Injection mould with ejection and linkage mechanisms

A technology of ejection mechanism and linkage mechanism, which is applied in the field of mold design, can solve problems such as high cost, complex oil cylinder structure, and low production efficiency, and achieve the effects of saving processing costs, improving production efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

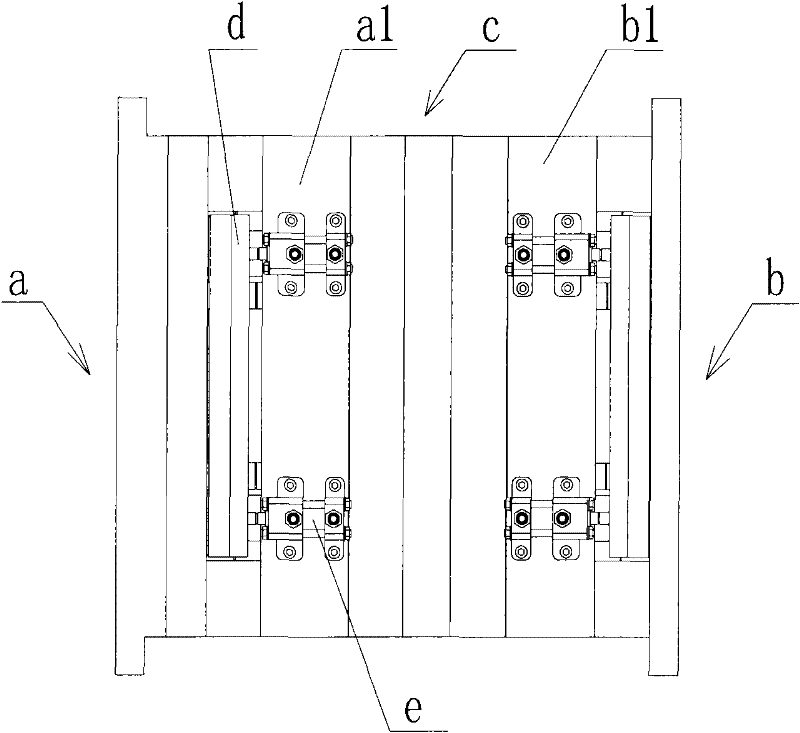

[0039] see figure 1 , an injection mold with an oil cylinder ejection mechanism includes a fixed platen assembly a, a movable platen assembly b, and an intermediate plate assembly c, the fixed platen assembly includes a fixed platen a1, the movable platen assembly includes a movable platen b1, a fixed platen assembly a, and a movable platen assembly b There are ejector plates d on both sides, oil cylinders e are respectively fixed on the fixed platen a1 and movable platen b1, and their heads are connected to the ejector plate d, in order to achieve synchronous ejection of products, a total of 8 oil cylinders e are required on both sides of the multi-layer mold Symmetrically installed, all cylinders e are connected to hydraulic equipment through oil separators; after the mold is opened, the hydraulic equipment drives cylinder e to move, and the head of cylinder e drives the ejector plate to eject the product.

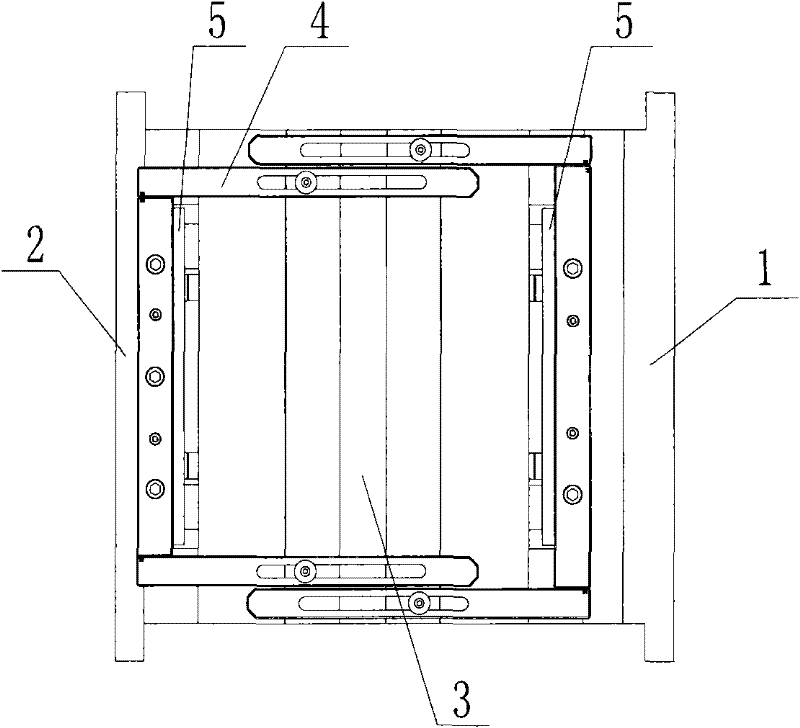

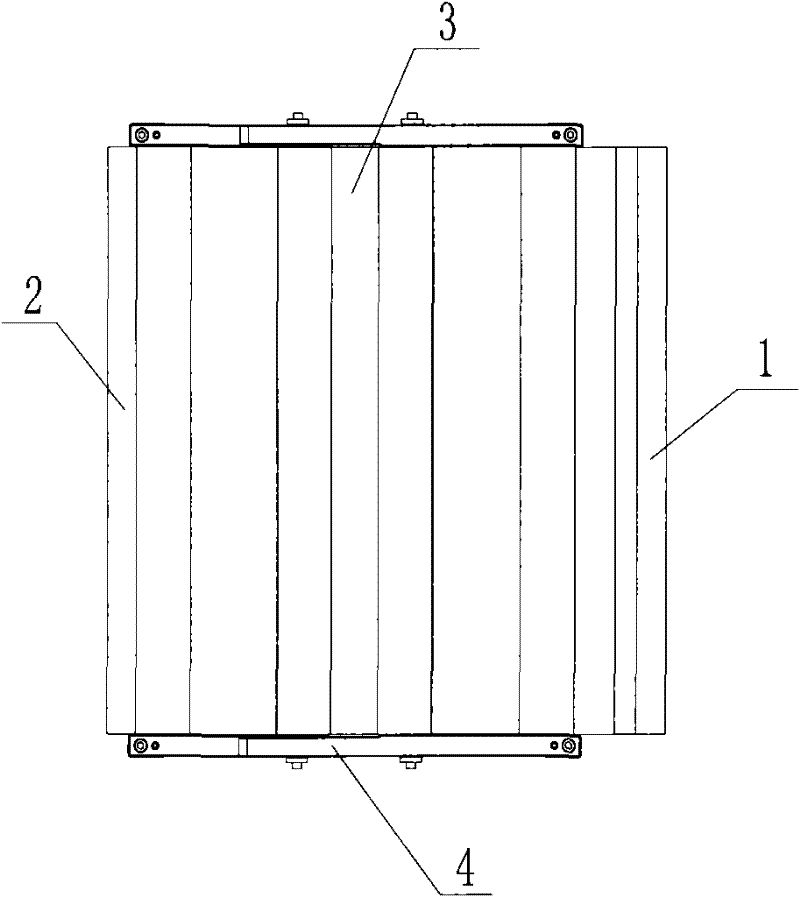

[0040] see Figure 2 to Figure 4 , an injection mold with an eject...

Embodiment 2

[0045] In this embodiment, the ejector mechanism is a limit rod mechanism, which is arranged in the inner cavity of the mold, and includes a limit rod 7 and a limit cavity 8. One end of the limit rod 7 is threaded as a threaded connection part 71, and the other end has a convex The edge-shaped limit blank head 72 and the threaded connection part 71 are screwed and fixedly connected with the ejector plate 5 . When the injection mold of the present invention is a multi-layer injection mold, a limit rod mechanism is also respectively set between the movable template assembly and the intermediate plate assembly, and between the intermediate plate assembly and the fixed template assembly. If the mold opening stroke is small, the two directions The limit pull rod mechanisms on the top can be set relatively. If the mold opening stroke is large, in order to avoid increasing the thickness of the mold, the limit pull rod mechanisms in the two directions should be staggered. Wherein, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com