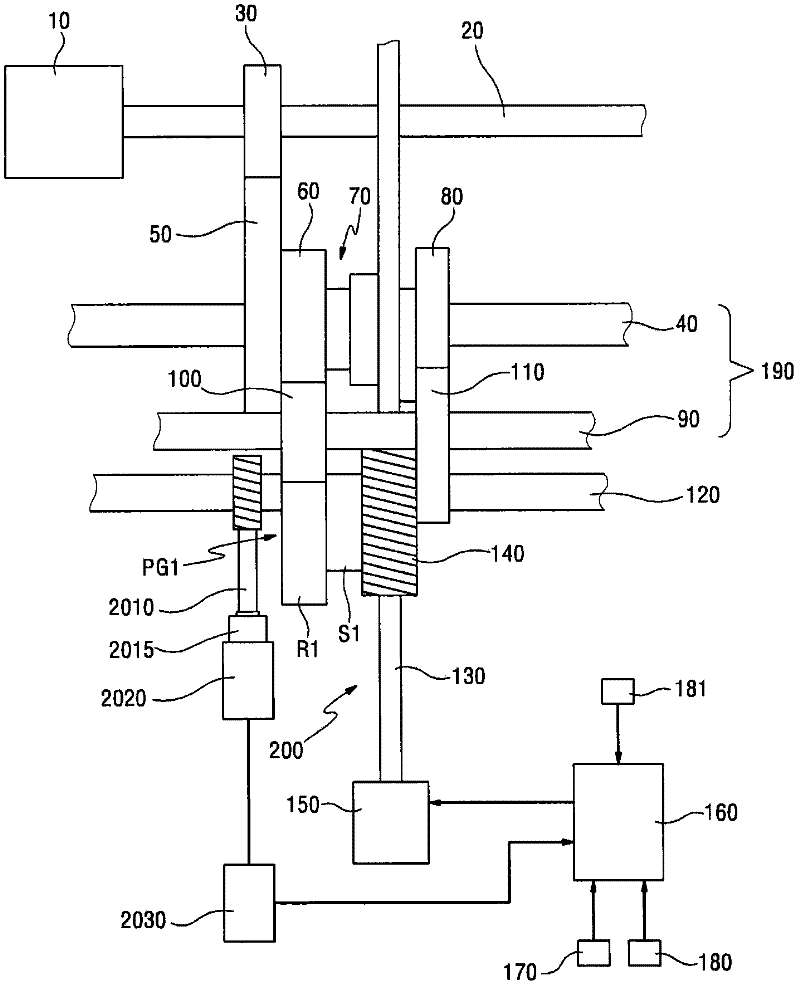

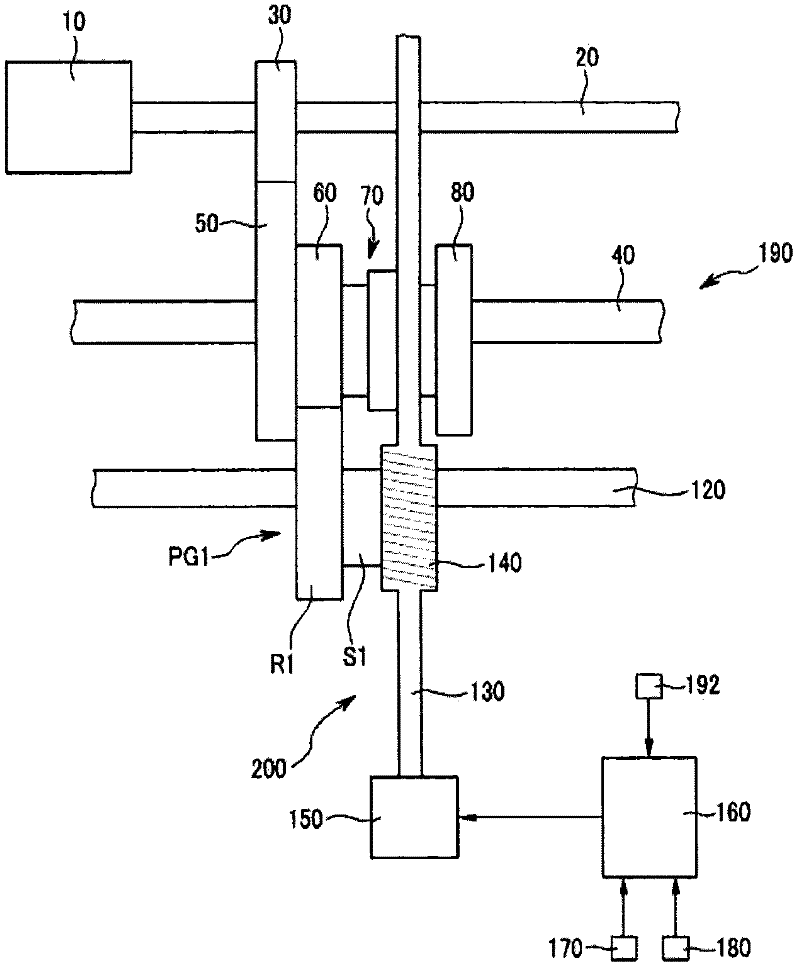

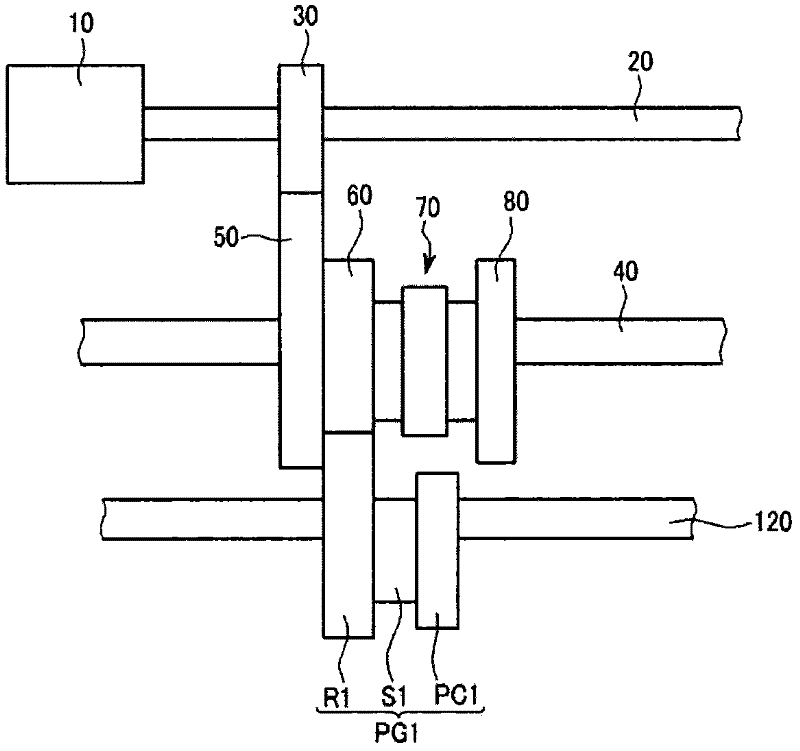

Device and method for hydraulically controlling continuously variable transmission for vehicle

ActiveCN108027047AIncreased line pressureSmooth shiftingToothed gearingsGearing controlControl theoryPressure control

This continuously variable transmission for a vehicle is provided with a transmission controller (12) for shifting gears in a variator (20) and an auxiliary gearshift mechanism (30), a line pressure regulating valve (11a), a primary pressure regulating valve (11b), and a secondary pressure regulating valve (11c). The transmission controller (12) is provided with a line pressure control unit (fig.4) that, when oil vibration occurs in the actual oil pressure at the primary pressure (Ppri) and / or secondary pressure (Psec), the line pressure (PL) is caused to exceed the line pressure (PL) beforeoil vibration occurred. The line pressure control unit (fig. 4) continues to increase the line pressure (PL) until gear shifting in the auxiliary gearshift mechanism (30) concludes in order to yield stable gear shifting when the gears are shifted in the auxiliary gearshift mechanism (30) with the line pressure (PL) in an increased state.

Owner:JATCO LTD +1

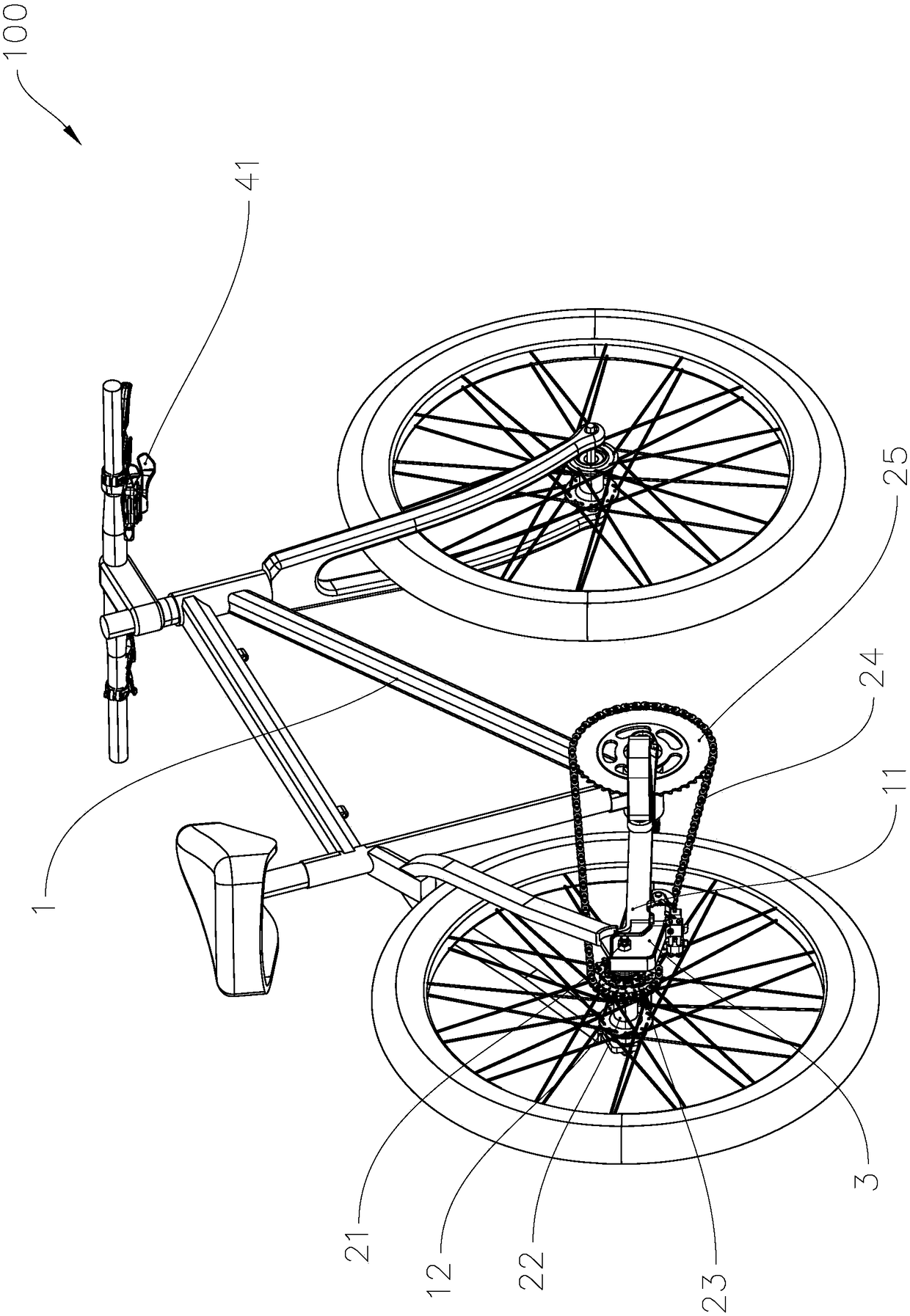

Bicycle chain shifting structure and bicycle

PendingCN108284914AAvoid damageThe overall structure is simple and reliableChain/belt transmissionRider propulsionVehicle frameSprocket

The invention provides a bicycle chain shifting structure and a bicycle. The bicycle chain shifting structure comprises a bicycle frame provided with a first rear fork and a second rear fork, a hub shaft arranged between the first rear fork and the second rear fork in a straddling mode, a first chain wheel rotatably connected to the middle of the bicycle frame around the axis of the first chain wheel, a hub shell mounted on the hub shaft in a sleeving mode and rotatably connected with the hub shaft, a flywheel set mounted on the hub shell in a sleeving mode, a chain shifting device, and a chain connected with the first chain wheel, the flywheel set and a chain expansion unit. The flywheel set is located between the first rear fork and the second rear fork, the chain shifting device comprises a fixing seat connected with the first rear fork and the chain expansion unit, and the fixing seat is provided with a guiding column facing the flywheel set. The chain expansion unit is slidably connected with the guiding column. The bicycle comprises the bicycle chain shifting structure. The bicycle chain shifting structure and the bicycle have the advantages that the structure is simple and reliable, the production cost is low, and the chain shifting device can be protected.

Owner:ZHUHAI L-TWOO SPORT TECH CO LTD

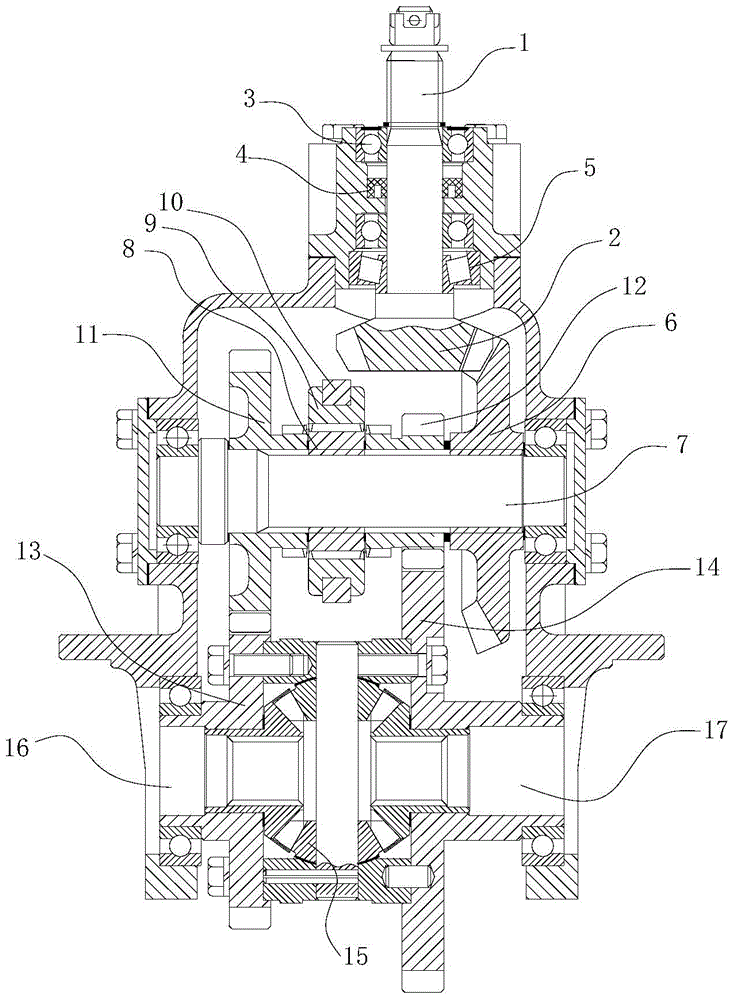

Servomotor-speed reduction integrated mechanism

InactiveCN104214319AGuaranteed integrated structureReduce mating partsShaftsGearing detailsAgricultural engineeringServomotor

The invention discloses a servomotor-speed reduction integrated mechanism, which comprises a servomotor output shaft, planetary gears, a planetary gear disk, an upper gearbox cover and a lower gearbox cover, a shaft end gear is arranged on one end of the servomotor output shaft, and is engaged with the planetary gears, the center of each planetary gear is provided with a through hole, the planetary gears are fitted on planetary gear-fixing pins, the planetary gear-fixing pins run through the through holes and are fixed on the planetary gear disk, the other end of the planetary gear disk is an output shaft, an output shaft bearing is arranged on the output shaft, the lower gearbox cover is provided with a through hole, the output shaft runs through the through hole, an output shaft oil seal is arranged in the through hole, an inner gear ring is arranged around the planetary gears, and is engaged with the planetary gears, an input end bearing is mounted on the inner side of the upper gearbox cover, the inner gear ring is fixed on the inner wall of the lower gearbox cover by positioning pins, and the upper gearbox cover is fixedly connected with the lower gearbox cover through big bolts.

Owner:梁想超

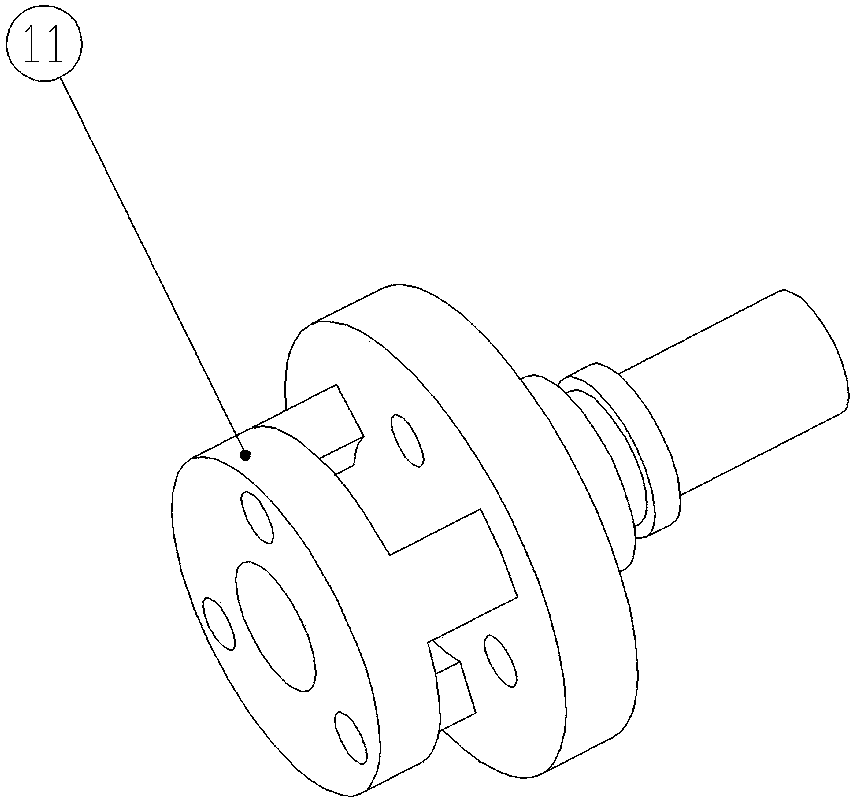

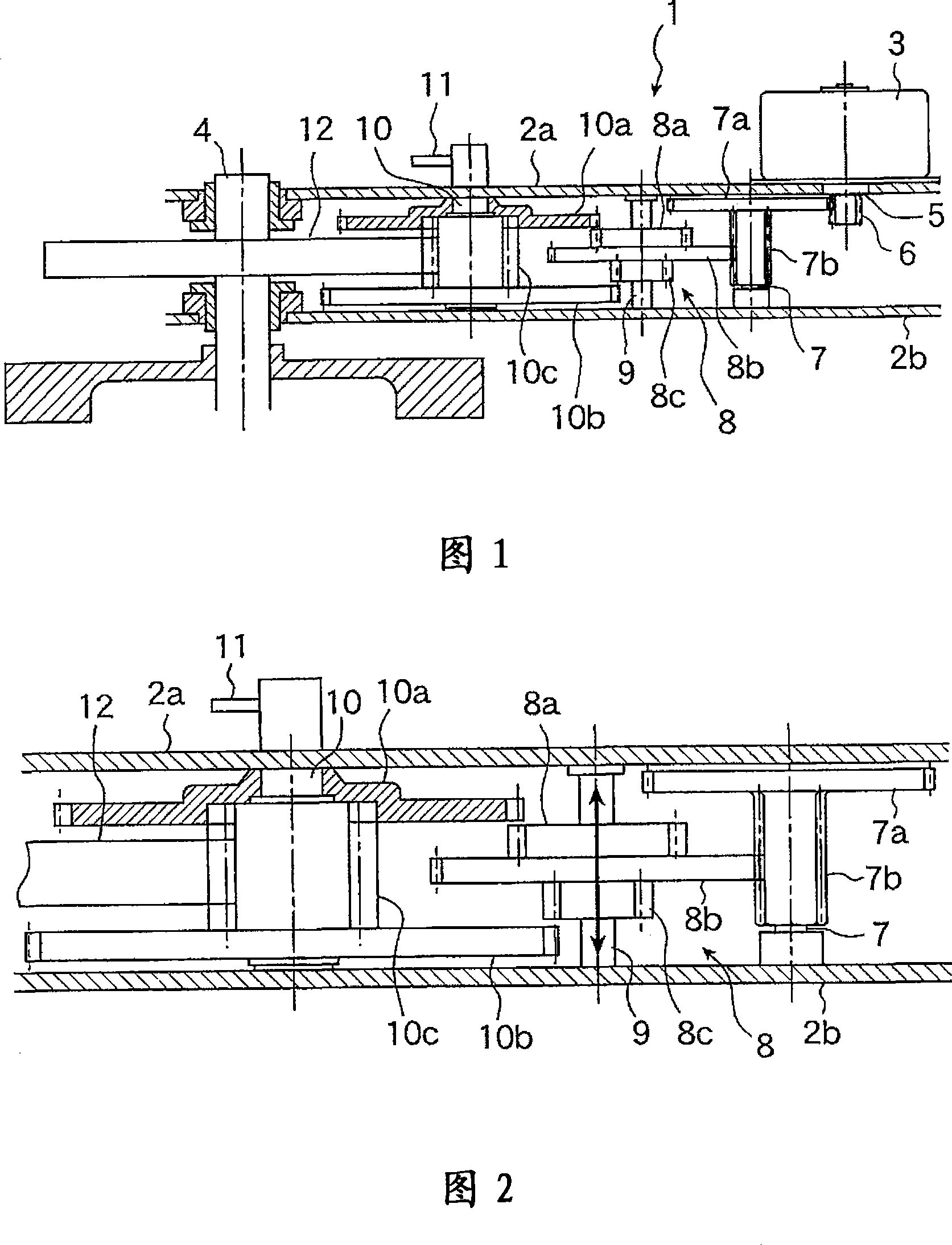

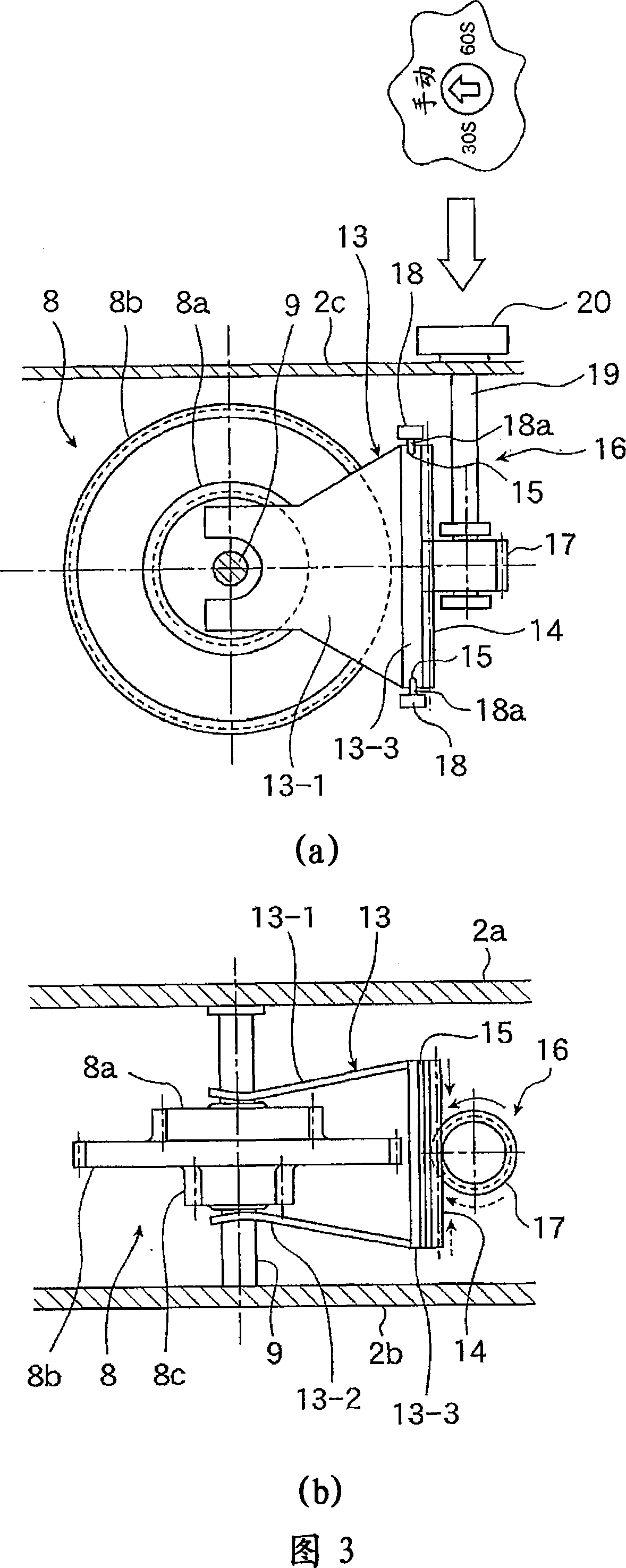

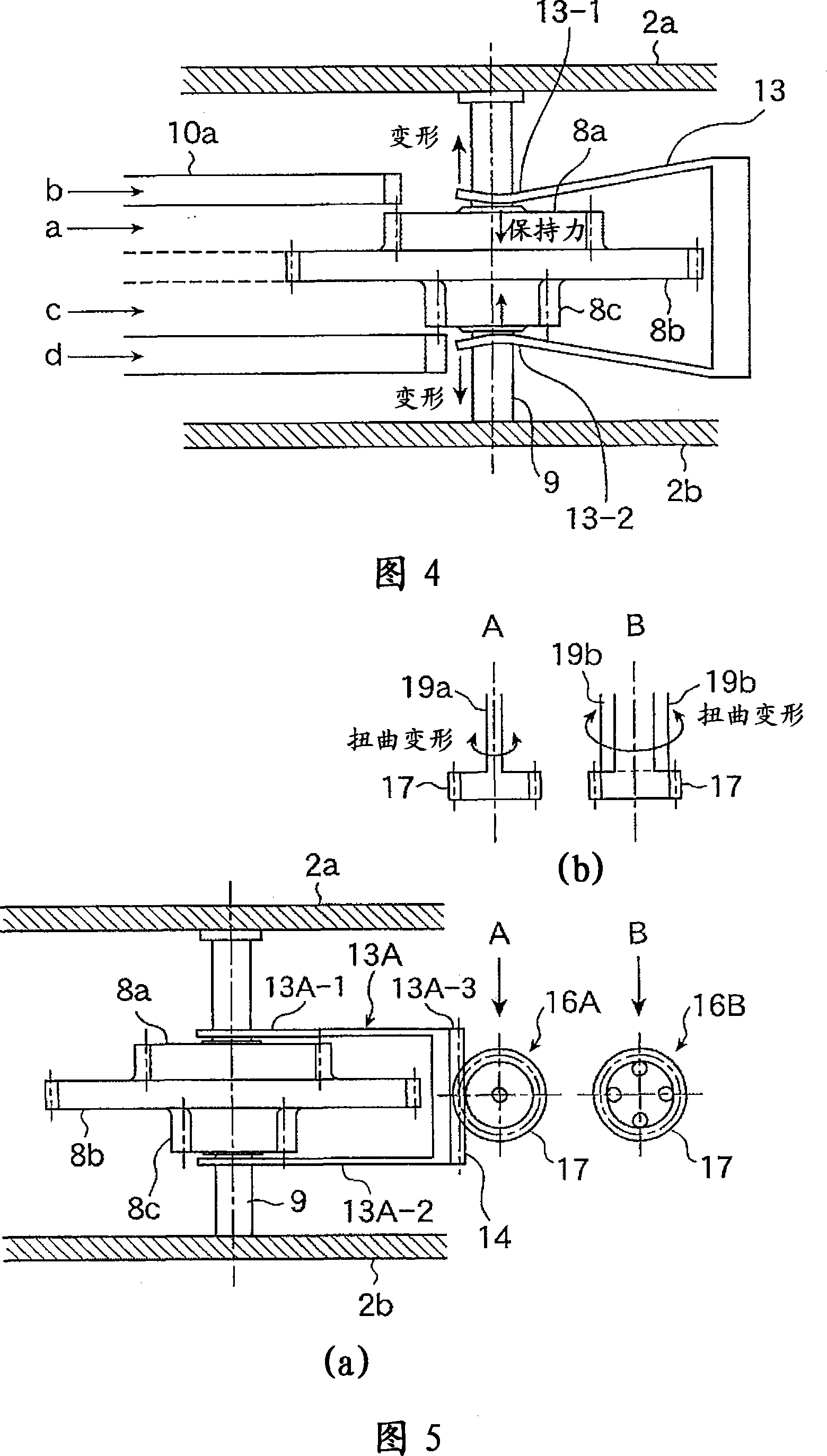

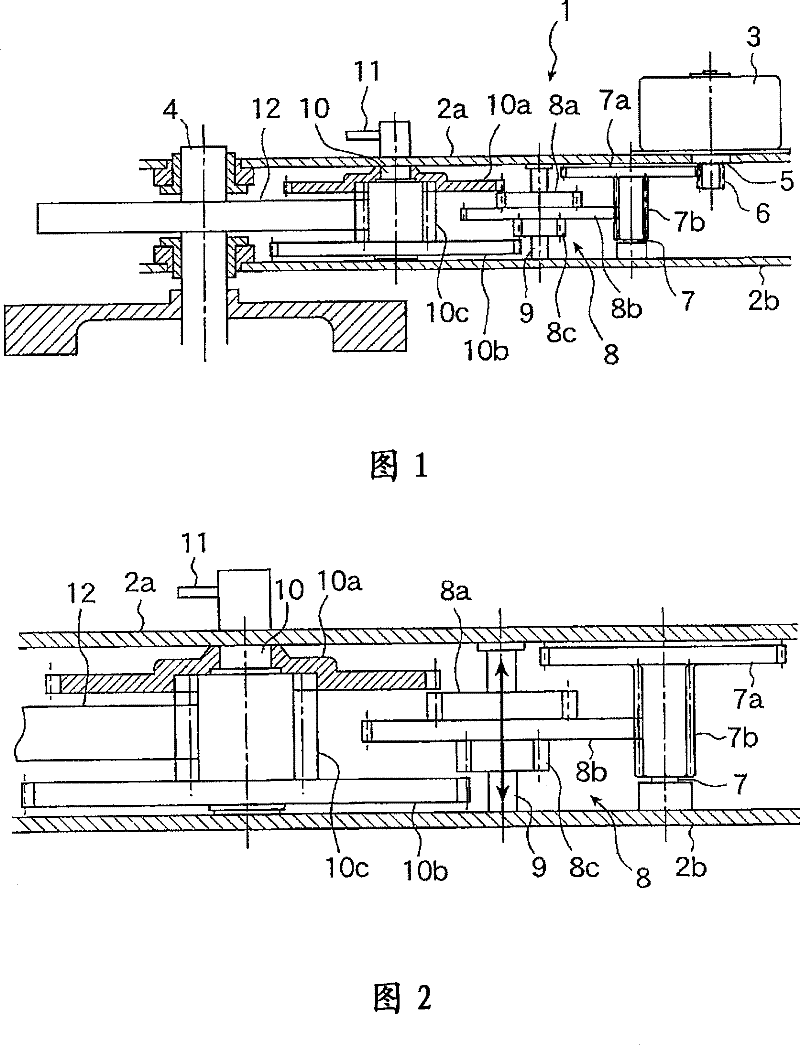

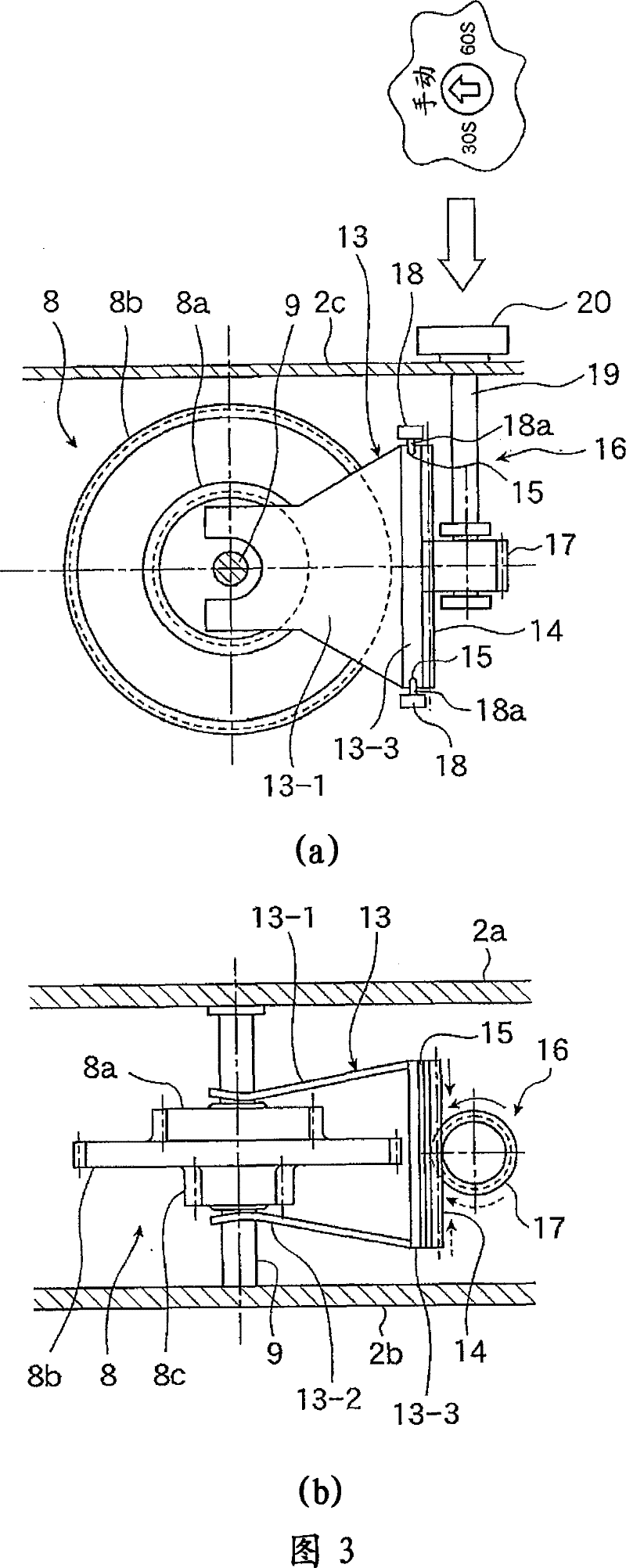

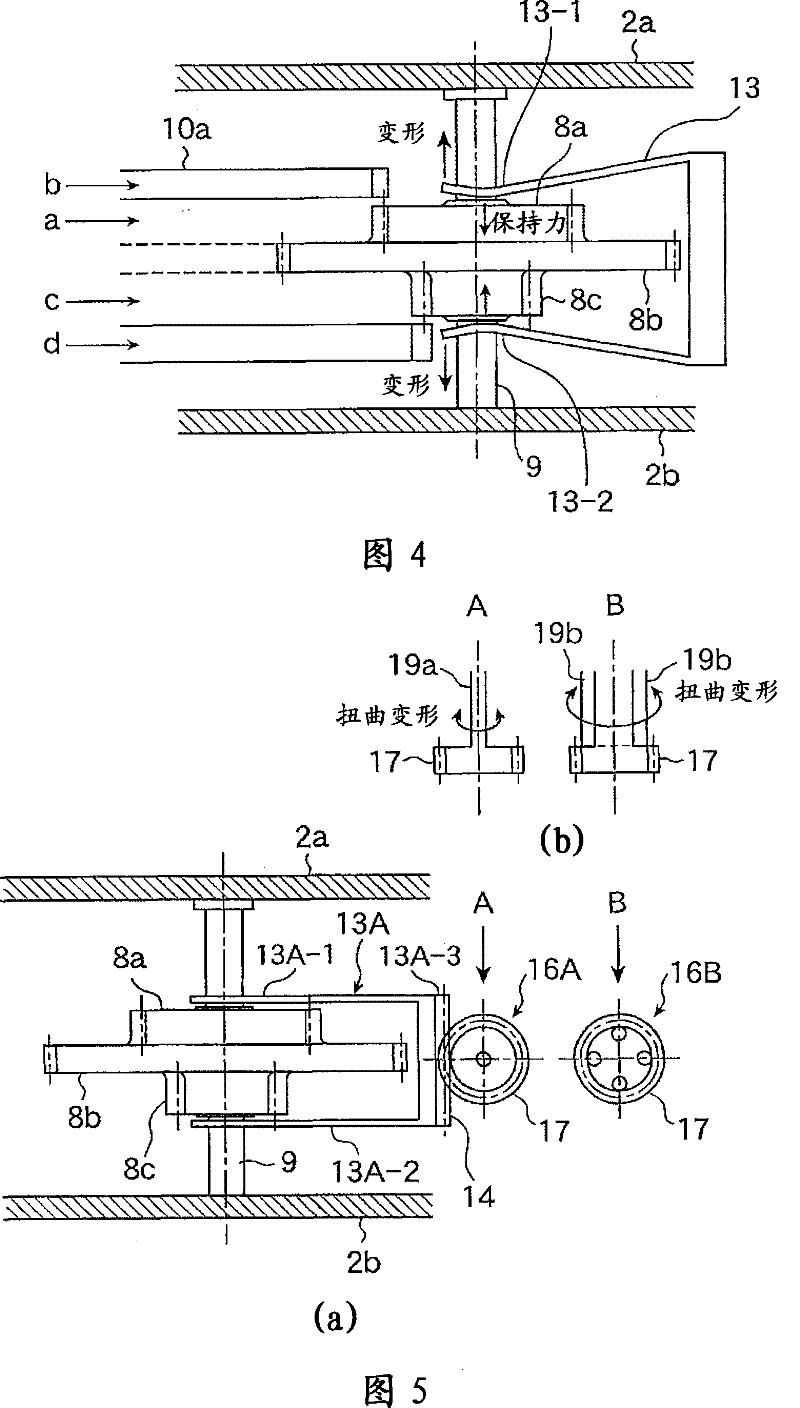

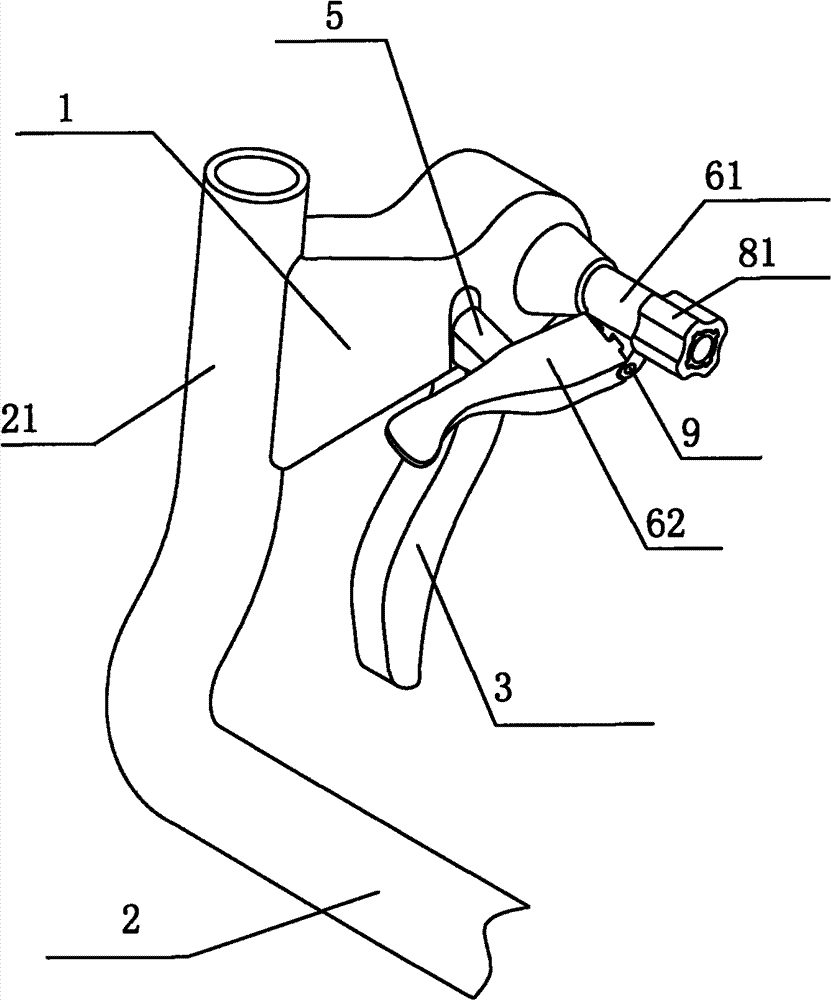

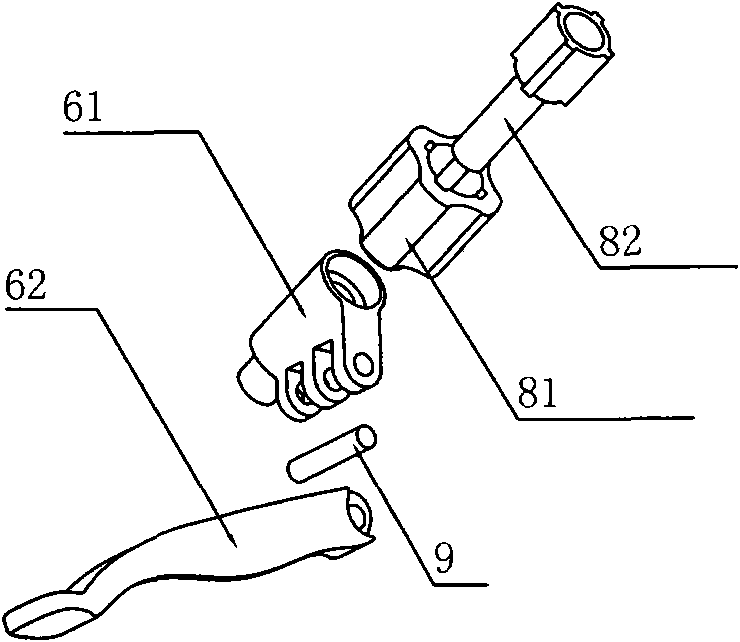

Executing element, valve device and air door device

InactiveCN101205990AIncrease the number ofVariable speed realizationOperating means/releasing devices for valvesToothed gearingsEngineeringAir door

The invention provides an executing element which achieves the manual / electric operation switching and changes the speed of an output shaft with a simple structure, as well as a valve device and a throttle device using the executing element. The executing element achieves movable operations to a manual / electric clutch gear (8) which consists of a plurality of gears which are coaxial and rotate integrally along a fixing shaft (9), thereby canceling the joggling between a front-stage side transmission gear or a rear-stage side transmission gear and the manual / electric clutch gear (8) and joggling the manual / electric clutch gear (8) and the rear-stage side transmission gear which produces a desired deceleration ratio.

Owner:YAMATAKE HONEYWELL CO LTD

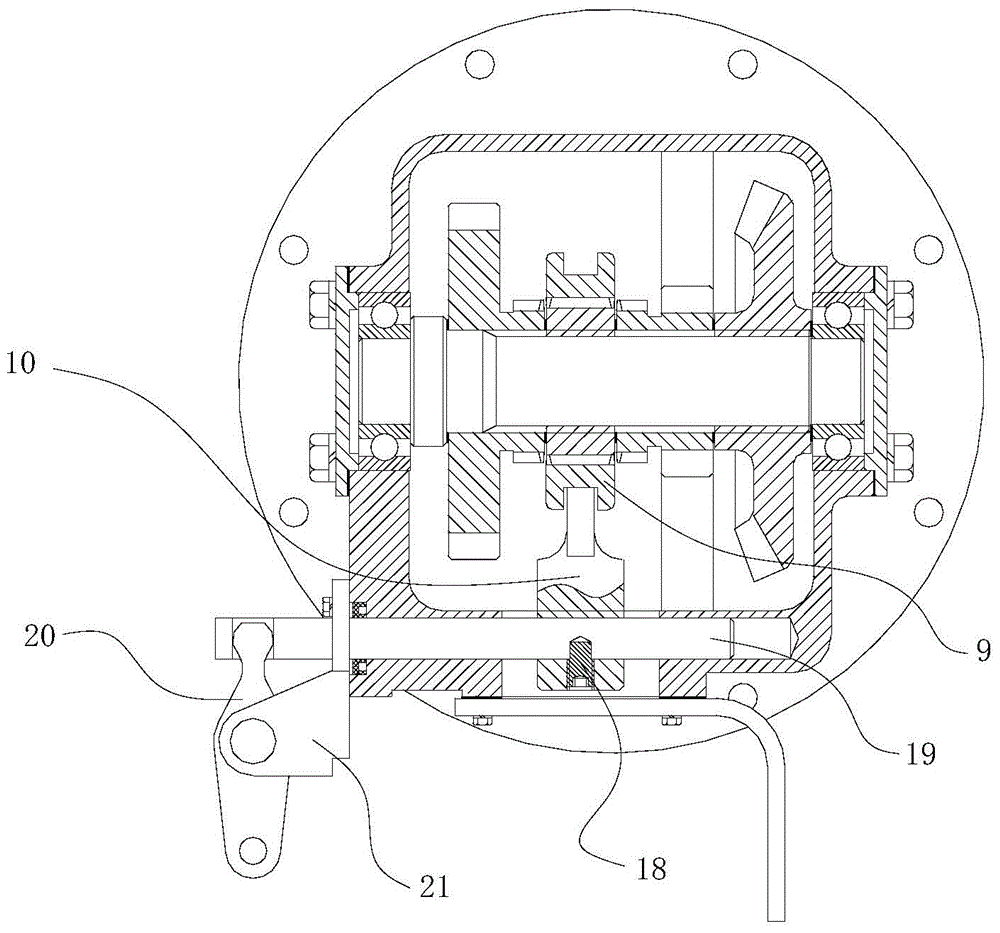

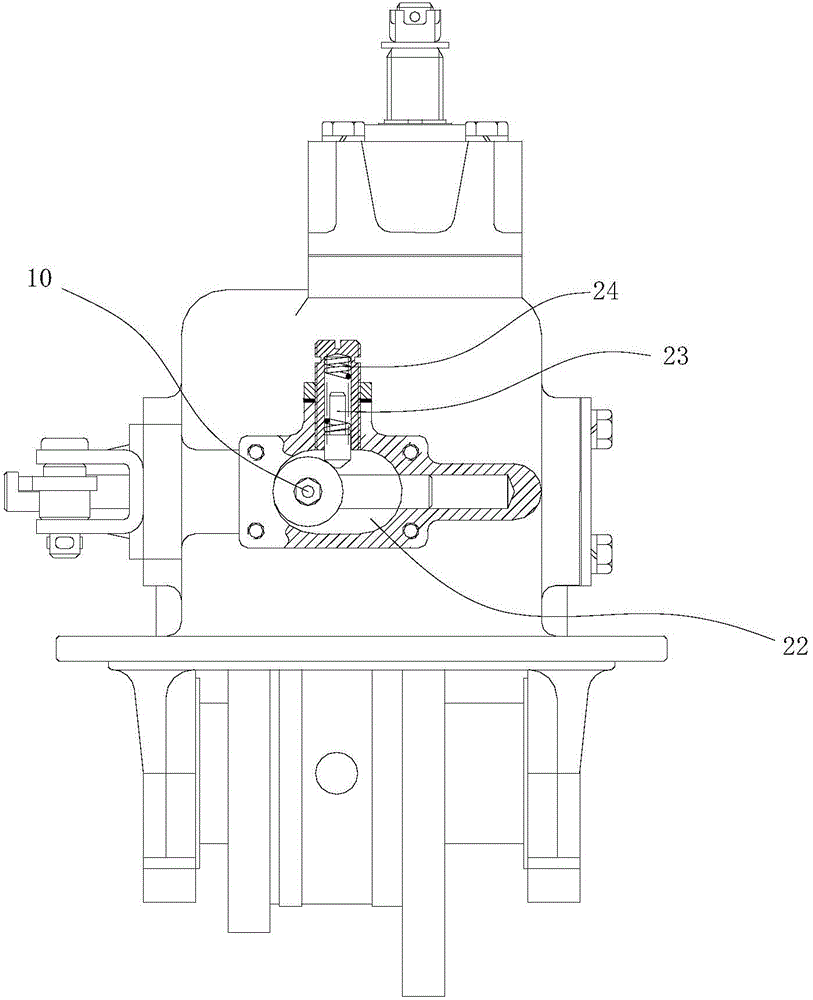

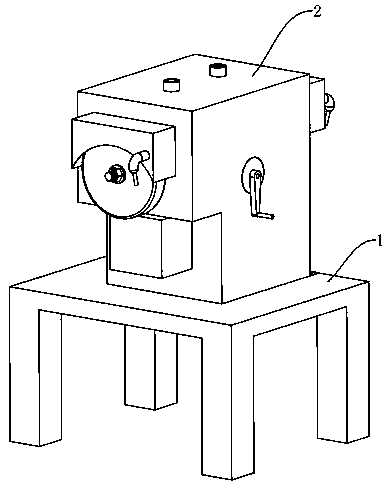

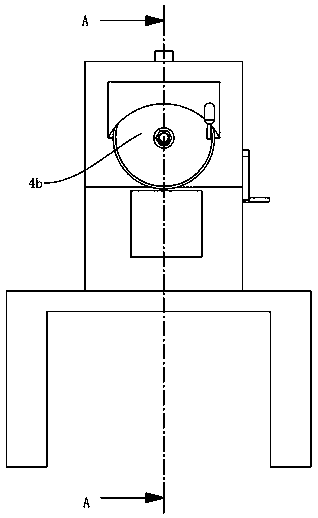

Gearbox with internal support gear shifting mechanism

PendingCN109854689ASimple structureReduce volumeFluid actuated clutchesPortable liftingClutchPower output

The invention relates to the technical field of gearboxes, in particular to a gearbox with an internal support gear shifting mechanism. The gearbox comprises a gearbox body, a power input shaft, a power output shaft and a clutch; a gear shifting output shaft I and a gear shifting output shaft II are arranged in parallel in the gearbox body; the gear shifting output shaft I and the gear shifting output shaft II respectively comprise a solid section and a hollow section; the solid section is sleeved with fixed gears with the diameters increasing or decreasing in sequence; the hollow section is sleeved with ring gears or fixed gears with the diameters increasing or decreasing in sequence; the ring gears and the fixed gears with the diameters increasing or decreasing in sequence which sleeve the outer side of the gear shifting output shaft I are correspondingly engaged with the fixed gears and the ring gears with the diameters increasing or decreasing in sequence which sleeve the outer side of the gear shifting output shaft II to form variable gear pairs; one end of the gear shifting output shaft I is in transmission connection with the power input shaft through the clutch; and one endof the gear shifting output shaft II is in transmission connection with the power output shaft through an output gear. The gear shifting control operation is simple, and speed changing of more gearsis realized.

Owner:牛清锋

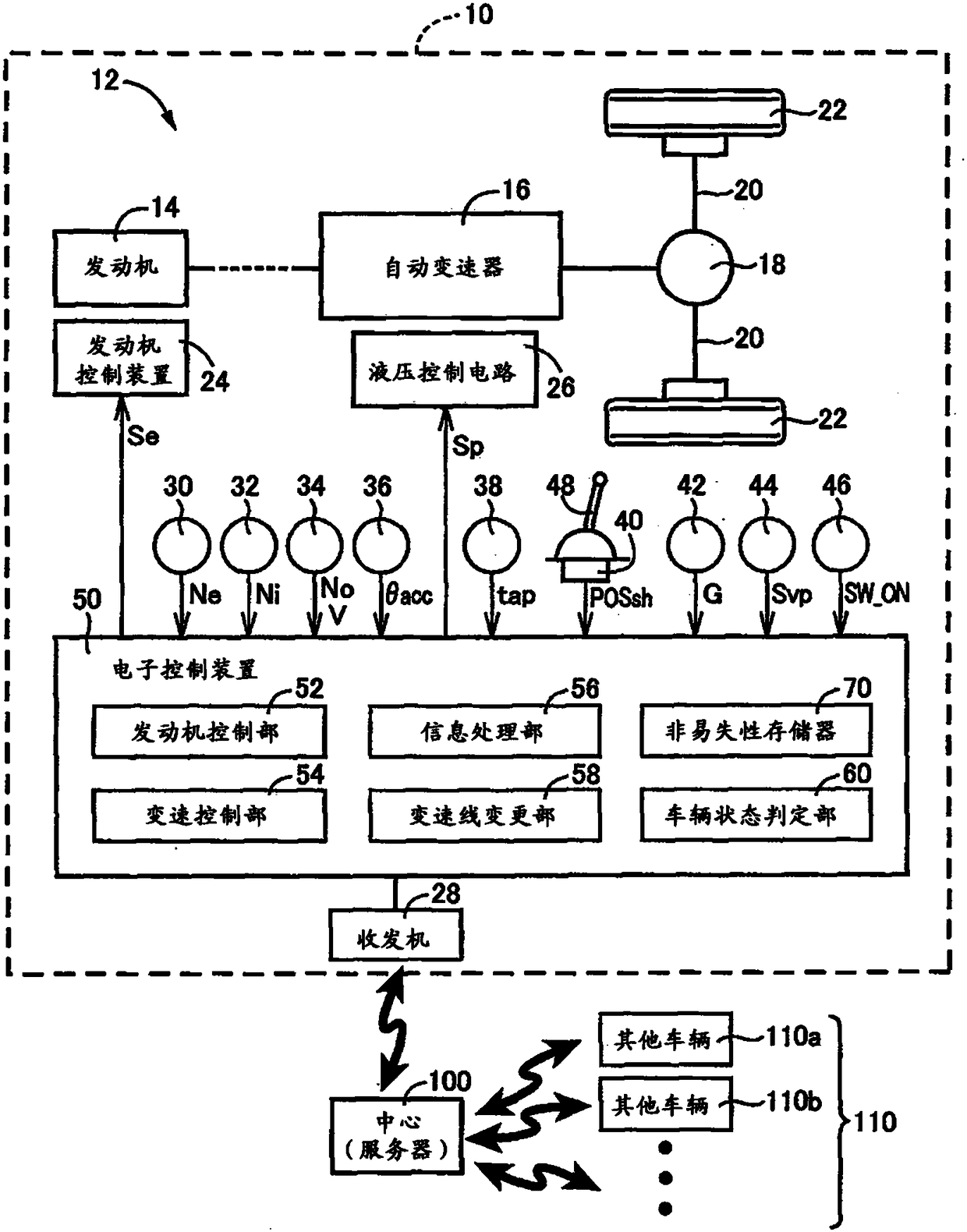

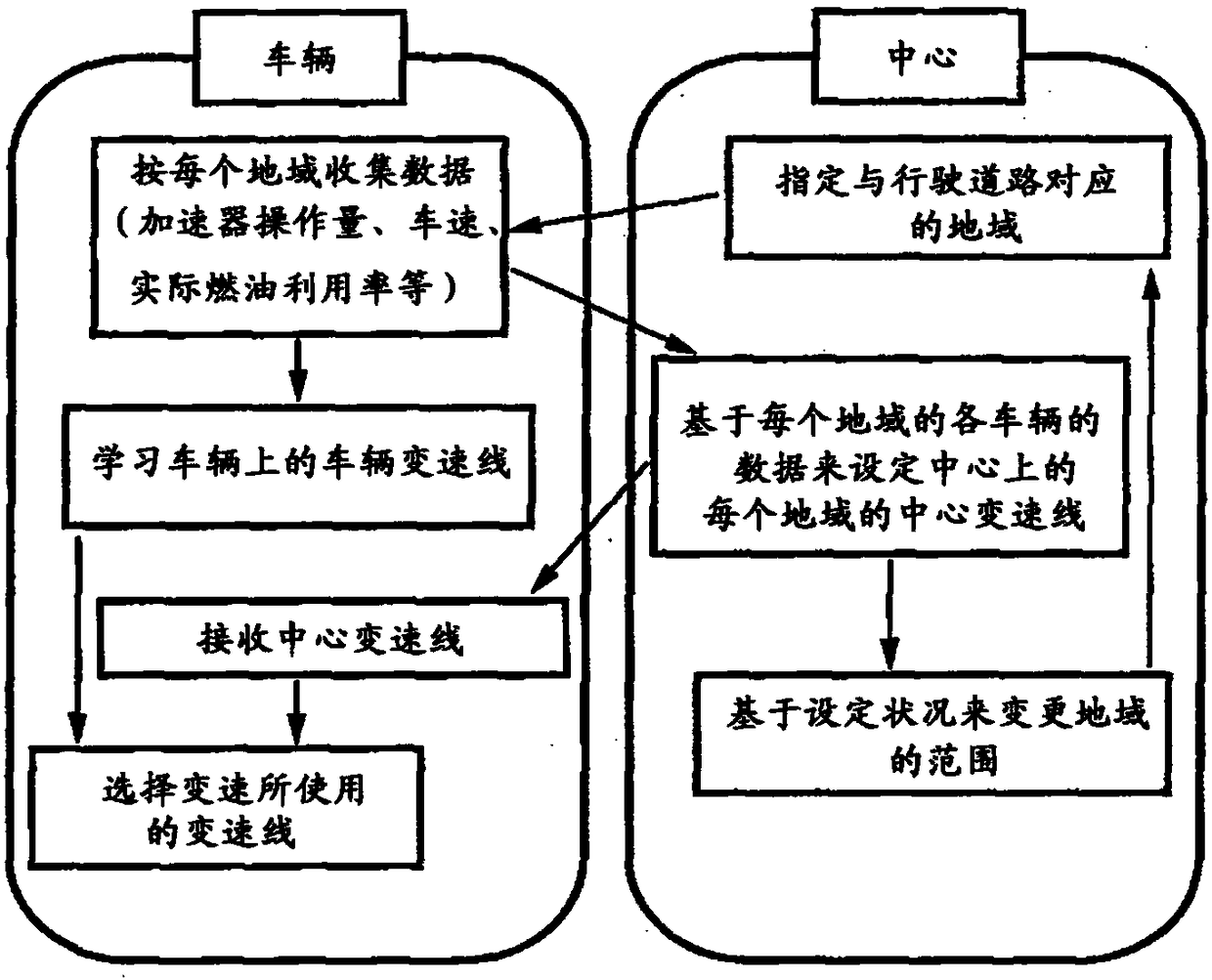

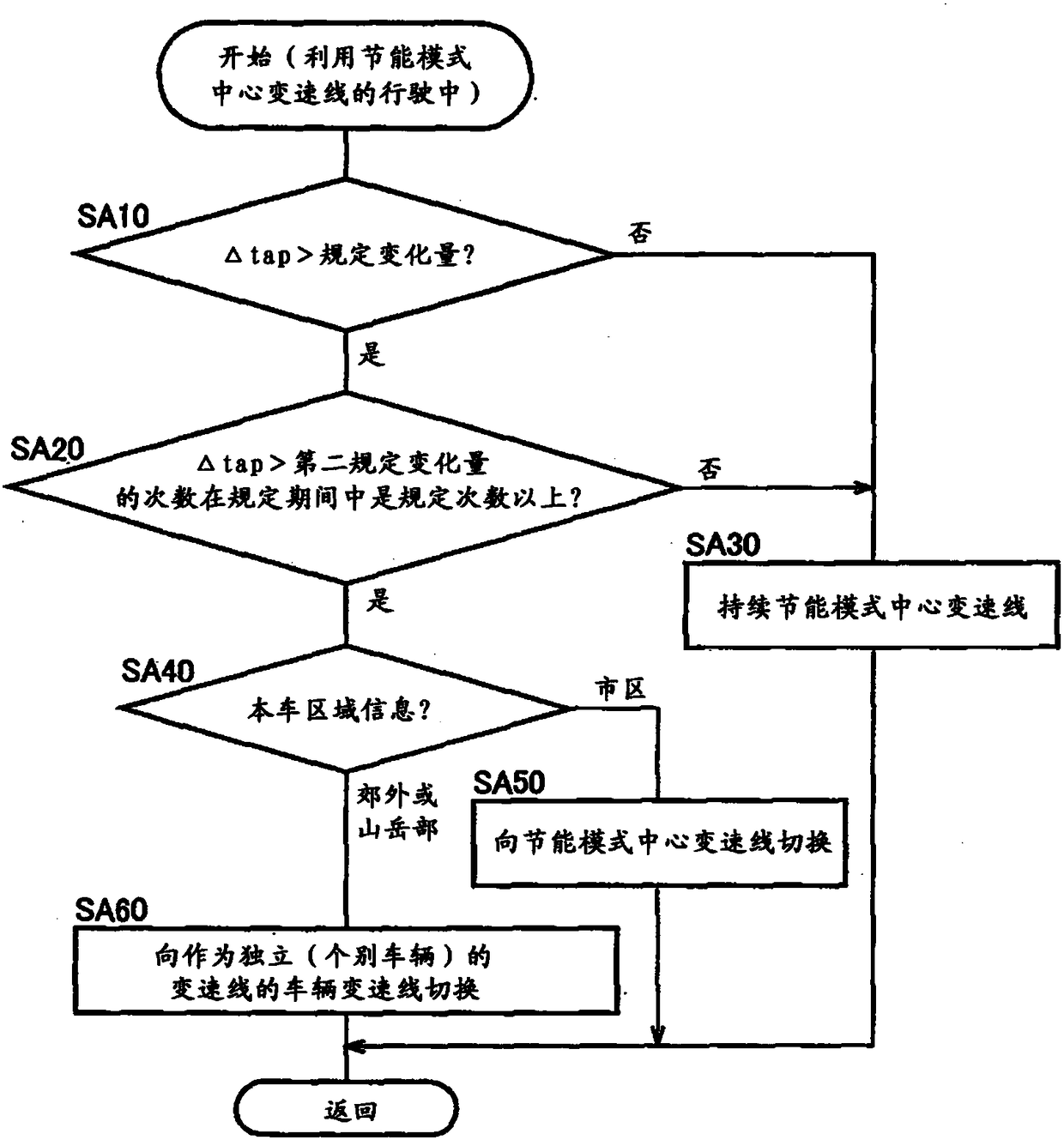

Vehicle control apparatus

ActiveCN108374887AAccelerated implementationVariable speed realizationRoad vehicles traffic controlGearing controlCenter shiftEngineering

The invention relates to a vehicle control apparatus, which can carry out speed change, which meets the traffic rules and intention of drivers, of automatic gearbox. The information based on the valueindicating the acceleration request reflecting the driver's intention or satisfaction, and the current information of the vehicle (10) reflecting the number of other vehicles (110) or driving tendency different for each area (Area) The information at the location distinguishes between the vehicle shifting line that is suitable for the vehicle (10) (for example, reflecting the difference in acceleration requirements), although the information of other vehicles (110) is not reflected, and the information transmitted by other vehicles (110) reflects each different center shift lines for each area (Area). Thereby, the shift of the automatic transmission (16) in accordance with the traveling road and the intention of the driver can be realized.

Owner:TOYOTA JIDOSHA KK

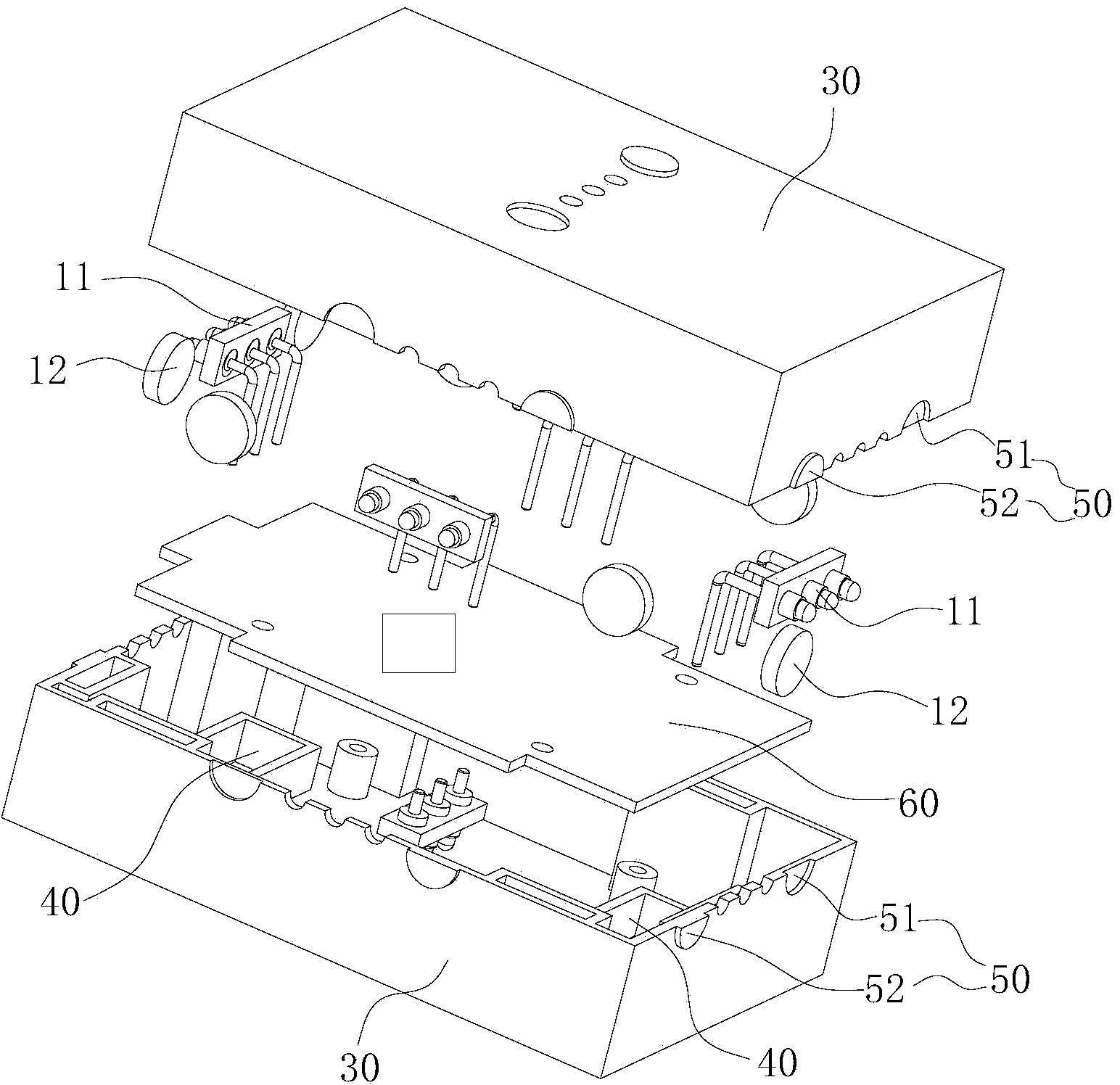

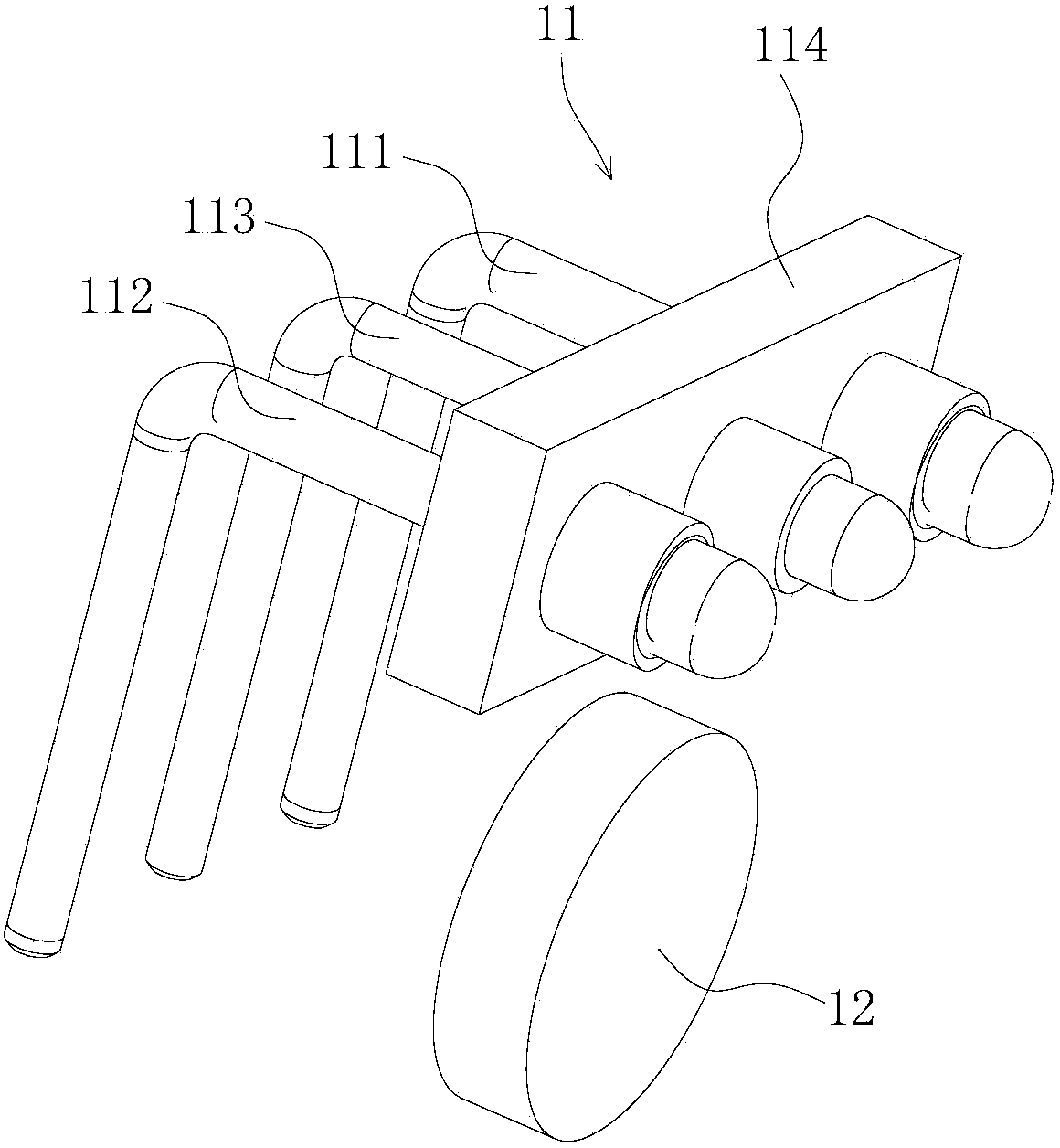

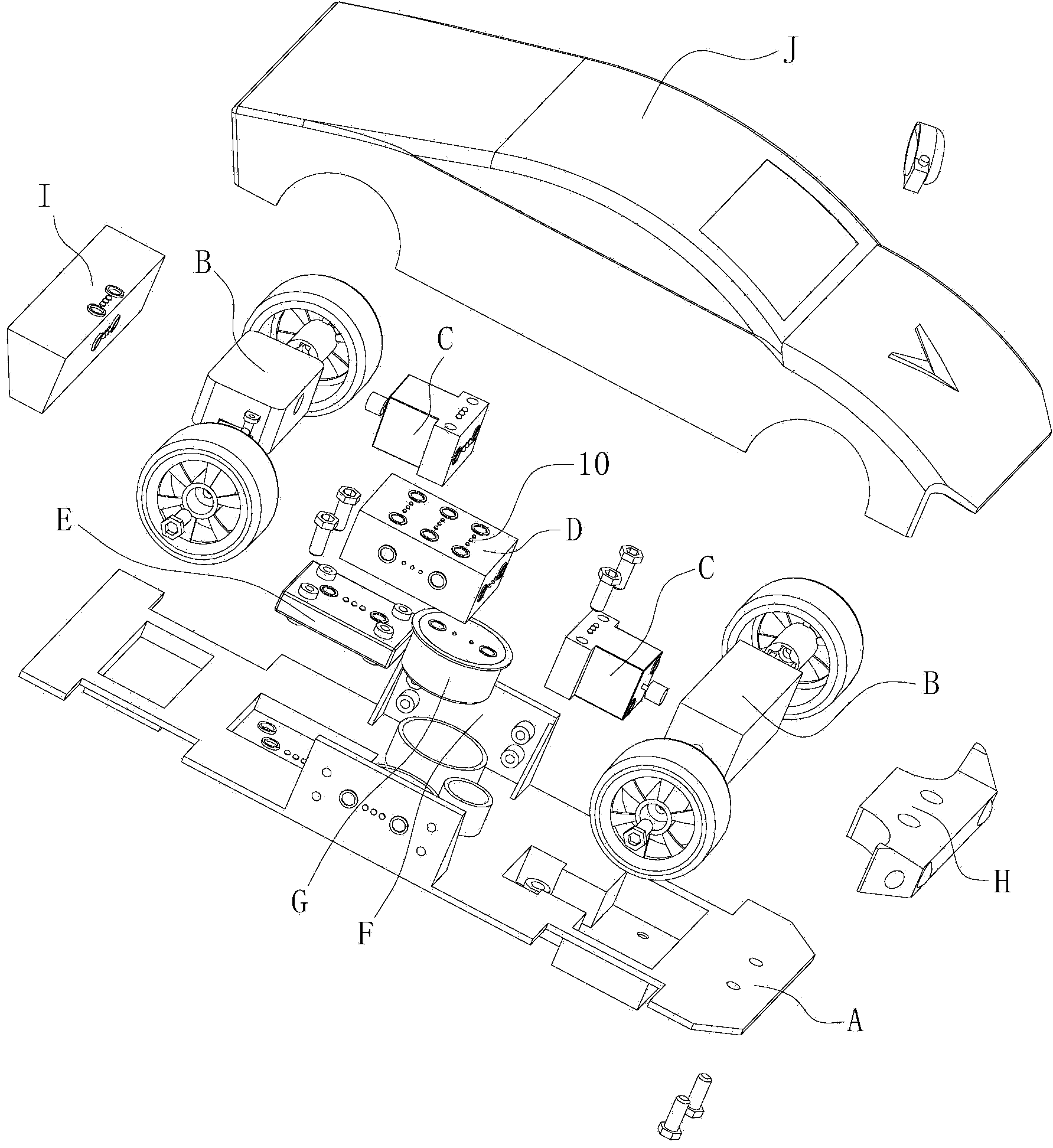

Connecting device, spliced toy and spliced toy car

InactiveCN104056455AAchieve magnetic connectionEnable connectivityToy vehiclesComputer moduleData transmission

The invention discloses a connecting device. The connecting device comprises a shell, at least one connector and a magnet. The connectors and the magnet are located on the same side of a module. One end of each connector extends out of the shell. The other end of each connector is connected with an inner component in the shell. Each connector comprises a positive-electrode power supply contact terminal, a negative-electrode supply contact terminal and a power signal contact terminal. Connection, power supply connection and data transmission between connecting devices can be achieved through the magnet and the connectors. Connection between the connecting devices and control over the connecting devices can be achieved, and the connection effect is good. The invention further provides a spliced toy and a spliced toy car, wherein the spliced toy is composed of multiple connecting devices, and the spliced toy car is composed of multiple modules containing the connecting devices. Through different combination modes between the multiple modules of the spliced toy car, toys with various functions and shapes can be spliced, so that the spliced toys have multiple functions. By the adoption of the connecting device, the spliced toy and the spliced toy car, the practical ability and the intelligence of children can be greatly improved, and the connecting device, the spliced toy and the spliced toy car are good tools for development of the intelligence, the imagination and the creativity of children.

Owner:SHENZHENSHI HANTONG TECH CO LTD

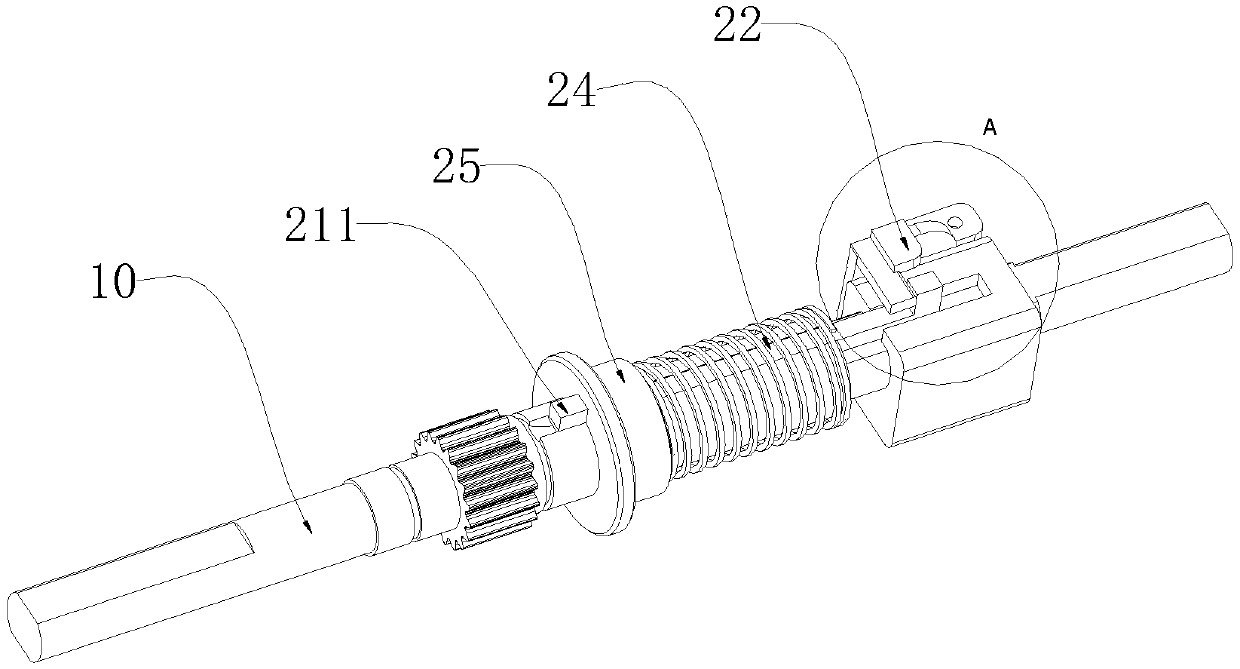

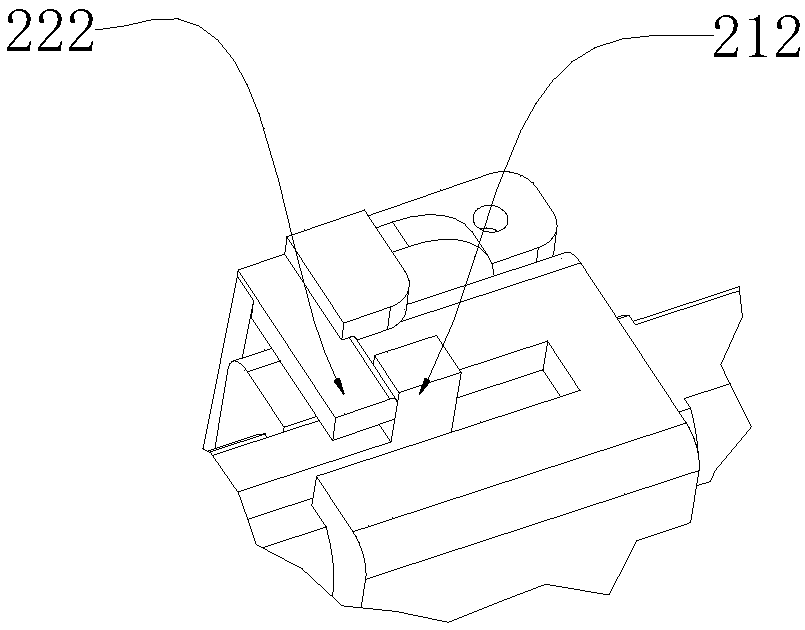

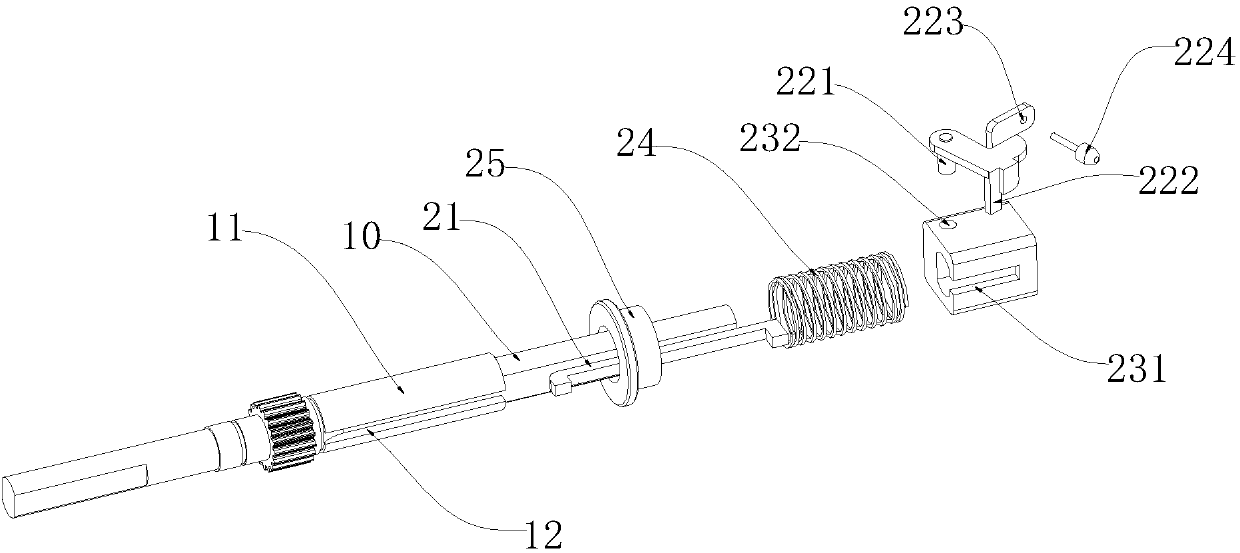

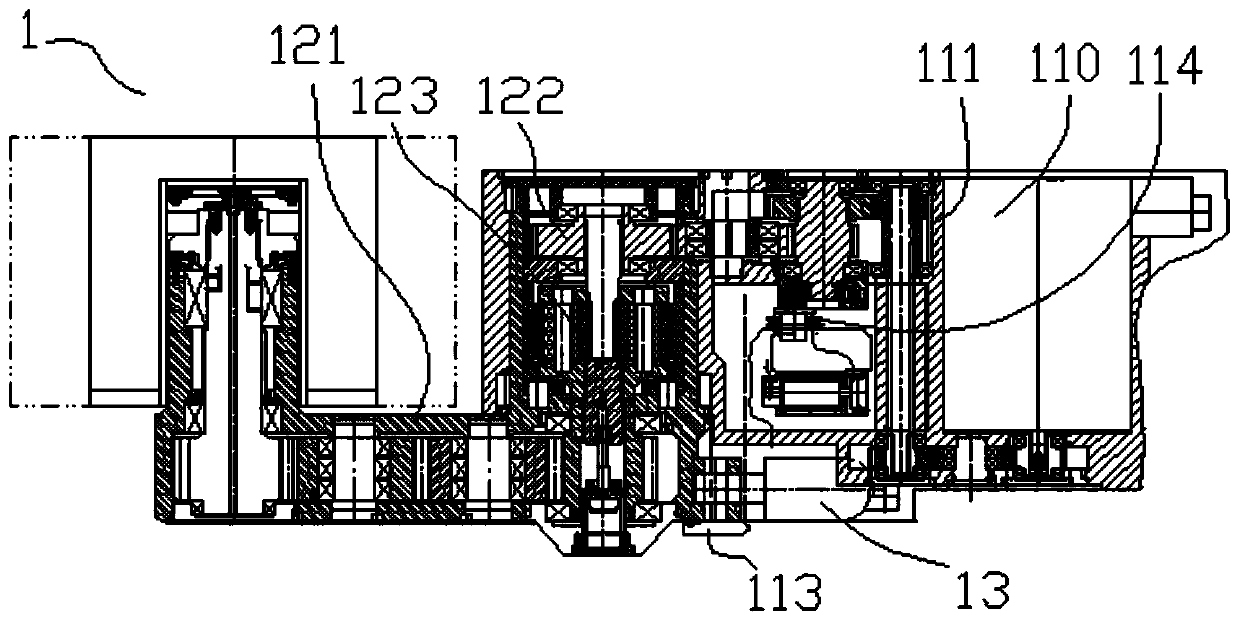

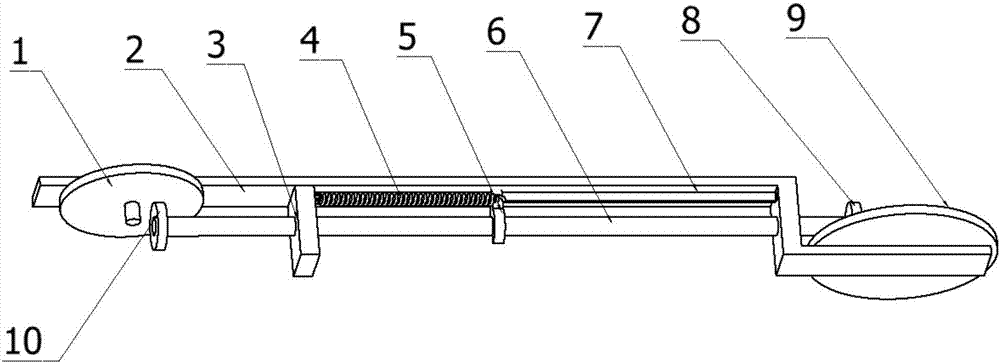

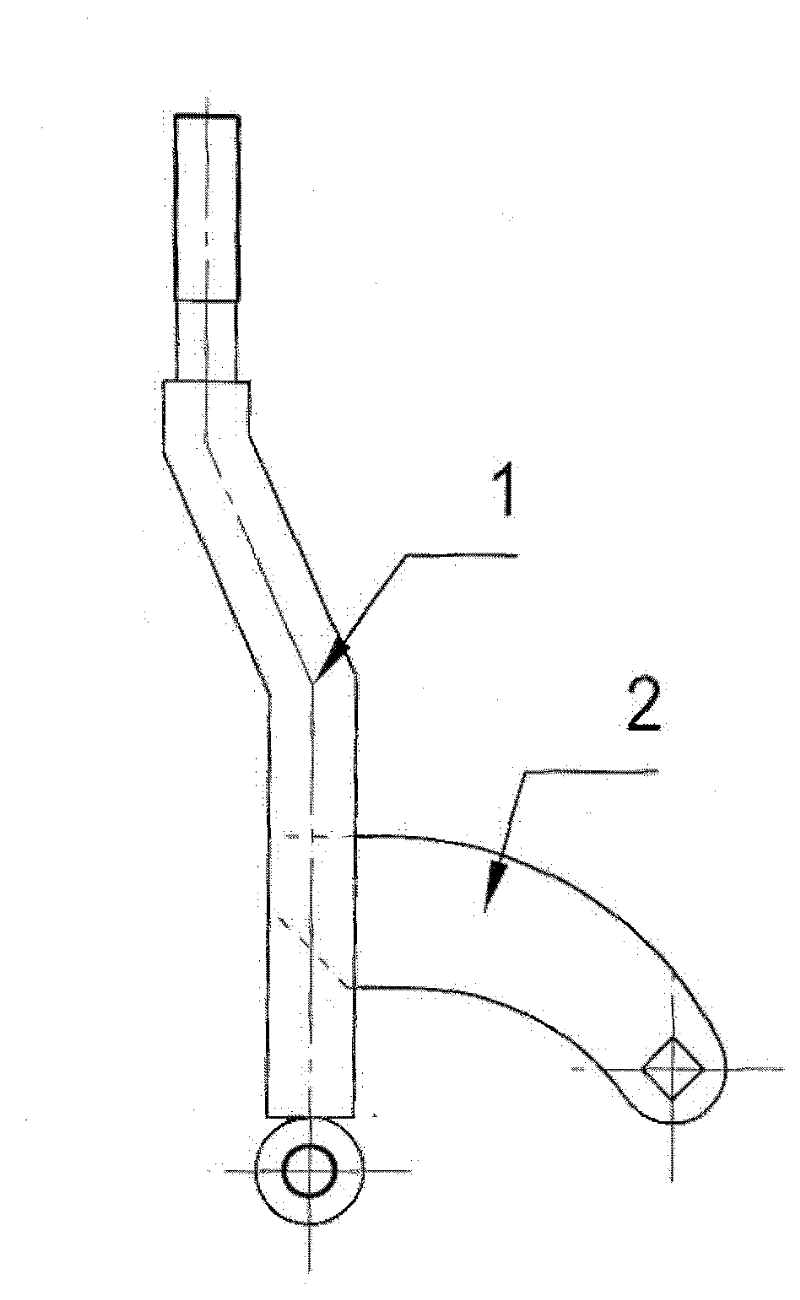

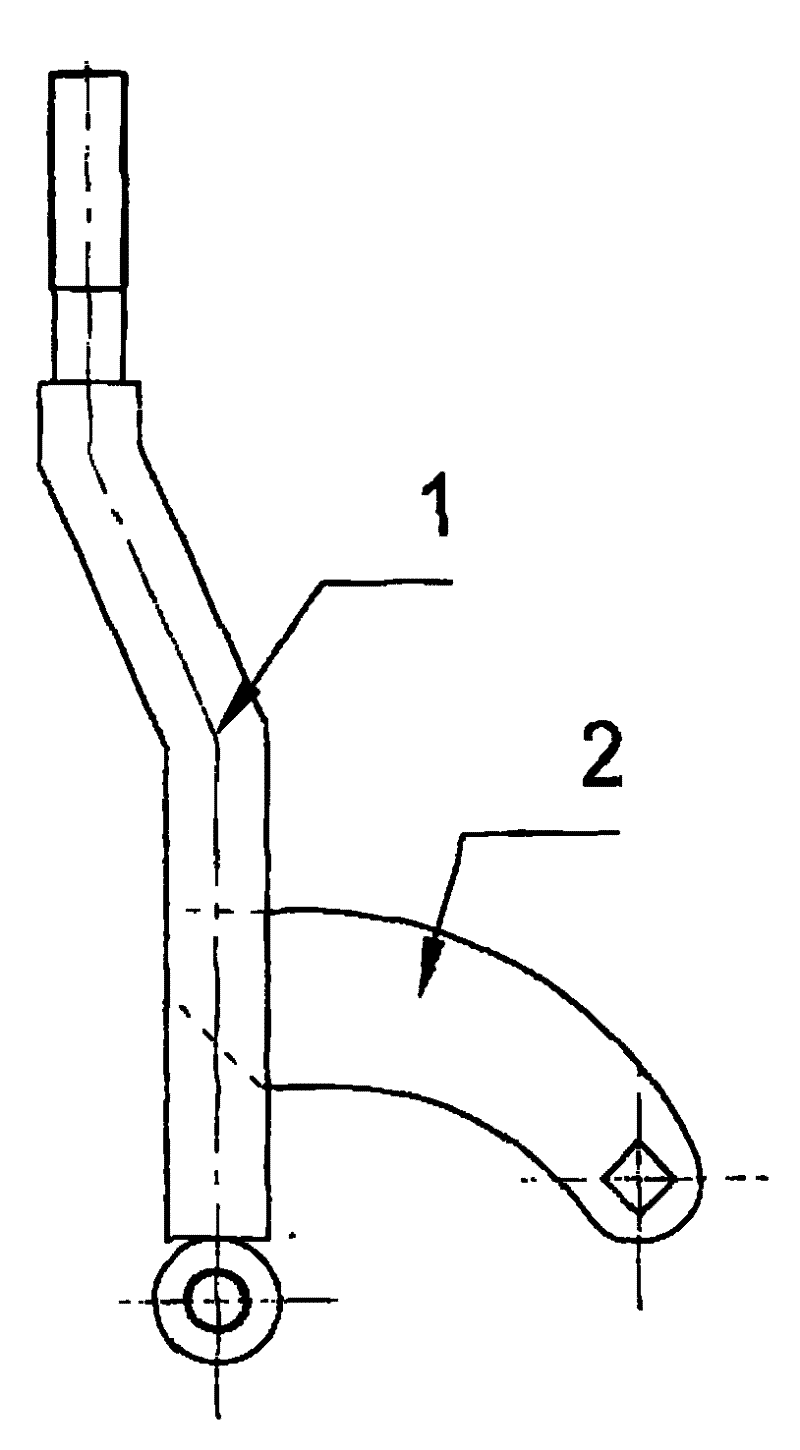

Clutch control mechanism, inner speed changer and bicycle

The invention discloses a clutch control mechanism which is mounted in a hub of a wheel and comprises a control rod, a stay seat and a mounting seat. The control rod is arranged on a hub shaft and isused for driving a clutch to axially move along the hub shaft of the hub; the stay seat is used for driving the control rod to axially move along the hub shaft; the fixing seat is fixedly connected with the hub shaft; the mounting seat is connected with the clutch by a compressed first elastic component. The clutch control mechanism has the advantages that clutch gear-shifting procedures can be smoothly carried out under the control of the clutch control mechanism, and accordingly the use experience feeling of users can be improved.

Owner:GUANGDONG LOFANDI INTELLIGENT TECH CO LTD

Short-span thin coal seam coal mining machine

PendingCN111425196ARealize the arrangementReduce the height of the fuselageToothed gearingsDriving meansThermodynamicsGear wheel

The invention relates to a short-span thin coal seam coal mining machine. The coal mining machine comprises a cutting system, a machine body, a guide sliding shoe, a dragging connecting device and a supporting sliding shoe; the root of a motor-free rocker arm of the cutting system is rotationally supported in a standing shell of a non-swing transmission part, and large and medium size parts such as a cutting motor, a large gear and a planetary mechanism of the cutting system do not change positions along with swing of the rocker arm; the standing shell is fixed to the machine body and locatedin front of the machine body, and the standing shell and the machine body form a basic frame of the coal mining machine; and the guide sliding shoe and the supporting sliding shoe are both installed on the basic frame, the guide sliding shoe and the supporting sliding shoe support the rear portion and the middle portion of the basic frame from the lower portion respectively, and the machine body is in floating connection with a dragging chain of a scraper conveyor through the dragging connecting device. According to the short-span thin coal seam coal mining machine, the structural arrangementproblem of the short-machine-body high-power thin coal seam coal mining machine for the ultra-thin or thin coal seam working face with the complex conditions of low mining height, high coal rock hardness and the like can be solved.

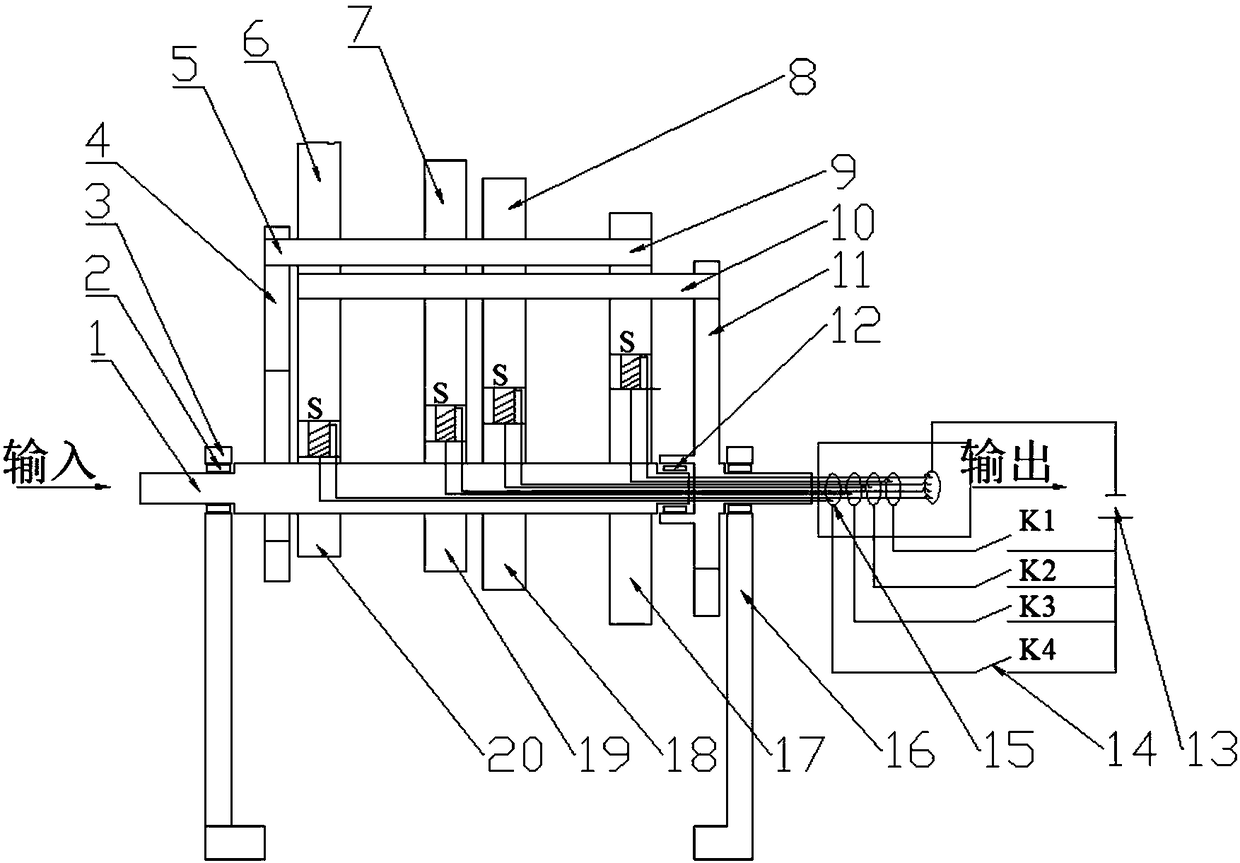

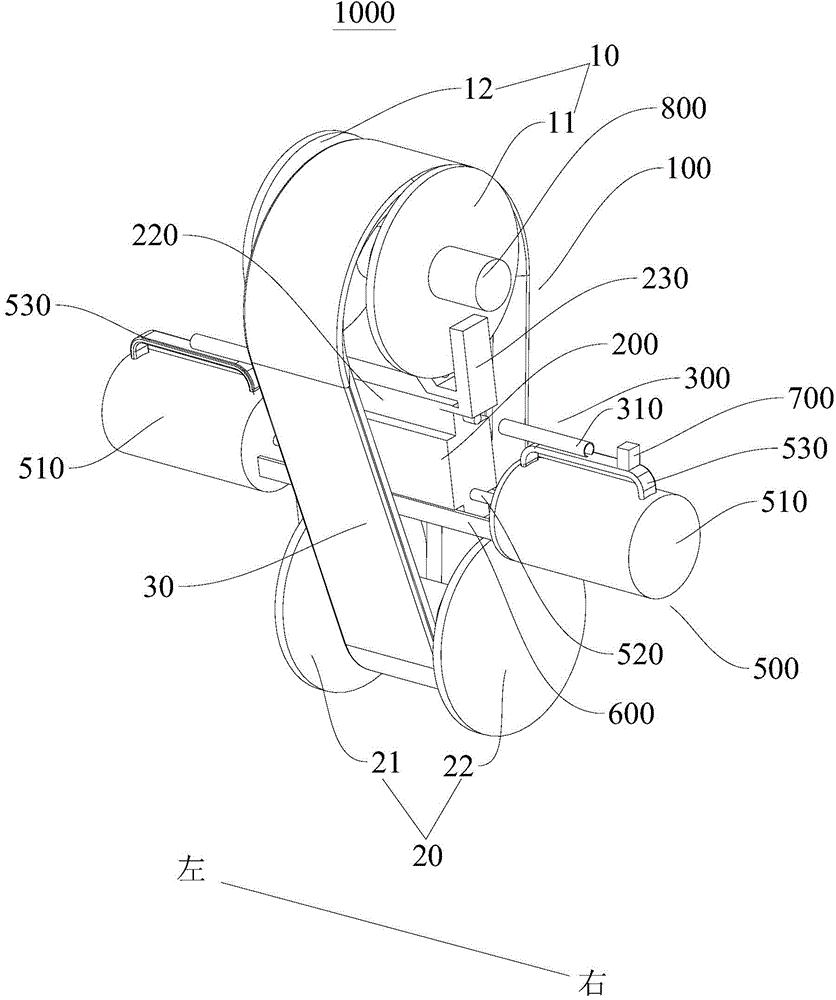

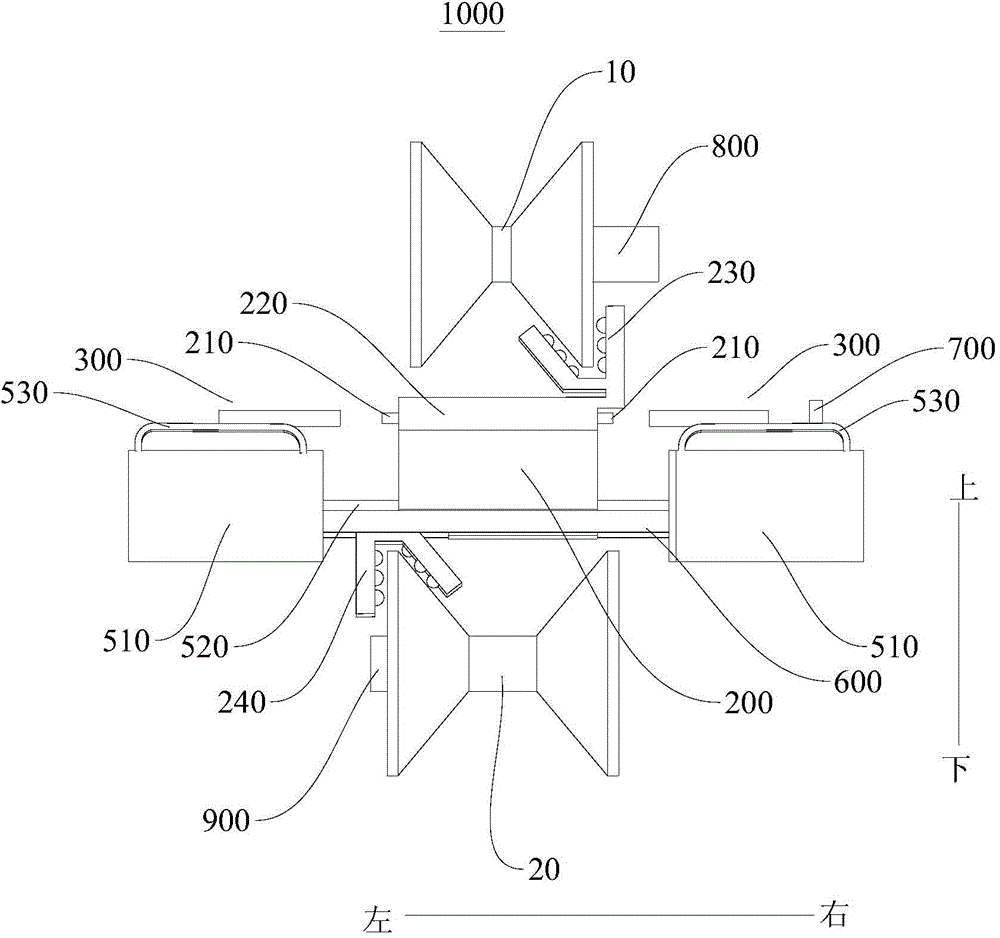

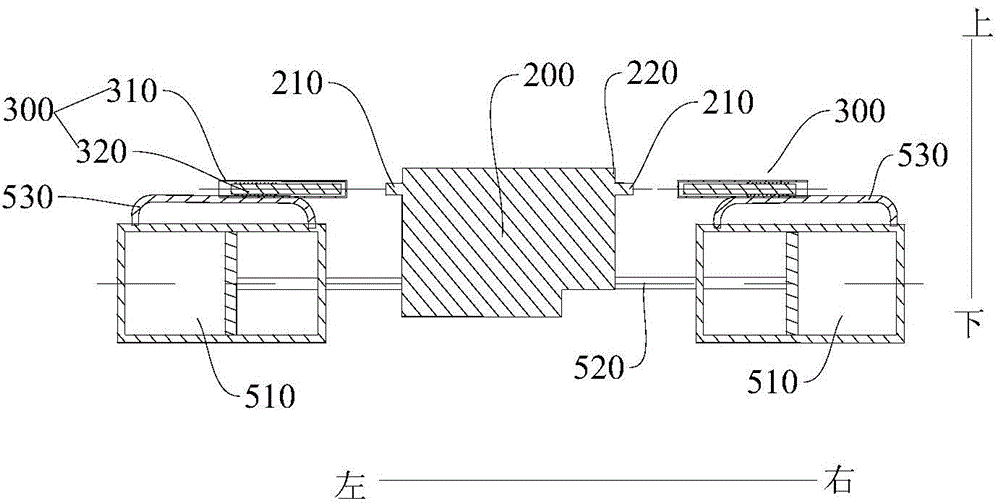

Stepless speed changer and vehicle provided with stepless speed changer

ActiveCN106151423AVariable speed realizationEasy to controlGearingGearing controlDrive wheelTransmission belt

The invention provides a stepless speed changer and a vehicle provided with the stepless speed changer. The stepless speed changer comprises a transmission component, an actuator, first magnetic components, second magnetic components and a PLC; the transmission component comprises a driving wheel group, a driven wheel group and a transmission belt; the driving wheel group comprises a first driving disc and a first driven disc; the driven wheel group comprises a second driving disc and a second driven disc; the actuator is used for driving the first driving disc to move in the direction close to or far from the first driven disc and is also used for driving the second driving disc to move in the direction close to or far from the second driven disc; the first magnetic components are arranged on the actuator; the second magnetic components can be matched with the first magnetic components to drive the actuator to drive the first driving disc and the second driving disc to move; at least one of the first magnetic components and the second magnetic components is a first electromagnetic coil; and the PLC is connected with the first electromagnetic coils. The stepless speed changer is high in safety.

Owner:GREAT WALL MOTOR CO LTD

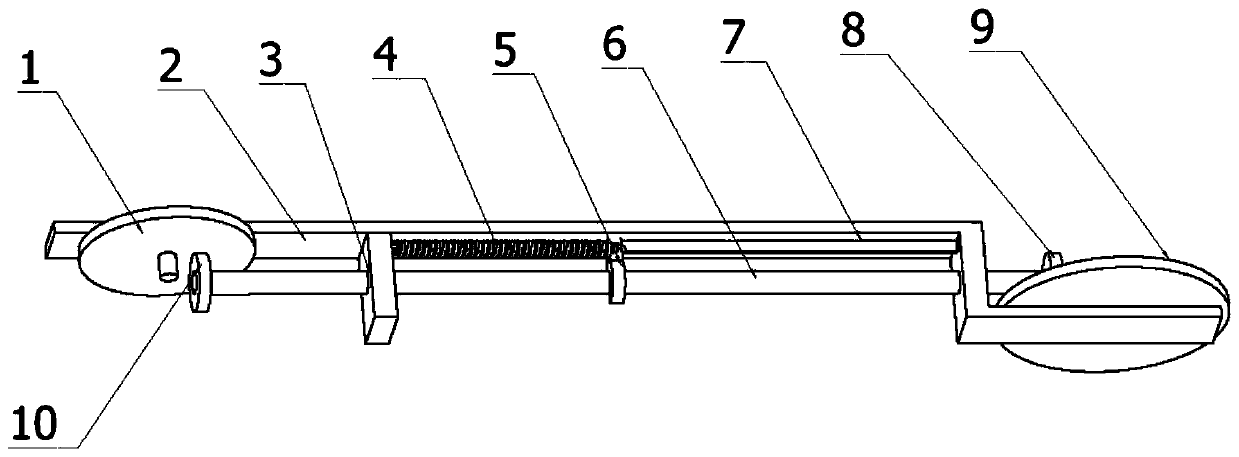

Stepless speed change device

The invention discloses a stepless speed change device which comprises a vehicle frame, wherein the vehicle frame comprises a front frame and a rear frame which are connected fixedly by a connecting frame and are arranged in parallel; a front friction disc is arranged at the front end of the front frame; a rear friction disc is arranged at the rear end of the rear frame; a transmission shaft support is arranged on the front frame; the transmission shaft sequentially penetrates through the connecting frame of the vehicle frame and the transmission shaft support. According to the stepless speed change device disclosed by the invention, by utilizing friction wheels, the power conveys to the rear friction disc from the front friction disc through the transmission shaft, and the shaft sleeve can control different positions of a front friction wheel and a rear friction wheel which are located on the front friction disc and the rear friction disc to realize speed change; gear cables penetrate through gear cable holes, the gear cables are pulled by utilizing fingers, and sliding of the shaft sleeve on the vehicle frame is realized by cooperating with a reset spring; and the friction wheels are shifted in the radial directions of the friction discs, so that the speed change is realized. In addition, the device is simple in structure, convenient to operate, and high in efficiency and economic.

Owner:DALIAN UNIV OF TECH

Two-stage speed changing main reducer assembly for vehicle

InactiveCN104482132AVariable speed realizationRealize differential operationGearboxesToothed gearingsGear driveLeft half

The invention provides a two-stage speed changing rear axle assembly for a vehicle. The two-stage speed changing rear axle assembly for the vehicle comprises a main reducer and a rear axle, wherein the rear axle comprises a first half shaft, a second half shaft, an axle rack, axle shells, brake drums, brake discs, inserting keys, reinforcing ribs, a shock absorber bearing and an oil tube card; the axle shells are arranged on two sides of the axle rack; the inserting keys are respectively arranged at one end of the first half shaft and one end of the second half shaft; the first half shaft and the second half shaft are connected with a left half shaft and a right half shaft which are arranged on two sides of a differential mechanism; the brake discs are respectively arranged at one end of the first half shaft and one end of the second half shaft; each brake disc is provided with the corresponding brake drum; each brake drum is connected with the corresponding brake plate through bolts; and a differential case of the main reducer is connected with a high-gear driven tooth, an intermediate-gear driven tooth and a low-gear driven tooth. The rear axle assembly is compact in structure and reliable in operation, and can be used with a speed changing box of an engine; a gear shifting and torque changing range of the motor vehicle can be expanded; the optimal running speed of the motor vehicle is increased obviously; the climbing ability of the motor vehicle is improved; and the service life of the two-stage speed changing rear axle assembly for the vehicle is long.

Owner:CHONGQING XIANYOU TECH DEV

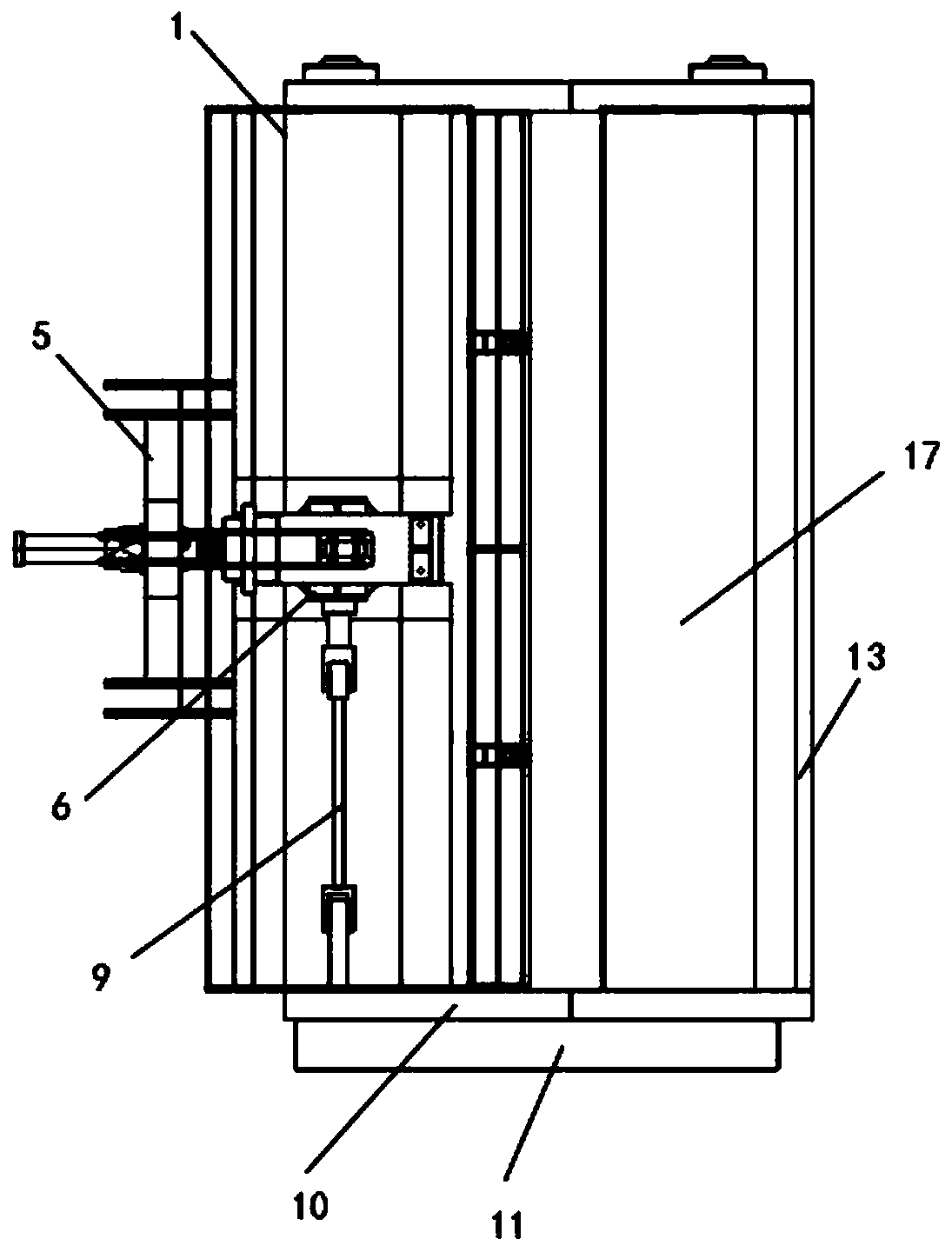

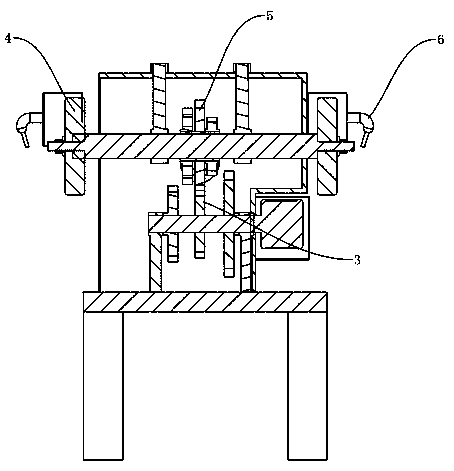

Workpiece grinding double-power high-precision grinding machine capable of achieving intelligent transmission switching

InactiveCN109623601AVariable speed realizationGrinding drivesGrinding machinesTransmission switchingGear wheel

The invention discloses a workpiece grinding double-power high-precision grinding machine capable of achieving intelligent transmission switching. The workpiece grinding double-power high-precision grinding machine comprises a workbench, a protective housing, a driving assembly, a grinding assembly, a speed changing assembly and a cooling assembly. The driving assembly is arranged at the top of the workbench. The speed changing assembly is arranged on the protective housing and is in transmission connection with the driving assembly. When the grinding machine works, a main motor is powered upto drive the driving assembly to rotate; at the moment, the driving assembly is in transmission connection with the speed changing assembly; the speed changing assembly drives the grinding assembly torotate through rotation; the protective housing is provided with a rotatable stop handle; the stop handle is rocked manually, so that gears on the speed changing assembly are engaged with gears on the driving assembly; when a large gear on each speed changing gear is engaged with the small gear of the driving assembly, the speed of the grinding machine is increased; when the large gear on the driving assembly is engaged with the small gear on the speed changing assembly, the speed of the grinding machine is decreased; and through engagement of the large gears and the small gears, the transmission ratio is changed, and speed changing is achieved.

Owner:QINGYUAN CHUQU INTELLIGENT TECH CO LTD

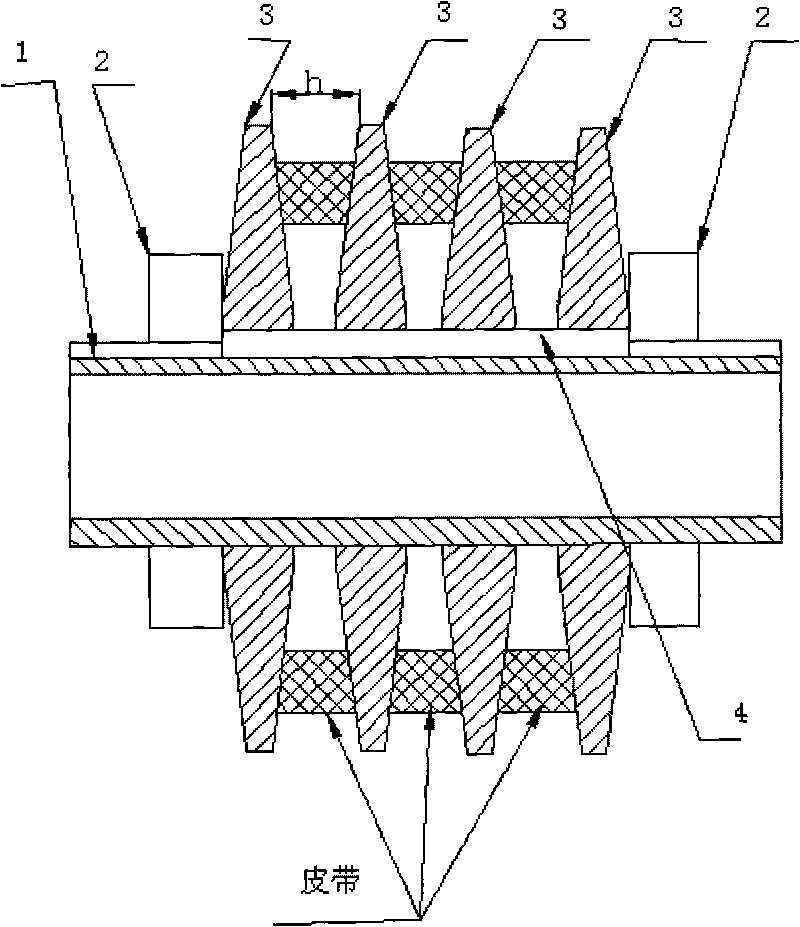

Novel v-belt pulley structure

InactiveCN101737482AEasy to change transmissionVariable speed realizationPortable liftingGearing elementsTransmission systemEngineering

The invention relates to a novel v-belt pulley structure, according to the number of v-belts which are needed in the transmission, transmission plates (3) with proper quantity are arranged on the outer circle of a transmission shaft sleeve (1), the transmission plates (3) are located circumferentially by keys (4), locking screw nuts (2) are respectively screwed on two sides of the transmission shaft sleeve, the distance h between ladder-shaped grooves is adjusted to form a suitable enveloping radius on the belt pulley of the v-belt. In order to avoid the deflection of the v-belt between two belt pulleys, the belt pulleys need to be in the same structure. The novel v-belt pulley structure has the beneficial effects that the change of the transmission can be conveniently realized, thereby being suitable to the requirement of a transmission system which needs to change the transmission frequently.

Owner:刘士民

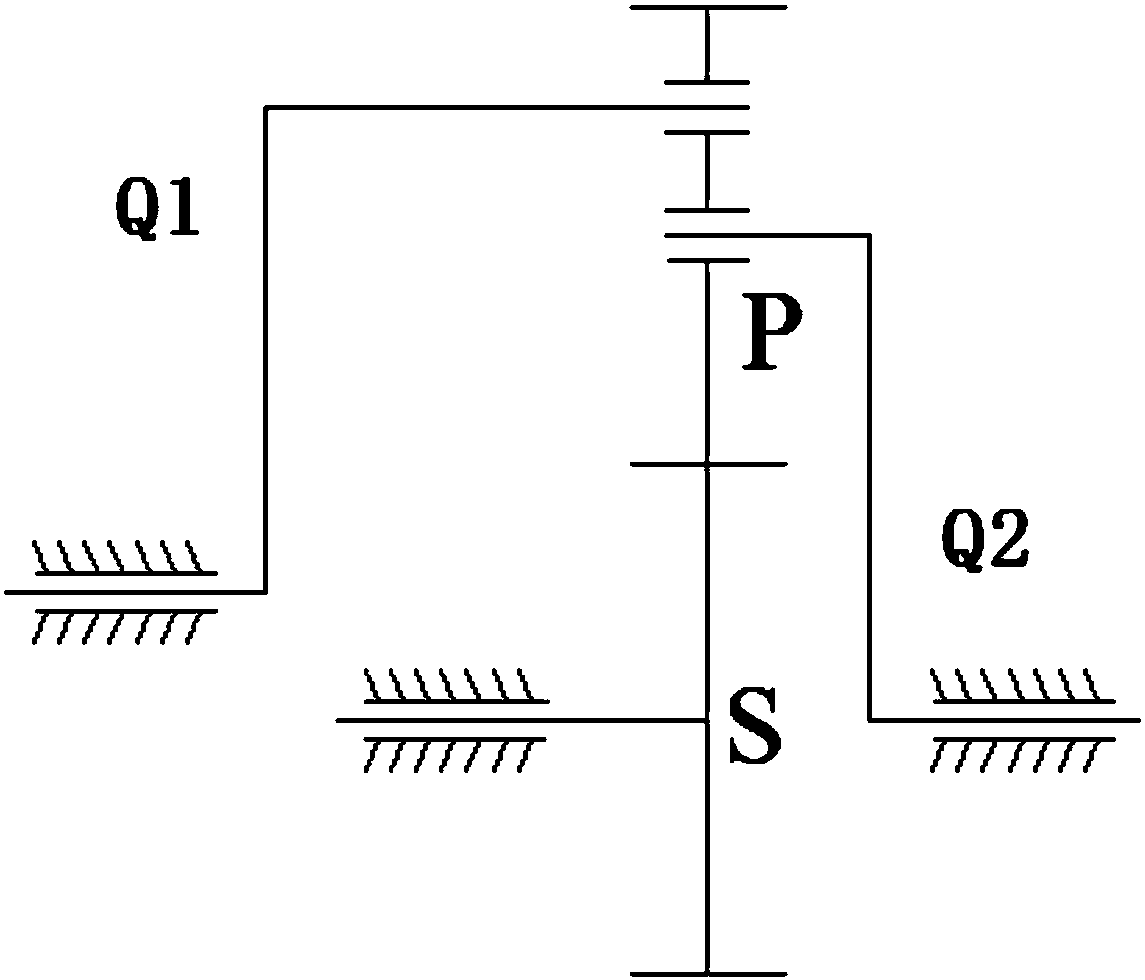

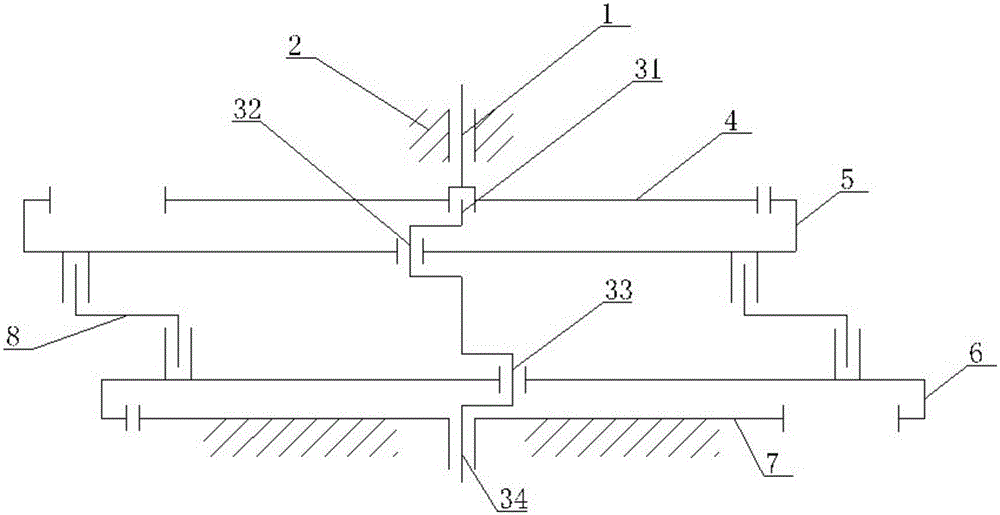

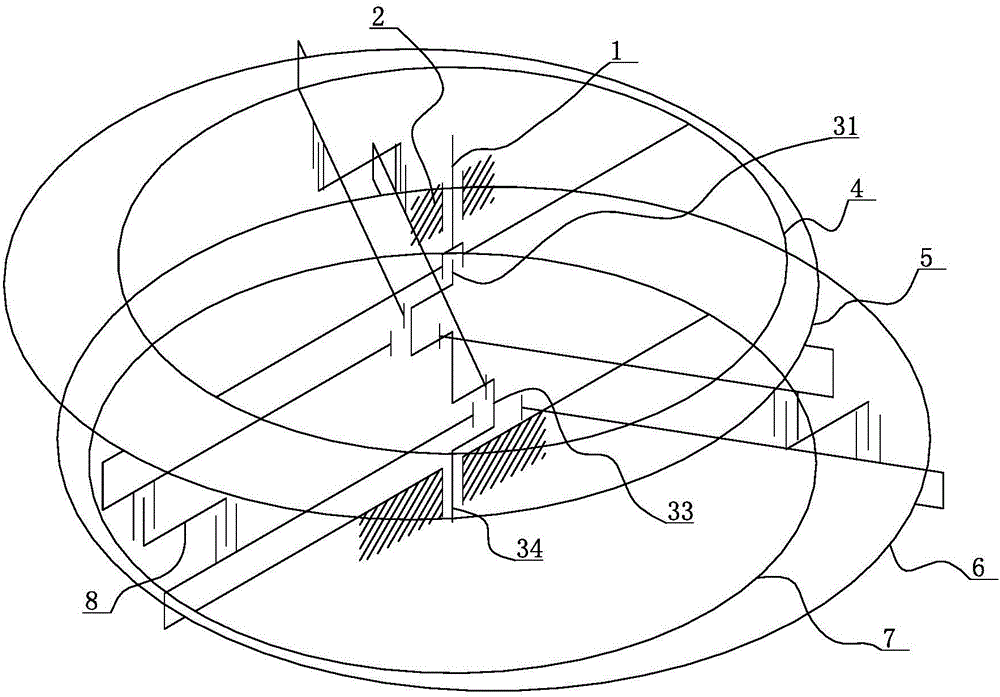

Power transmission apparatus using a planetary gear

InactiveCN102348910ASimple structureReduce manufacturing costHybrid vehiclesToothed gearingsElectricityTransmitted power

The present invention relates to a planetary gear set with one side of a planetary carrier extending to form gear teeth, and to a power transmission apparatus having reduced rotating speed input from a driving power source and input to one actuating means of the planetary gear set and a transmission power source rotating speed is input to the other actuating means to achieve a plurality of gear shifts, and which receives generating power from an output shaft, stores electrical energy, and utilizes the stored electrical energy to control transmission power source, thereby controlling the transmission input shaft with ease. The power transmission apparatus comprises: an input shaft, one end of which is constantly connected to the driving power source to receive power, and to which a driving gear is fixed; a deceleration unit coupled to the driving gear to reduce the rotating speed of the input shaft; a planetary gear set including 1st actuating means coupled to the deceleration unit to receive rotating speed of the deceleration unit, 2nd actuating means for receiving gear-shifting power, and 3rd actuating means for generating output speed; a gear shift unit connected to the transmission power source to receive power for gear-shifting, and coupled to the 2nd actuating means to transmit power for gear-shifting to the 2nd actuating means; and an output shaft fixed at the 3rd actuating means to deliver an output speed. The 2nd actuating means has a rotary shaft and the gear shaft unit has a rotary shaft, wherein the two rotary shafts are arranged vertically to one another. A torque control shaft is connected to the 2nd actuating means to receive rotating force of the 2nd actuating means via power transmission means. The torque control shaft is equipped with a generator for generating electrical energy. A battery for supplying power to the transmission power source is connected to the generator.

Owner:河太焕

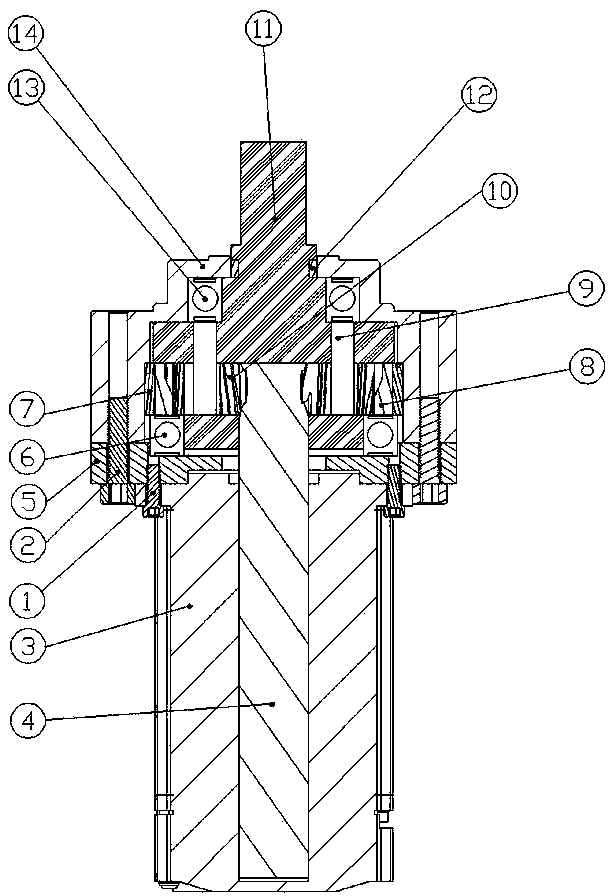

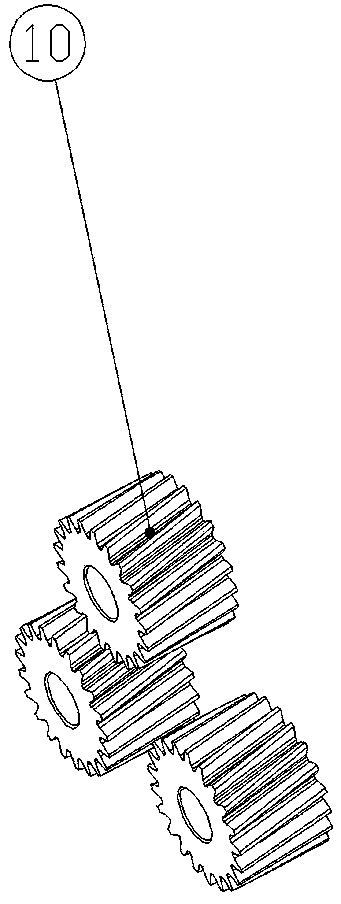

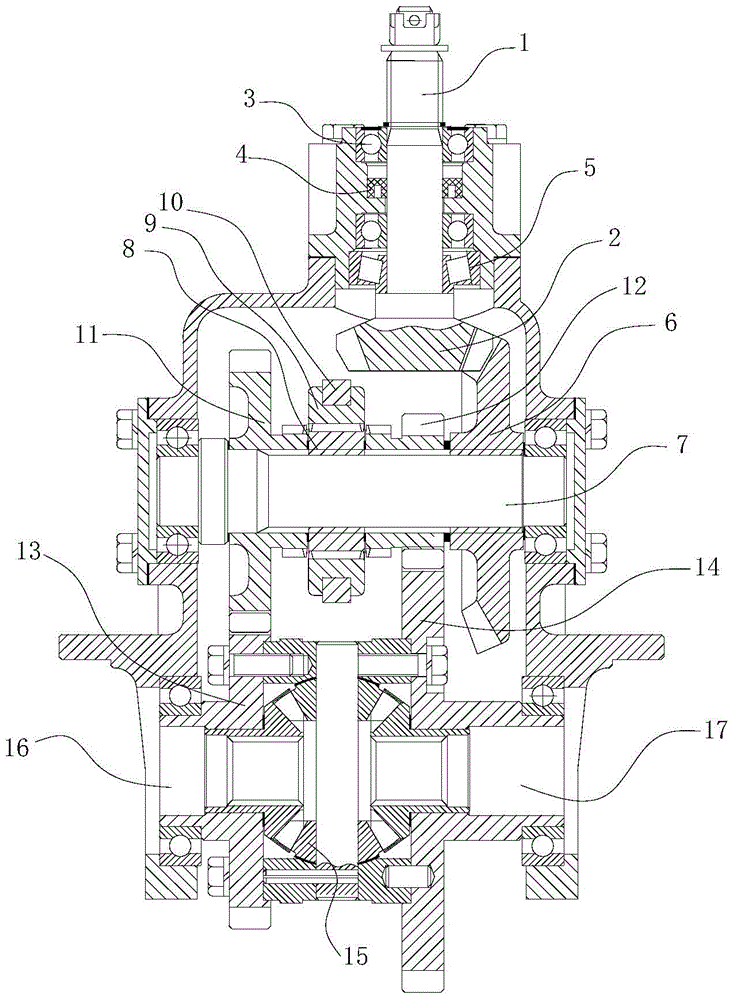

Speed reducer, differential drive device, robot and mechanical arm

ActiveCN105805244AReduce lossVariable speed realizationToothed gearingsTransmission elementsReduction driveReducer

The invention relates to a speed reducer, a differential drive device comprising the speed reducer, a robot comprising the speed reducer and / or the differential drive device and a mechanical arm. The speed reducer comprises an output shaft and an input shaft, wherein the output shaft and the input shaft are installed on a shell in a rolling mode; the output shaft is fixedly provided with a second sun gear relative to the circumferential direction, the second sun gear is meshed with a second inner ring, the second inner ring is connected to a first inner ring through at least one eccentric coupler connection rod, and the first inner ring is meshed with a first sun gear fixed to the shell; the input shaft is a crankshaft and comprises an output shaft connection section, a second crank throw, a first crank throw and an input section, wherein the output shaft connection section, the second crank throw, the first crank throw and the input section are sequentially arranged from the output end to the input end of the speed reducer, the output shaft connection section and the input section are arranged concentrically, and the other sections are arranged in a relative eccentric mode; the input section is installed on the shell in a rotating mode; the axis of the second crank throw is collinear with the axis of the second inner ring, and the axis of the first crank throw is collinear with the axis of the first inner ring. The speed reducer is high in speed ratio and rigidity.

Owner:ROBOT TIME BEIJING TECH CO LTD

Executing element, valve device and air door device

InactiveCN101205990BIncrease the number ofVariable speed realizationOperating means/releasing devices for valvesToothed gearingsClutchEngineering

The invention provides an executing element which achieves the manual / electric operation switching and changes the speed of an output shaft with a simple structure, as well as a valve device and a throttle device using the executing element. The executing element achieves movable operations to a manual / electric clutch gear (8) which consists of a plurality of gears which are coaxial and rotate integrally along a fixing shaft (9), thereby canceling the joggling between a front-stage side transmission gear or a rear-stage side transmission gear and the manual / electric clutch gear (8) and joggling the manual / electric clutch gear (8) and the rear-stage side transmission gear which produces a desired deceleration ratio.

Owner:YAMATAKE HONEYWELL CO LTD

Automobile gear shift rod seaming

InactiveCN102506157AVariable speed realizationFlexible and lightweightGearing controlEngineeringAutomotive transmission

The invention discloses an automobile gear shift rod seaming, which is characterized in that: a ball shaft is welded at the lower end of a gear shift rod; a joint bearing is arranged at one end of the ball shaft; a cambered gear shift rocker arm is arranged above the ball shaft; and one end of the cambered gear shift rocker arm is welded with the gear shift rod. According to the arrangement, the other end of the cambered gear shift rocker arm is connected with a gear shift pull rod on an automobile gear box, so that the speed of an automobile can be changed; furthermore, due to the joint bearing, the speed change of the automobile is flexible and easy.

Owner:SHANDONG SUNSHINE TAILI TECH

CVT

InactiveCN107061652BVariable speed realizationSimple structureFriction gearingsVehicle frameDrive shaft

The invention discloses a stepless speed change device which comprises a vehicle frame, wherein the vehicle frame comprises a front frame and a rear frame which are connected fixedly by a connecting frame and are arranged in parallel; a front friction disc is arranged at the front end of the front frame; a rear friction disc is arranged at the rear end of the rear frame; a transmission shaft support is arranged on the front frame; the transmission shaft sequentially penetrates through the connecting frame of the vehicle frame and the transmission shaft support. According to the stepless speed change device disclosed by the invention, by utilizing friction wheels, the power conveys to the rear friction disc from the front friction disc through the transmission shaft, and the shaft sleeve can control different positions of a front friction wheel and a rear friction wheel which are located on the front friction disc and the rear friction disc to realize speed change; gear cables penetrate through gear cable holes, the gear cables are pulled by utilizing fingers, and sliding of the shaft sleeve on the vehicle frame is realized by cooperating with a reset spring; and the friction wheels are shifted in the radial directions of the friction discs, so that the speed change is realized. In addition, the device is simple in structure, convenient to operate, and high in efficiency and economic.

Owner:DALIAN UNIV OF TECH

Bicycle variable speed bar end

The invention discloses a bicycle variable speed bar end which is installed on the front side of the bending part of one end of a bicycle cross handle. The bottom of the variable speed bar end is provided with a brake lever; the inner side part of the variable speed bar end is provided with a variable speed driving lever capable of being wrenched up and down; the front end of the inner side of the variable speed bar end leads a shift cable out and is connected with a wrench in a rotating mode; the other end of the wrench extends to the cross handle and is arranged above the variable speed driving lever; the wrench is composed of a wrench seat and a wrench handle, wherein the wrench seat movably passes through and is sleeved in the shift cable; the wrench seat and the wrench handle are connected in a rotating mode by a spindle; the wrench handle extends to the cross handle and is arranged above the variable speed driving lever; the wrench and the variable speed driving lever can be formed in a whole; and the wrench extends to the cross handle. The invention not only can hook the brake lever to brake the bicycle but also can pull the variable speed driving lever to realize speed variation and improve the safety of a rider on the premise that palms can hold the cross handle.

Owner:GIANT BICYCLES

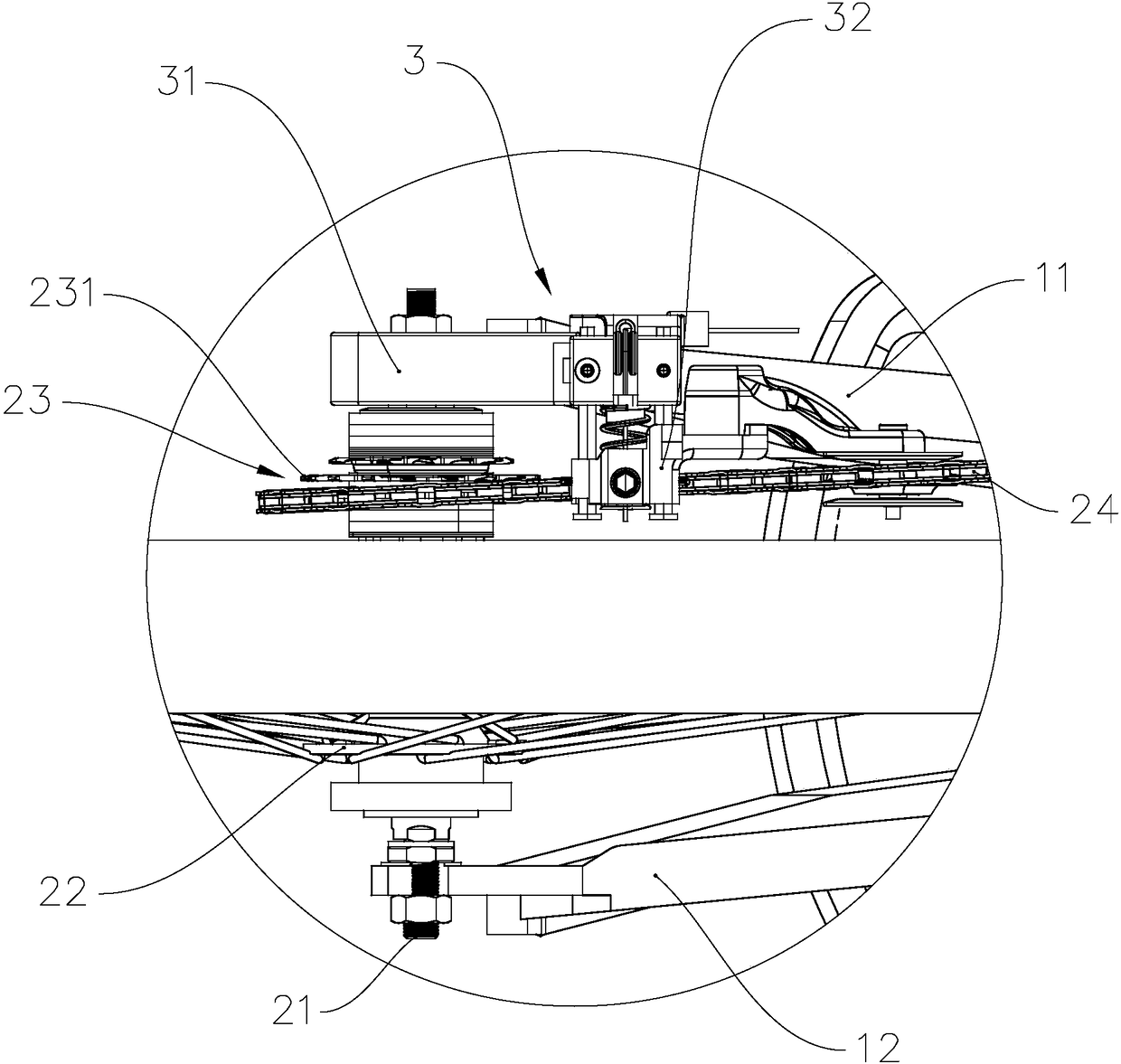

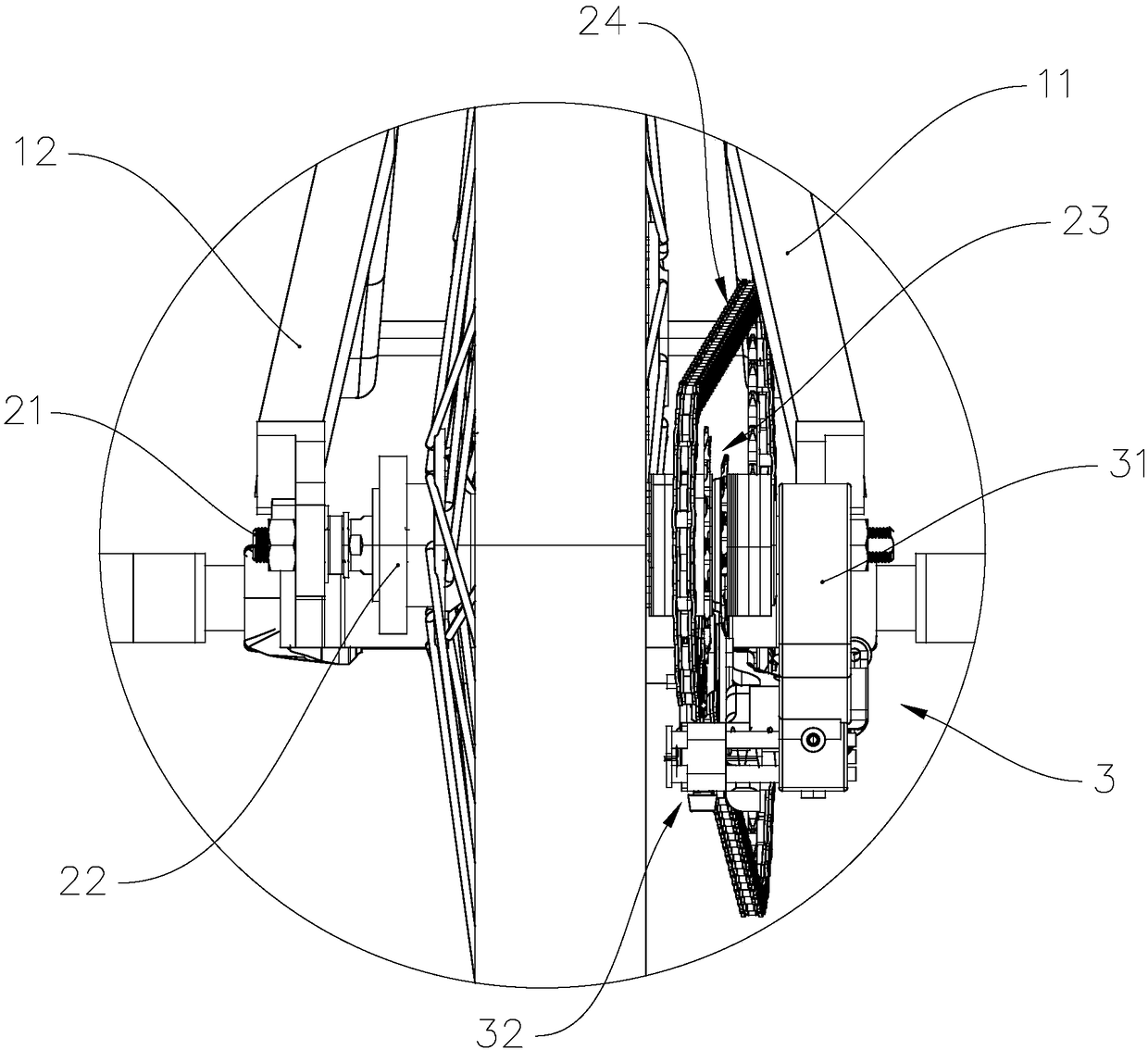

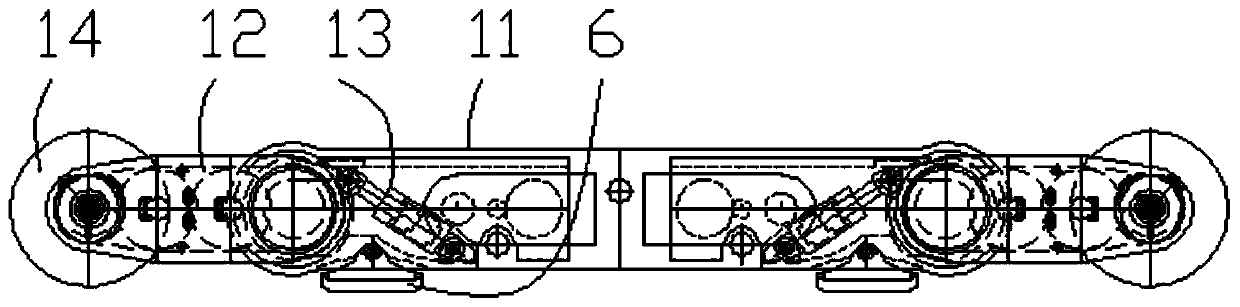

A powertrain for a crawler tractor

ActiveCN113200087BVariable speed realizationFew transitive logarithmsFluid steeringNon-deflectable wheel steeringDrive wheelGear wheel

A power assembly for a crawler tractor, comprising an engine, a steering pump driving device, a steering pump, a clutch, a shuttle gear device, a main transmission device, an auxiliary transmission device, a power output, and a main reduction gear composed of a small bevel gear and a large bevel gear device, a differential steering device group composed of a first differential steering device and a second differential steering device, and a driving wheel; the present invention adopts the auxiliary transmission device and the main transmission device staggered; the main transmission device and the auxiliary transmission can be realized. The common gears between the devices reduces the number of transmission gears and shortens the axial distance of the gearbox; the dual power confluence technology of the planetary gear train and the idler and three-stage gear reduction; the steering process is precise and can be continuously changed. The controllability is good, the left and right wheels can rotate in opposite directions, and the in-situ steering can be realized; the pump drive device is set before the main clutch; the steering action is not affected by the main clutch cut off, and the steering safety of the tractor is high when shifting gears.

Owner:FIRST TRACTOR

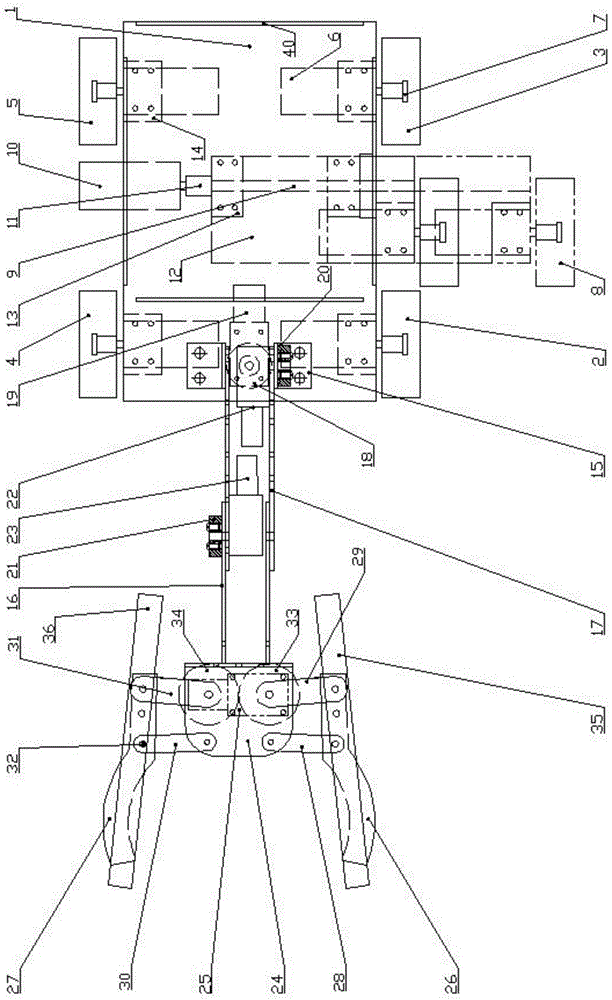

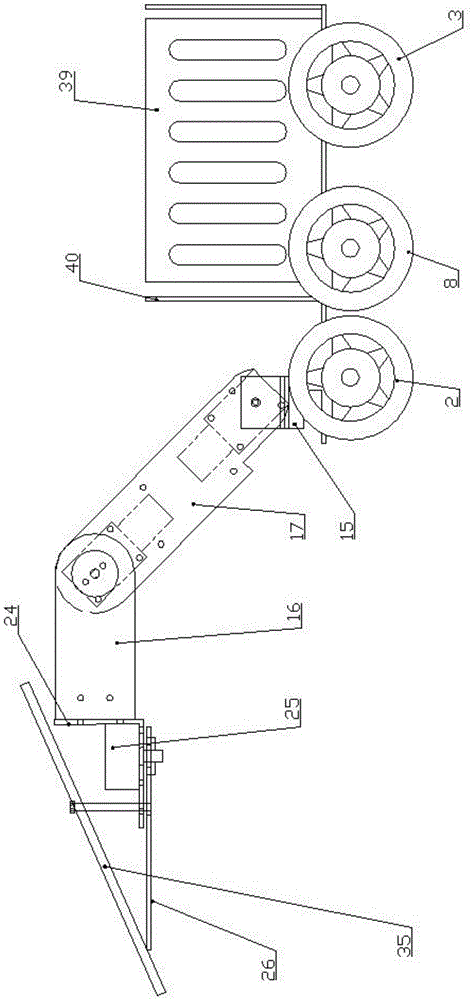

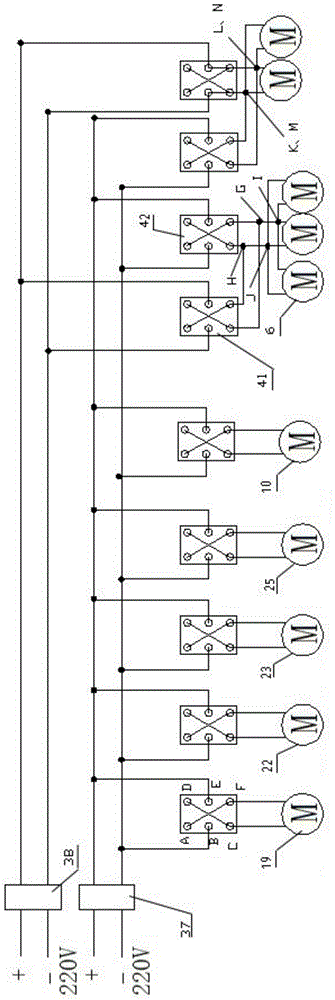

robot

Owner:TONGLING RUIPU PEONY IND DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com