Character processing method and jet printing equipment

A character processing and character technology, applied in image data processing, instruments, computing, etc., can solve problems such as poor printing effect of complex graphics, achieve the effect of avoiding ink adhesion and improving printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] An embodiment of the present invention provides a character processing method, which relates to the technical field of circuit board printing, and optimizes characters by preprocessing layers before printing on a circuit board, thereby improving the printing effect of a printing device.

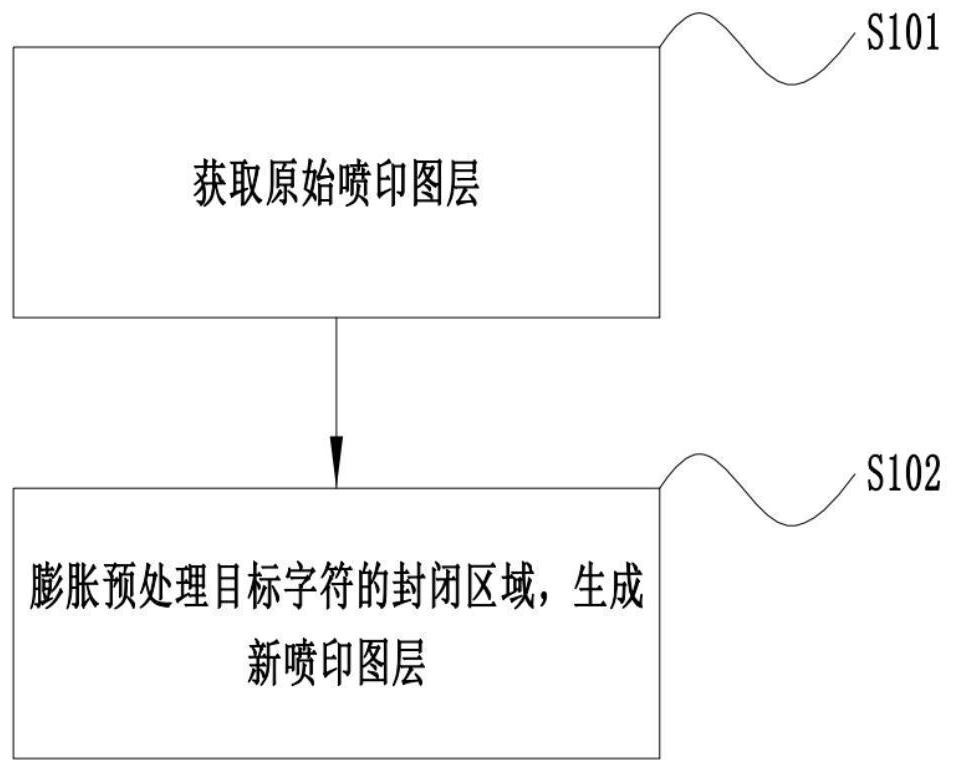

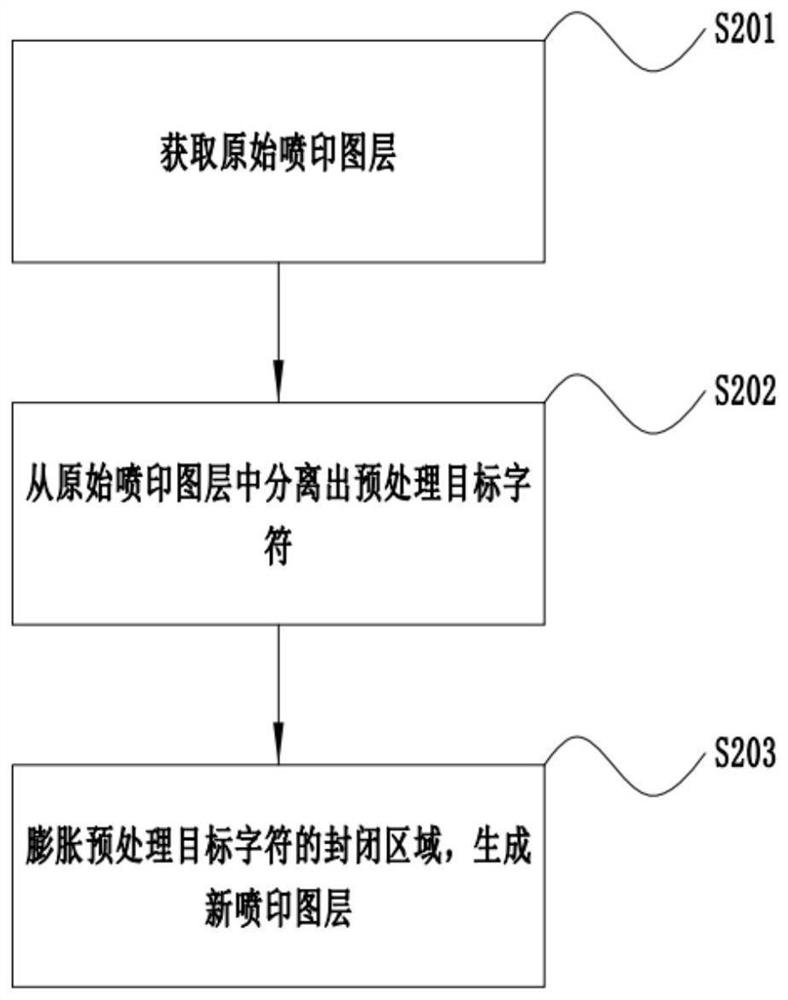

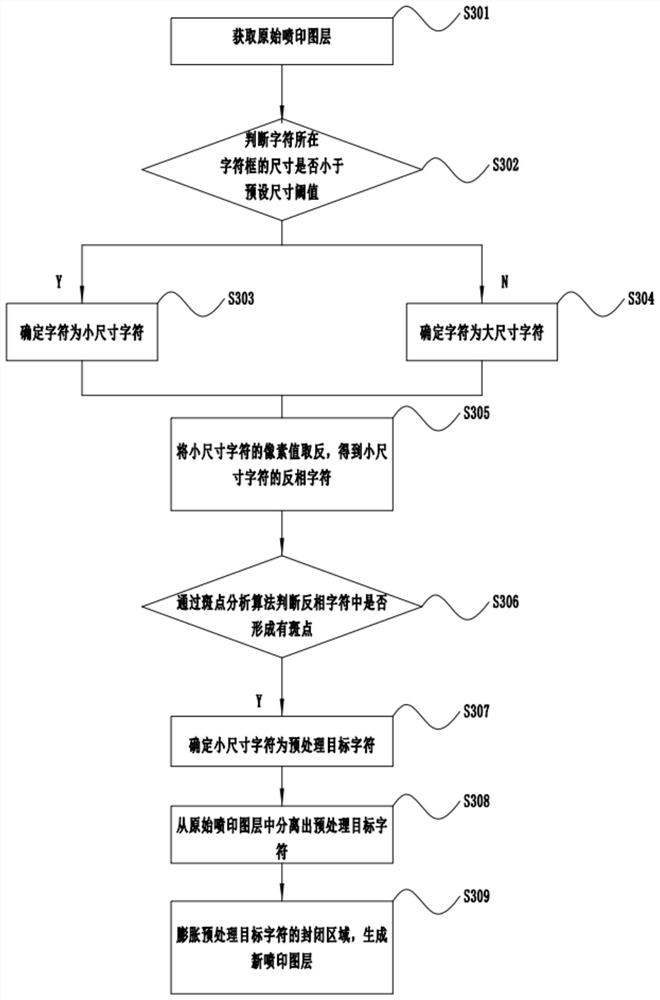

[0064] Such as figure 1 As shown, a character processing method provided in this embodiment includes the following steps:

[0065] S101. Obtain the original inkjet printing layer; the original inkjet printing layer includes several characters; the several characters include several preprocessing target characters formed with closed areas; for example, the preprocessing target characters with closed areas include "0", "8", "4", "A", "D" and other characters;

[0066] S102. Inflate the closed area of the pre-processed target character to generate a new printing layer; wherein, the new printing layer will also be converted into a Gerber file for recognition by the control unit in the p...

Embodiment 2

[0101] This embodiment provides a jet printing device, which relates to the technical field of circuit board printing. By preprocessing the layers before printing the circuit board, small characters are individually optimized, thereby improving the printing effect and printing efficiency.

[0102] Such as Figure 4 As shown, the jet printing device includes a character processing system; the character processing system includes an input module 1 and a character optimization module 2;

[0103] The input module 1 is used to obtain the original inkjet printing layer; the original inkjet printing layer includes several characters; the several characters include some preprocessing target characters formed with closed areas;

[0104] The character optimization module 2 is used to expand the closed area of the pre-processed target character to generate a new printing layer.

[0105] Further, as Figure 5 As shown, the character processing system also includes a character separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com