Positioning support leg for printed circuit board ink printing

A printed circuit board, ink printing technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of affecting product quality, ink sticking, large contact area, etc., to avoid ink sticking and reduce contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

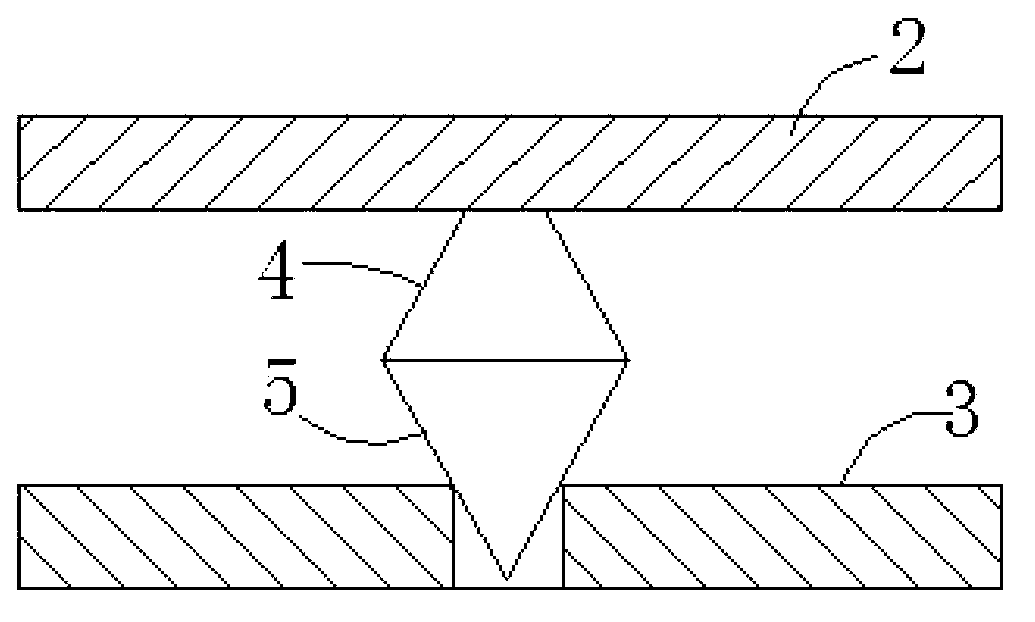

[0009] Embodiment: A positioning support for printed circuit board ink printing, consisting of an upper support 4 and a lower positioning pin 5, the upper support is in the shape of a truncated cone, the lower positioning pin is conical, and the upper plane of the upper support is Smaller than the lower plane of the upper support, the cone point of the lower positioning pin faces downward, and the lower positioning pin extends downward from the lower plane of the upper support, and the cone point of the lower positioning pin 5 Smaller than the positioning hole of the backing plate 3 on the machine platform and the upper end is larger than the positioning hole of the backing plate on the machine platform, and the lower positioning pin is inserted in the positioning hole of the backing plate, the upper plane of the upper support 4 supports the A printed circuit board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com