In recent years, the mechanical long taper-roller continuously variable transmission mechanism has received extensive attention and research, but there are few major innovations and breakthroughs in the structure

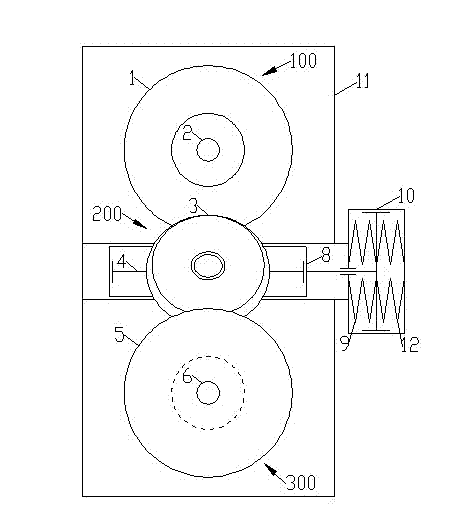

[0003] The belt-driven continuously variable transmission mainly relies on variable-

diameter driving and driven wheels and

metal belts to achieve stepless change in speed ratio. It has

high transmission efficiency and a wide range of speed changes. The best match between the

transmission system and the engine operating conditions improves the fuel economy of the vehicle; in the last ten years, CVT (Continuously Variable Trans-mission) technology has made great progress and is widely used in In the field of low-power vehicles, however, it is limited by the material and technology of the

metal strip, making the manufacturing cost very high

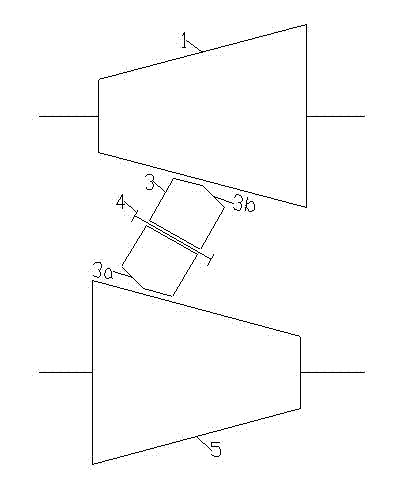

[0004]The bevel wheel type continuously variable transmission is mainly driven by the

contact friction and lubricating

oil film traction of the main and driven rigid elements (or through the intermediate element), and can be changed by changing its The working

radius of the contact point is continuously variable. It has the advantages of stable transmission,

low noise, simple structure, overload protection effect, and various forms. At present, there are more cone-disk ring-disk types, multi-disk types, and

steel ball-cone types. Wheel type,

diamond cone type, planetary cone disc type and

planetary ring cone type continuously variable transmission, etc.; in the cone wheel friction type continuously variable transmission, when the cone wheel and the contacted transmission elements are under load and friction work, due to the cone wheel and the contacted transmission element Due to the geometric shape of the contacting transmission elements, the speed distribution in the contact area of the two rolling elements is different, resulting in geometric slippage between the two rolling elements. The geometric slippage in the mechanism will increase the temperature of the traction oil and reduce the traction coefficient, resulting in transmission transmission of the transmission. Power and efficiency decline, etc., and at the same time, it will accelerate the wear of the traction surface and reduce the life of the transmission

[0005] In the prior art, in order to reduce the spin phenomenon of the friction transmission contact area in the bevel wheel type continuously variable transmission, many designers will minimize the contact area between the bevel wheel and the contacted transmission elements according to the size of the transmission power. In order to reduce the geometric

slip rate; to minimize the geometric

slip rate in the bevel wheel friction continuously variable transmission, only when the contact area between the bevel wheel and the contacted transmission element is a

point contact, theoretically it is not Geometric sliding will occur, and the transmission efficiency at this time is also the highest; however, the smaller the contact area between the cone wheel and the contacted transmission element, the worse the load-

carrying capacity and the smaller the transmission power; there is a contradiction between the above two phenomenon, how to solve the above technical problems, there is no

ideal solution in this field

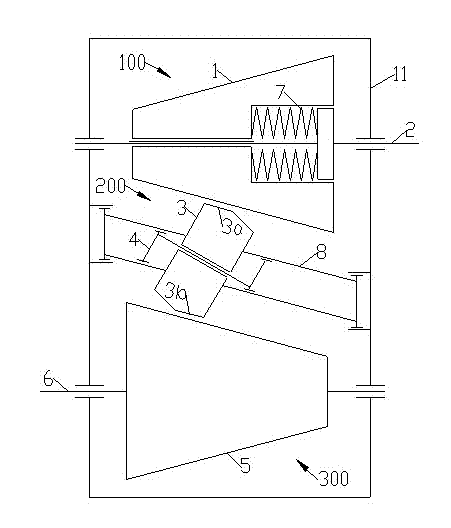

[0006] In summary, the present invention proposes a novel structure of a mechanical continuously variable transmission, which can reduce the geometric

slip rate in the

bevel gear transmission mechanism while increasing the contact area between the

bevel gear and the contacted transmission element; For example, when the length of the

contact transmission area between the cone wheel and the cone wheel in the present invention is 10 mm, the geometric slip=0 when the

transmission ratio is 1 to 1, and the maximum geometric slip within the range of 1 to 0.4 to 2.5 is less than 0.04; The geometric slip of the present invention in the entire range of adjustable

transmission ratio is very small, almost negligible, and can effectively improve the quality and performance of the product, so that it can better adapt to the working conditions of various transmission machinery. At present, the same type of cone Wheel CVTs can't do it

Login to View More

Login to View More  Login to View More

Login to View More