Bicycle inner transmission and manufacture method thereof

A technology for internal transmissions and bicycles, which is applied to vehicle gearboxes, vehicle components, wheel transmissions, etc., and can solve problems such as excessive oil pollution, unsuitable for airtight and dust-proof production, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail in conjunction with accompanying drawing:

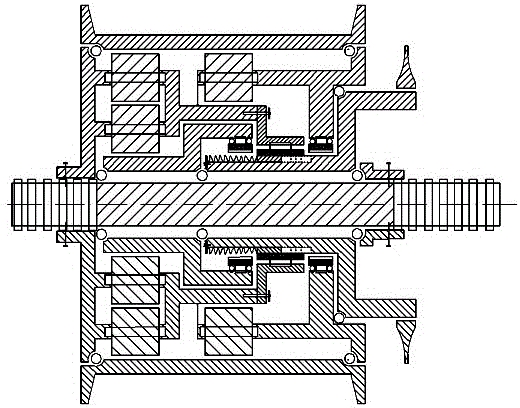

[0038] see figure 1 Shown: It is the overall sectional view of the internal transmission, which is divided into four parts: the deceleration part, the acceleration part, the active part, and the reverse chain shifting system. Set up three gears.

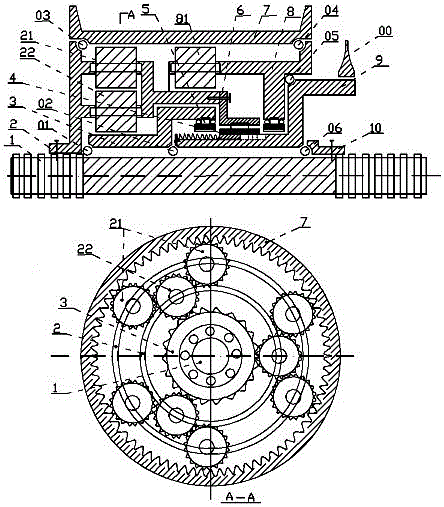

[0039] see figure 2 Shown: is the half-section index diagram of the internal transmission, including the large bowl set 01\02\03\04\05\06, axle 1, fixed star frame 2, sun gear 3, shift cylinder 4, pawl 5, Fixed gear ring 6, shell tube 7, moving star frame 8, driving tube 9, positioning ring 10, positive star wheel 21\81, anti-star wheel 22, pawl circle 55 etc. are formed. The sectional view A-A is the relational sectional view of the deceleration part.

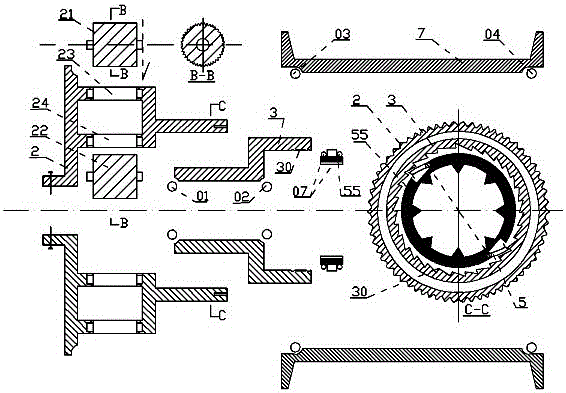

[0040] see image 3 Shown: It is the sectional view of the deceleration part of the internal transmission, which consists of the fixed star frame 2, the positive star wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com