Gearbox with internal support gear shifting mechanism

A technology of shifting mechanism and gearbox, applied in the field of gearbox, can solve the problems that the gearbox cannot adapt to meet the demand, the space is limited, the structure is complex, etc., and achieves light weight, reduced volume and weight, and meets the layout requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

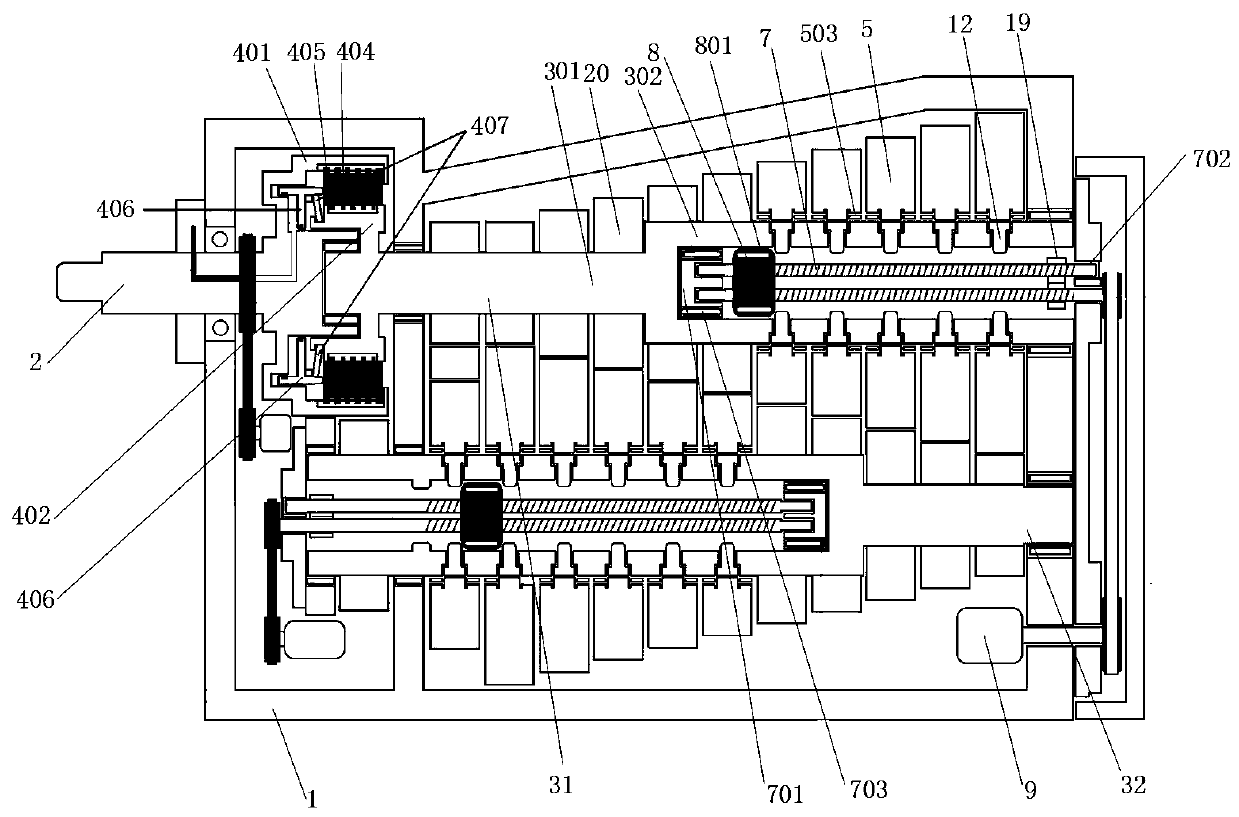

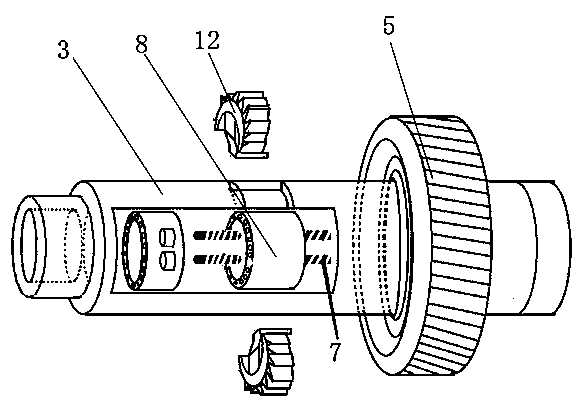

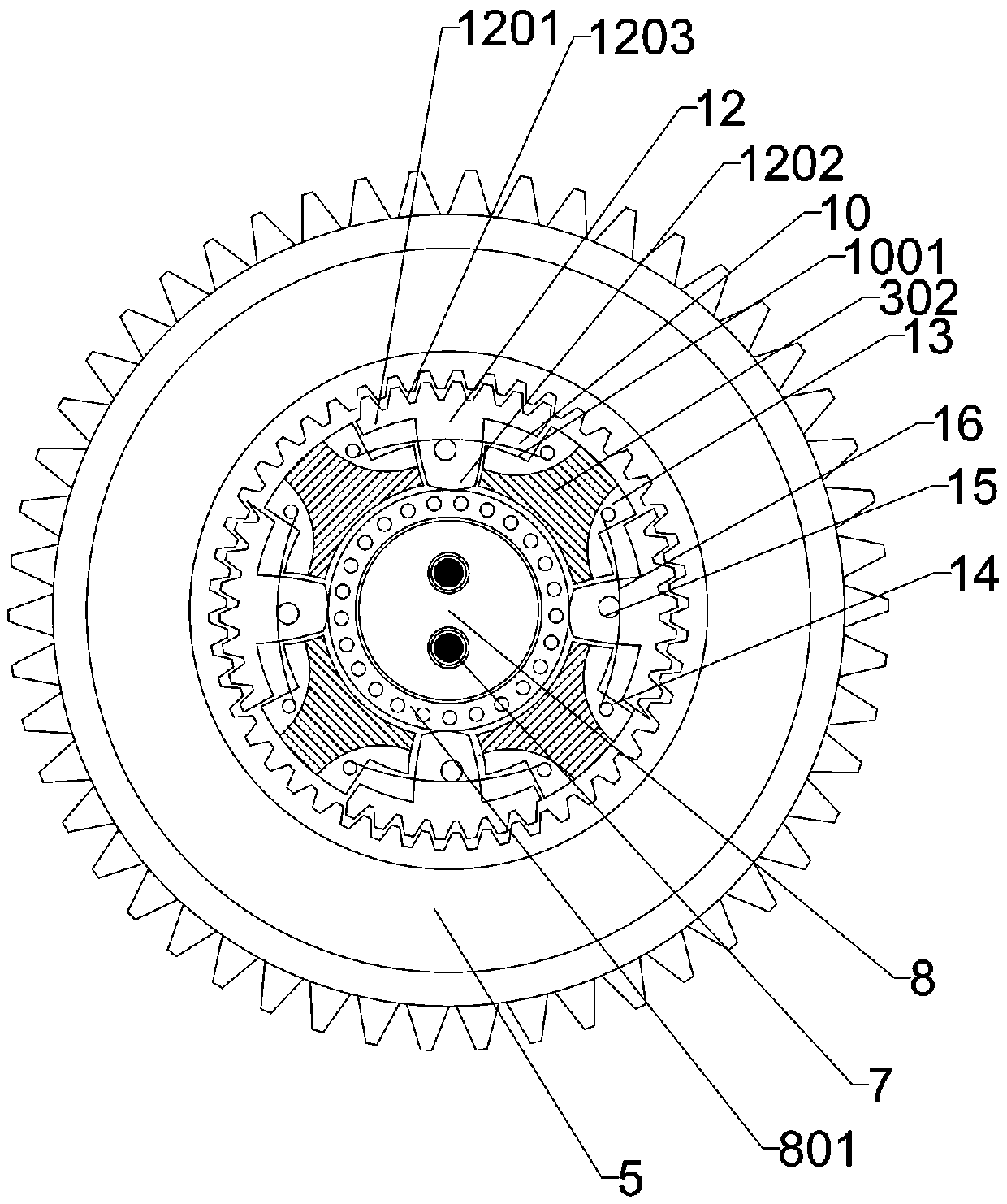

[0028] Embodiment 1: a kind of internal support type shift mechanism gearbox, such as Figure 1-10As shown, including gearbox body 1, power input shaft 2 and clutch, shift output shaft one 31, shift output shaft two 32 are installed in parallel in the gearbox body, shift output shaft one 31, shift output shaft two 32 It includes a solid section and a hollow section respectively, the solid section is fitted with a fixed gear whose diameter increases or decreases sequentially, and the hollow section is fitted with a ring gear 5 or a fixed gear 20 with a successively increased or decreased diameter; located on the shift output shaft The ring gear 5 and the fixed gear 20 whose diameters are successively increased or decreased in the outer casing of the first 31 and the fixed gear 20 and the ring gear 5 whose diameters are successively reduced or increased in the outer casing of the shift output shaft two 32 are correspondingly meshed to form a transmission gear Yes; the outer end ...

Embodiment 2

[0034] Embodiment 2: a kind of internal support type shift mechanism gearbox, such as Figure 1-10 As shown, including gearbox body 1, power input shaft 2 and clutch, shift output shaft one 31, shift output shaft two 32 are installed in parallel in the gearbox body, shift output shaft one 31, shift output shaft two 32 It includes a solid section and a hollow section respectively, the solid section is fitted with a fixed gear whose diameter increases or decreases sequentially, and the hollow section is fitted with a ring gear 5 or a fixed gear 20 with a successively increased or decreased diameter; located on the shift output shaft The ring gear 5 and the fixed gear 20 whose diameters are successively increased or decreased in the outer casing of the first 31 and the fixed gear 20 and the ring gear 5 whose diameters are successively reduced or increased in the outer casing of the shift output shaft two 32 are correspondingly meshed to form a transmission gear Yes; the outer end...

Embodiment 3

[0040] Embodiment 3: The internal support type shift mechanism gearbox of this embodiment will be described centering on the differences from Embodiment 2;

[0041] In this embodiment, the inner bearing 703 is arranged in the central cavity 6, and the inner shaft seat 701 is installed in the inner bearing, and the screw rod 7 and the positioning shaft (where the original second screw rod is located) are installed in the axial direction on the inner shaft seat 701. position), the shaft-shift shift slider 8 is set on the screw 7 and the positioning shaft together, and one end of the positioning shaft and the screw 7 is installed on the inner wall of the shift output shaft 3 through the inner shaft seat 701, and the other end is passed through the side shaft seat 702 Installed on the gearbox body, the end of the screw rod 7 is equipped with a belt pulley, and the screw rod is connected with the output pulley transmission of the screw drive motor 9 power output end through a belt, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com