Single-spindle woodworking milling machine with high-speed spindle

A high-speed spindle and single-axis technology, applied in wood processing equipment, manufacturing tools, special forming/shaping machines, etc., to achieve stable performance, convenient speed change, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

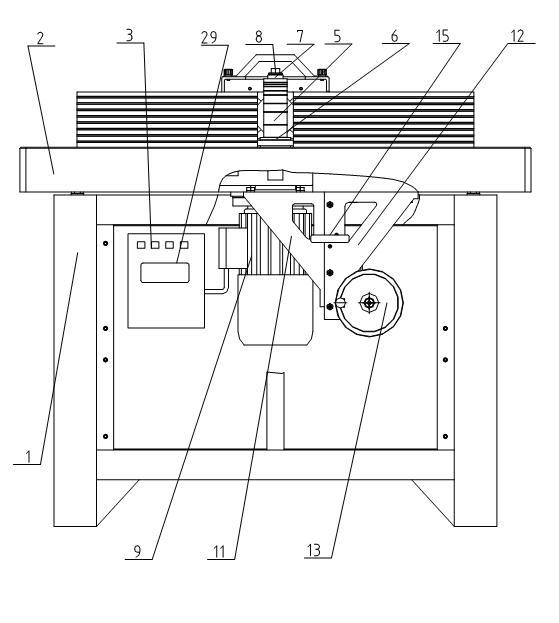

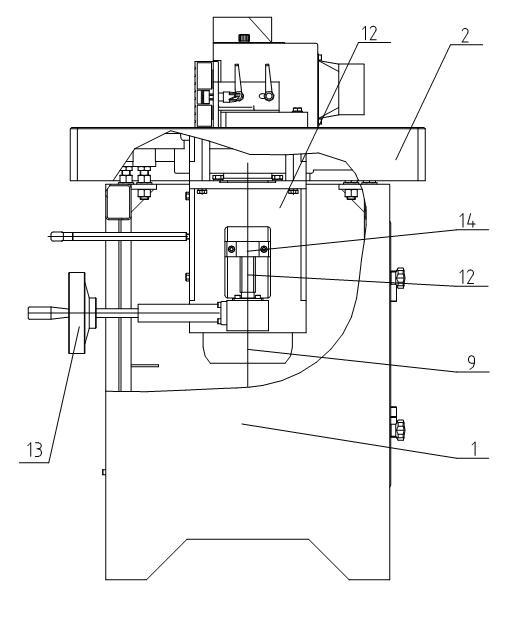

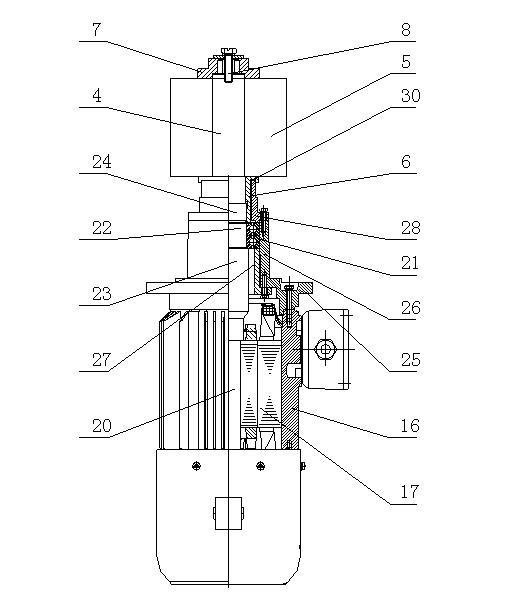

[0016] Below in conjunction with accompanying drawing, the present invention is further described:

[0017] As shown in the accompanying drawings, a high-speed spindle single-axis woodworking milling machine includes a frame 1, a worktable 2, a milling cutter device, a milling cutter lifting device and a motor. The workbench 2 is fixedly connected to the frame 1, and the frame 1 A control device 3 is provided, and the milling cutter device includes a main shaft 4, a milling cutter 5, a cutter nut 6, a flat hole sleeve 7 and a pressure screw 8, a main shaft 4, a milling cutter 5, a cutter nut 6, a flat hole sleeve 7, a pressure screw The connection relation of knife screw 8 is identical with prior art, and this does not go into details, and milling cutter elevating device is made of elevating screw 10, slide plate 11, slide plate seat 12, elevating hand wheel 13, elevating nut 14, locking device 15, worm gear, Composed of worm, bearing and bearing seat, the connection relations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com