Dedicated electromagnetic torque-variable speed adjuster for oil pumping unit

A technology of speed governor and pumping unit, which is applied in the direction of electromechanical devices, electromechanical transmission devices, electric components, etc., and can solve problems such as unusable, easily damaged driving parts, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

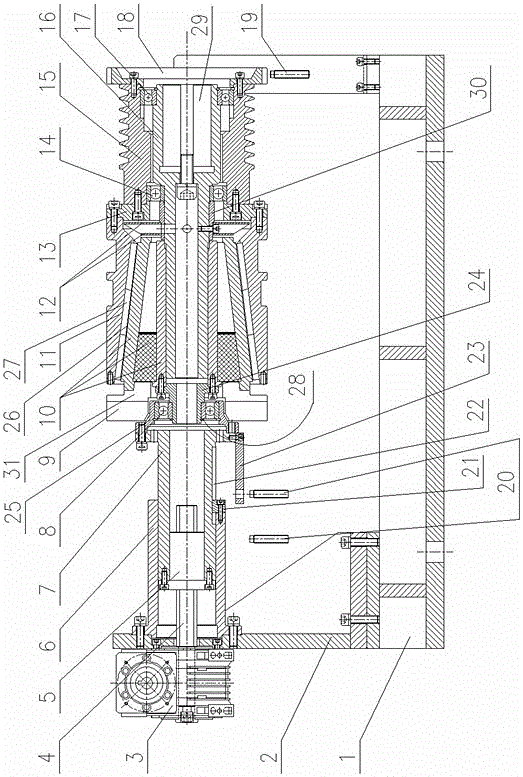

[0013] Such as figure 1 Shown: 1 is the base, on which a bracket 2 is fixed at one end of the base 1, a servo driver 3 including a servo motor and a reduction mechanism is installed on the outside of the bracket 2, and a guide sleeve 6 is fixed on the other side by bolts, and a guide sleeve 6 is fixed on the outside of the bracket 2. A guide shaft 7 that can move axially relative to the guide sleeve 6 is provided inside;

[0014] The lead screw 4 connected with the servo driver 3 is equipped with a screw nut 5, and the screw nut 5 is located in the guide shaft 7 and fixedly connected with the guide shaft 7;

[0015] The end of the guide shaft 7 is supported by a connecting sleeve 24 through the casing 25 and the bearing A8, and the connecting sleeve 24 is fixedly connected with the squirrel-cage active rotor 10 whose periphery is in the shape of a conical surface. A permanent magnet 27 is fixed on the surface of the inner hole of the cone surface of the permanent magnet passi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com