Soil crushing device with screening function

A crushing device and screening technology, applied in the field of environmental remediation, can solve the problems of inability to achieve powder or finer particle size, inability to mix the remediation agents with soil, and inability to guarantee the remediation effect, so as to improve the crushing rate and efficiency, The effect of improving soil fragmentation efficiency and promoting transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

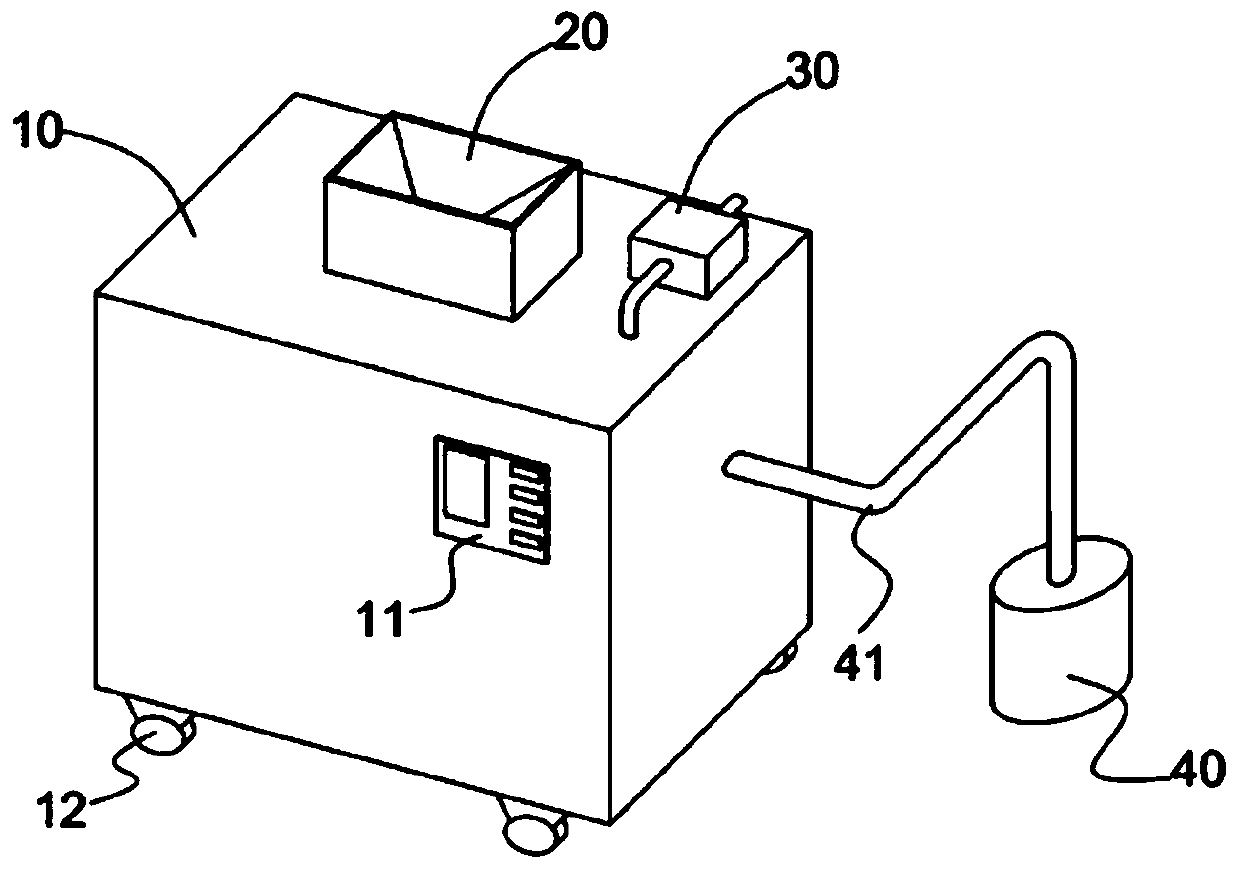

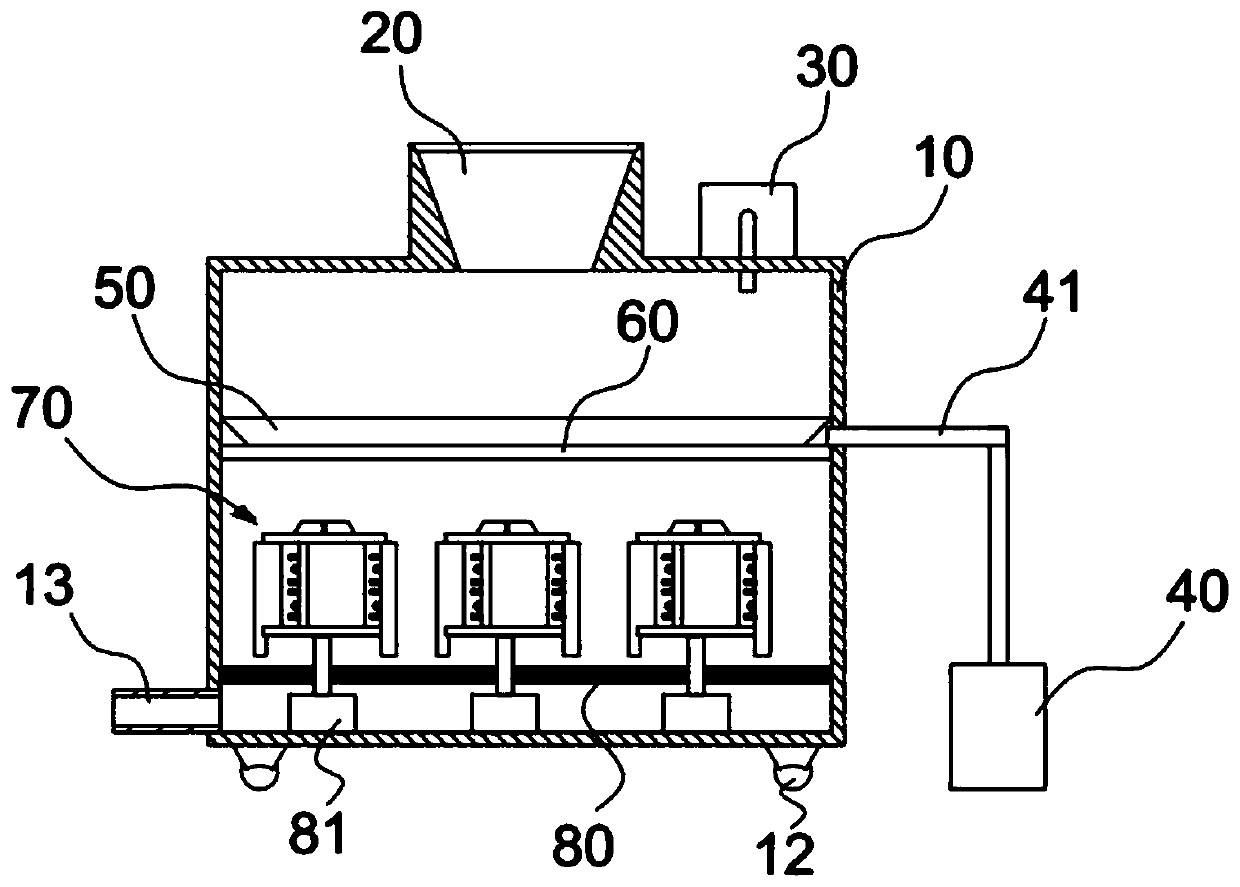

[0031] see Figure 1-6 As shown, the soil crushing device with screening function includes:

[0032] The casing 10 has a feed hopper 20 at the top,

[0033] The partition assembly 60 is arranged in the box body 10 to divide the inside of the box body 10 into upper and lower chambers. The inner wall of the upper chamber of the box body 10 is surrounded by an air guide 50, and the air guide 50 is connected to the box body through the air delivery pipe 41 10 outside the steam generator 40 is connected, and the box body 10 is provided with an air pump 30 for extracting gas in the upper chamber of the box body 10,

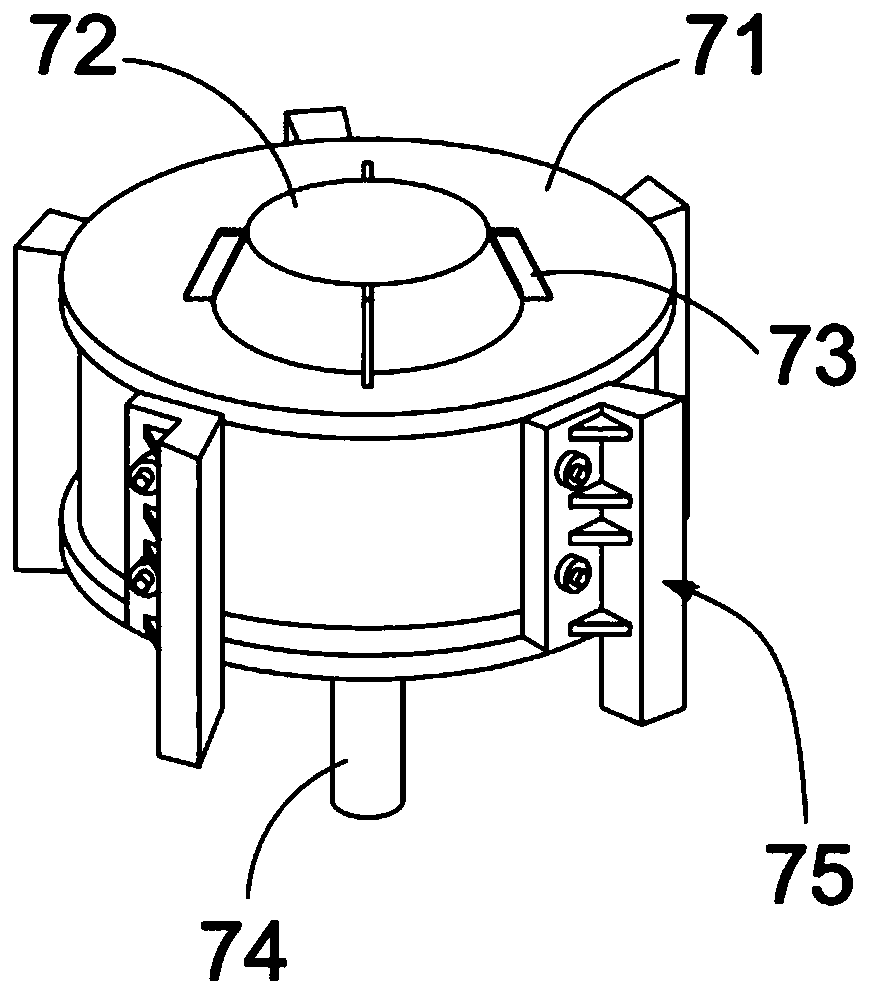

[0034] The crushing assembly 70 is located in the lower chamber of the box body 10. The crushing assembly 70 is driven by a motor 81 to crush objects. A sieve plate 80 is provided below the crushing assembly 70 for screening the crushed particles. One side of the box body 10 is provided with a The particles screened by the sieve plate 80 are discharged.

[0035] The ...

Embodiment 2

[0048] When the soil crushing device with screening function of the present invention is actually used:

[0049] The electromagnet 63 on the rotating plate 61 of the partition assembly 60 is controlled by the control panel 11 to be energized to separate the space in the box body 10, and the steam generator 40 is controlled to input steam to the box body 10 to preheat the upper chamber of the box body 10, and steam The input temperature and vapor pressure are determined according to the volatile liquid content of the treated soil. At the same time, the air pump 30 is turned on to extract the gas in the box 10 to be discharged, and then the soil block to be crushed is put into the upper cavity of the box 10 through the feeding hopper 20. Indoors, the steam generator 40 continuously inputs steam to steam extract the soil and reduce the volatile liquid content of the soil, and then controls the energizing current of the electromagnet 63 to expand the gap between the two rotating pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com