High-efficiency energy-saving type double-screw automatic injection molding machine

An automatic injection molding machine, energy-saving technology, applied in the field of injection molding machines, can solve problems such as heat accumulation, workpiece adhesion, and affecting the quality of injection molded workpieces, and achieve the effects of avoiding waste, avoiding overheating of workpieces, and safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

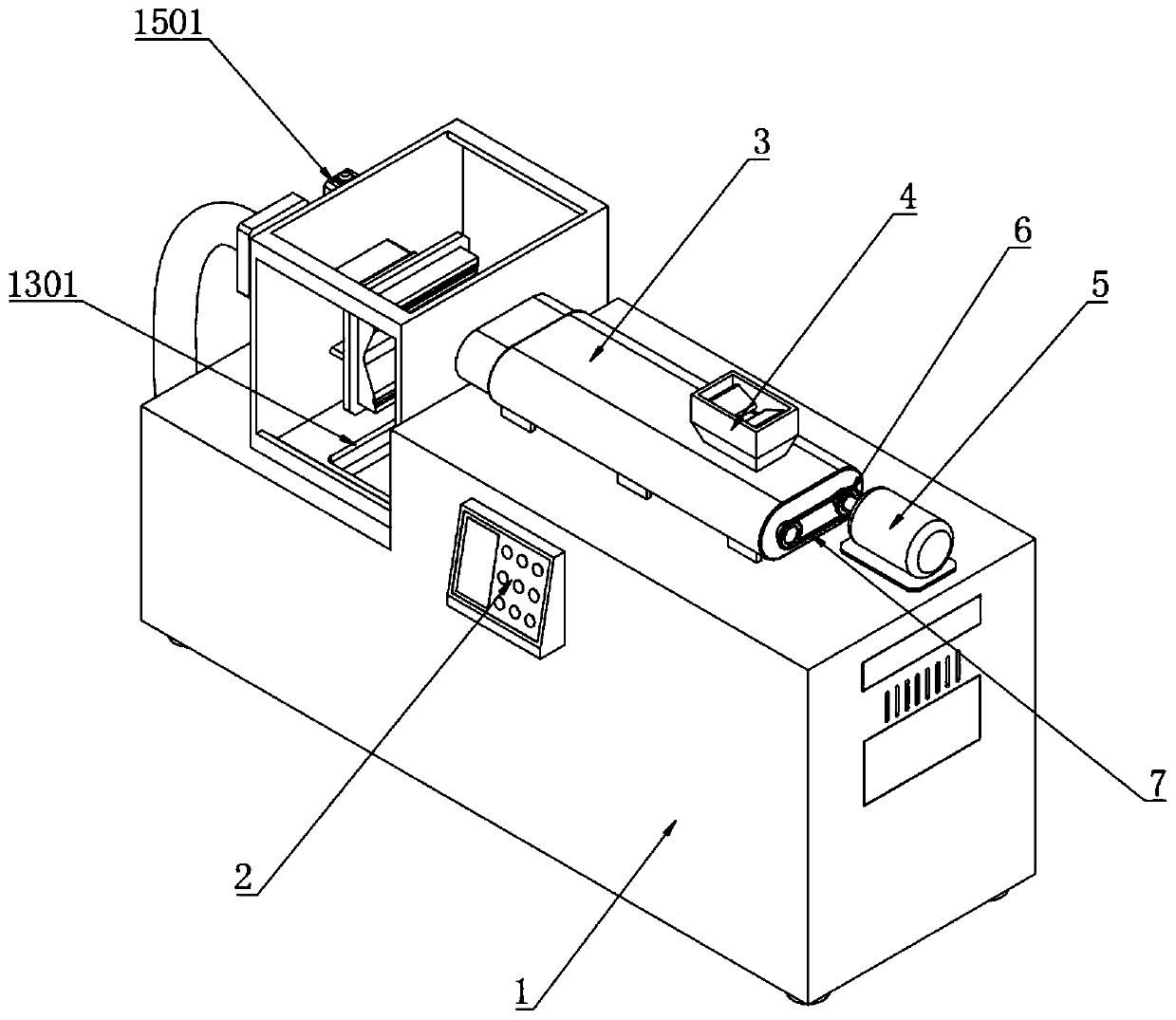

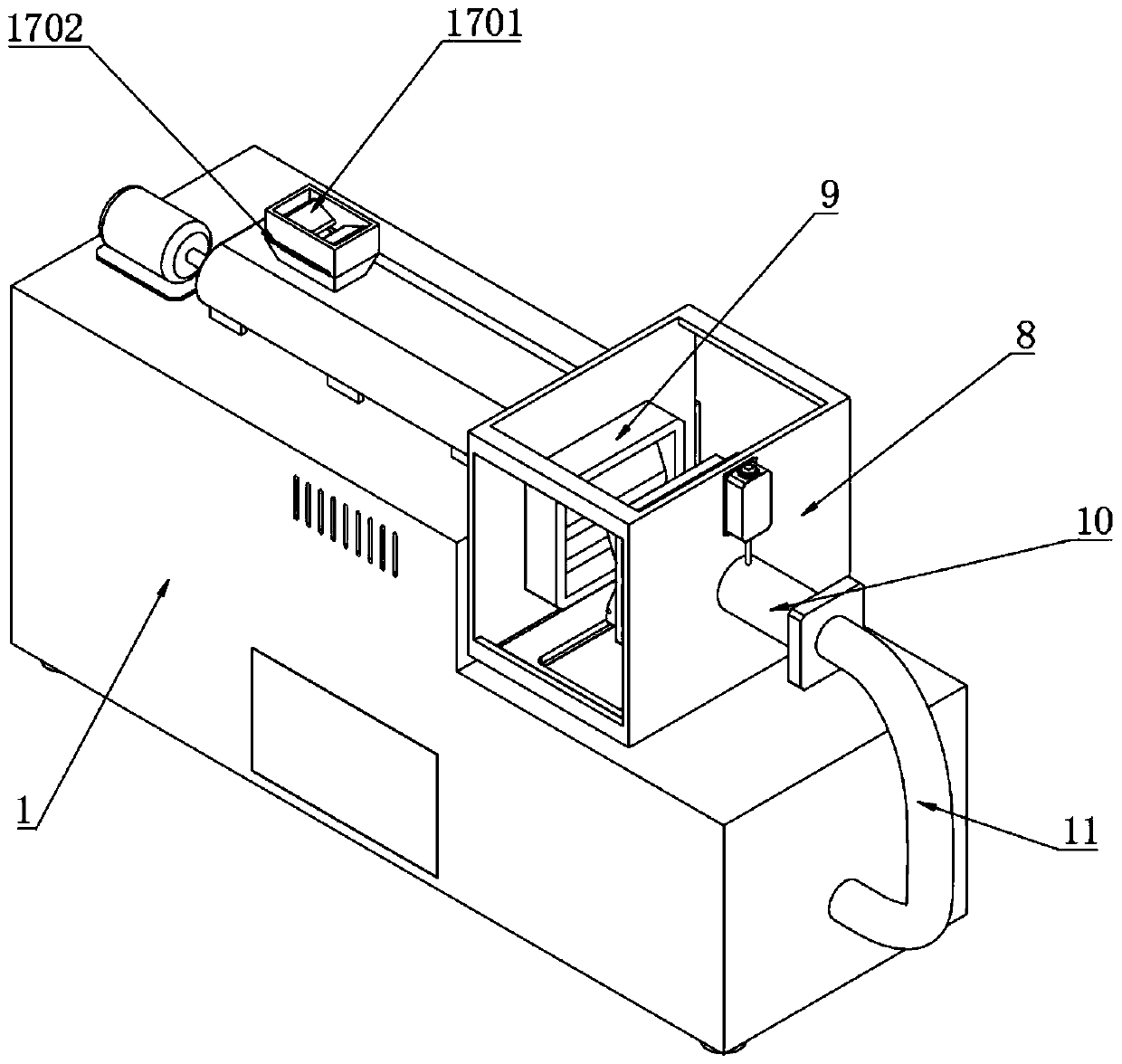

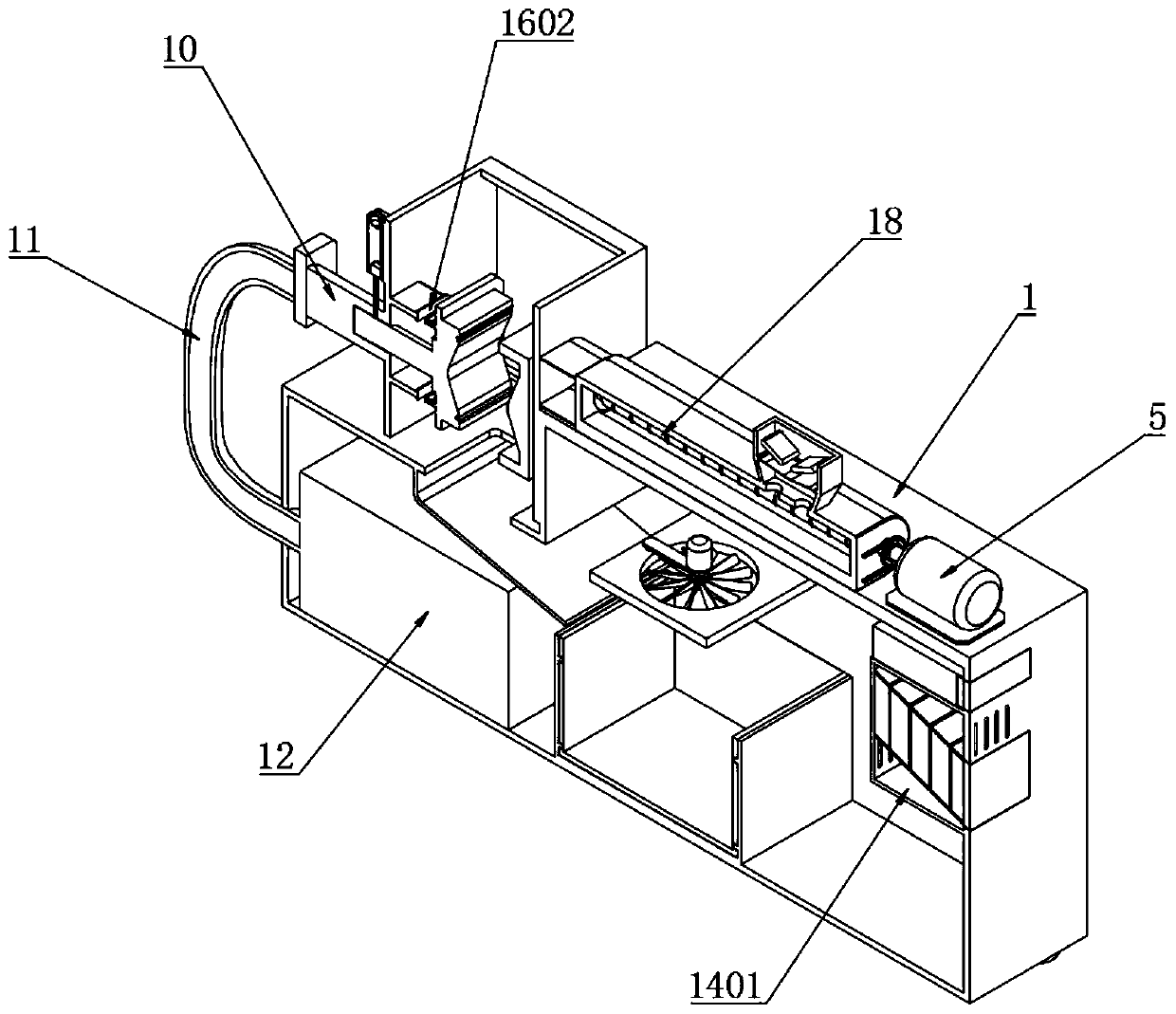

[0051] Example: such as Figure 1-11 As shown, the present invention provides a technical solution, a high-efficiency and energy-saving twin-screw automatic injection molding machine, including an injection molding box 1, a control switch 2 is fixedly installed on one end of the injection molding box 1, and an injection molding chamber 3 is connected to the top of the injection molding box 1 , the top of the injection molding bin 3 is connected with the feeding bin 4, the top of the injection molding box 1 corresponds to the side of the injection molding bin 3, and the drive motor 5 is installed, and one end of the injection molding bin 3 rotates symmetrically. The outer meshing connection is connected with the transmission tooth chain 7, and the top of the injection molding box 1 is fixedly connected with the molding frame 8 at the position corresponding to the side of the injection molding chamber 3. The inner wall of the molding frame 8 is installed with an injection mold 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com