High-speed frame stranding machine

A stranding machine and frame-type technology, which is applied in the field of high-speed box-type stranding machines, can solve the problems of difficulty in centralized loading, limitation of the cage body, low positioning accuracy, etc., to improve production efficiency, increase the speed of the cage, and maintain simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

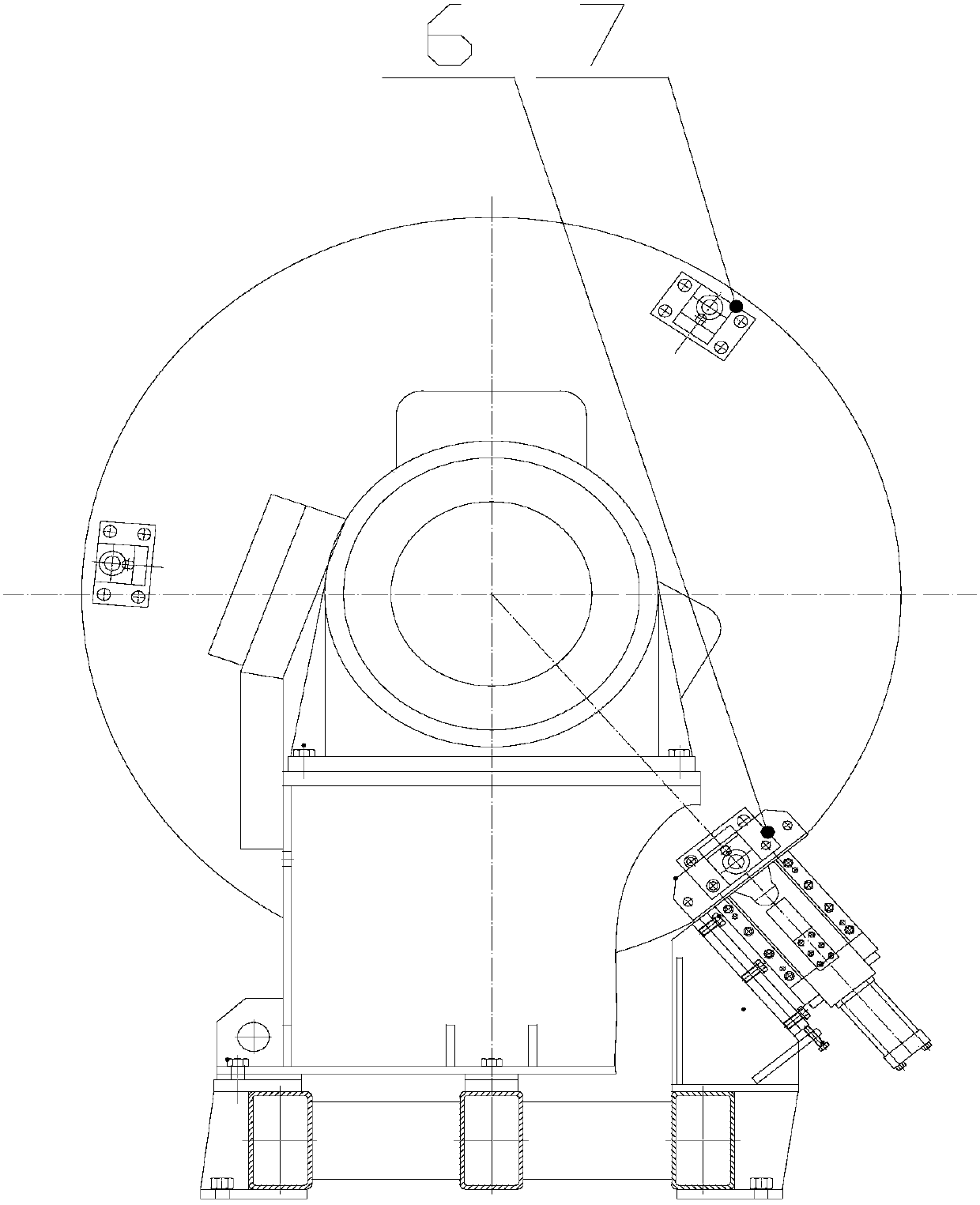

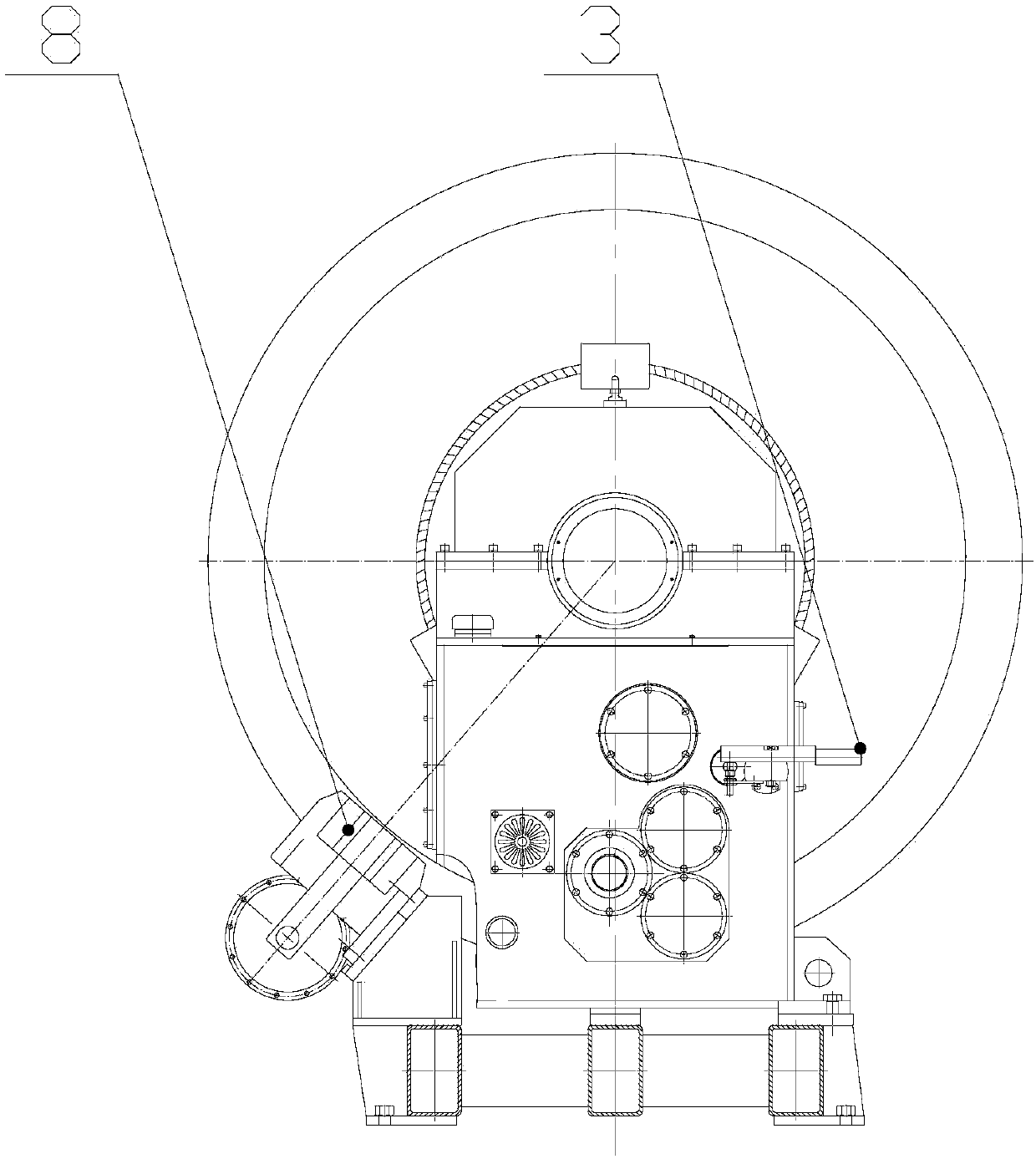

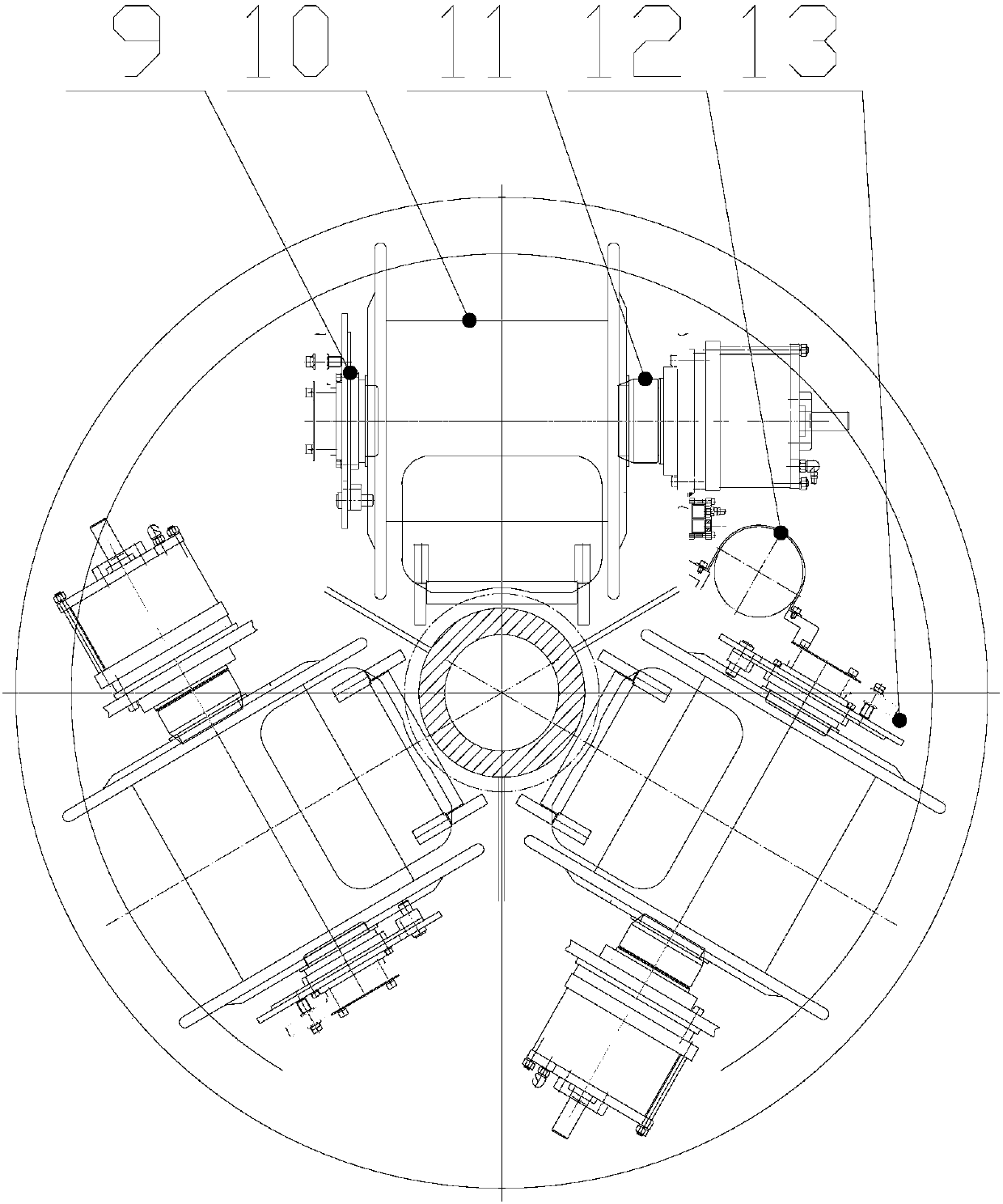

[0034] The present invention will be further described now in conjunction with accompanying drawing.

[0035] see figure 1 , Figure 6-Figure 9 , figure 1 , Figure 6-Figure 9 Shown is an embodiment of the present invention, which is a high-speed frame-type wire stranding machine that combines the upper plate motor and the stranding cage running motor into one to achieve no pitch blind zone, including the central spindle 17, the stranding cage body 5 and Winch cage gearbox 4, speed-regulating main motor 1 and coupling 2, speed-regulating main motor 1 is connected to input shaft 21 of winch cage gearbox 4 through coupling 2, and winch cage gearbox 4 includes a rotatable output Shaft 18, switching shaft 20, transition shaft 19 and input shaft 21. The two ends of the output shaft 18, the switching shaft 20, the transition shaft 19 and the input shaft 21 are respectively connected by bearings, so that the rotation around their axes can be realized. in:

[0036] The output sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com