Novel v-belt pulley structure

A technology of V-belts and pulleys, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve problems such as inability to realize transmission conversion, and achieve the effect of convenient transmission conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

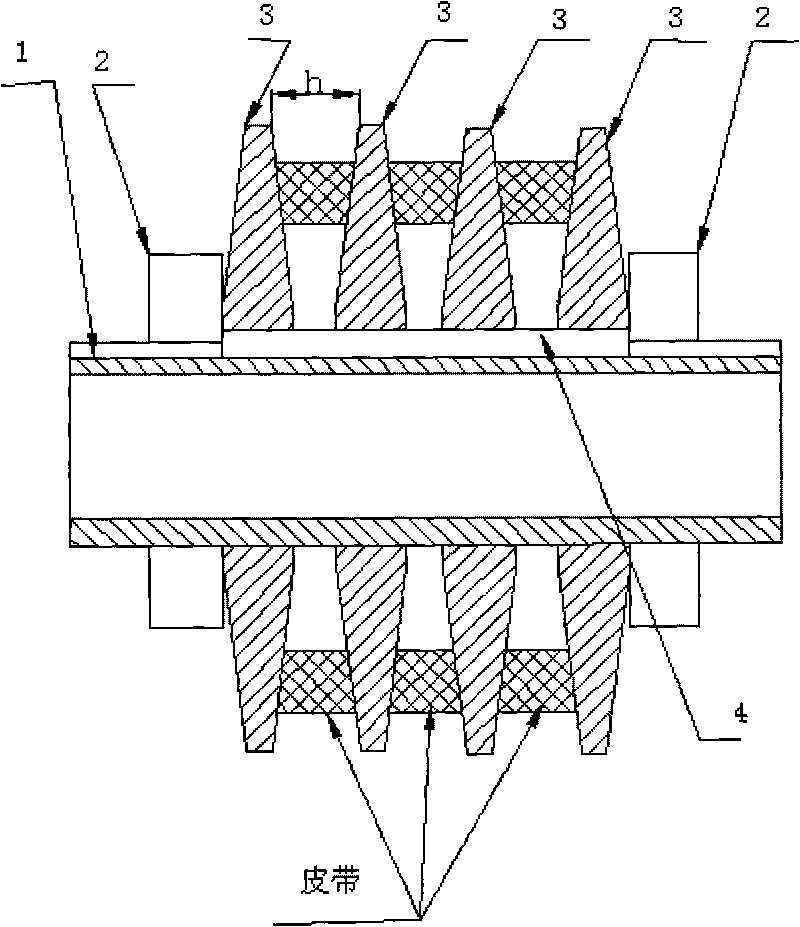

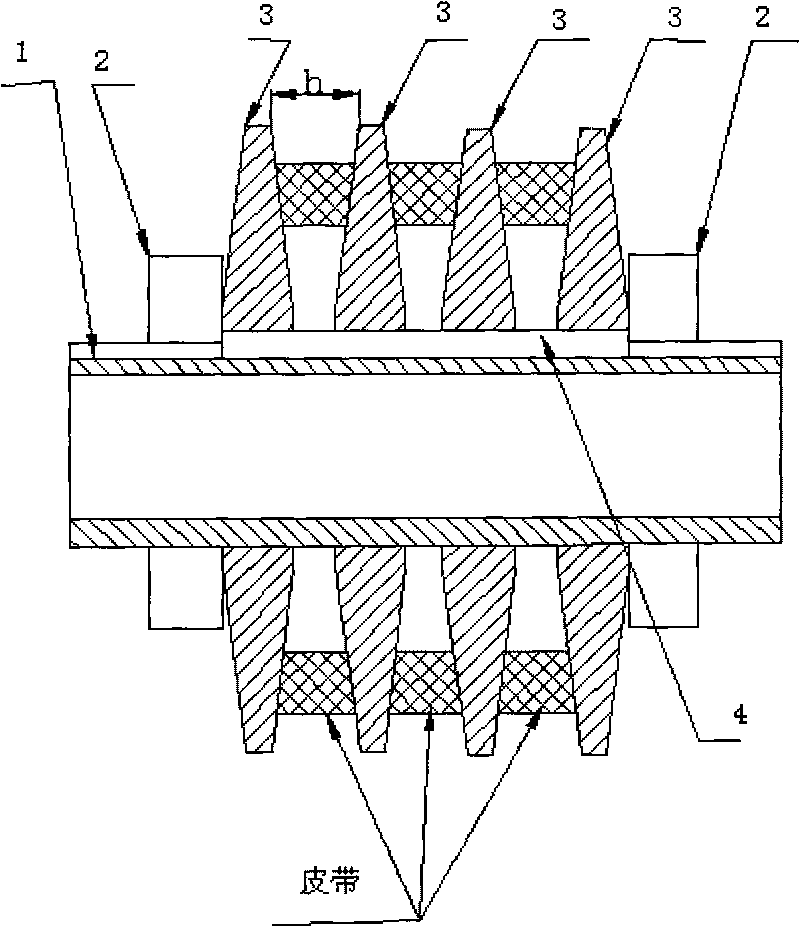

[0008] The present invention will be specifically described below in conjunction with the accompanying drawings.

[0009] According to the number of V-belts required in the transmission, an appropriate number of transmission discs (3) are installed on the outer circle of the transmission shaft sleeve (1), and the keys (4) are used for circumferential positioning between them. Lock nuts (2) are respectively screwed on both sides of the sleeve, and the distance h between the trapezoidal grooves is adjusted so that the V-belt forms a suitable envelope radius on the pulley. In order to prevent the V-belt between the two pulleys from deflecting, the two pulleys must use the same structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com