Automobile lampshade stamping die and stamping demolding method thereof

A stamping die and die technology, applied in the field of automobile lampshade stamping die and its stamping and demoulding, can solve the problem of easy occurrence of sticking material in the parting mold, and achieve the effects of reducing labor input, simplifying the stamping process, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

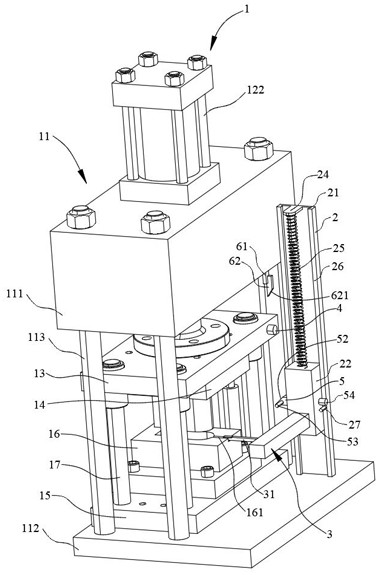

[0035] In this embodiment, the workpiece is a sheet material used for an automobile lampshade, and the workpiece is punched through the stamping die to remove waste materials in the middle of the workpiece.

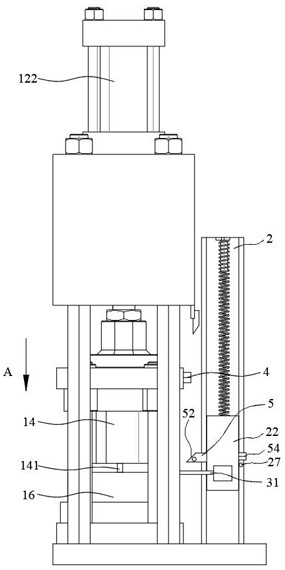

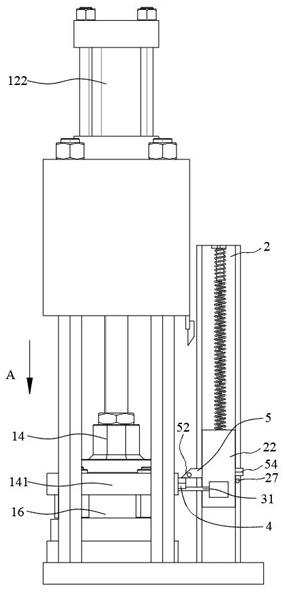

[0036] A direction is the moving direction of the upper template 14, and B direction is the moving direction of the workpiece.

[0037] as shown in Figure 1 to Figure 9 As shown, the present embodiment provides a stamping die for an automobile lampshade, comprising:

[0038] mold body 1,

[0039] The mold body 1 includes an outer frame 11, which is composed of two top plates 111 and a bottom plate 112 arranged parallel to each other, and the top plate 111 and the bottom plate 112 are fixed by four fixing columns 113 at four corners. The top of the outer frame 11 is fixed with a drive cylinder 122. Specifically, the fixed end of the drive cylinder 122 is fixed on the top of the top plate 111, and the drive cylinder 122 is set upside down. The movable end of the drive cyli...

Embodiment 2

[0058] On the basis of Embodiment 1, this Embodiment 2 also provides a stamping and demoulding method for stamping dies for automobile lampshades, wherein a stamping die for automobile lampshades is the same as Embodiment 1, and will not be repeated here. In the gap 33, insert the locking block 321 into the locking groove 311, and when a "click" is heard, the upper plate 32 is clamped to clamp the workpiece; the upper mold base 13 is driven by the driving cylinder 122 to drive the upper template 14 and the lower template 16 Close the mold to stamp the workpiece; push the linkage surface 52 through the push rod 4 to drive the connecting rod 5 to compress the telescopic spring 51, so that the push rod 4 crosses the connecting rod 5 downward; drive the upper mold base 13 through the driving cylinder 122 to drive the upper template 14 and The lower template 16 is divided into molds, the push rod 4 drives the slider 22 to lift upward along the longitudinal guide rail 2 through the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com