Complementary wheels balancing stepless speed changer

A technology of continuously variable transmission and positive wheel, applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., to achieve the effect of solving special requirements, increasing friction, and not easy to slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

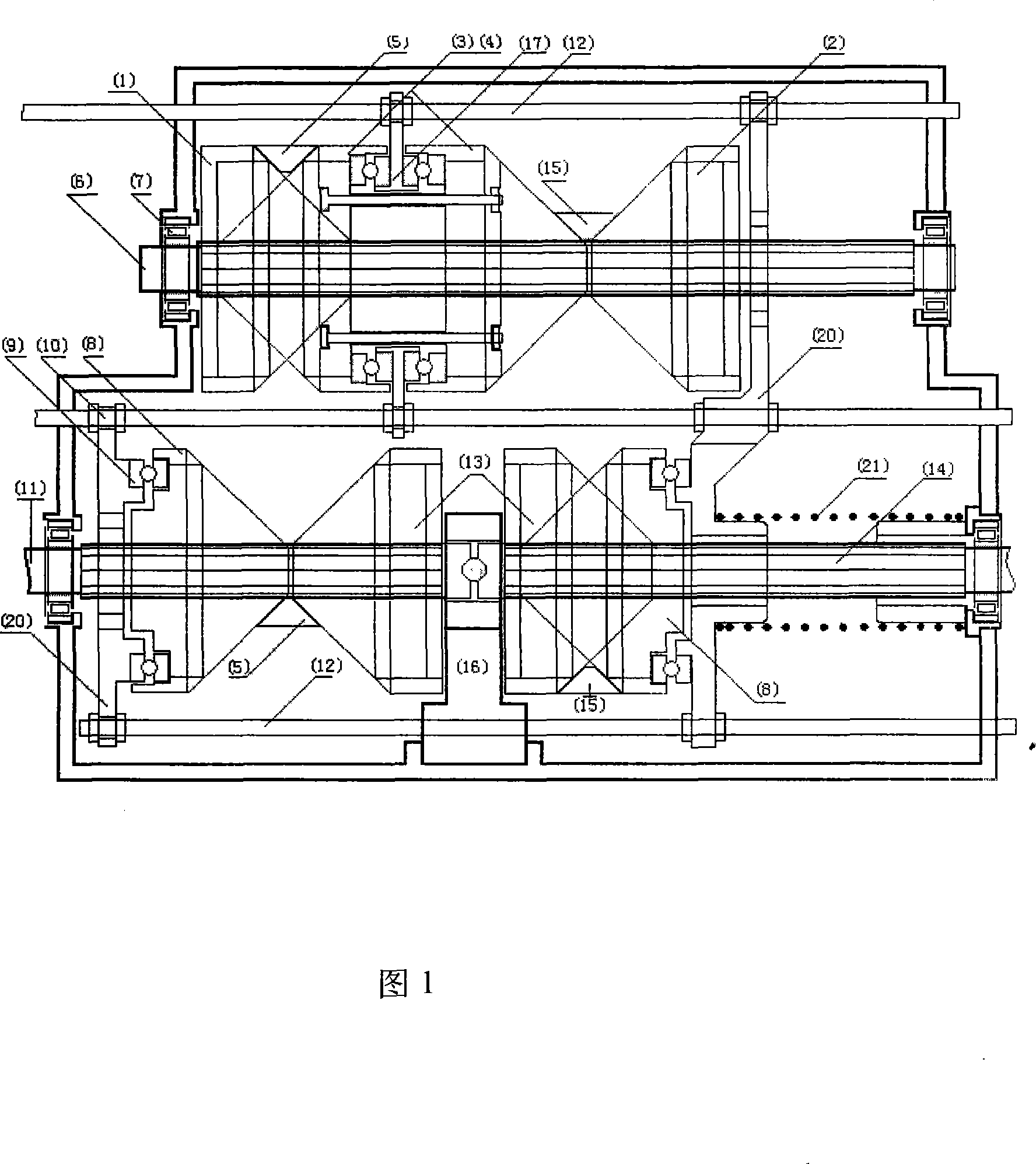

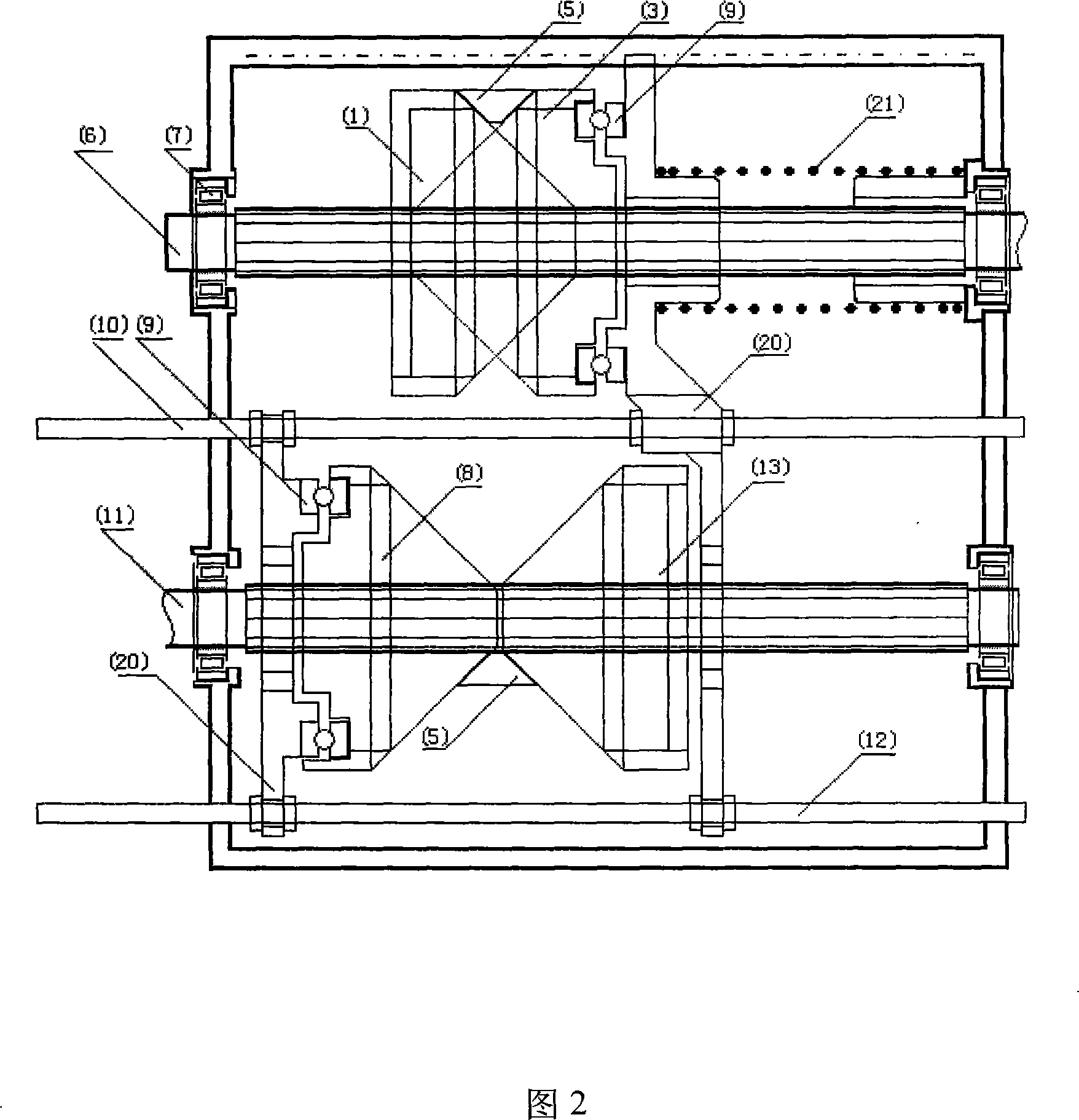

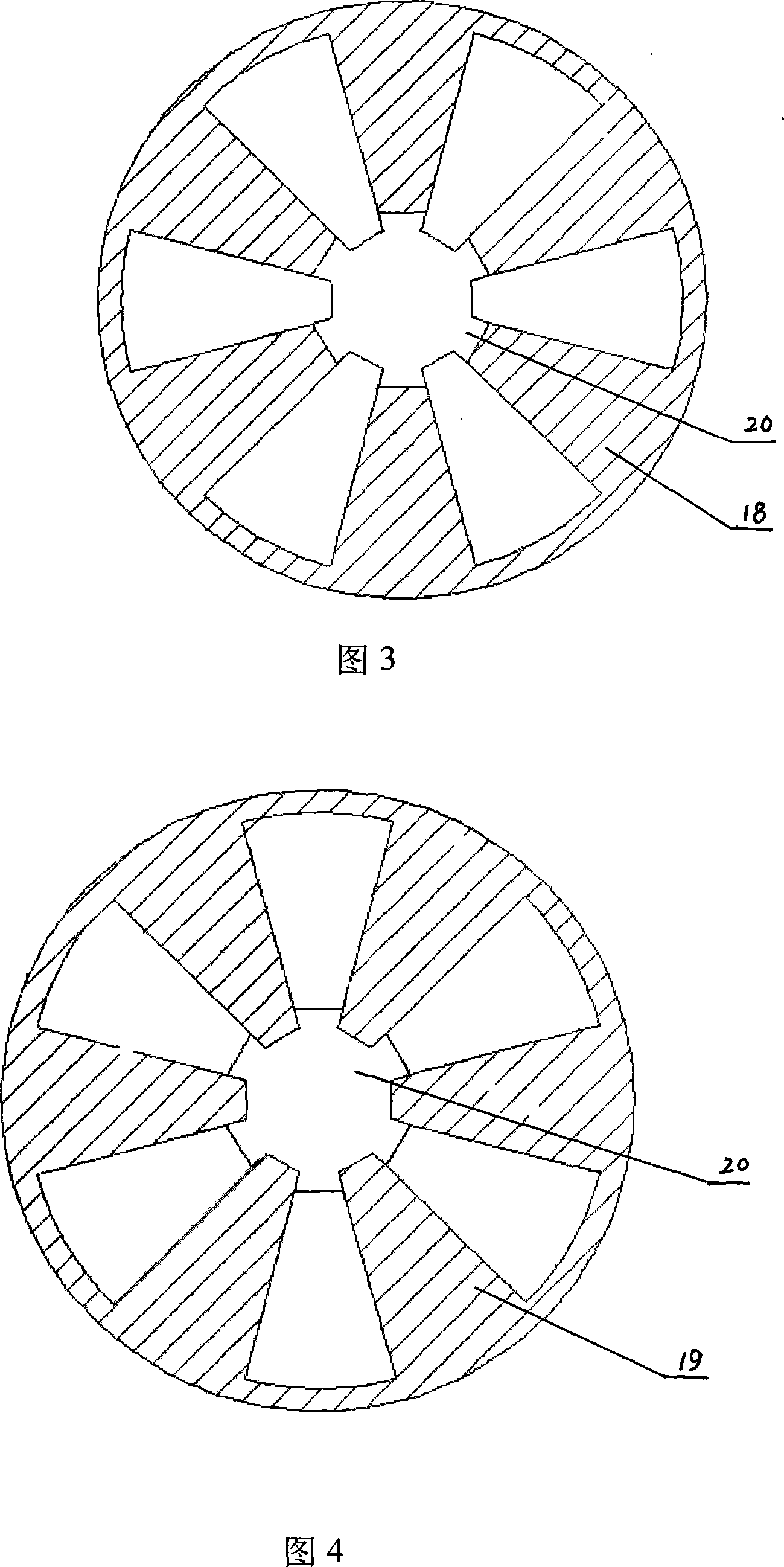

[0039] The basic structure of the yin and yang balance continuously variable transmission includes an active input unit and a first-stage driven output unit, which are connected by a transmission belt I5 between the active input unit and the first-stage driven output unit. It is characterized in that the active input unit has a pair of mutual Interlaced yin wheel 18 and yang wheel 19, the yin wheel and the yang wheel have yin and yang staggered conical surfaces and the conical surfaces of the yin wheel and the yang wheel are complementary, the yin wheel is fixed on the drive input shaft 11, and the yang wheel is sleeved on the drive input shaft 11 can slide left and right; the first-stage driven output unit has a pair of yin and yang wheels that can be interlaced with each other. Fixed on the driven output shaft 6, the male wheel sleeve can slide left and right on the driven output shaft 6; in addition, it is equipped with an adjustment mechanism that simultaneously drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com