Building smashing device

A crushing device and construction technology, applied in grain processing, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of unhealthy workers, affecting air quality, and reducing performance, so as to benefit human health and reduce Pollution, the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

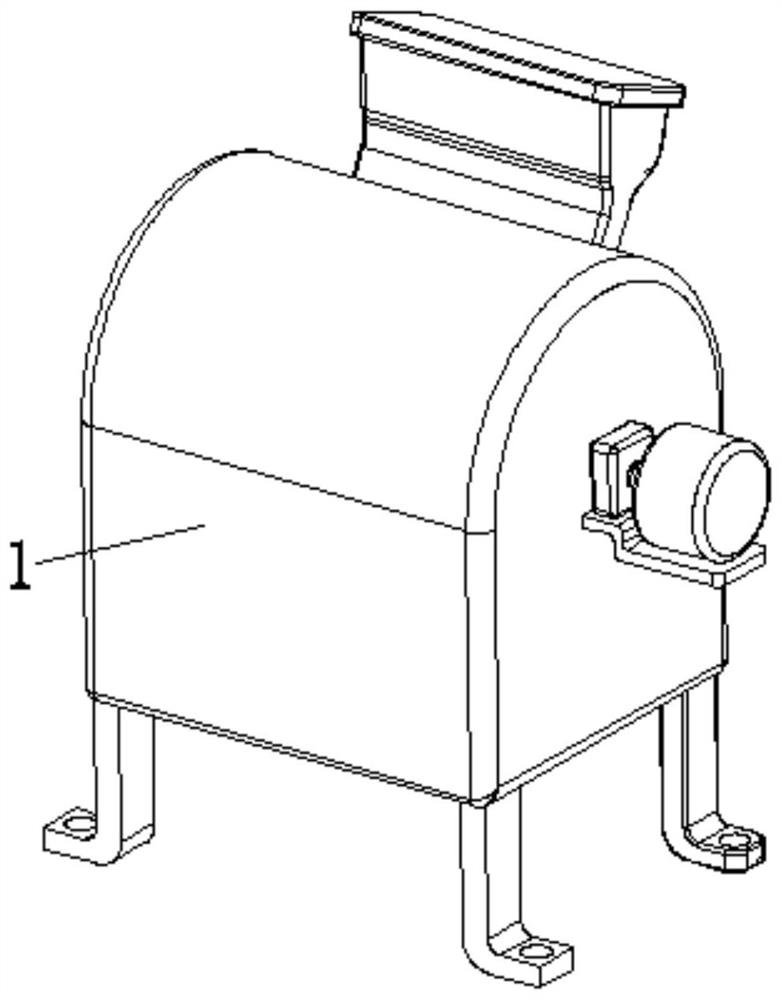

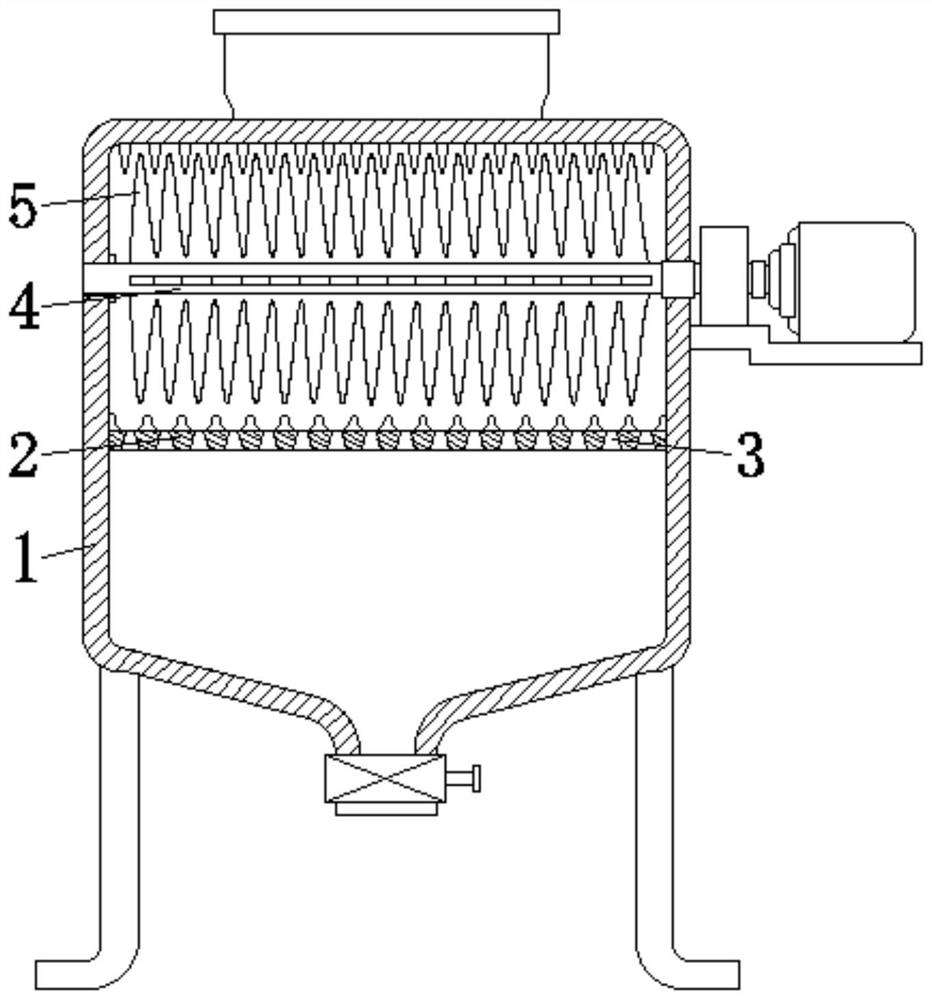

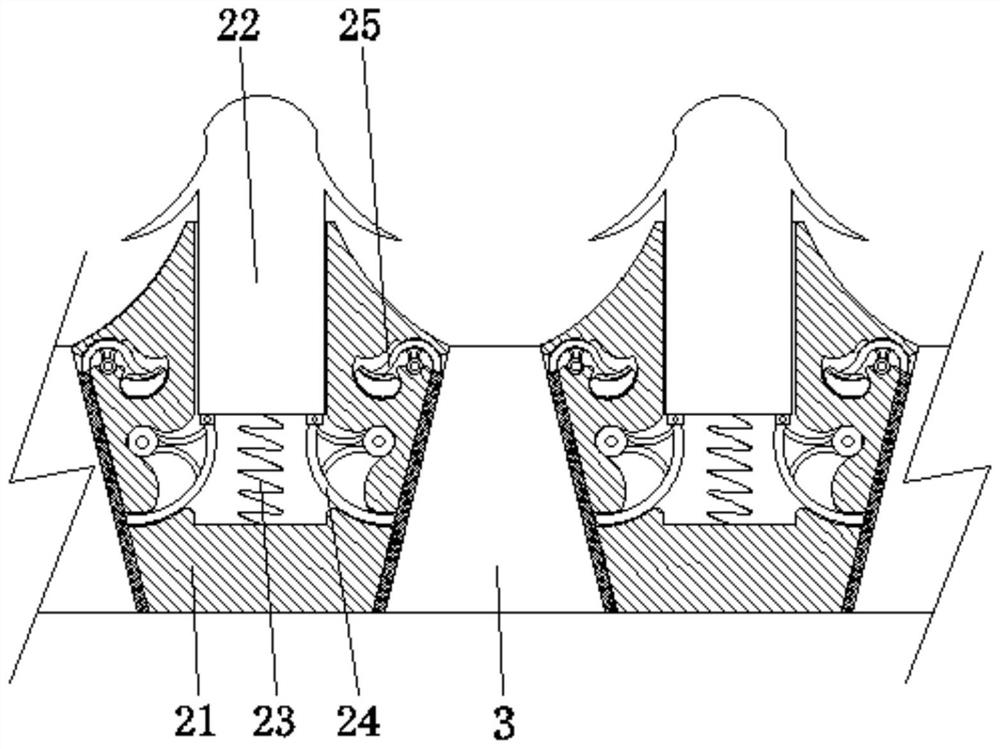

[0032] see Figure 1-7 , the present invention provides a technical solution: a crushing device for construction, comprising a crushing chamber 1, a sieve plate device 2, a sieve hole 3, a drive shaft 4, and a crushing device 5, the sieve plate device 2 is fixed on the inner wall of the crushing chamber 1 and Located in the central position, the sieve hole 3 is opened on the surface of the sieve plate device 2, the drive shaft 4 is rotatably connected between the two sides corresponding to the inner wall of the crushing chamber 1, the crushing device 5 is fixed on the surface of the drive shaft 4, and the sieve plate device 2 is set There are sieve plate body 21, pressure block 22, return spring 23, arc-shaped ejector rod 24, instigation device 25, pressure block 22 is slidably connected to the top of sieve plate body 21, return spring 23 is fixed on the bottom of pressure block 22 and sieve plate body 21, the arc-shaped ejector rod 24 is rotatably connected to the inside of t...

Embodiment example 2

[0036] The crushing device 5 is provided with a crushing main body 51, an air flow channel 52, a dust removal device 53, a channel 54, an air port 55, and a second magnetic block 56. The air flow channel 52 is set inside the crushing main body 51, and the dust removal device 53 is fixed inside the crushing main body 51. And be positioned at the position of air passage 52, passage 54 is opened in the inside of drive shaft 4, and air port 55 is provided on the surface of crushing main body 51, and passage 54 communicates with air port 55 through air passage 52, and the second magnetic block 56 is arranged on the crushing main body The inside of 51 is located at the edge, which can filter the dust generated during crushing, has the function of dust removal, reduces the spread of dust, is beneficial to human health, and reduces air pollution.

[0037] The dust removal device 53 is provided with a filter main body 531, an arc surface 532, an air outlet 533, and an air inlet 534. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com