Vertical roll mill capable of vertically shifting roll

A technology of vertical roll mill and roll shifting, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of wasting time, high cost and waste, etc., to reduce the cost of use and save the replacement of rolls The time of the system and the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

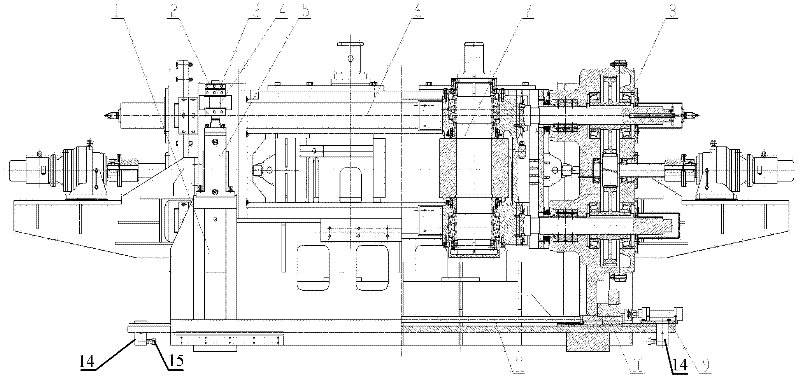

[0023] Below in conjunction with accompanying drawing, the vertical roll rolling mill that can shift up and down of the present invention and the use process are described:

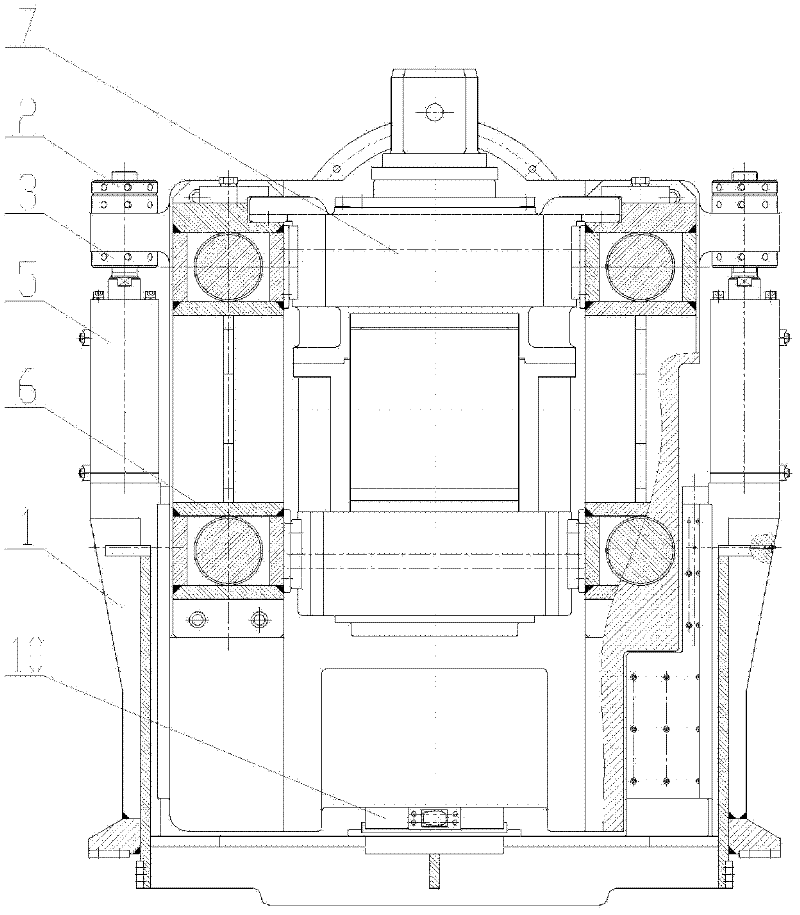

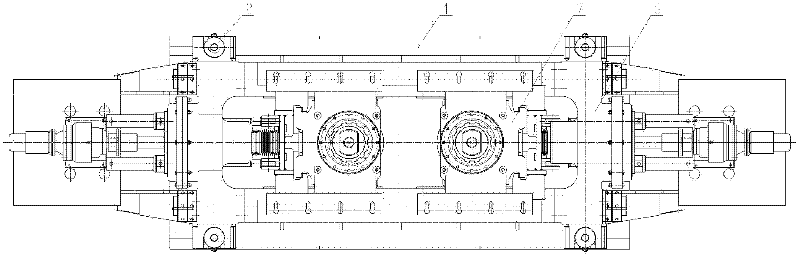

[0024] like Image 6 As shown, the structure of the vertical roller mill body described in the present invention is basically the same as that of the traditional vertical roller mill, and is mainly composed of a rolling mill frame 6, a vertical roller system 7 and a pressure measuring device 8. In this embodiment, only two vertical rollers are used. The vertical roller system composed as an example, but not limited thereto.

[0025] like Figure 4 , Figure 5 As shown, the vertical rolling mill body is installed in the frame composed of the base of the lifting device, four columns and the lifting hydraulic cylinders on the columns. The piston rod of each lifting hydraulic cylinder is covered with a jacking nut 3, a spacer 4 and lock nut 2, four trunnions 12 are provided on the corresponding columns of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com