Patents

Literature

81results about How to "Feeding is simple and convenient" patented technology

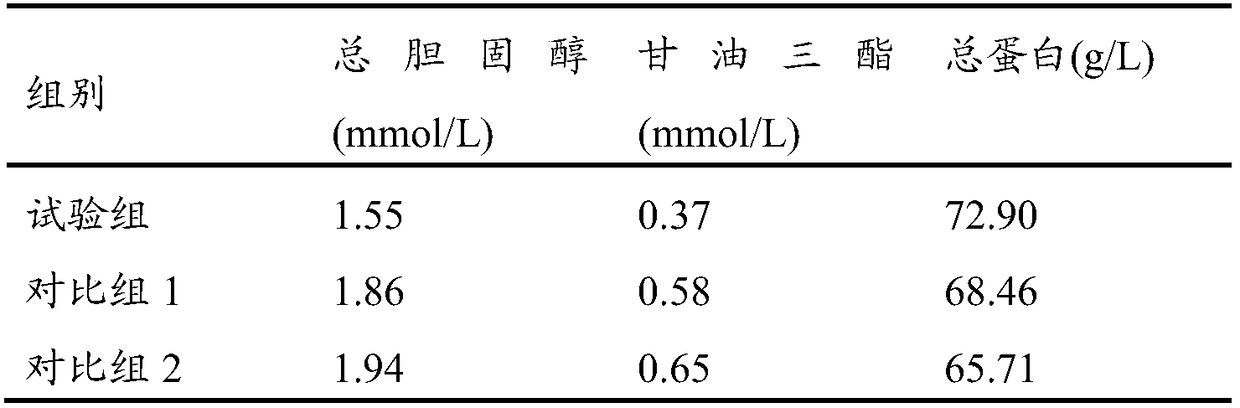

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

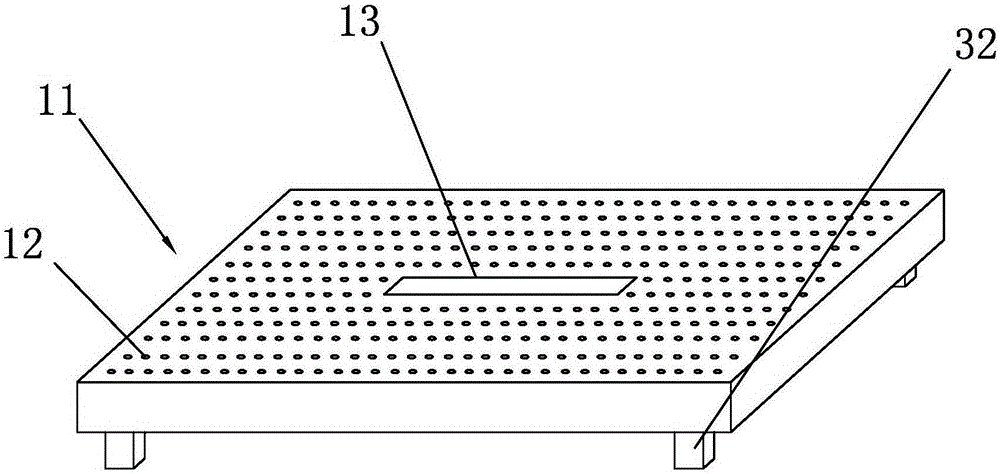

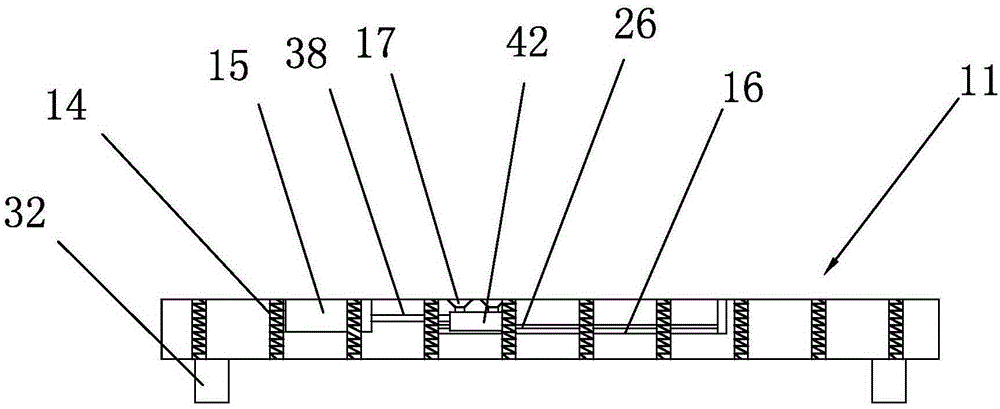

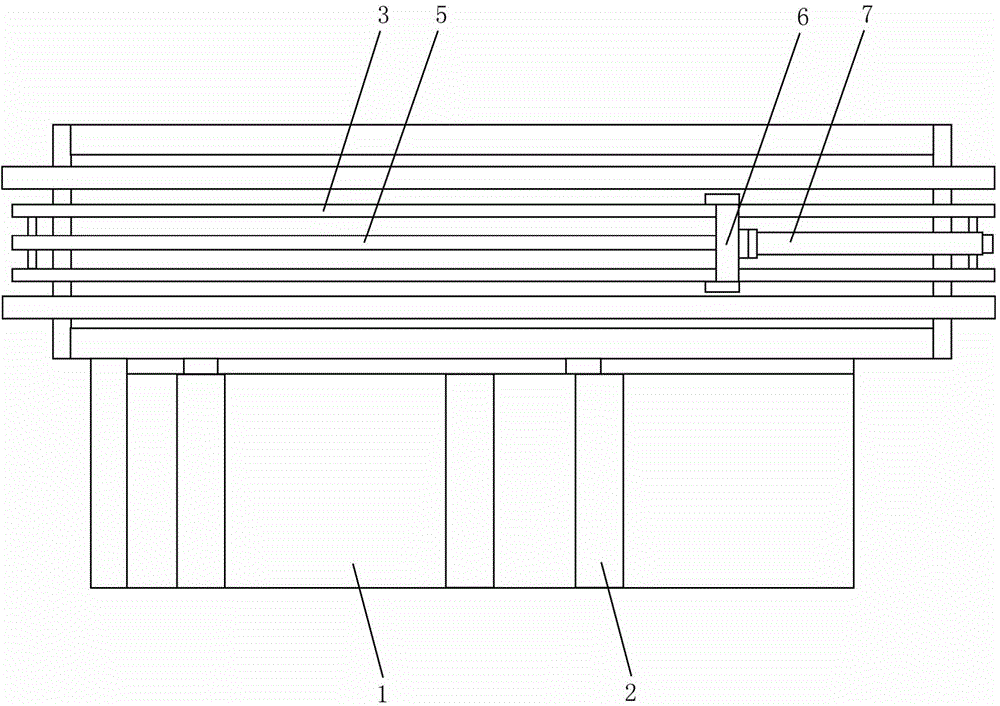

Glass lamination machine for producing insulating glass

InactiveCN105174753AImprove securityFeeding is simple and convenientCharge manipulationConveyor partsFixed frameEnergy consumption

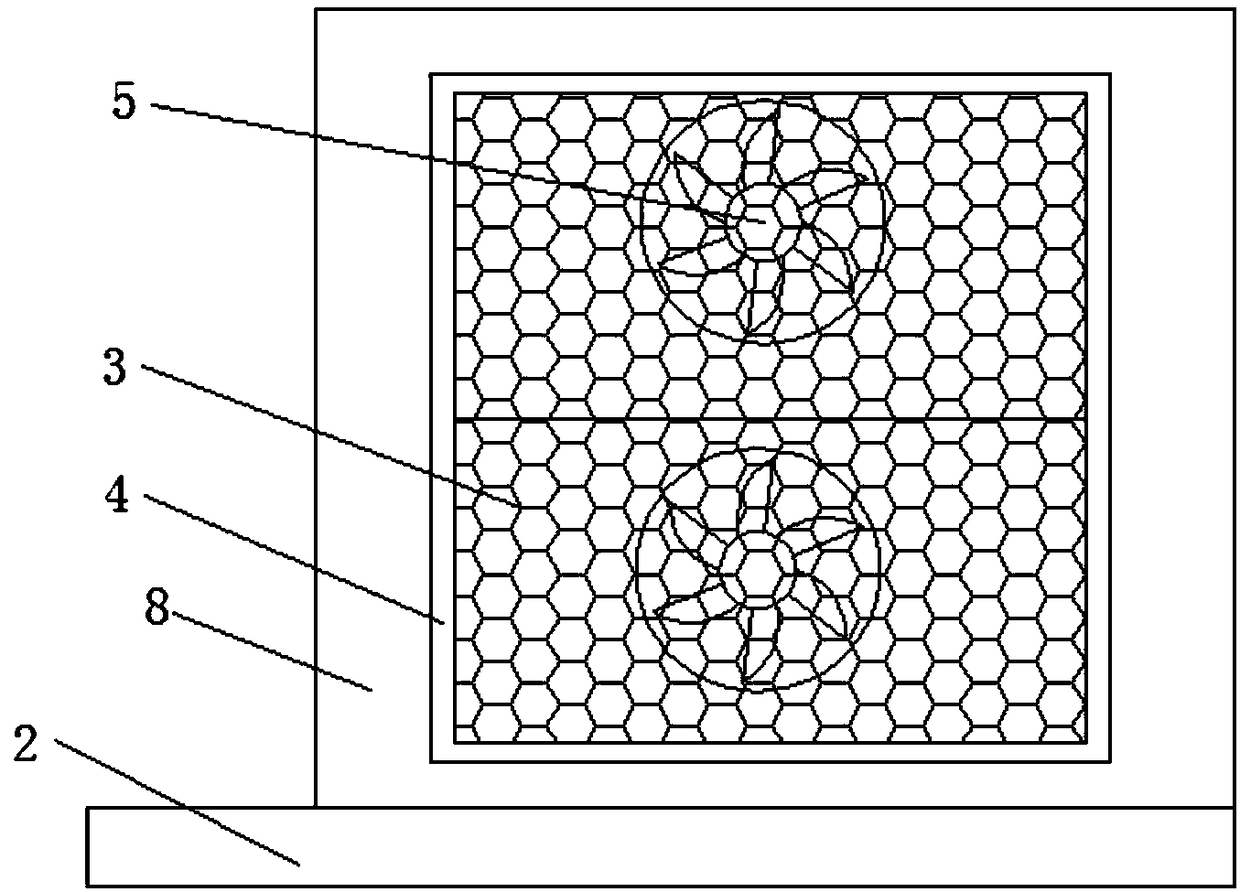

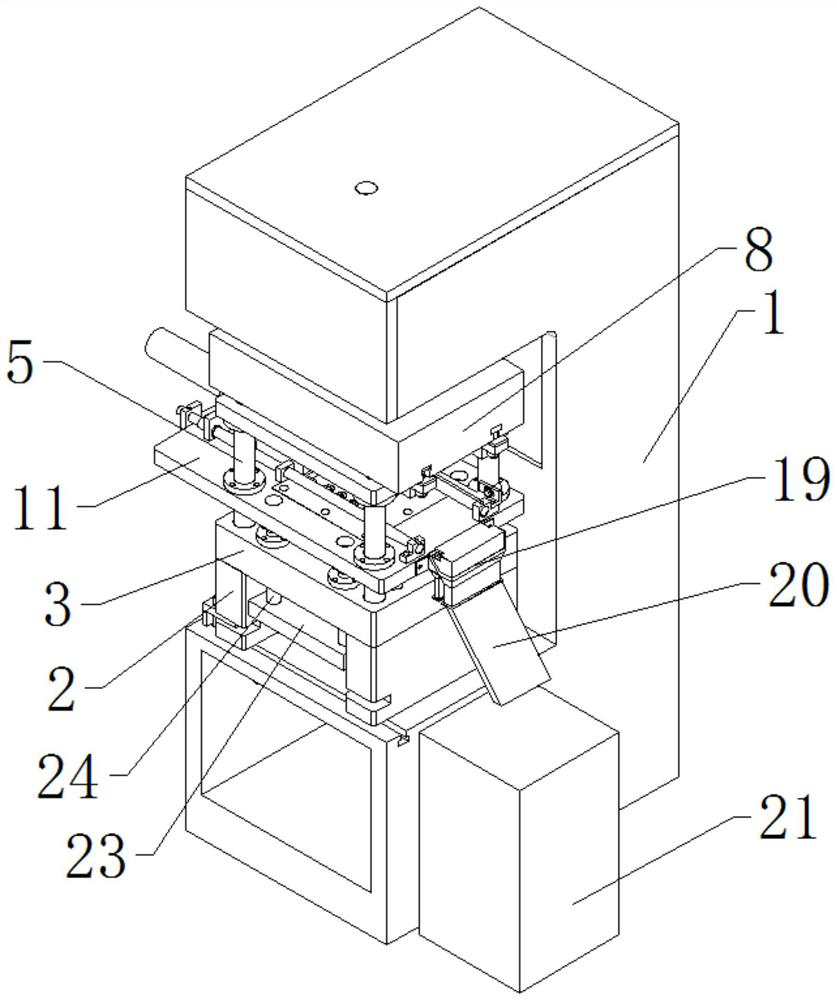

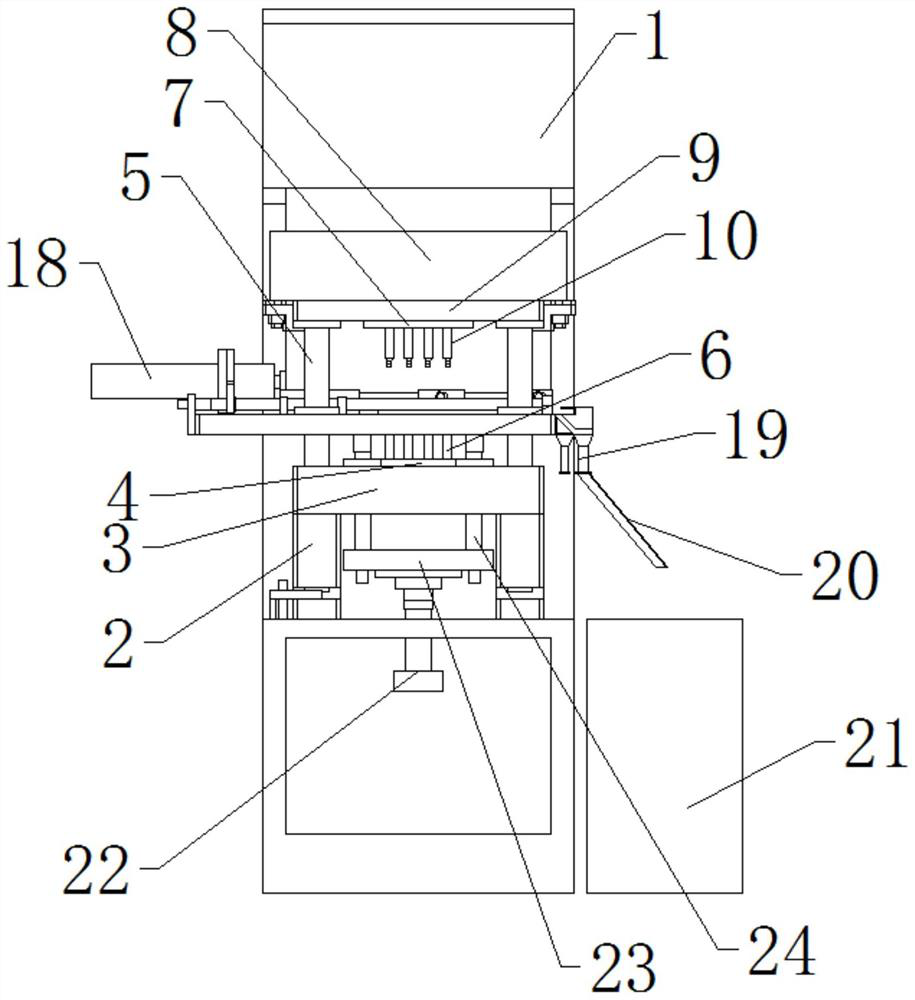

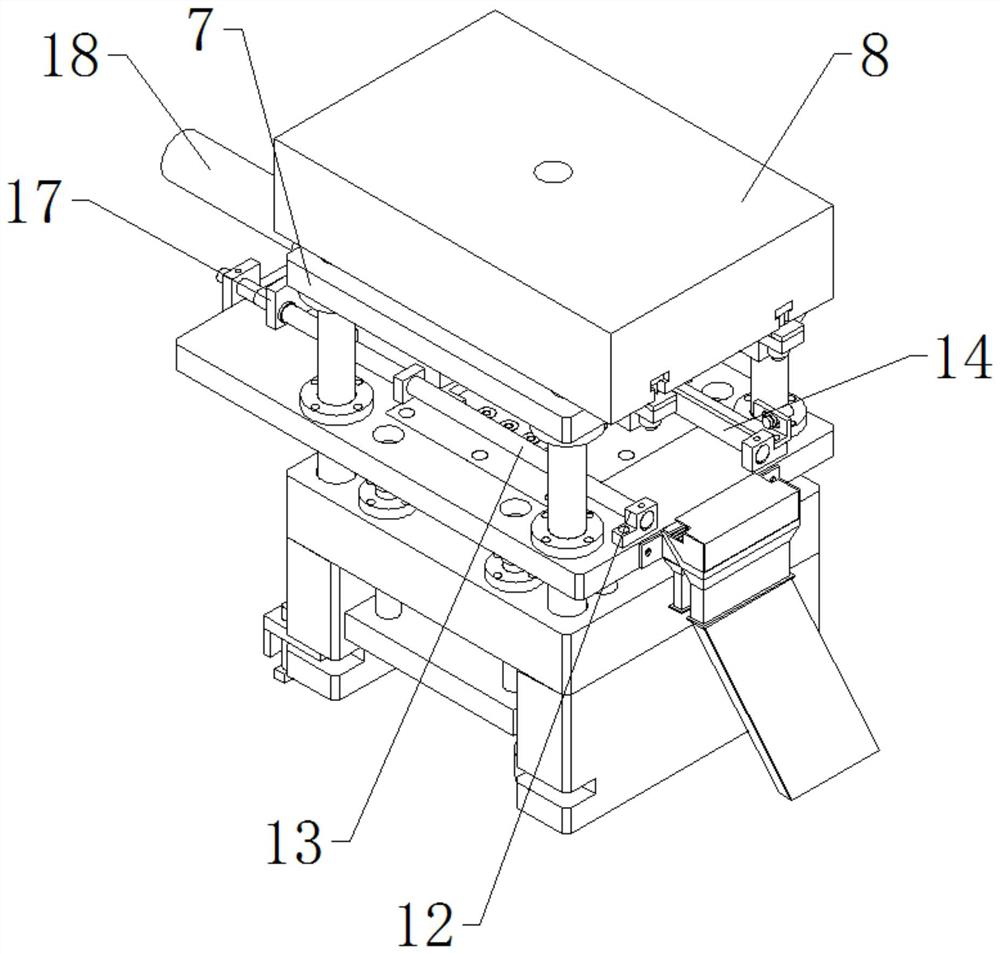

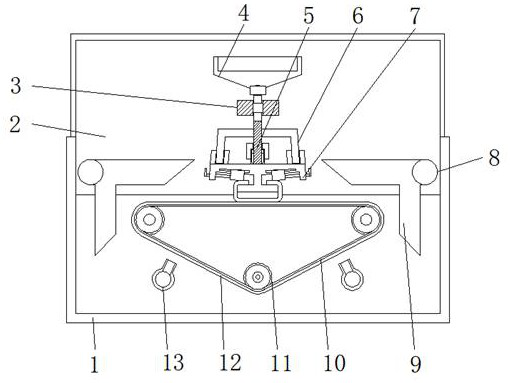

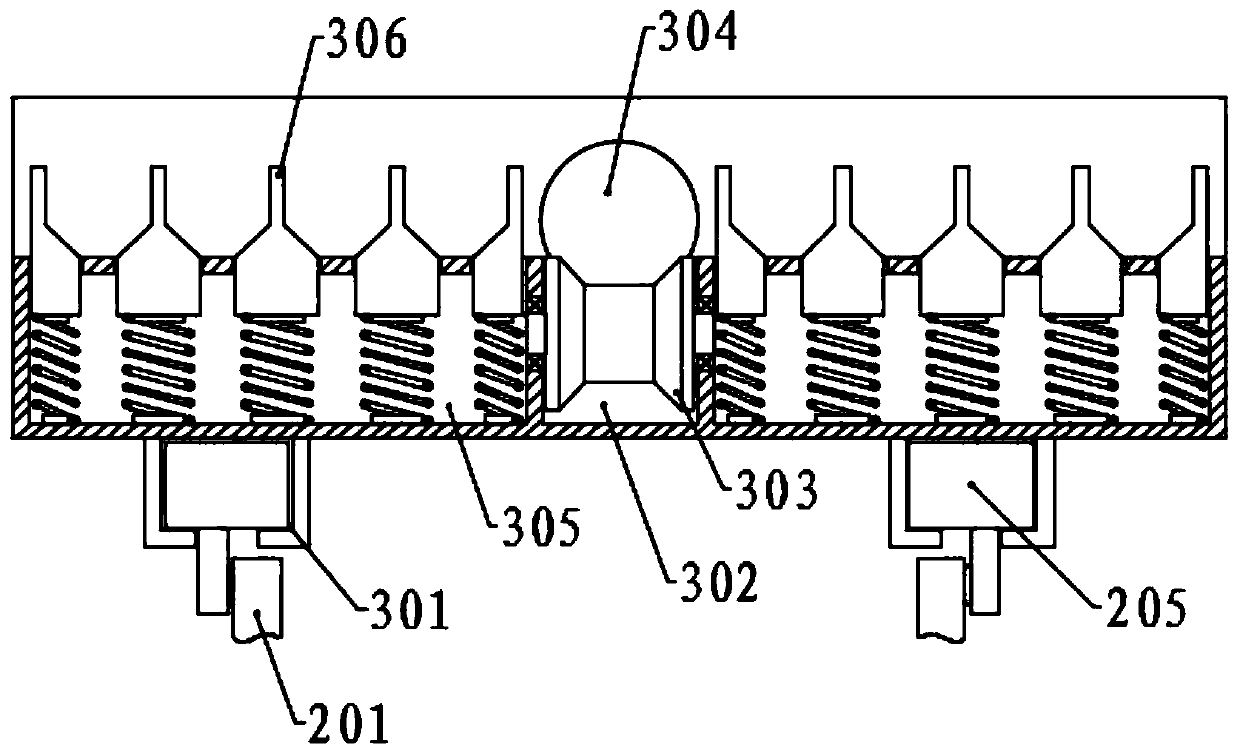

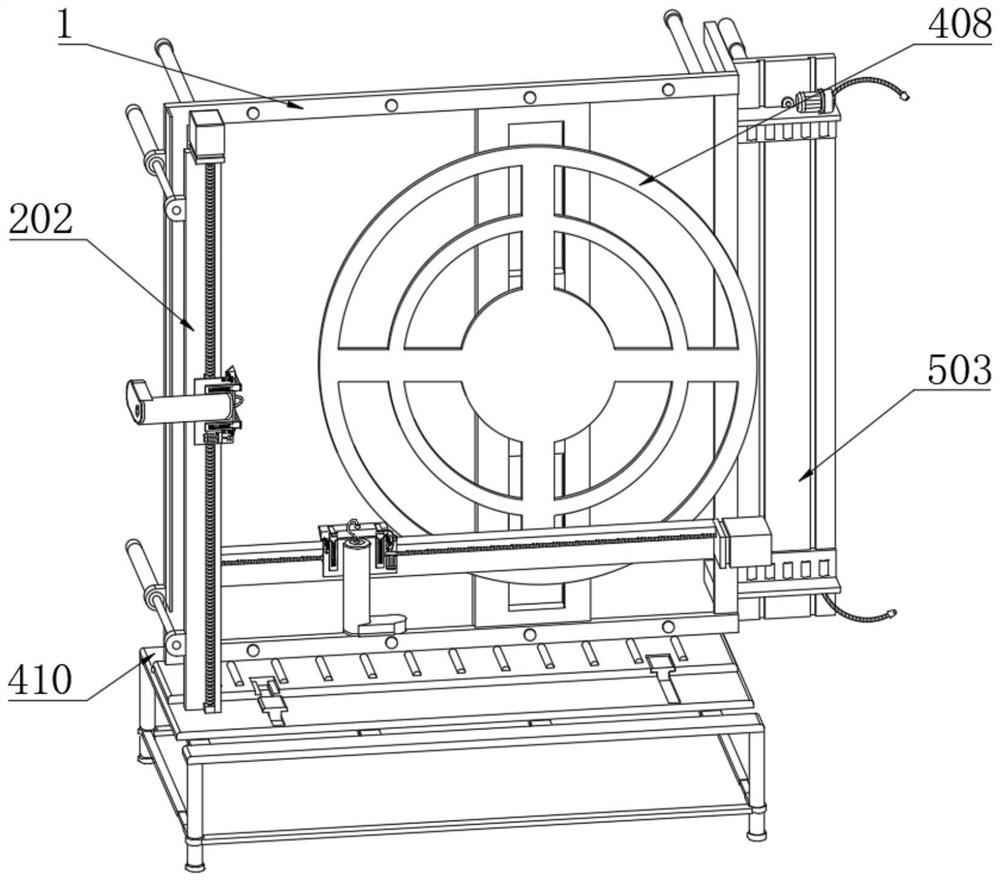

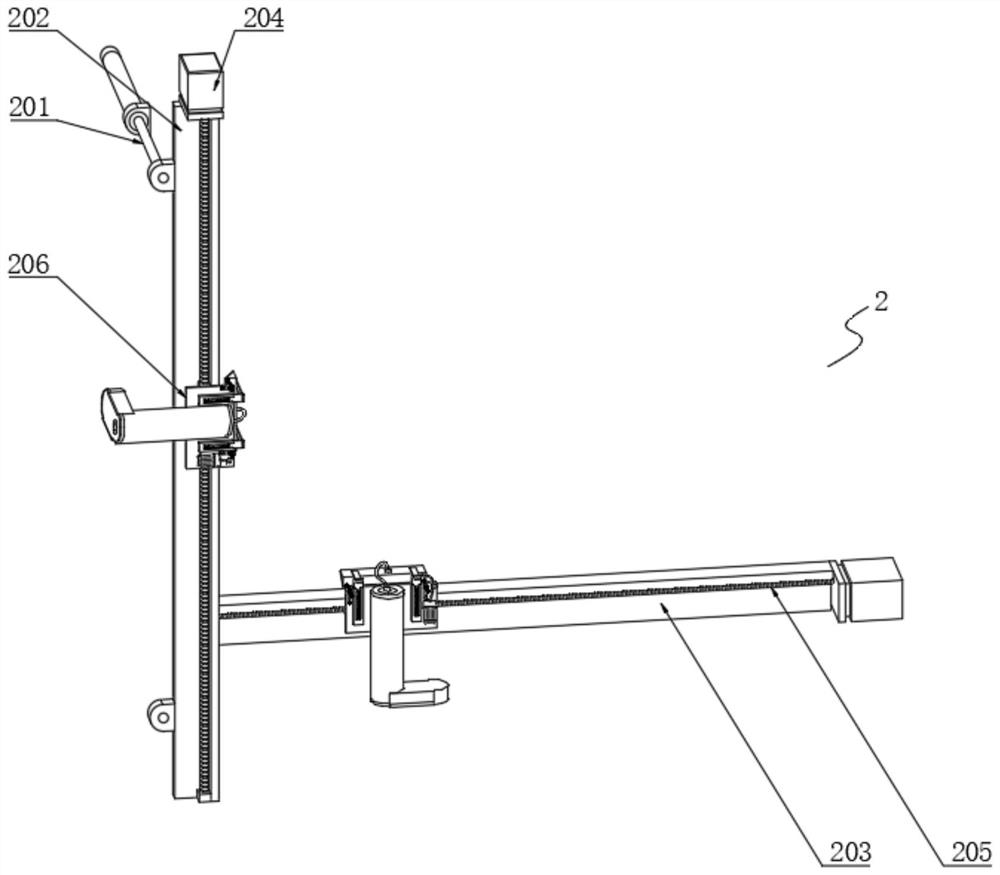

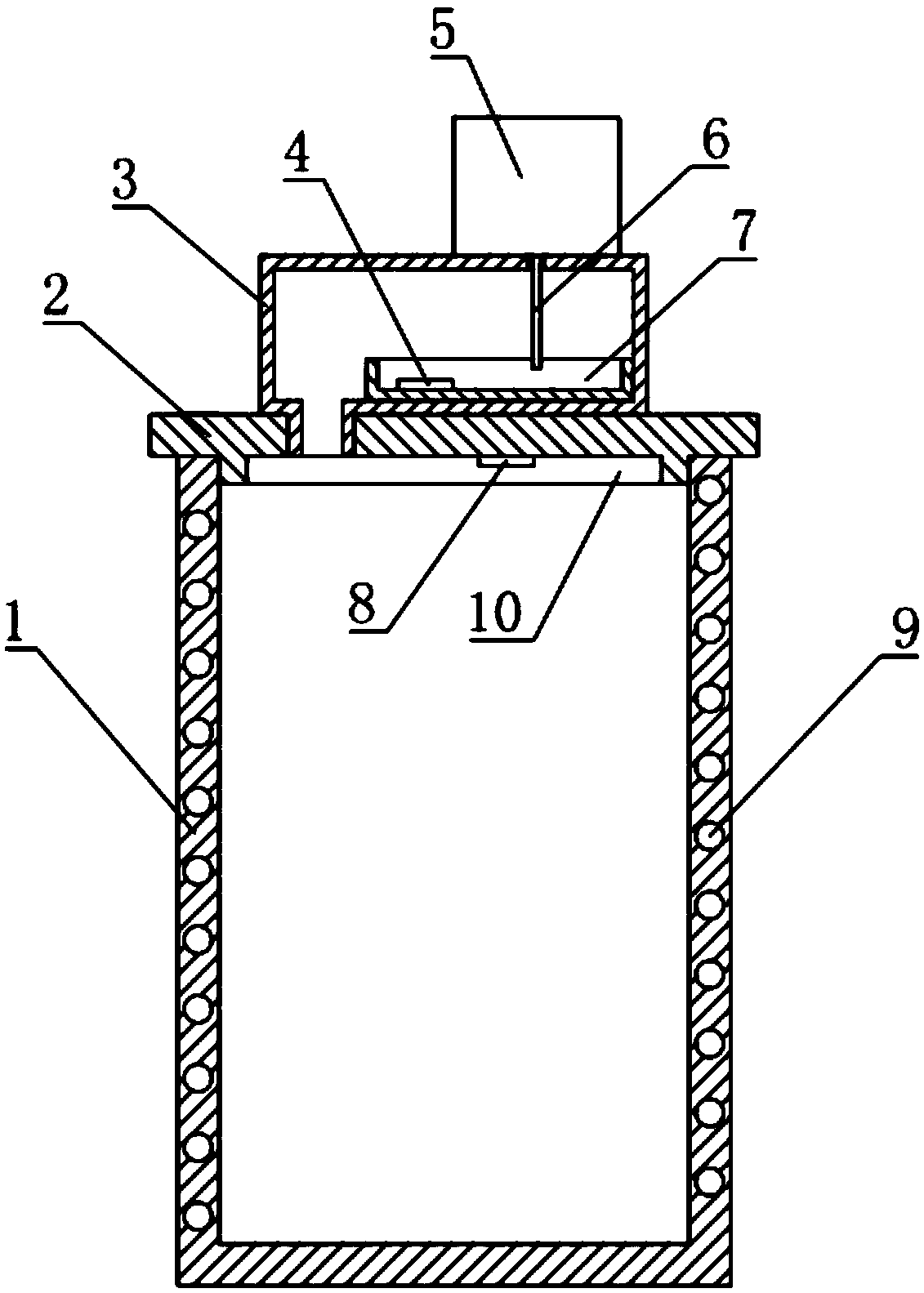

The invention discloses a glass lamination machine for producing insulating glass. The glass lamination machine for producing the insulating glass comprises a feeding device, a lamination working table, a suction cup device, a film frame and a protective cover, the feeding device comprises a feeding rack and a feeding plate, the lamination working table is provided with a cushion, vent holes are evenly formed in the surface of the cushion, supporting springs and a horizontal sliding device are arranged in a cavity of the cushion, the suction cup device comprises fixing frames and vertical suction cups, the two adjacent fixing frames are connected through a connecting rod, and a lead screw is arranged at the upper end of each vertical suction cup. The glass lamination machine for producing the insulating glass is simple in structure and strong in practicability; the original design of feeding through an escalator is improved; by means of a traction motor, feeding of glass is more convenient and simple, and the safety performance of operation is improved; by means of the cushion, a protective effect on the glass can be achieved, the placed glass can be firmly sucked by horizontal suction cups in the cushion, the movement of the glass is avoided, the energy consumption is reduced, and the comprehensive utilization efficiency is increased.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

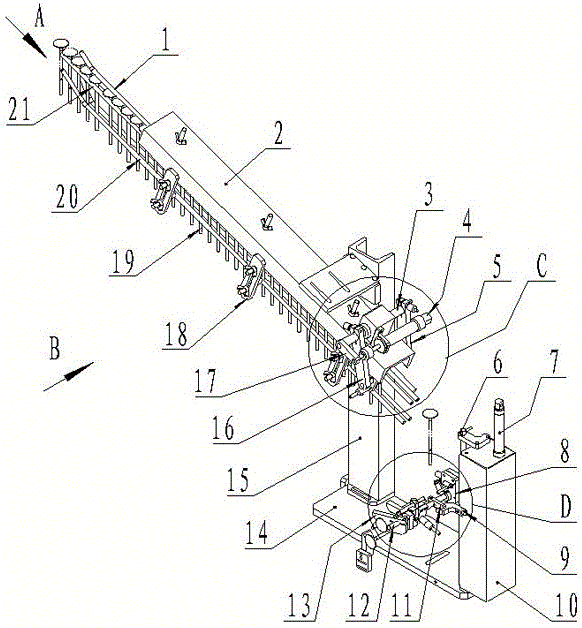

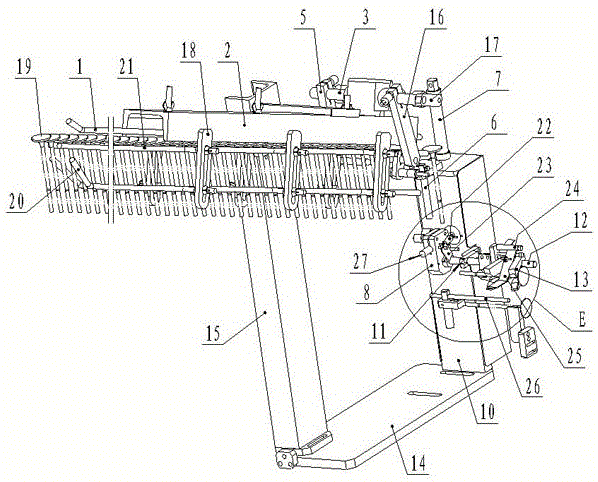

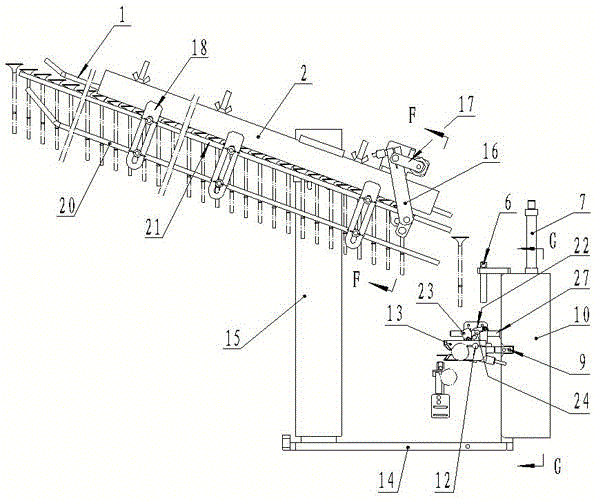

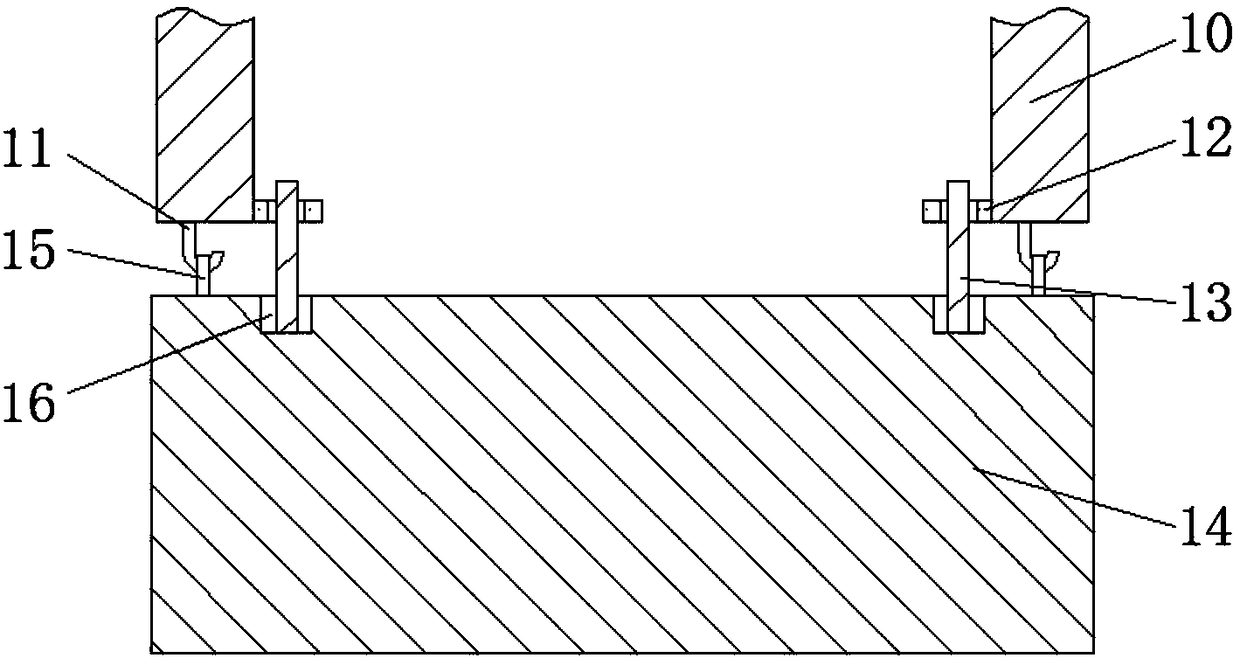

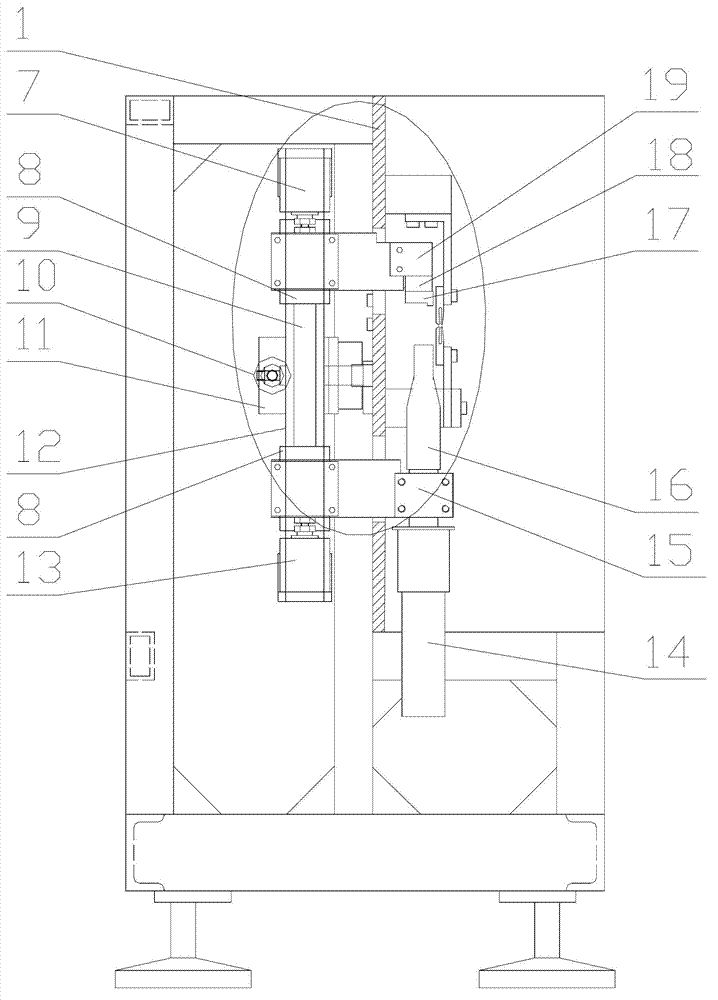

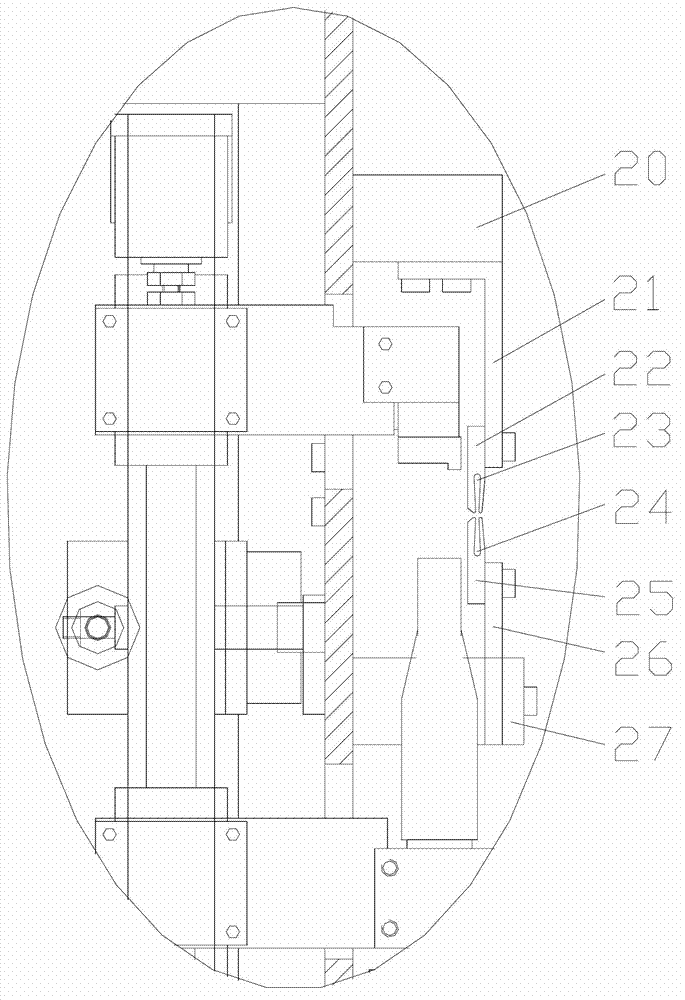

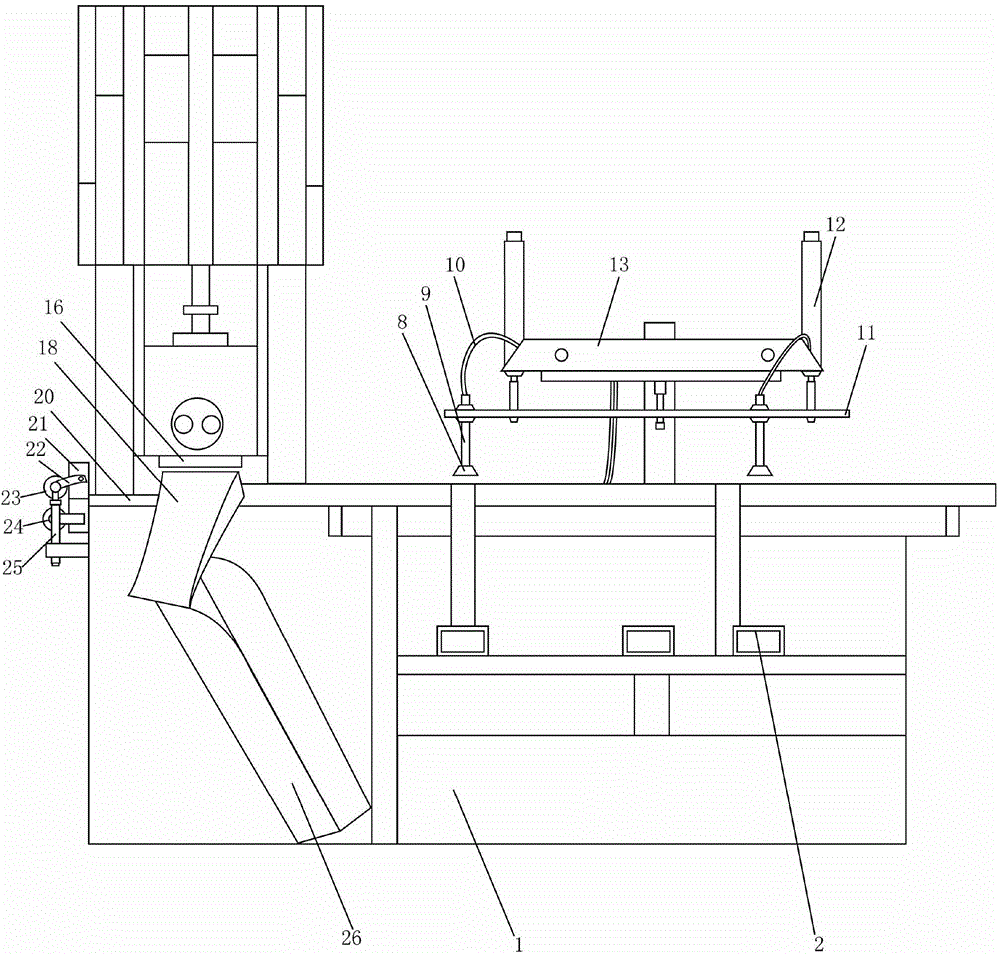

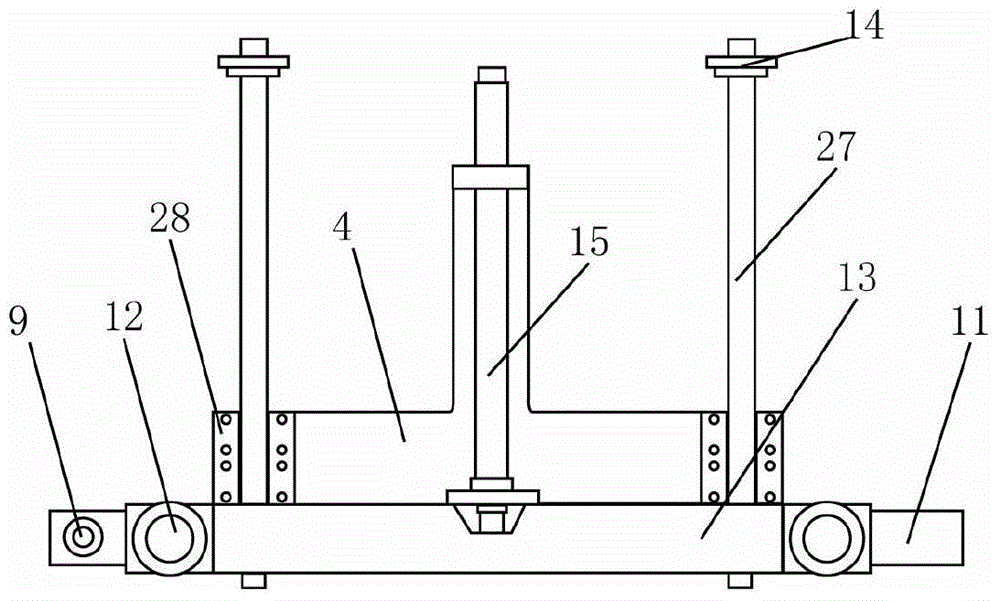

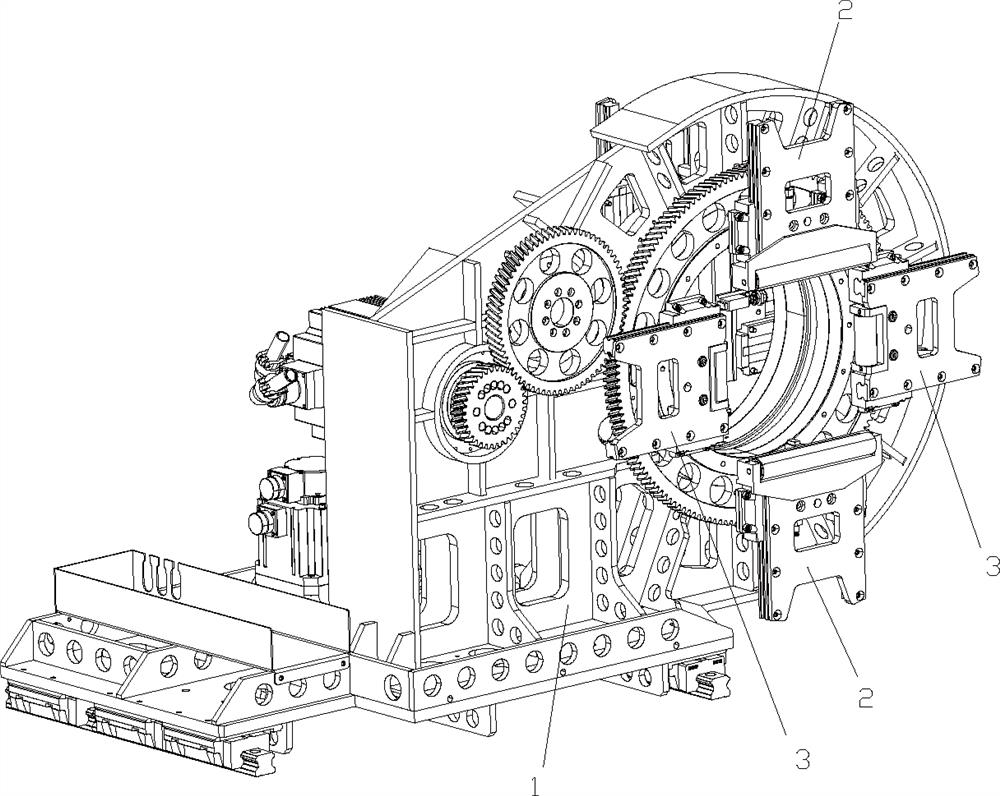

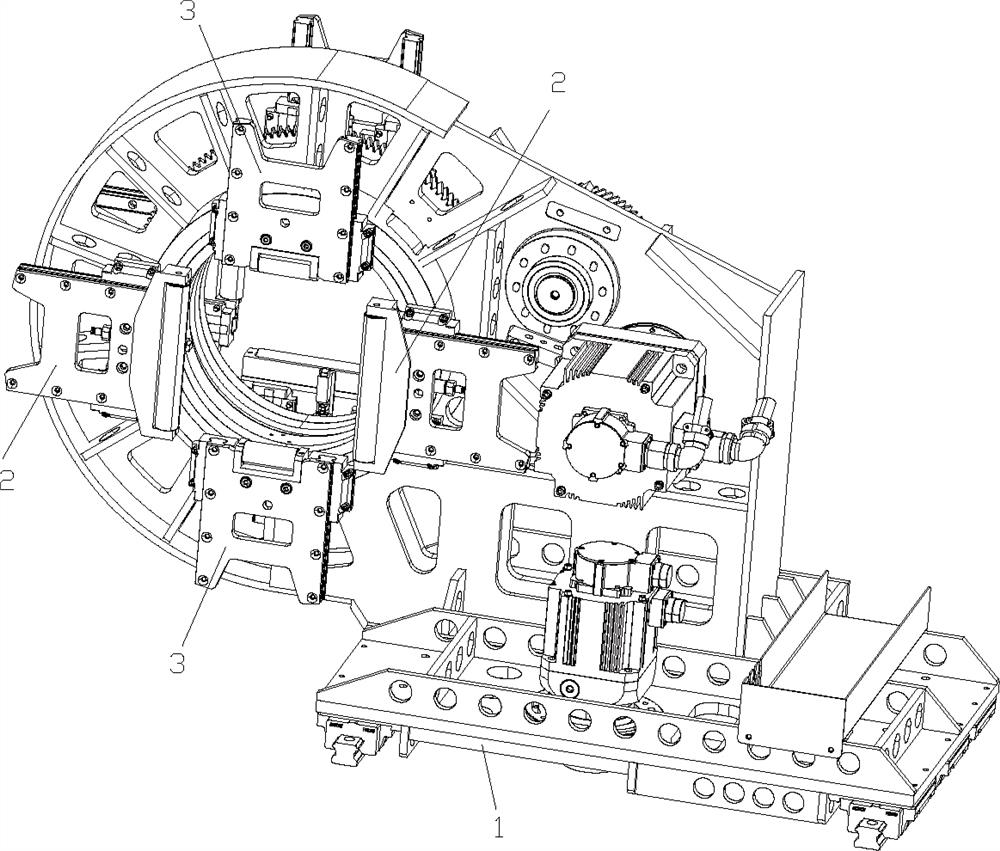

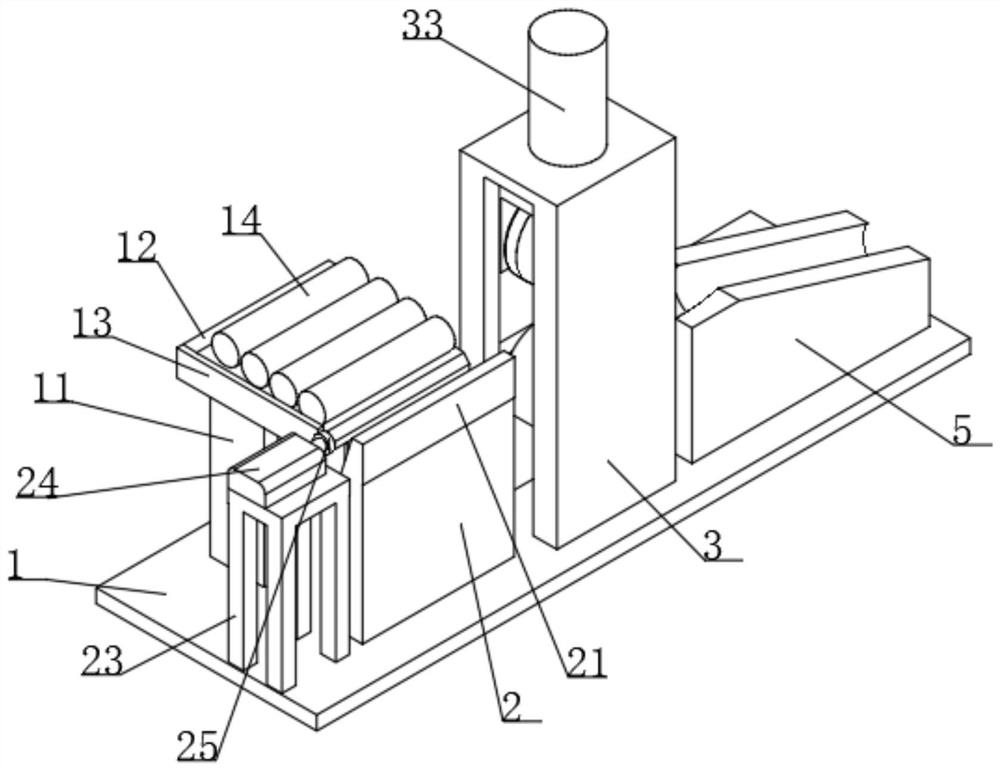

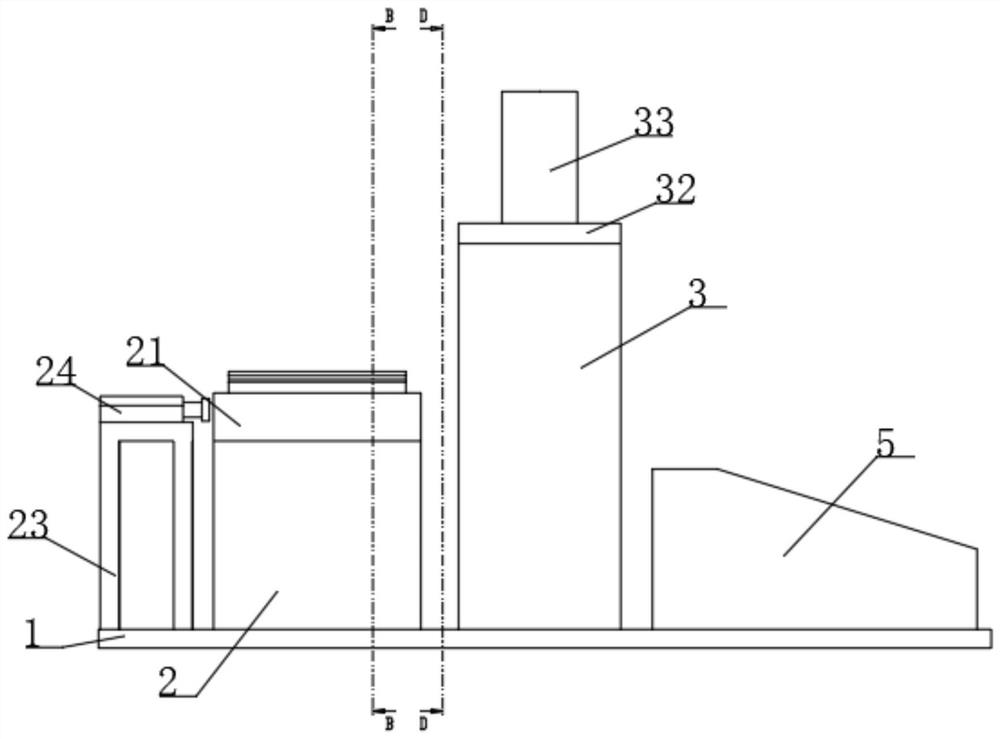

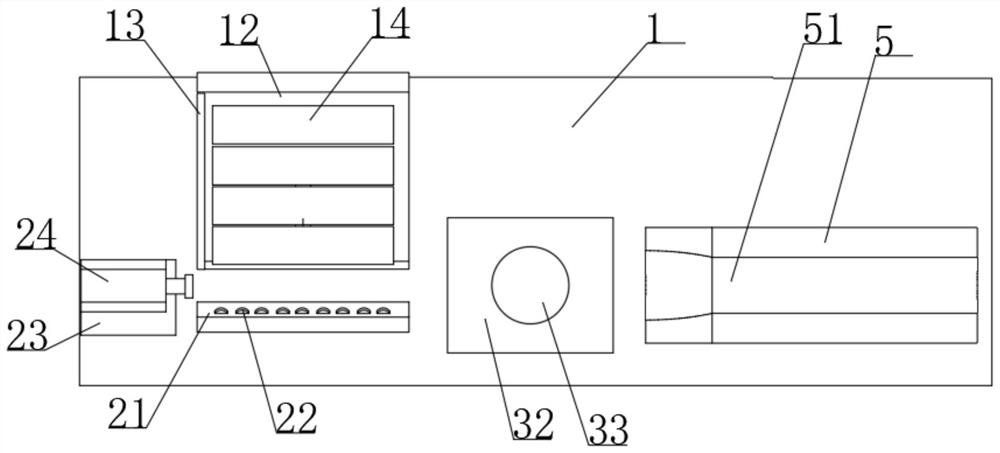

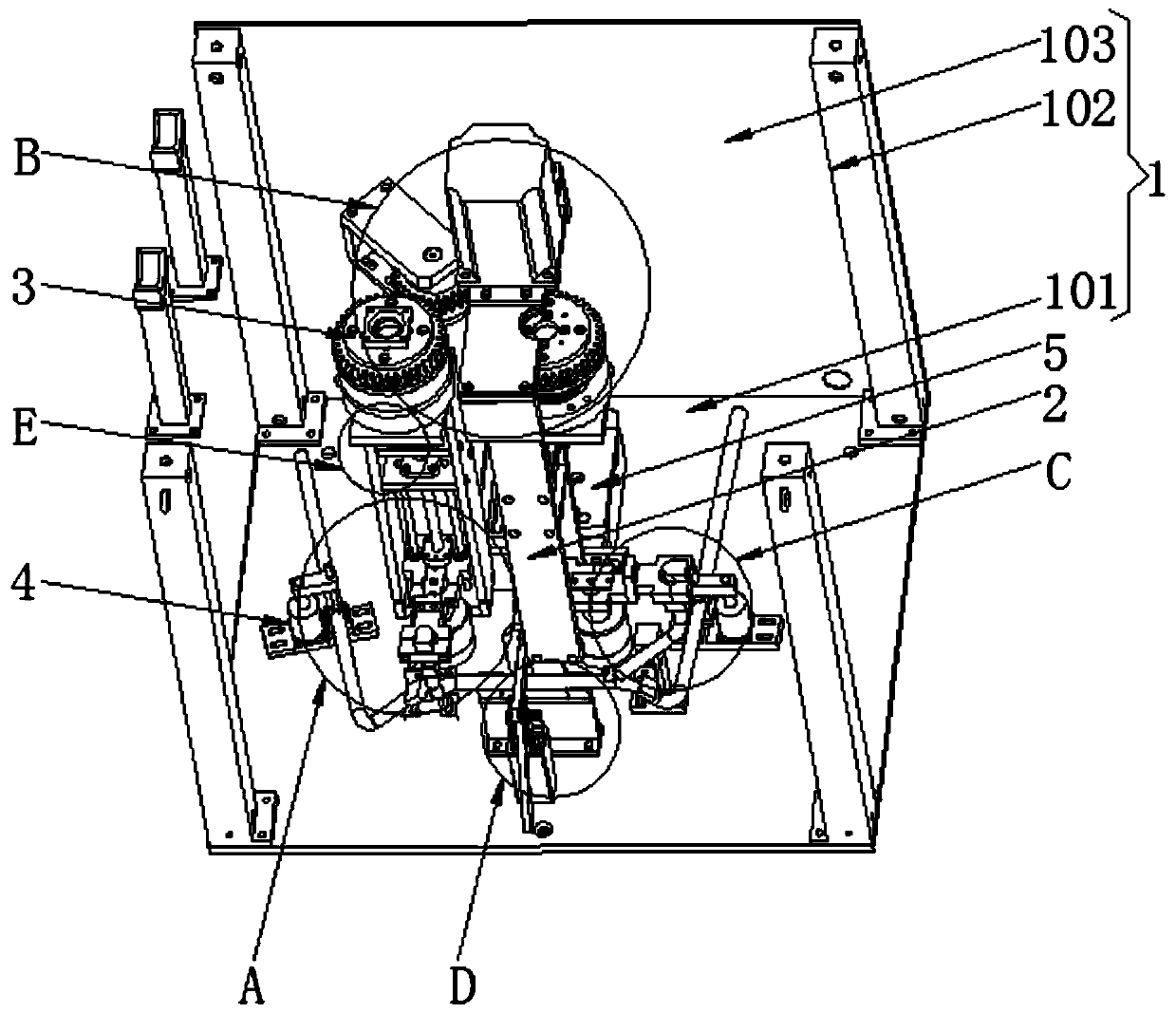

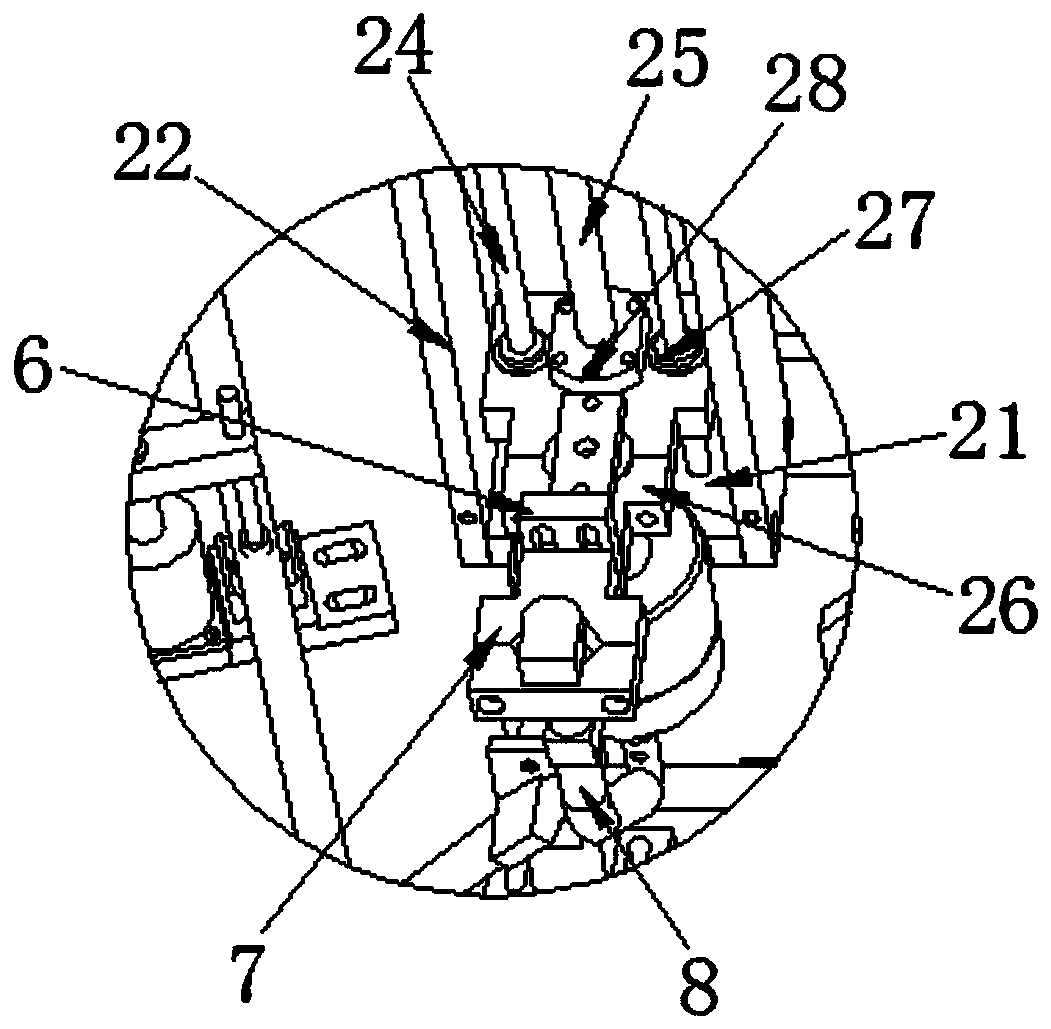

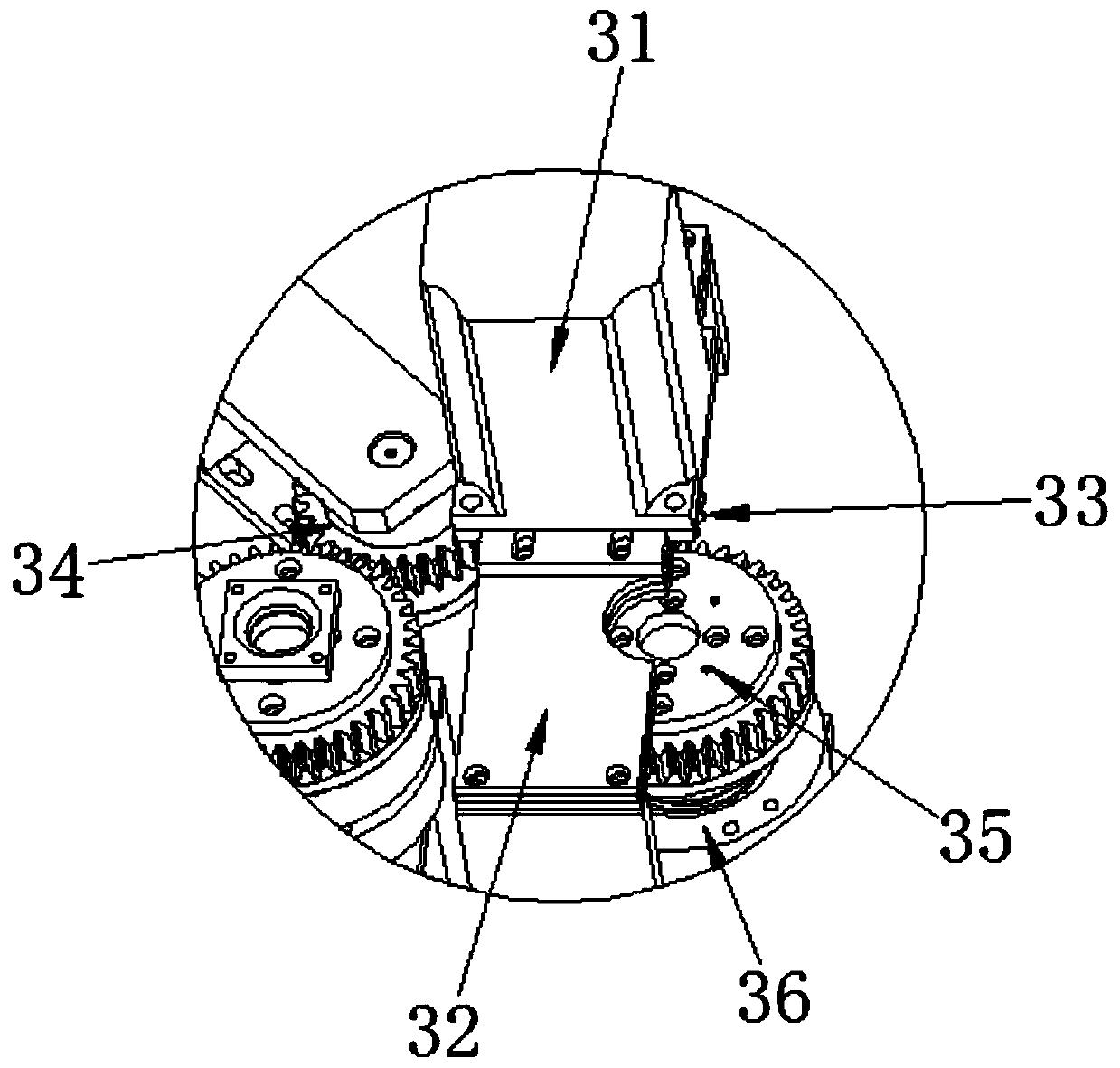

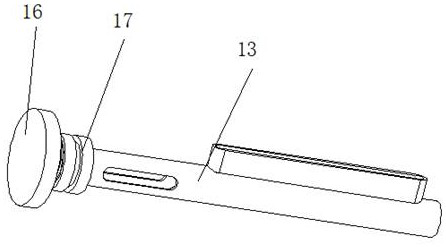

Loading device for automatic detection of valve rods

ActiveCN105109988AFeeding is simple and convenientFeeding positioning is accurateConveyor partsAutomatic testingMechanical engineering

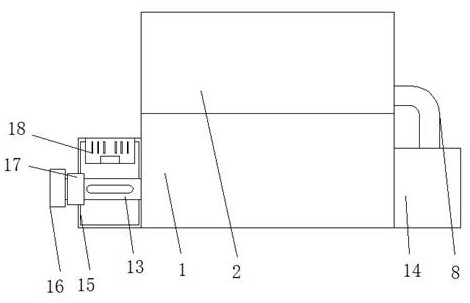

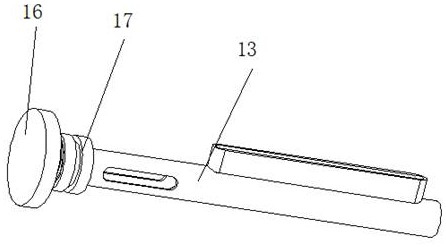

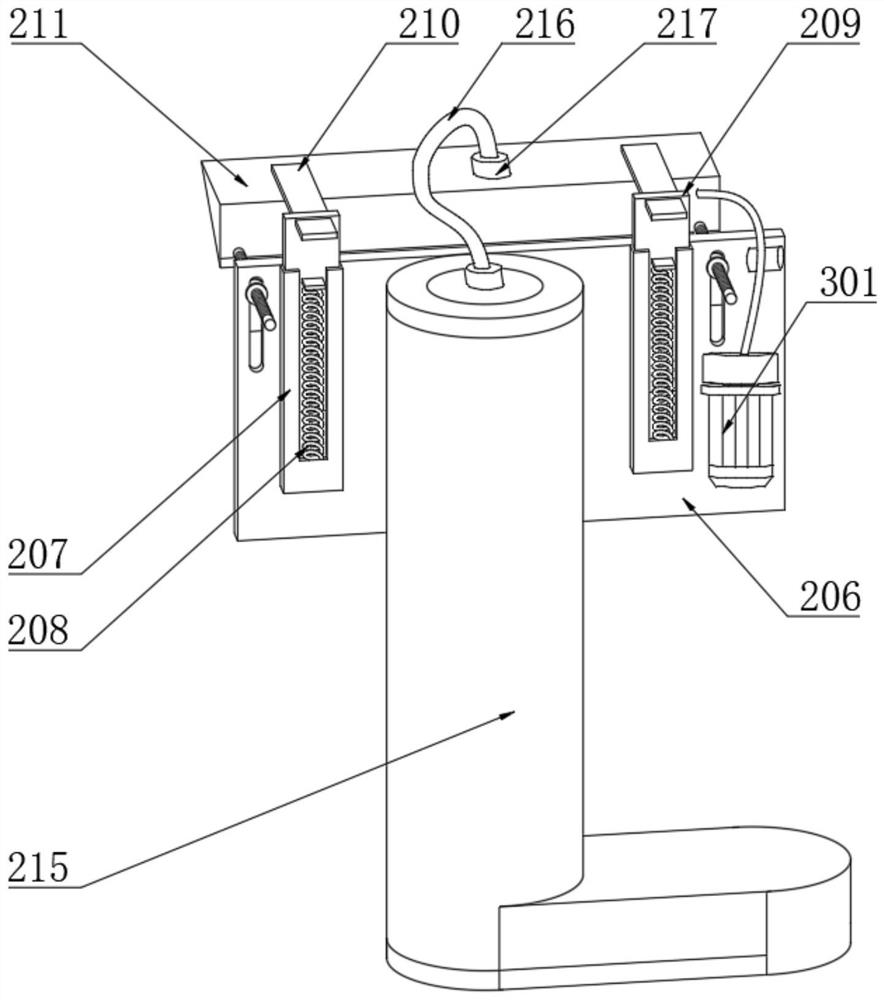

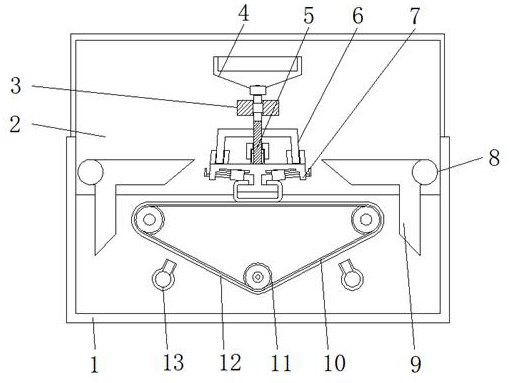

The invention discloses a loading device for automatic detection of valve rods, and belongs to the field of valve rod conveying devices. The loading device can continuously, orderly and efficiently convey the valve rods. The loading device comprises a machine base, a loading mechanism, a material stopping mechanism and a material catching and turning mechanism; the loading mechanism is composed of a stand column (15) fixed on the machine base (14) and upper sliding rails (21) fixed on the stand column; the material stopping mechanism is composed of a spindle rod (3), installation blocks, stopping pins (31) and a first air cylinder (4); the material catching and turning mechanism is composed of a gear box (10) internally provided with a rack (33) and a gear (32), a rotating seat (8) fixed on a gear shaft (27), a rotating shaft (12) supported on the rotating seat, material catching jaws (13) fixed on the rotating shaft and a second air cylinder (7). The loading device is easy and convenient to load, accurate in loading and positioning, high in efficiency and small in labor intensity and is matched with an automatic valve rod detection device.

Owner:贵州德科纳精密设备制造有限公司

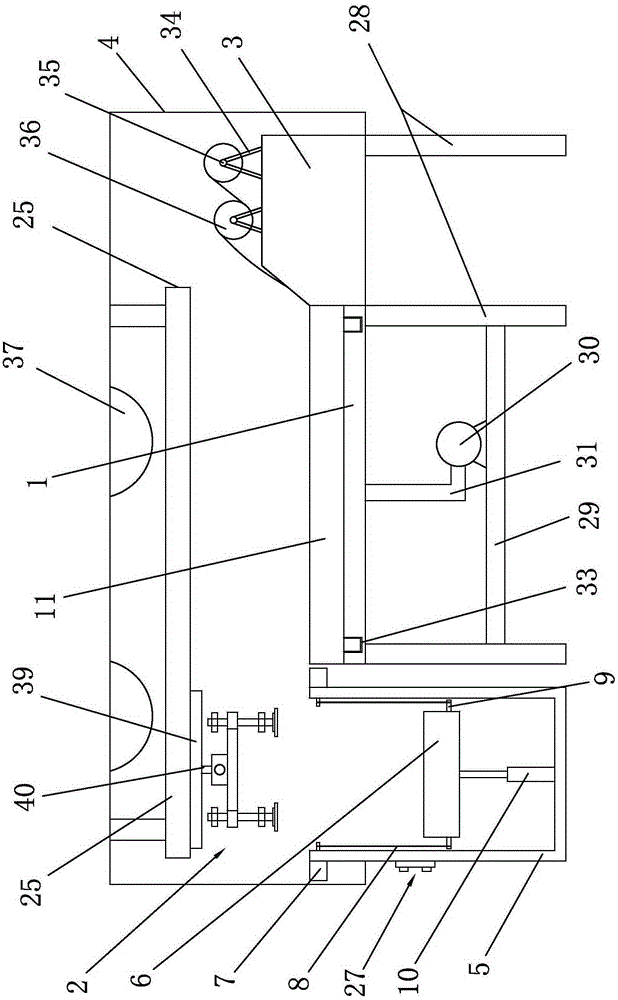

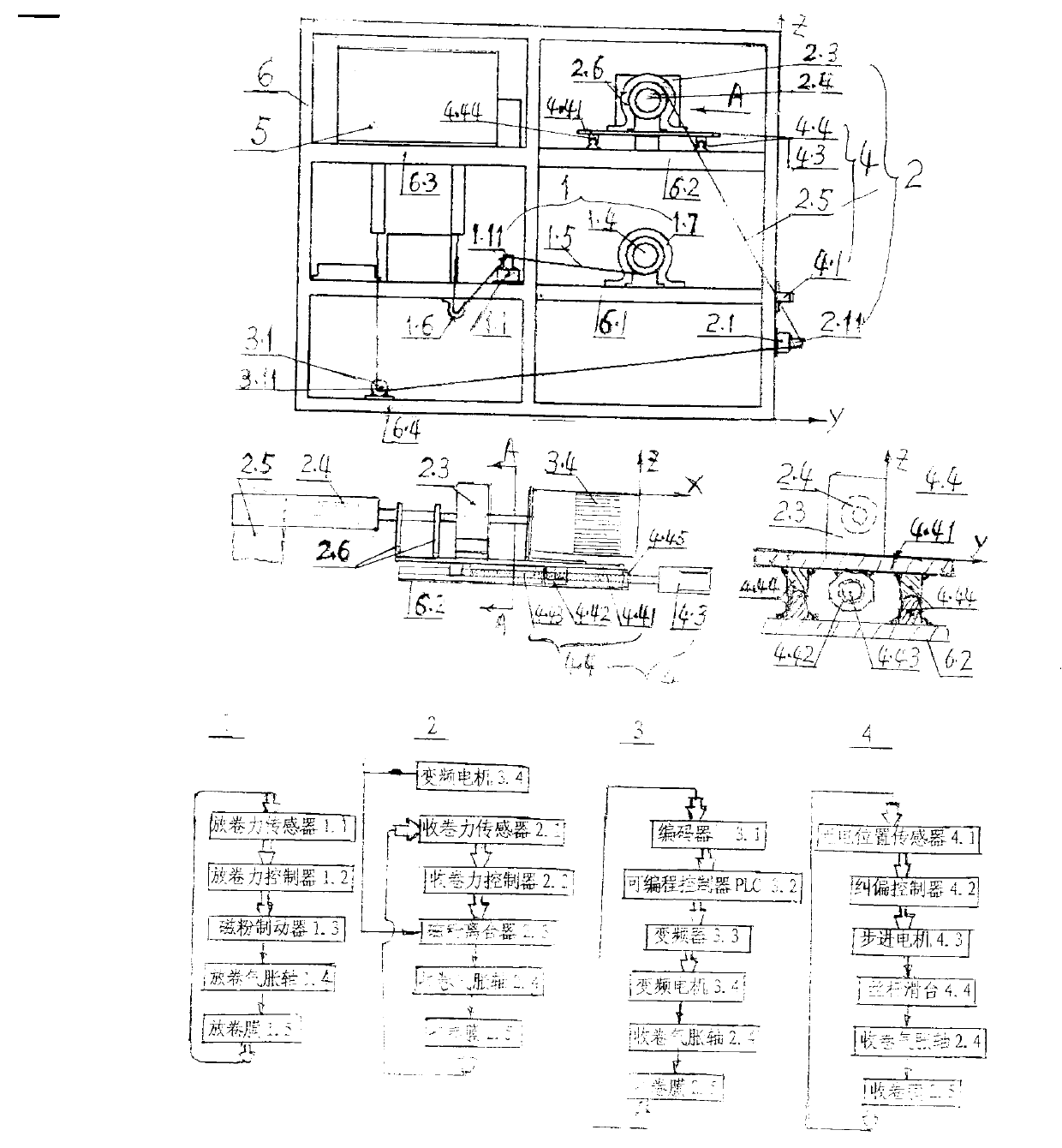

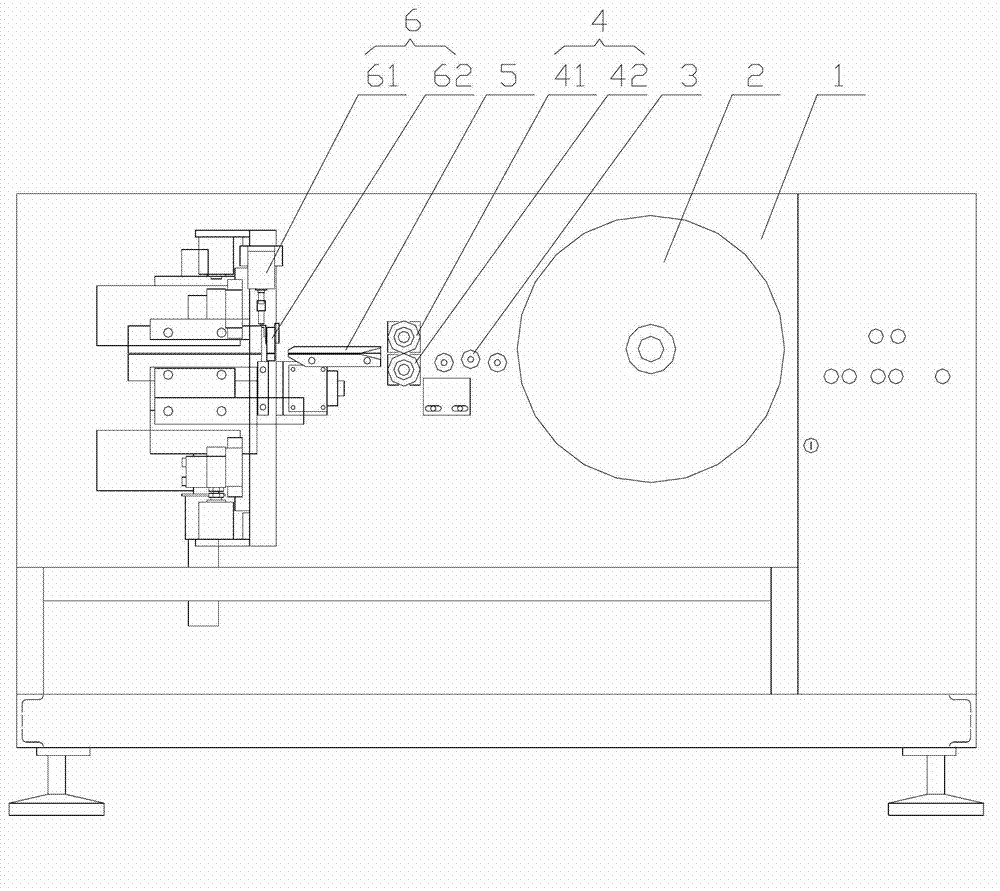

Automatic-deviation-rectification, constant-speed and constant-tension rewinding machine

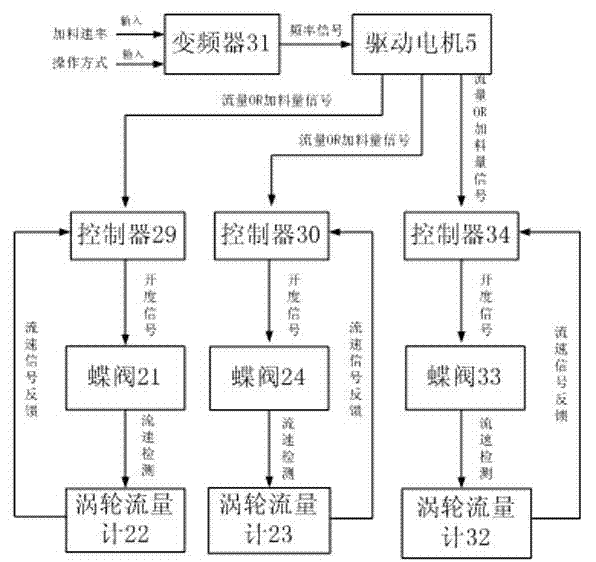

The invention relates to an automatic-deviation-rectification, constant-speed and constant-tension rewinding machine. A magnetic powder brake and a cantilever unwinding inflation shaft are mounted on a rack; an unwinding membrane passes through an unwinding force sensor roll and an unwinding guide roll, and is delivered into a membrane processing device to form an unwinding tension control device; a screw rod sliding table and a stepping motor are fixed on the rack; a variable frequency motor, a magnetic powder clutch and a cantilever winding inflation shaft are fixed on the surface of the screw rod sliding table; a winding membrane sequentially passes through a photoelectric position sensor, a winding force sensor roll and an encoder roll, and finally passes into the membrane processing device to form a device for controlling winding tension, winding speed, deviation rectification and the like; and an unwinding force, winding force and deviation rectification controller with a program-controlled preset value is utilized to control constant tension of the membrane, and to rectify deviation automatically. The programmable logic controller (PLC), a frequency converter and the variable frequency motor are arranged to control the transmission of the membrane at the constant speed. The machine achieves multifunctional control, solves the problems of high stress deformation, non-uniform viscosity, the deviation and the like, is high in quality and efficiency, simple, reasonable in design, and convenient to operate and maintain, and is particularly applicable to rewinding of a polytetrafluoroethylene adhesive tape coil.

Owner:SICHUAN UNIV

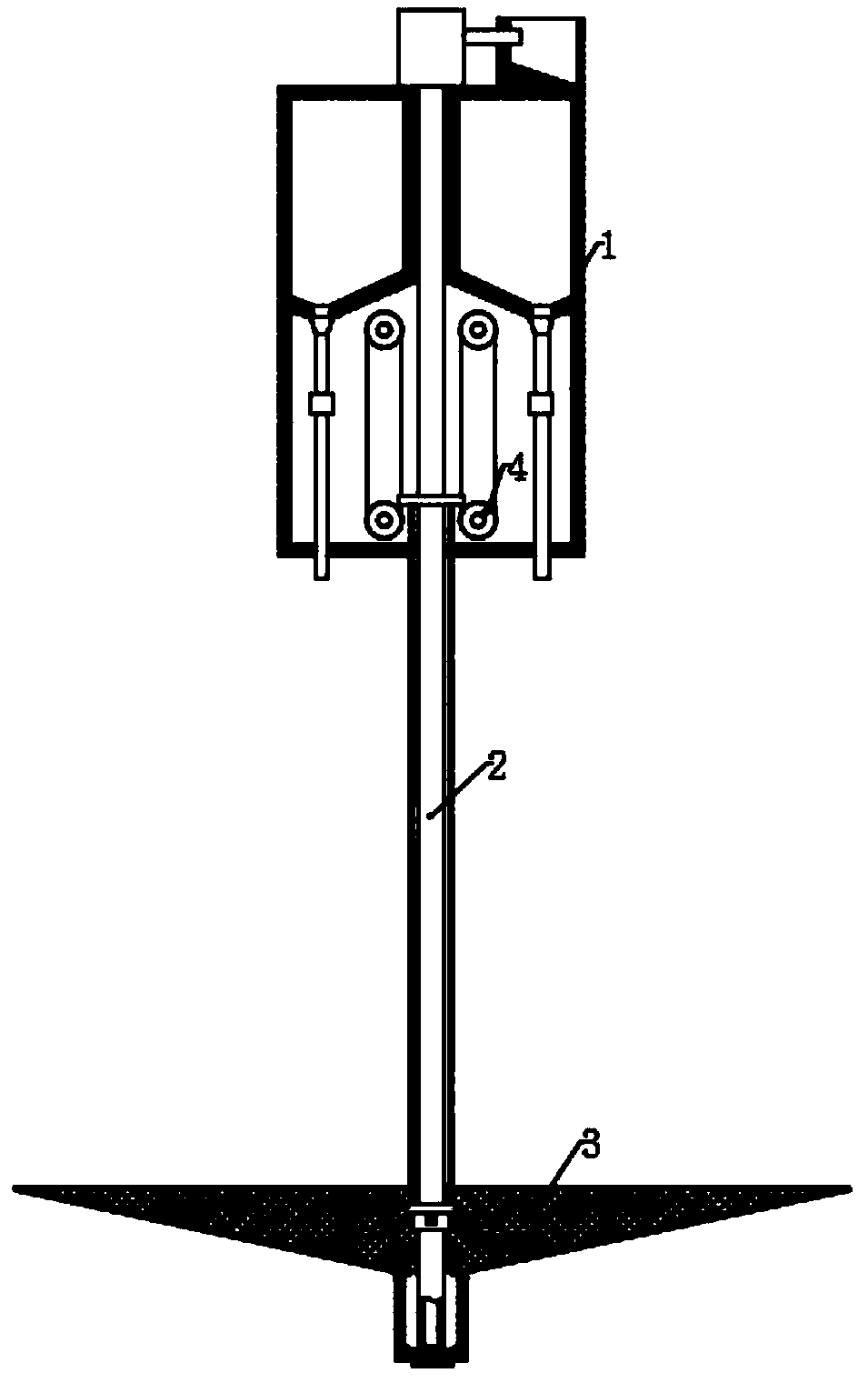

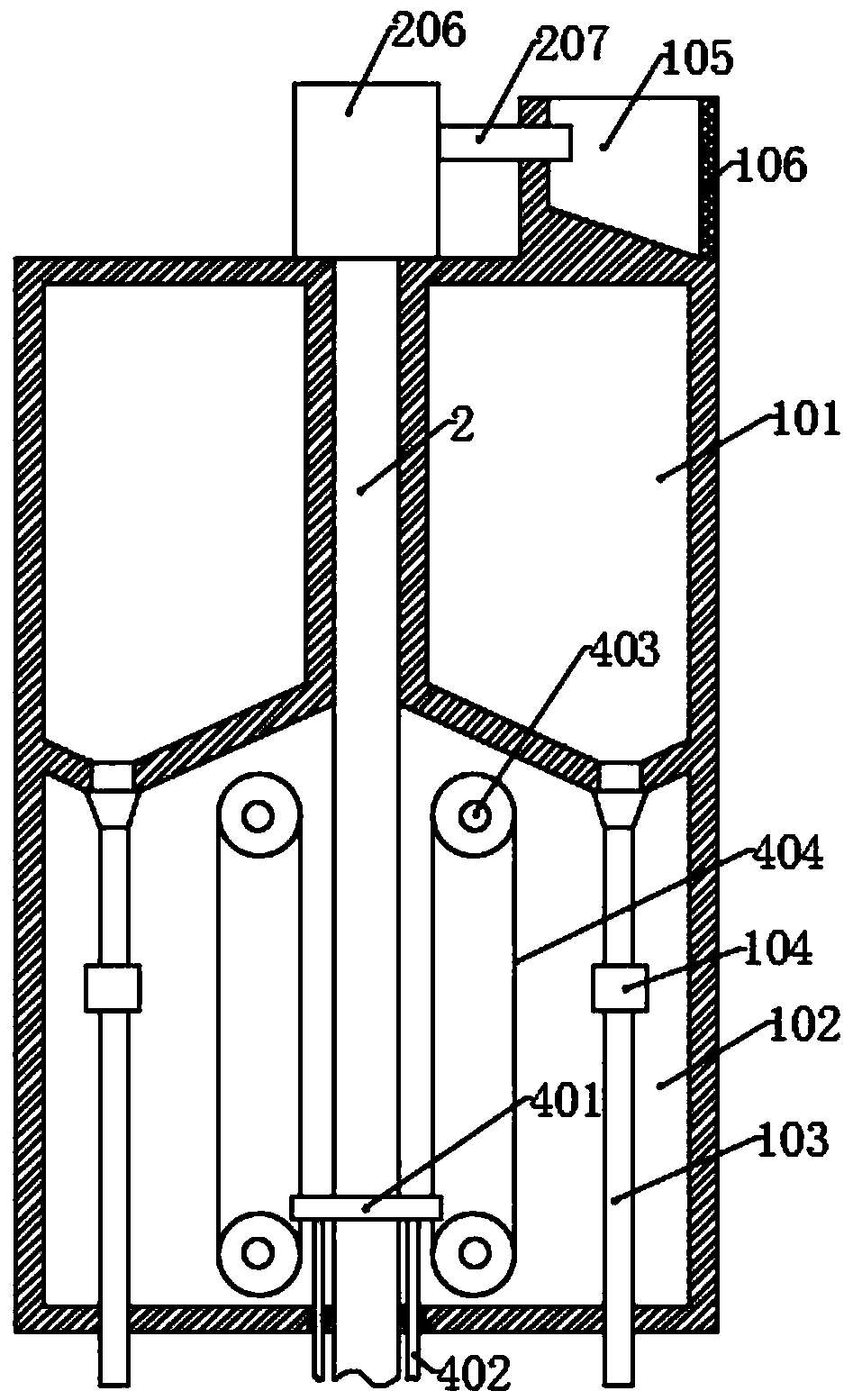

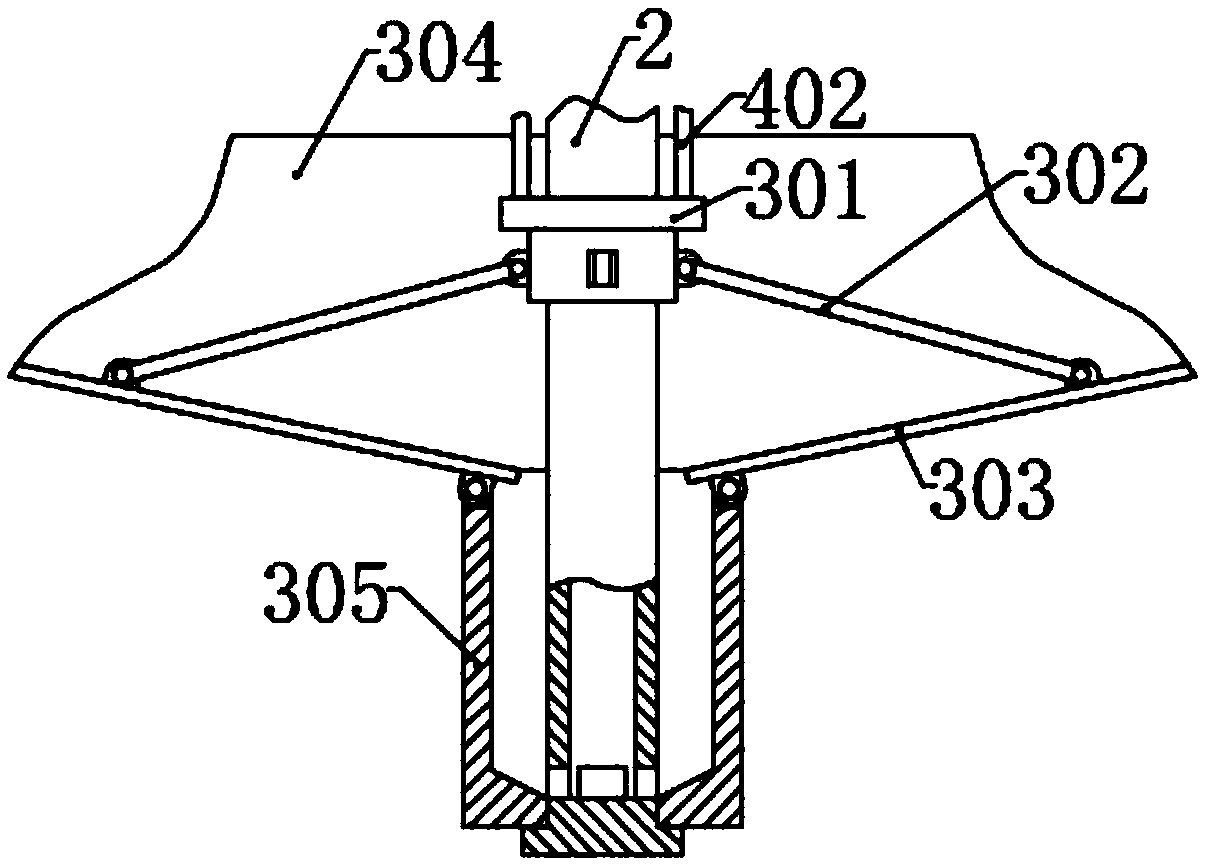

Environmentally-friendly feeding device for aquaculture

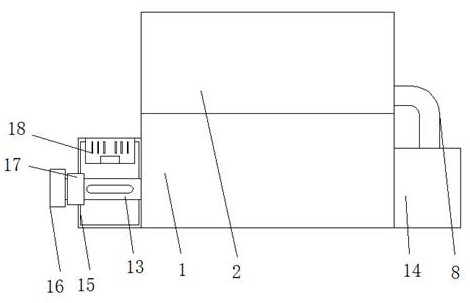

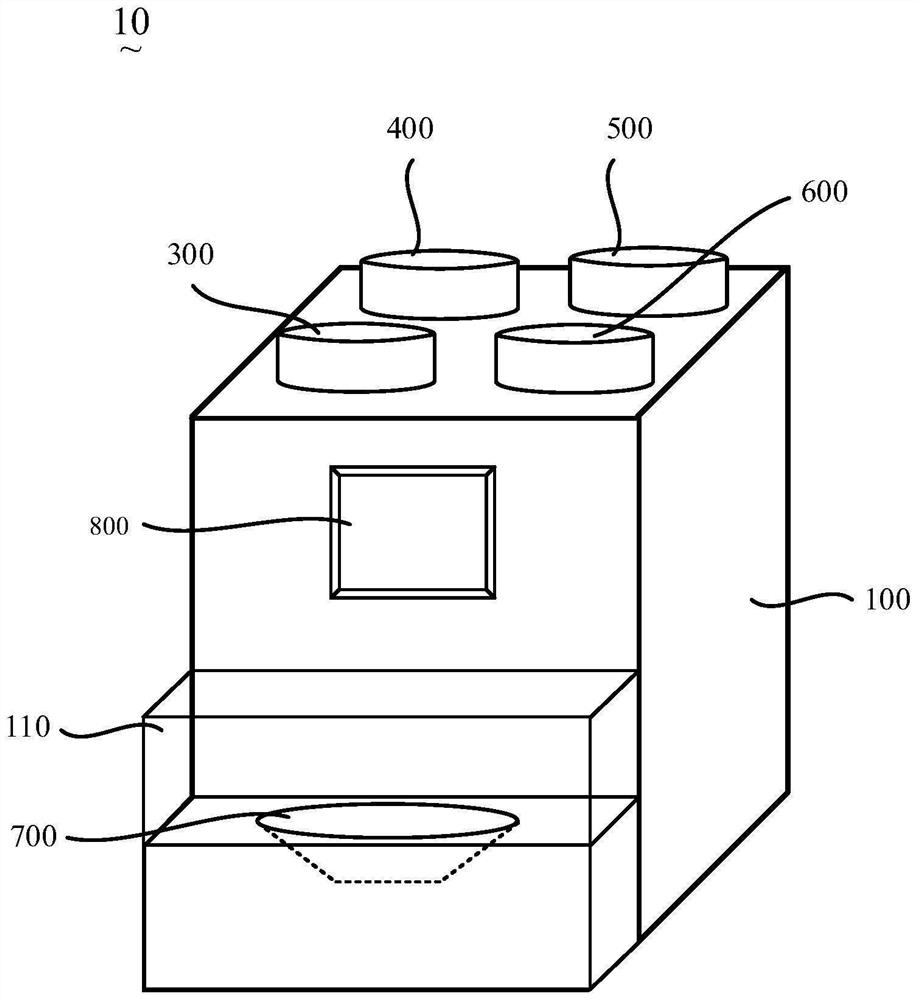

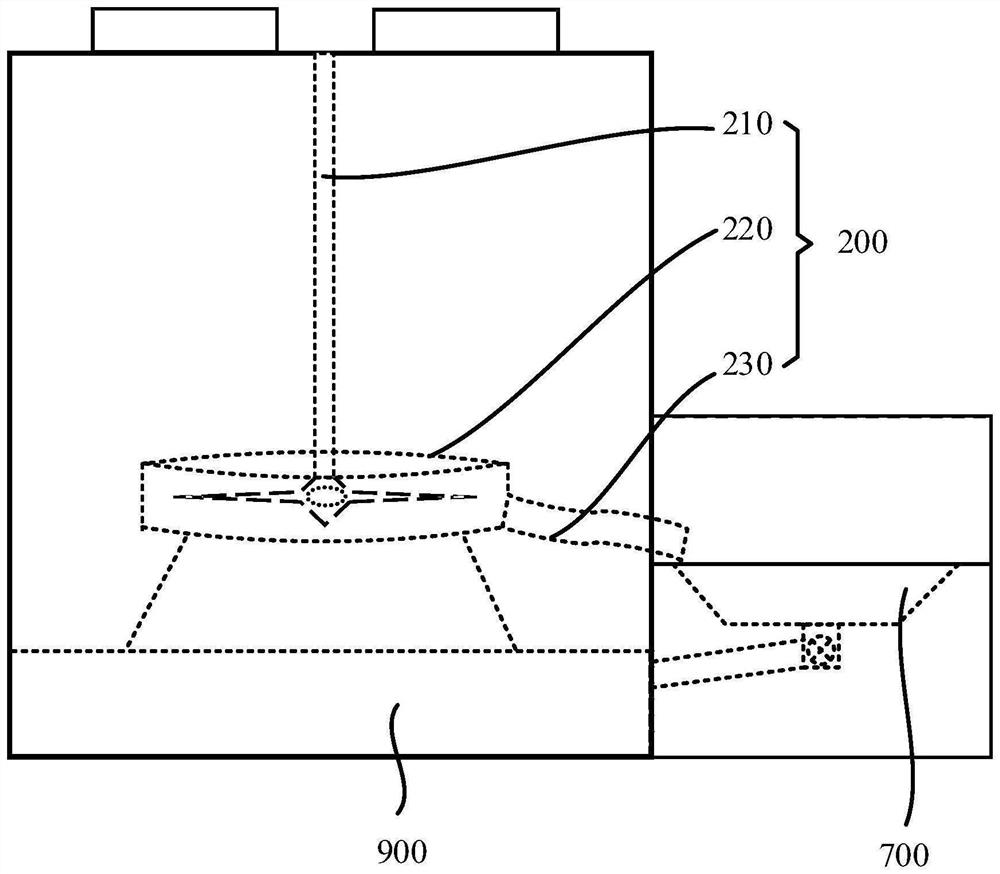

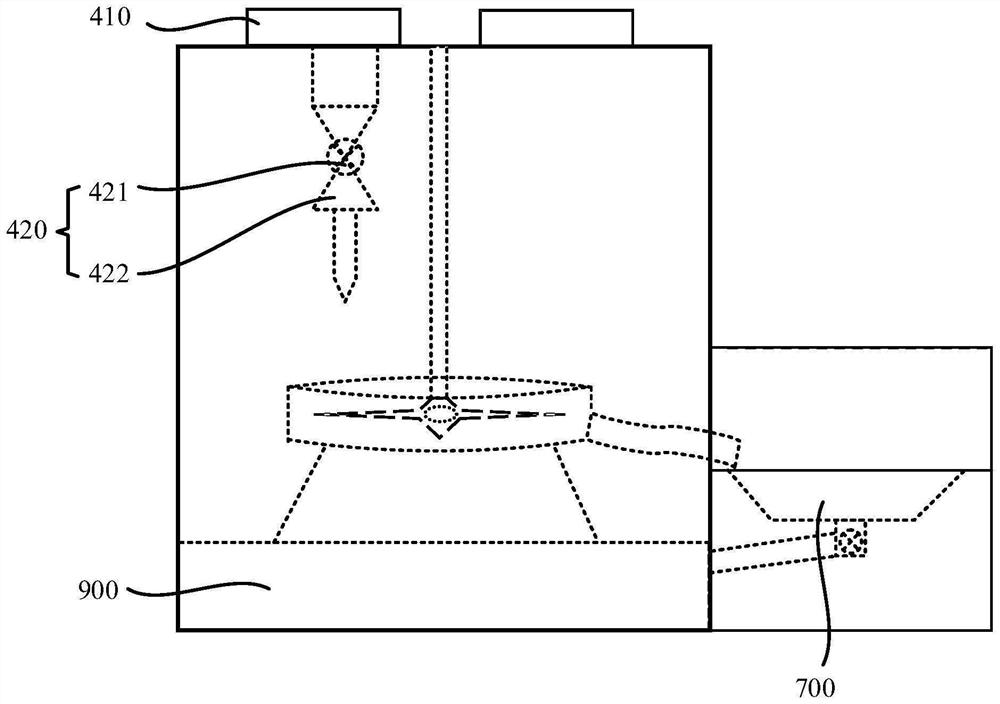

ActiveCN109122511AFeeding is simple and convenientExpand the scope of collectionClimate change adaptationPisciculture and aquariaEngineeringControl valves

The invention discloses an environmentally-friendly feeding device for aquaculture, belonging to the technical field of aquaculture. The environmentally-friendly feeding device comprises a fixed box,a water pumping pipe, a collection mechanism and a lift-drop mechanism. According to the invention, a feed is stored through a feed chamber, and when feeding is needed, control valves and feeding pipes are opened for feeding, so feeding is simple, convenient, time-saving and labor-saving; a motor is started to enable the lift-drop mechanism to drive a moving sleeve to move upward, and connecting rods enable rotating rods to rotate to enable the connecting rods to open collection nets, so a residual feed remained after completion of feeding falls onto the collection nets and finally falls intothe collection drum, and larger collection range and convenient and effective collection are realized through the collection nets; and the residual feed located at the bottom part of the water pumpingpipe together with pond water are pumped out through a water pump and discharged into a collection groove, so the pond water passes through a first filter screen and returns to a culture pond, whilethe residual feed remains in the collection groove.

Owner:汕头市深投科技有限公司

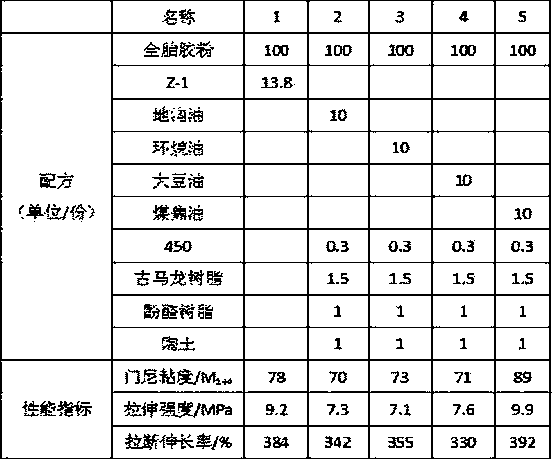

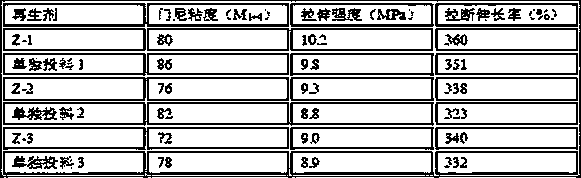

Regenerant for regenerated rubber and preparation method of regenerant

ActiveCN104194036AWell mixedAvoid the problem of direct mixing and not easy to dispersePlastic recyclingPolymer scienceViscosity

The invention provides a regenerant for regenerated rubber and a preparation method of the regenerant. The regenerant for the regenerated rubber comprises an activator, a softener, a tackifier and a fortifier which are uniformly mixed, wherein the softener comprises a main softener and an auxiliary softener, the viscosity of the main softener is 20-40mPa.s and the main softener accounts for 24-70% by mass of the whole system. The regenerant for the regenerated rubber has the advantages that (1) various regenerating auxiliaries are fused together by virtue of processes of heating, stirring and the like, and materials are convenient and simple to input; (2) the regenerating auxiliaries are not heated again, so that the regenerant is safe to operate; (3) the solid regenerating auxiliaries are not crushed and stirred, so that materials are easy to input; (4) the defect that conventional activator and softener are sticky and adverse to automatically weigh, convey and uniform spray is overcome; (5) main and auxiliary softeners are matched in use, so that the regenerant is convenient to use and excellent in regenerating effect; and (6) the regenerant is low in viscosity, single in character, flowable at normal temperature and easy to store, package and convey.

Owner:CHINA RUBBER RESOURCE REGENERATION QINGDAO

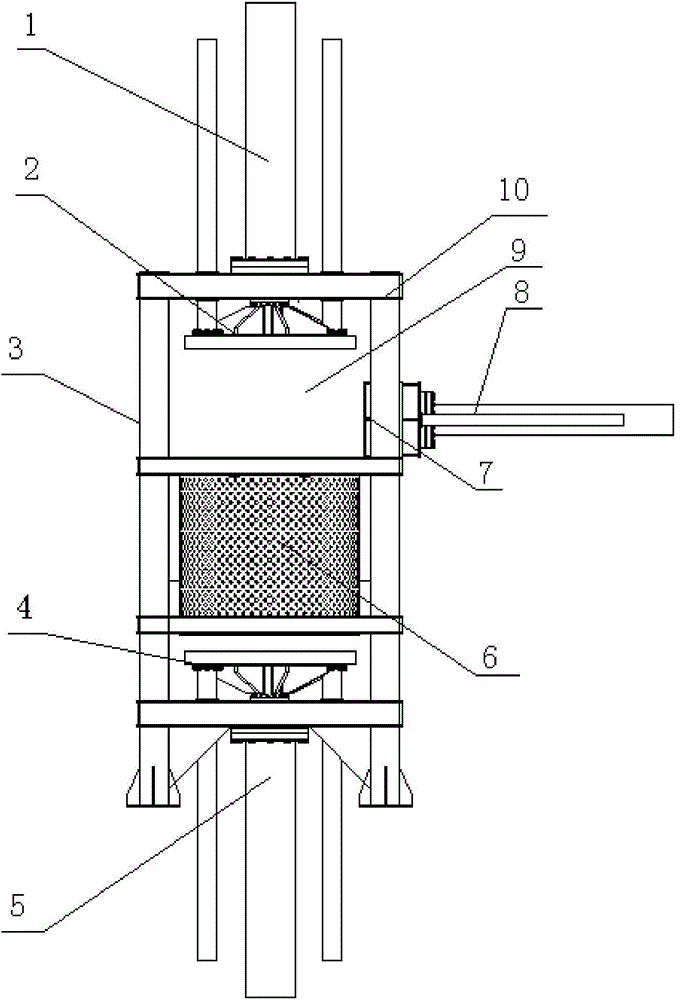

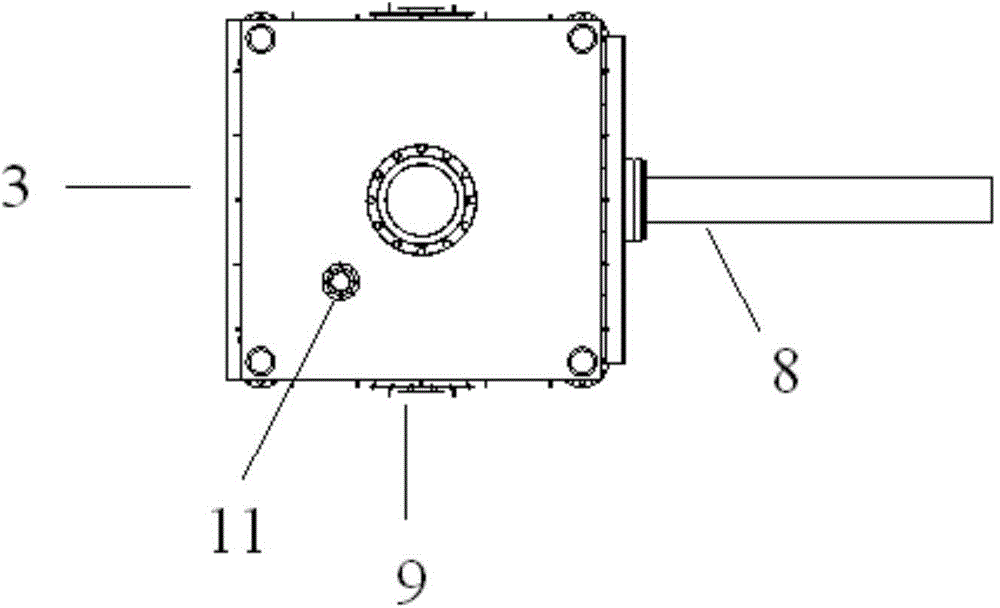

Rubbish dehydration solid-liquid separation device

The invention discloses a rubbish dehydration solid-liquid separation device. The rubbish dehydration solid-liquid separation device comprises a closed solid-liquid separation cylinder body, a downward-moving hydraulic system with a lower push plate, a discharging hydraulic system with a discharging push plate and an upward-moving hydraulic system with an upper push plate. A feeding opening and a discharging opening are formed in the upper portion of the solid-liquid separation cylinder body. The lower push plate of the downward-moving hydraulic system is arranged on the top of the solid-liquid separation cylinder body and can move up and down along an inner cavity of the solid-liquid separation cylinder body. The upper push plate of the upward-moving hydraulic system is arranged at the bottom of the solid-liquid separation cylinder body and can move up and down along the inner cavity of the solid-liquid separation cylinder body. The discharging push plate of the discharging hydraulic system is arranged at the position, corresponding to the discharging opening, of the solid-liquid separation cylinder body, and can make transverse movement along the inner cavity of the solid-liquid separation cylinder body. According to the rubbish dehydration solid-liquid separation device, a double-direction vertical hydraulic squeezing mode is adopted, powerful squeezing can be provided, the problems of winding and hard object sticking in material dehydration can be solved, the adaptability to materials is high, the effects of rubbish reduction and volume reduction are obvious, the automation degree is high, and sealed deodorization can be achieved.

Owner:BEIJING JIELV ENVIRONMENTAL TECH CO LTD

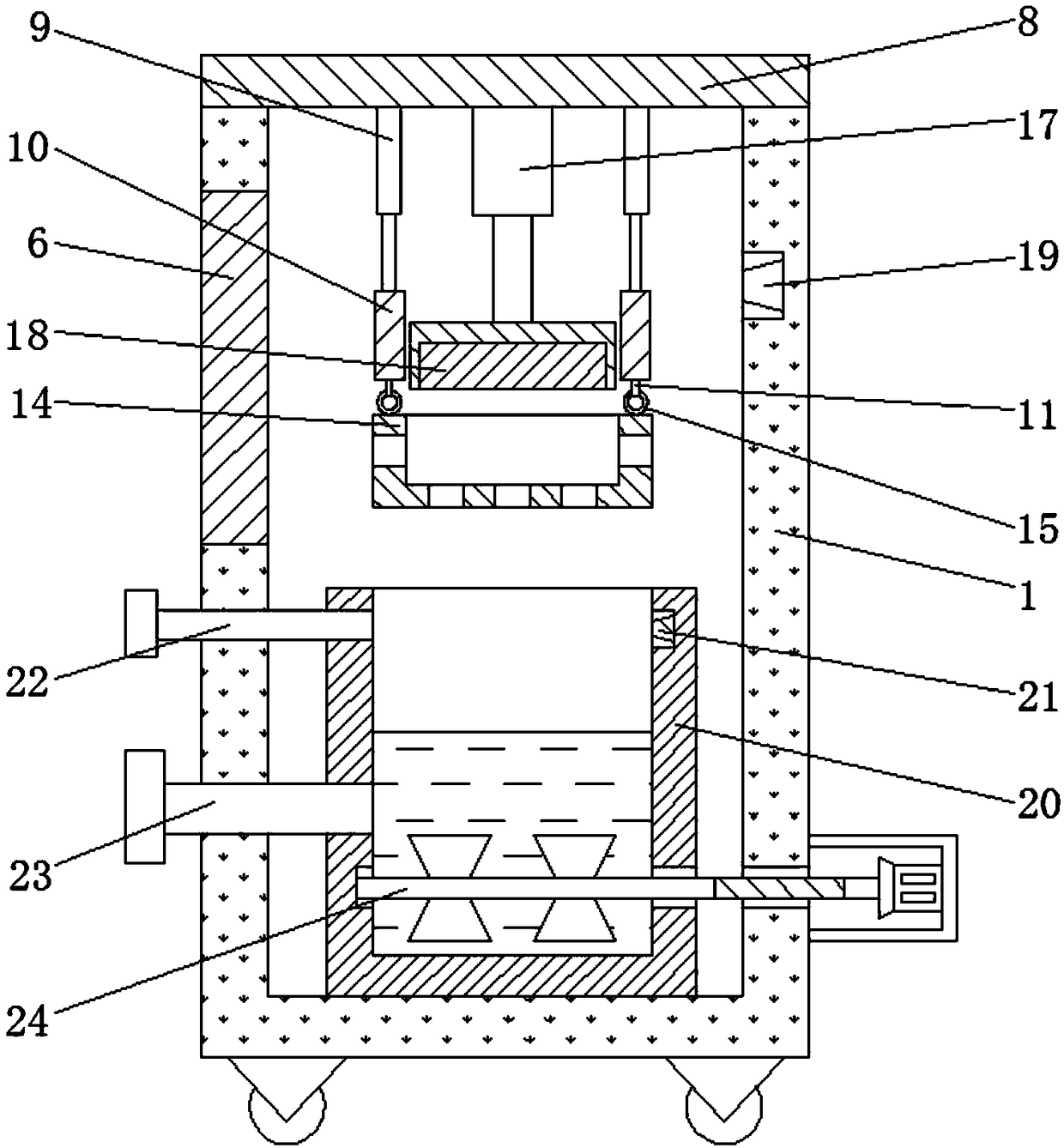

Quenching device with high safety performance for metal production

ActiveCN108531697AEasy to install and disassembleFeeding is simple and convenientFurnace typesHeat treatment furnacesMetal workingQuenching

The invention belongs to the technical field of metal working, and particularly relates to a quenching device with high safety performance for metal production. The quenching device aims to solve theproblem that an existing metal quenching device is inconvenient in feeding and discharging. The quenching device comprises a protective box, supporting wheels are arranged at the four corners of the outer wall of the bottom of the protective box through bolts, supporting plates which are horizontally arranged are arranged at the two ends of the bottoms of the outer walls of the two sides of the protective box through bolts, first hydraulic rods which are vertically arranged are arranged on the outer walls of the bottoms of the supporting plates through bolts, foundation bases are arranged on the outer walls of the bottoms of the first hydraulic rods through bolts, and damping bases are arranged on the outer walls of the bottoms of the foundation bases through bolts. The quenching device has the advantages that four hanging rings at the top of a placement box are hung on hooks, fixing rods are rotated to enable the fixing rods to be connected to fixing holes in a threaded mode, the placement box is kept stable, and therefore dismounting and mounting are simple and convenient, feeding and discharging can be conveniently carried out by dismounting and mounting the placement box through a protective door, use is simple, convenient and rapid, and the working efficiency can be improved.

Owner:广州丰东热炼有限公司

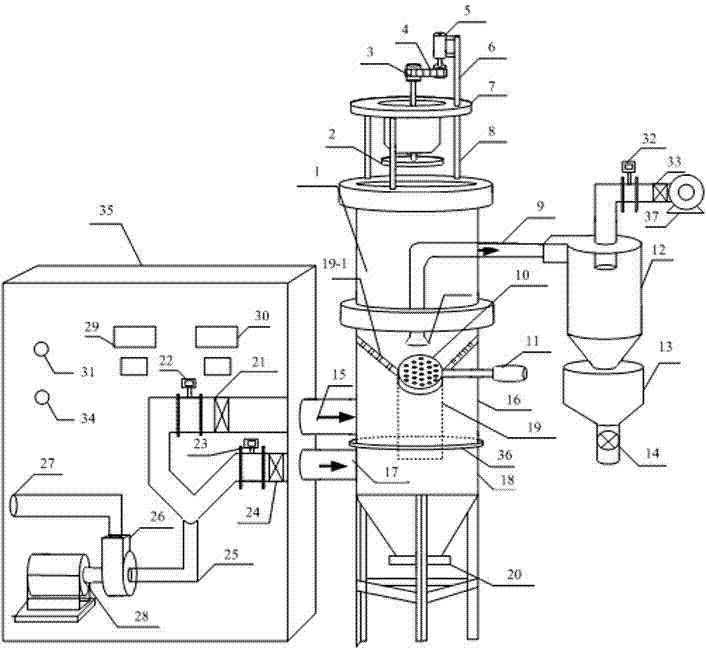

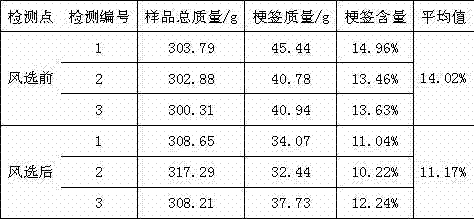

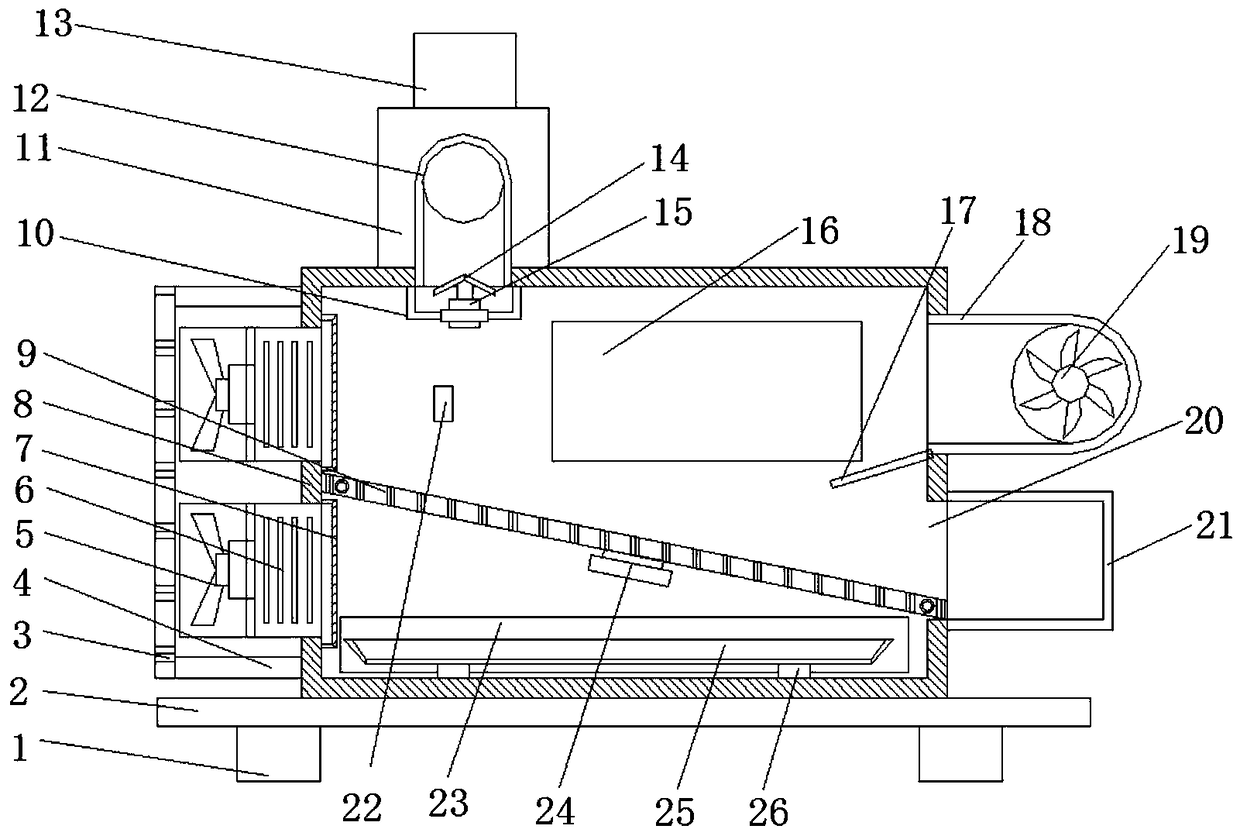

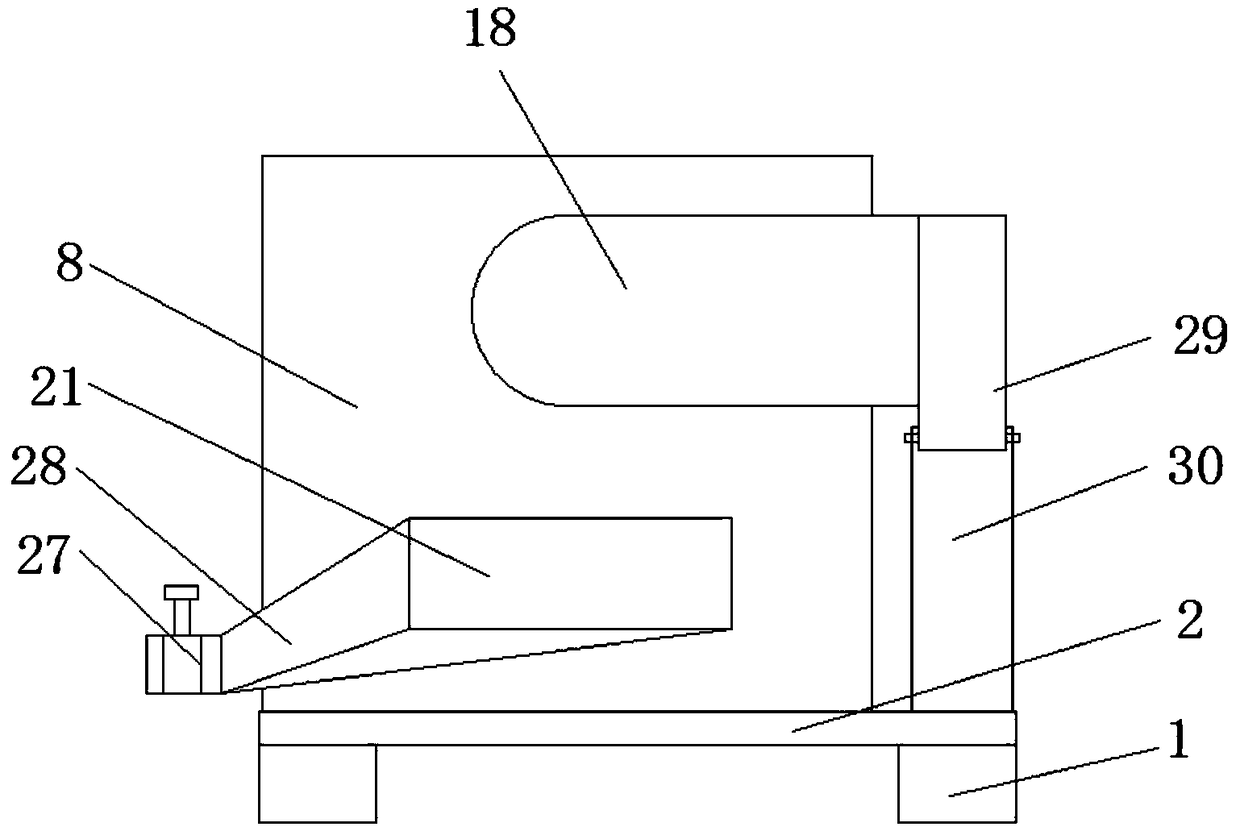

Detection device for content of stems in cut tobacco

InactiveCN104266928AThe measurement process is convenientFeeding is simple and convenientMaterial weighingPhencycloneStructural engineering

The invention relates to a detection device for the content of stems in cut tobacco. The detection device comprises an air supply mechanism, a fluidized air control system and an upright cylinder body, wherein the cylinder is divided into a fluidizing chamber, an upper air chamber and a lower air chamber by a distribution plate with a central tube and a baffle, the lower end opening of the central tube penetrates through the baffle to extend into the lower air chamber, and the upper air chamber and the lower air chamber are respectively communicated with the air supply mechanism through the fluidized air control system. The detection device is characterized in that a feeding device is arranged at the upper end of the cylinder body; a central cur tobacco suction tube is arranged in the fluidizing chamber, and the other end of the central cur tobacco suction tube is connected with a cyclone separator. The detection device has the advantages that the difference of critical fluidizing gas velocities of the cut tobacco and the stems is utilized, so that the cut tobacco and the stems can be rapidly separated in an air separation manner, the continuity of separation operation is realized, and the processing capacity of samples is increased; the detection process is convenient and quick, and the detection result of the content of stems in the cut tobacco is good in repeatability. The whole detection process can adopt two modes of operation of continuous separation and intermittent separation.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

High solid content PVC glove powder-free aqueous coating and its preparation method and use method

ActiveCN106318185AReduce moisture contentHigh hardnessPolyurea/polyurethane coatingsWater solubleSolid content

The invention discloses a high solid content PVC glove powder-free aqueous coating. The high solid content PVC glove powder-free aqueous coating comprises 30-40wt% of a delustering agent, 15-25wt% of a wetting levelling agent, 15-25wt% of water-soluble resin, 20-30wt% of redispersible polyurethane resin, 0.2-0.5wt% of a solid thickening agent and 1.5-10wt% of water. The preparation method comprises uniformly dispersing and mixing a wetting levelling agent and an inorganic delustering agent, mixing the mixture and an organic delustering agent, carrying out uniform mixing, uniformly mixing the mixture, redispersible polyurethane resin, water-soluble resin and a solid thickening agent and packaging and storing the mixture. The invention discloses the use method of the high solid content PVC glove powder-free aqueous coating. The high solid content PVC glove powder-free aqueous coating solves the prior art problems, has high solid content, large dilution multiple and a low transport cost and can be simply fed.

Owner:北京戍光科技有限公司

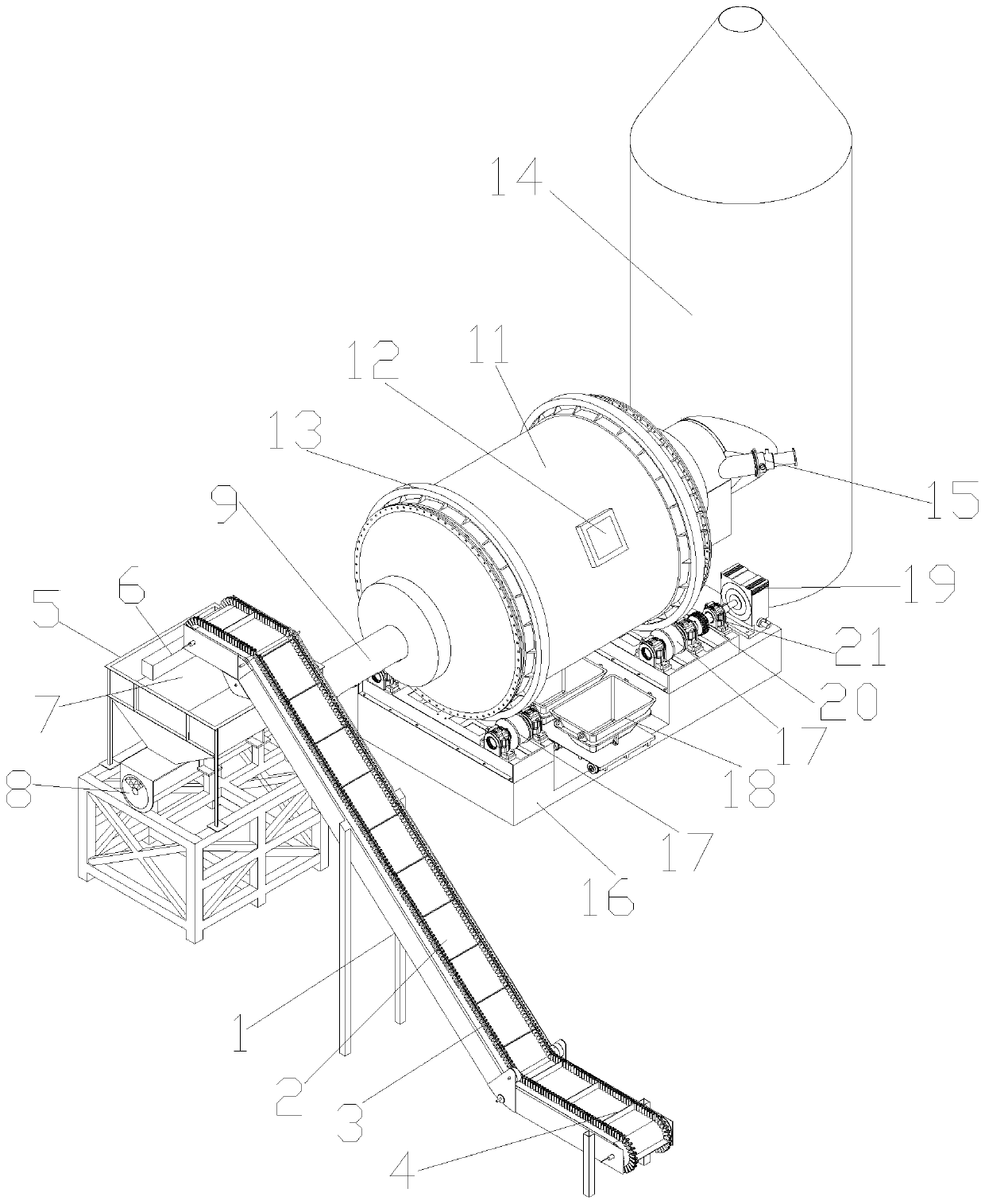

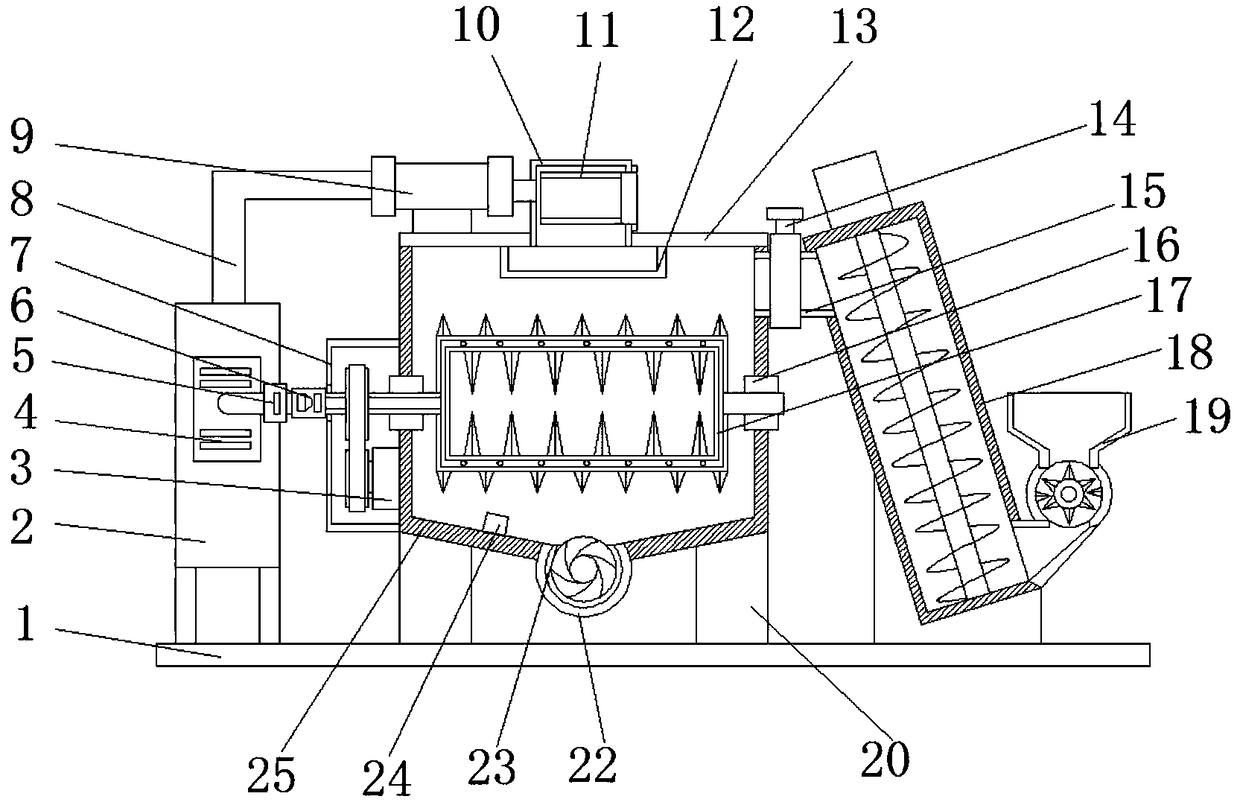

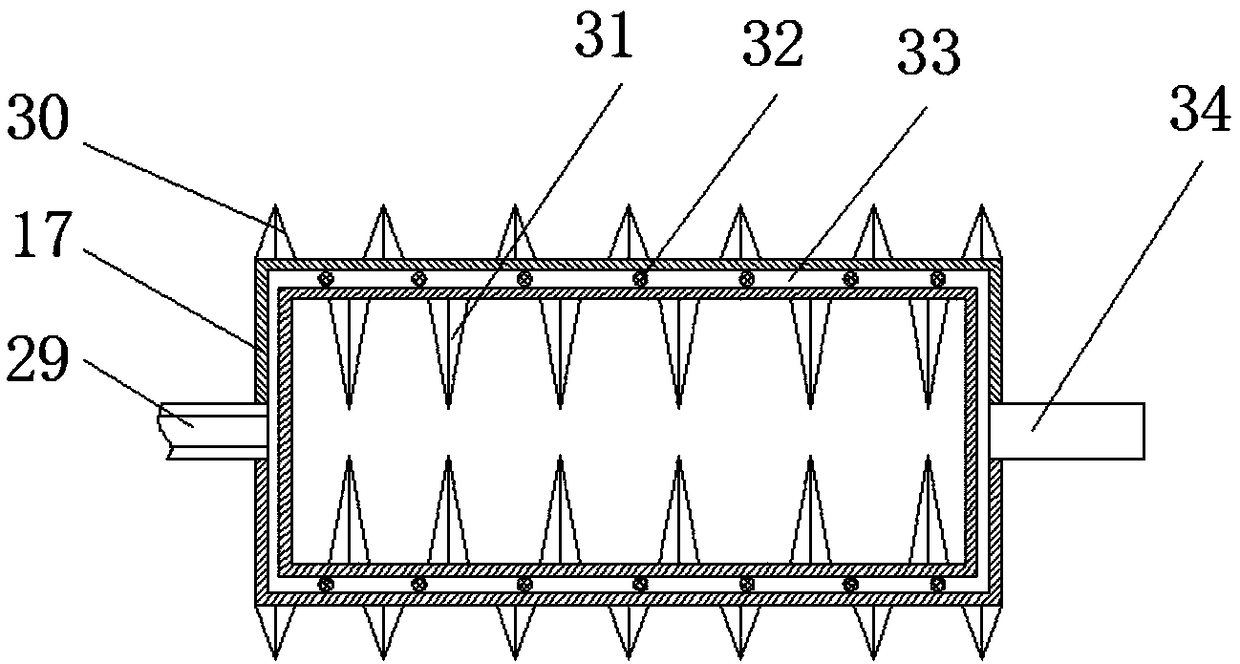

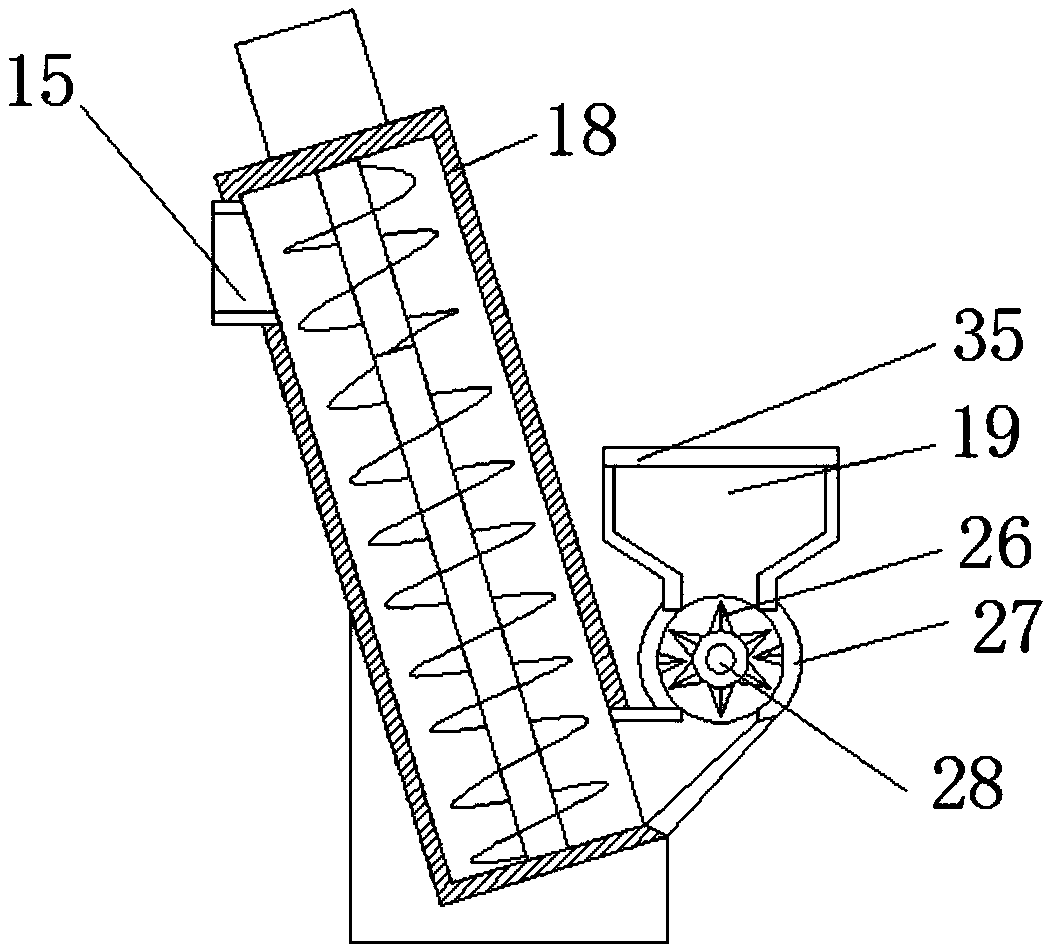

Convenient feeding type drying device for agricultural byproduct processing

InactiveCN109059516AFeeding is simple and convenientAvoid damageSievingScreeningAgricultural engineeringImpurity

The invention belongs to the technical field of agricultural byproduct processing and particularly relates to a convenient feeding type drying device for agricultural byproduct processing. In order tosolve the problems, such as single function, low drying efficiency and inconvenient feeding, of the existing drying device, the following technical scheme is provided. According to the technical scheme, the drying device comprises a base, wherein one side of the top of the base is connected with a drying box through bolts, one side of the drying box is connected with a conveying box through bolts, two round through holes are formed in one end of the drying box, the inner parts of both round through holes are connected with an air heater through bolts, and the inner wall of one side of the drying box is connected with a temperature sensor through bolts. In the invention, crops can be pushed into a feeding pipe through a rotating conveying paddle and dispersed in the drying box through a rotating dispersing rod, so that the feeding of the drying device is simple, convenient, uniform and stable; and at the same time, impurities can be cleared, the labor force is saved, further impurity clearing can be carried out on the crops during drying, and the quality of agricultural byproducts is ensured.

Owner:ANHUI HUARUI PHARMA TECH DEV CO LTD

Improved equipment for improving tabletting production capacity

The invention relates to the technical field of tabletting, in particular to an improved device for improving tabletting production capacity. The equipment comprises a rack, a lower mold plate is arranged at the end part of the rack, lower mold heads are uniformly arranged on the base surface of a lower mold plate pressing plate, an upper mold plate is arranged at the end part of a guide column, upper mold heads are uniformly arranged at the bottom of an upper mold plate pressing plate, a middle mold plate is arranged in the middle of a base face of a workbench, material scattering boxes are installed on the outer walls of a first guide polished rod and a second guide polished rod, the middle mold plate can be rapidly filled through the material scattering boxes, feeding of the middle mold plate is simple and convenient, tabletting forming can be rapidly conducted through an arranged upper mold heads, the tabletting efficiency is improved, formed tablets can be rapidly pushed and discharged through the material scattering boxes, feeding and discharging can be carried out at the same time, the overall tablet pressing capacity is improved, the height of the workbench can be controlled through a pull rod, the formed tablets can be rapidly ejected out through the lower mold heads, and the discharging efficiency is improved.

Owner:BEIJING WANHUI DOUBLE CRANE PHARMA

Low temperature sterilization equipment and method thereof

InactiveCN103990157AGood sterilization effectReduce the negative effects of thermal effectsFood preservationRadiationEngineeringRadiation

The invention discloses low temperature sterilization equipment and a method thereof. The equipment contains a microwave machine which is provided with a microwave cavity for generating a sterilization microwave radiation source. The sterilization equipment also comprises a container arranged inside the microwave cavity. The container is equipped with a feed inlet and a discharge port. An interlayer is disposed outside the container. The interlayer is provided with a fluid inlet and a fluid outlet. A fluid is arranged in the interlayer. The fluid is a mixed liquid containing microwave absorbing material. The method contains the following steps: a material enters the container arranged in the microwave cavity from the feed inlet; the mixed liquid containing the microwave absorbing material is guided into the interlayer through the fluid inlet to form an external wave-absorbing layer of a sterilized material, and temperature control can be carried out through the fluid; The microwave radiation acts on the wave absorbing layer and a material layer; the mixed liquid of the wave absorbing layer also absorbs part of heat energy of the sterilized material so as to adjust thickness of the material layer as well as material temperature; and the material is discharged out of the discharge port of the container after sterilization.

Owner:上海绿昂生物科技有限公司

Microorganism fermented organic fertilizer and preparation method thereof

PendingCN108863675AInhibition of hatchingImprove fertilizer efficiencyBio-organic fraction processingExcrement fertilisersMicroorganismFeces

The invention discloses microorganism fermented organic fertilizer and a preparation method thereof. After lotus corniculatus is cut, cattle, horses and sheep are fed with fresh grass or dry grass; the lotus corniculatus accounts for 50 percent or more of the total food weight of the cattle, the horses and the sheep; lotus corniculatus plants are partially decomposed and crushed when the cattle, the horses and the sheep ruminate and repeatedly chew the lotus corniculatus plants and the lotus corniculatus plants are fermented in stomachs, and then excrement is formed; the excrement is mixed with mixed straws, sawdust, plant ash and canteen waste dreg; then the materials are stacked together and are subjected to first-time fermentation; after the first-time fermentation is finished, fermented matters are turned; a microorganism nutrient solution and crushed lotus corniculatus root stalks are added layer by layer in a turning process and are subjected to secondary fermentation; a mixtureis turned for one time every other 3 to 10 days, so as to prepare the microorganism organic fertilizer. By adopting the organic fertilizer, the problem that underground insects are easy to hatch in afermentation and composting process of the biological organic fertilizer can be solved; meanwhile, after the fertilizer is applied, the breeding and reproduction capability of the underground insectsof a fertilized land can be inhibited, so that the problem of soil insect pests is radically solved, self-balance of soil is regulated and controlled and the self-recovery capability of the soil is improved.

Owner:内蒙古蒙苒生物科技有限公司

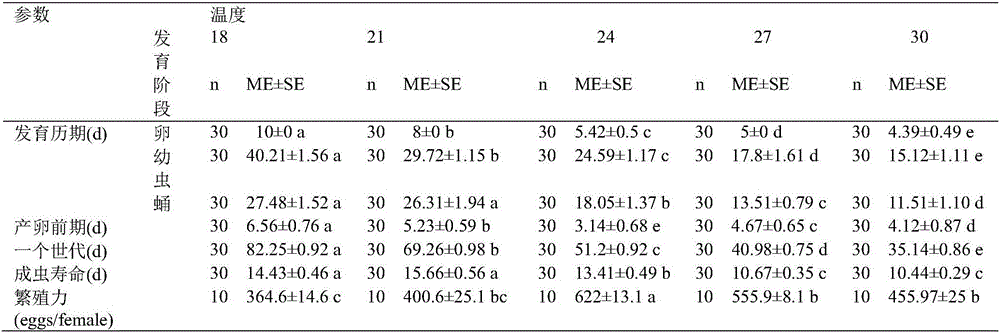

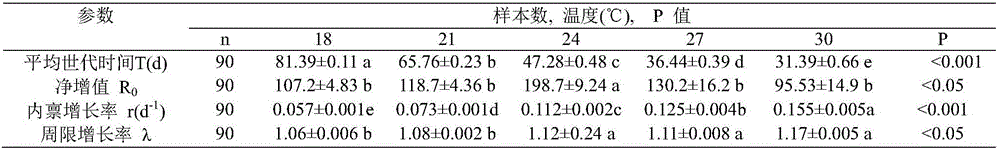

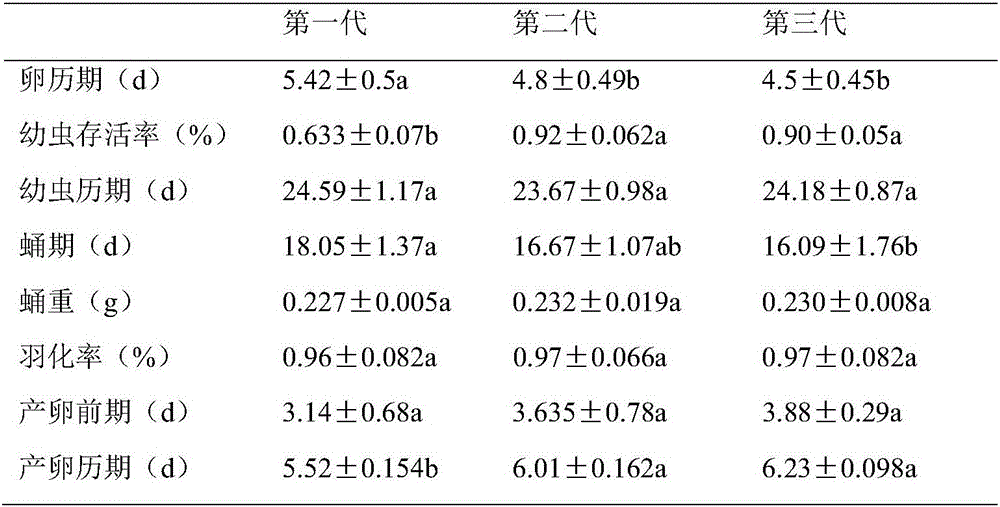

Leucania loreyi breeding method

InactiveCN106172251AFeeding is simple and convenientImprove survival rateAnimal feeding stuffAnimal scienceLeucania loreyi

The invention relates to a method for raising Armyworm lauleyi. The method mainly includes the following steps: (1) Preservation and hatching of eggs: eggs can be hatched as required at 4°C; (2) 1-3 instar larvae: hatched larvae need to be added with fresh and tender corn leaves (3) 4‑6 instar larvae: the larvae at the end of the 3rd instar stage start to pack, 10 heads / 750ml glass bottles, and replace fresh corn leaves every day; (4) Pupa: mature larvae need to be pupated in sterile water containing 10% (5) collecting adults: the adults that have emerged need to supplement nutrition. Adopt a kind of rearing technology of armyworm lauley described in the present invention, under the condition of temperature 24 ℃, photoperiod:dark period=14:10h, humidity 70%, have high survival rate, high egg production, simple and convenient feeding etc. Advantages, it can be used for scientific research and large-scale breeding.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

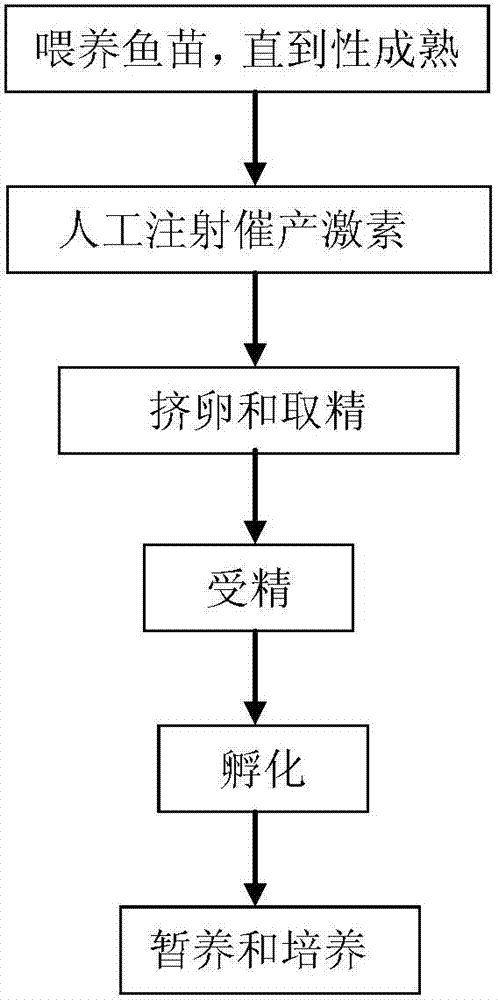

Artificial propagation method for mystus macropterus

ActiveCN104488760AFeeding is simple and convenientAchieve scale of reproductionClimate change adaptationPisciculture and aquariaFertilityLuteinizing hormone

The invention provides an artificial propagation method for mystus macropterus. The artificial propagation method comprises the following steps of fry feeding, artificial oxytocin injection, spawn taking and sperm collection, fertilization, incubation and temporary rearing and cultivating. LHRH (luteinizing hormone releasing hormone)-A2, DOM (dissolved organic matters) and HCG (human chorionic gonadotropin) serve as the oxytocin, the spawning rate in artificial hastening parturition reaches 74%, a circumstance that propagation is carried out by killing the mystus macropterus is avoided, the spontaneous delivery rate reaches 62%-76%, and the fertility rate reaches 14%-32%. In an incubation process, fertilized spawns are placed in hyperoxic flowing water, the incubation rate reaches 27.5%-76.19%, and the temporary rearing survival rate reaches 87.6%. The fries of the mystus macropterus eat feedstuff with 40% of protein level when the fries are small, the feedstuff is processed by fresh minced fillet and powder, the fries are easy and convenient to feed, and the mystus macropterus can be articially propagated in batches.

Owner:重庆市水产科学研究所

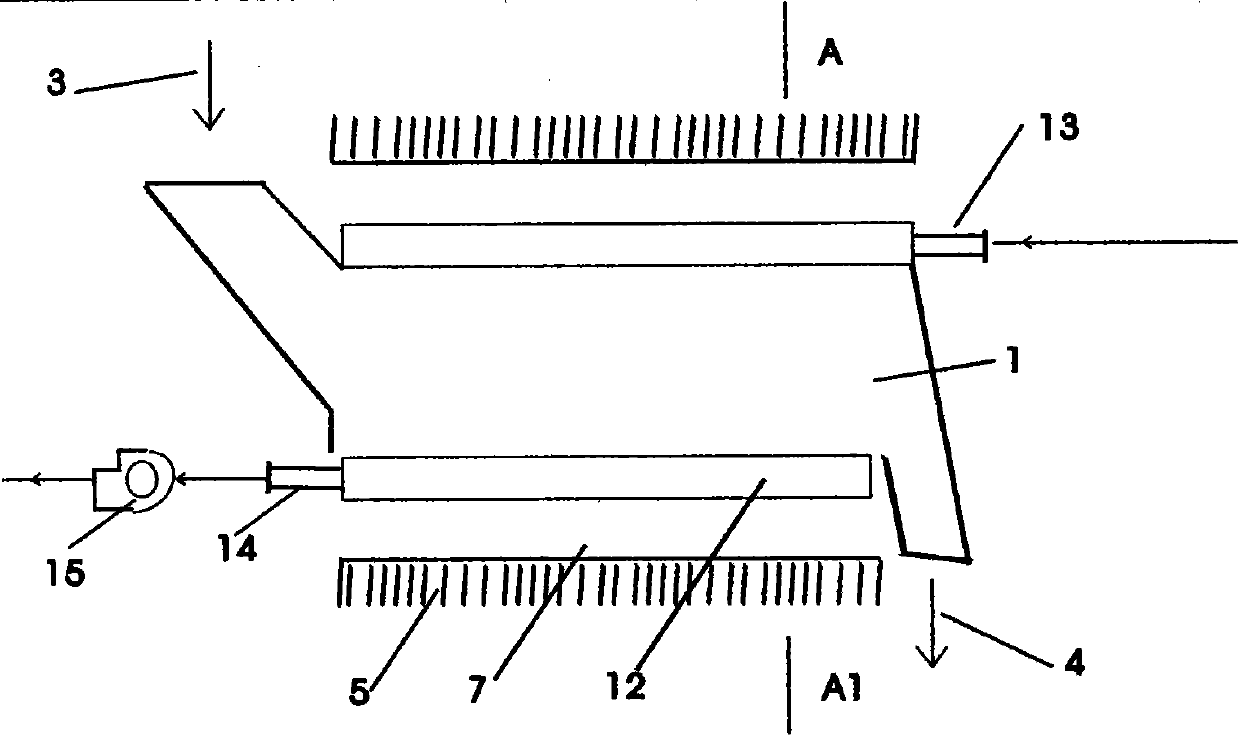

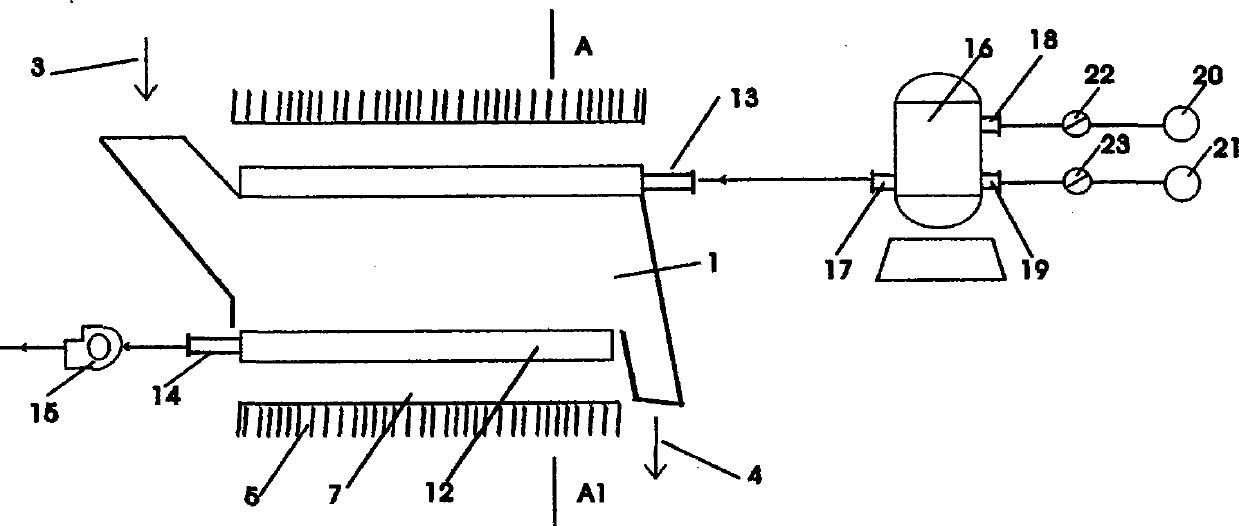

Ultrasonic batten machine

InactiveCN102785360APrecise positioningSimple and convenient refueling operationUltrasonic weldingPulp and paper industry

The invention relates to an ultrasonic batten machine, and relates to the field of special equipment for filter production. The ultrasonic batten machine mainly comprises a solder conveying and cutting unit, a paper core transport unit and a welding unit, wherein the solder conveying and cutting unit comprises a tray assembly, a roller assembly, a feeding stick assembly, a solder channel and a cutting mechanism which are arranged on a rack wall panel, and the paper core transport unit comprises an upper fixed rack and a lower fixed rack; an upper adjusting plate is arranged at the lower end of the upper fixed rack, and an upper material through plate is arranged at the lower end of the upper adjusting plate; an upper material through groove is arranged at the lower end of the upper material through plate, and a lower adjusting plate is arranged at the upper end of the lower fixed rack; a lower material through plate is arranged at the upper end of the lower adjusting plate, and a lower material through groove is arranged at the upper end of the lower material through plate; and the welding unit comprises an ultrasonic generator, an ultrasonic energy converter, and upper and lower molds of an ultrasonic welding head. The ultrasonic batten machine provided by the invention has the advantages that the structure is simple, the design is reasonable, and non-woven fabrics are used as a solder, so that the environment is protected; by utilizing an ultrasonic welding technology, the welding requirements of paper core battens can be met quickly within two seconds; and the welding reliability is high, the sealing performance is good, the bonding strength is high, the welding is smooth, the product quality is improved and simultaneously the production cost is reduced.

Owner:BENGBU HUAHONG ELECTRONICS TECH +1

Automatic tidying machine

InactiveCN105665572AReduce consumptionGuarantee personal safetyMetal-working feeding devicesStripping-off devicesEngineeringMechanical engineering

The invention belongs to the field of tank manufacturing equipment, and particularly relates to an automatic tidying machine. The automatic tidying machine is characterized in that one end of a screw nut is connected with a screw, and the other end of the screw nut is connected with a screw nut cylinder; suction cups are connected with air pipes, and connecting part fixing plate cylinders are connected with a connecting part fixing plate; a fixing frame pushing cylinder is mounted on a fixing frame pushing plate and connected with a connecting part fixing plate cylinder fixing frame; the upper end of a finished product discharging guide barrel and an air blowing pipe are oppositely arranged at the two sides of a lower stamping die; a waste guide rail and a screw nut slide rail are mounted at the two sides of the lower stamping die correspondingly; movable discharging roller connecting plates are connected with movable discharging roller fixing plates, the two ends of a movable discharging roller are connected with the movable discharging roller connecting plates, and movable discharging roller cylinders are connected with the movable discharging roller connecting plates.

Owner:TIANJIN FUDONG CAN MAKING

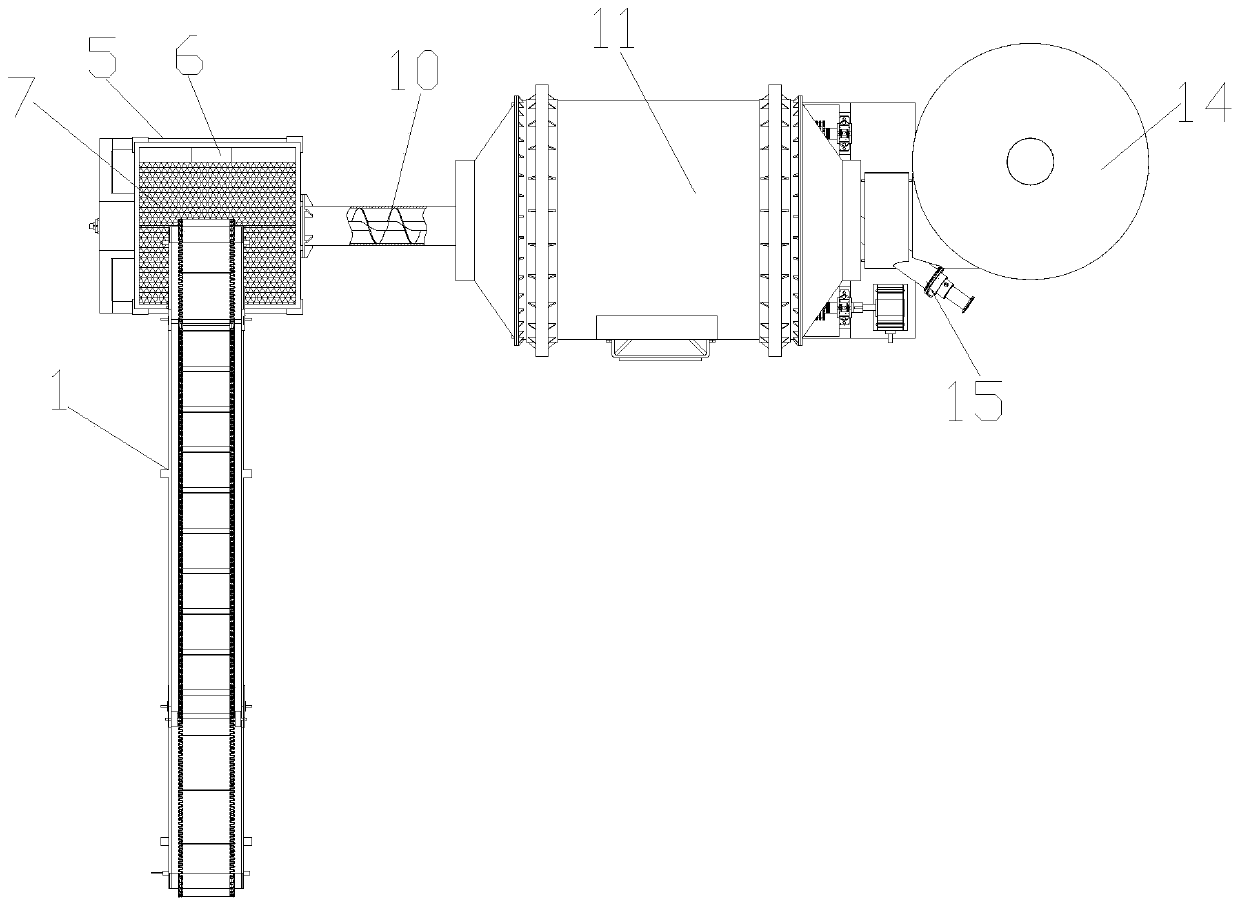

Smelting furnace feeding stirring conveyor for casting

InactiveCN111121458AQuality assuranceEasy to addCharge manipulationCharge treatment typeLiquid metalMechanical engineering

The invention discloses a smelting furnace feeding stirring conveyor for casting. The conveyor involves a smelting furnace, a stirring mechanism and a feeding mechanism; the feeding mechanism comprises a first supporting frame, a conveying belt is arranged on the first supporting frame, and a conveying mechanism is arranged below the top end of the conveying belt; the conveying mechanism comprisesa receiving chamber, the bottom of the receiving chamber communicates with a conveying pipe, and a pushing mechanism is arranged in the conveying pipe; the stirring mechanism comprises a stirring tank, the conveying pipe communicates with the stirring tank, supporting rollers are arranged below the two ends of the stirring tank, and one of the supporting rollers is provided with a driving gear ring through a connecting shaft; and a discharging port in the stirring tank communicates with a feeding port in the smelting furnace. According to the conveyor, raw materials needing to be added are conveyed into the conveying mechanism at the upper end, so that adding is convenient, and feeding is easy and convenient; and the raw materials which are evenly stirred can be rapidly conveyed into thesmelting furnace to be smelted, so that the quality of smelted liquid metal is guaranteed.

Owner:安徽依格尔精密铸造有限公司

Rubber wear-resisting property detection device and detection method thereof

ActiveCN112362519AHigh precisionMaintain frictional pressureInvestigating abrasion/wear resistanceElectric machineryEngineering

The invention belongs to the technical field of rubber detection, particularly relates to a rubber wear-resisting property detection device and a detection method thereof, and aims to solve the problems that the detection efficiency is influenced by the wear of detection equipment due to the fact that a sample is often easily worn through in the friction process and the sample is easily deviated due to uneven stress when being rubbed in the detection process, the following scheme is provided: the device comprises a shell, a sealing cover is hinged to the top end of the shell, a plurality of transmission rollers are installed in the shell through bearings, stepping motors in transmission connection with the transmission rollers are fixedly installed in the shell, and the outer sides of thetransmission rollers are sleeved with moving belts. In the feeding stage, the assembly for fixing the rubber sample can be lifted through the electric push rod to be separated from the abrasive clothbelt, the influence on the abrasive cloth belt in the feeding process can be effectively avoided, and in the detection process, after the rotating speed of the abrasive cloth belt is constant, the assembly fixed with the rubber sample is lowered to enable the sample to make contact with the abrasive cloth belt, so that the detection precision is improved.

Owner:JIANGXI JINLILONG RUBBER TRACK

Double-clamping-jaw chuck

PendingCN112191875ACNC landing action is simpleSimple logical actionTube shearing machinesChucksEngineeringMechanical engineering

The invention discloses a double-clamping-jaw chuck. The double-clamping-jaw chuck comprises a main body support, wherein a rotary disc is rotationally arranged on the main body support, clamping jawsare arranged on the front side surface and the rear side surface of the rotary disc, and the clamping jaws are used for clamping a pipe to be machined. The double-clamping-jaw chuck is simple in structure and operation, has good cutting precision for the pipe with the large length, can provide stable support, and solves the problem that the pipe swings when the two chucks are used for cutting; and zero tailing can be realized, so that the cost waste is reduced to a certain degree.

Owner:ZHEJIANG JINAOLAN MASCH TOOL CO LTD

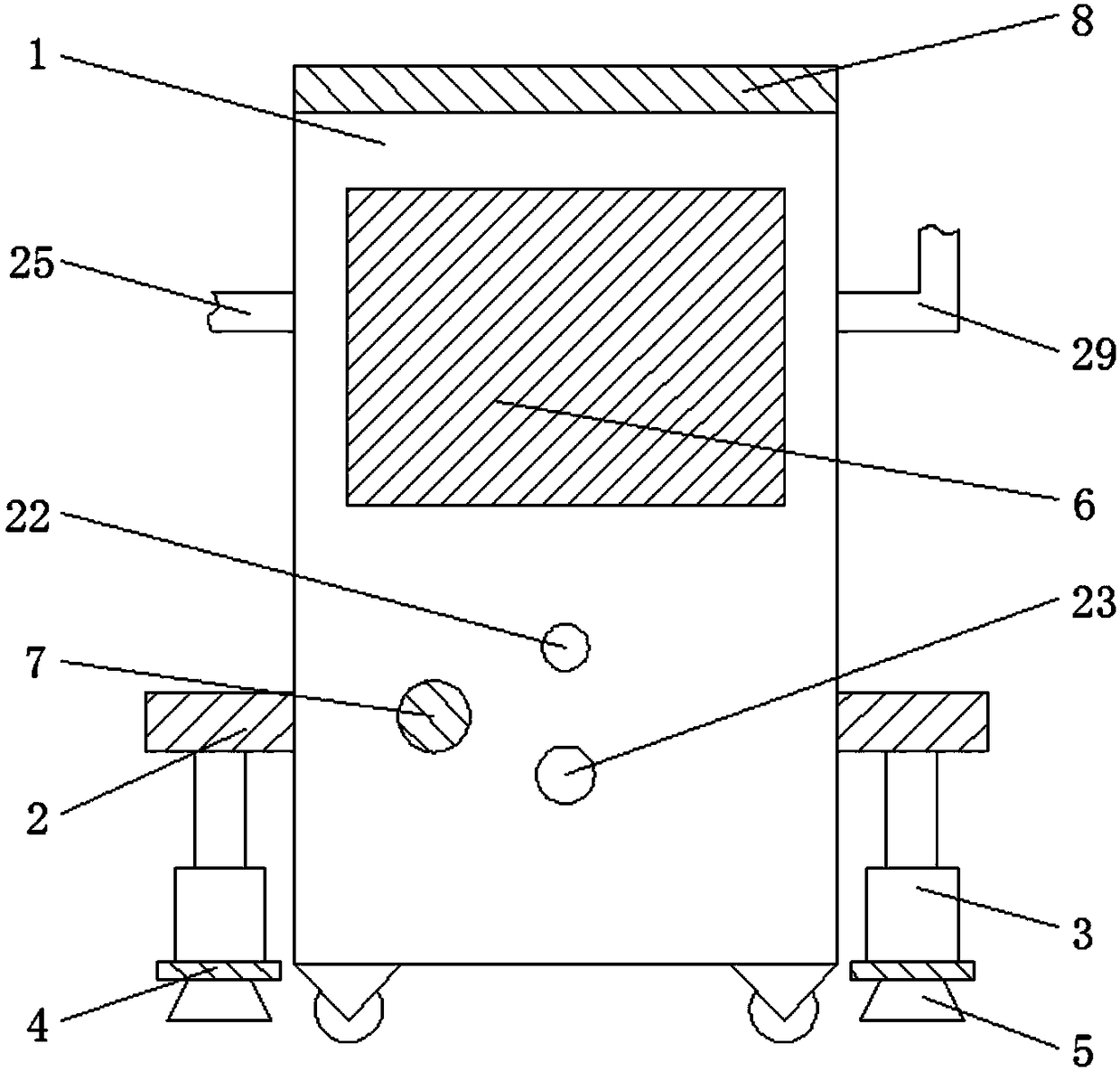

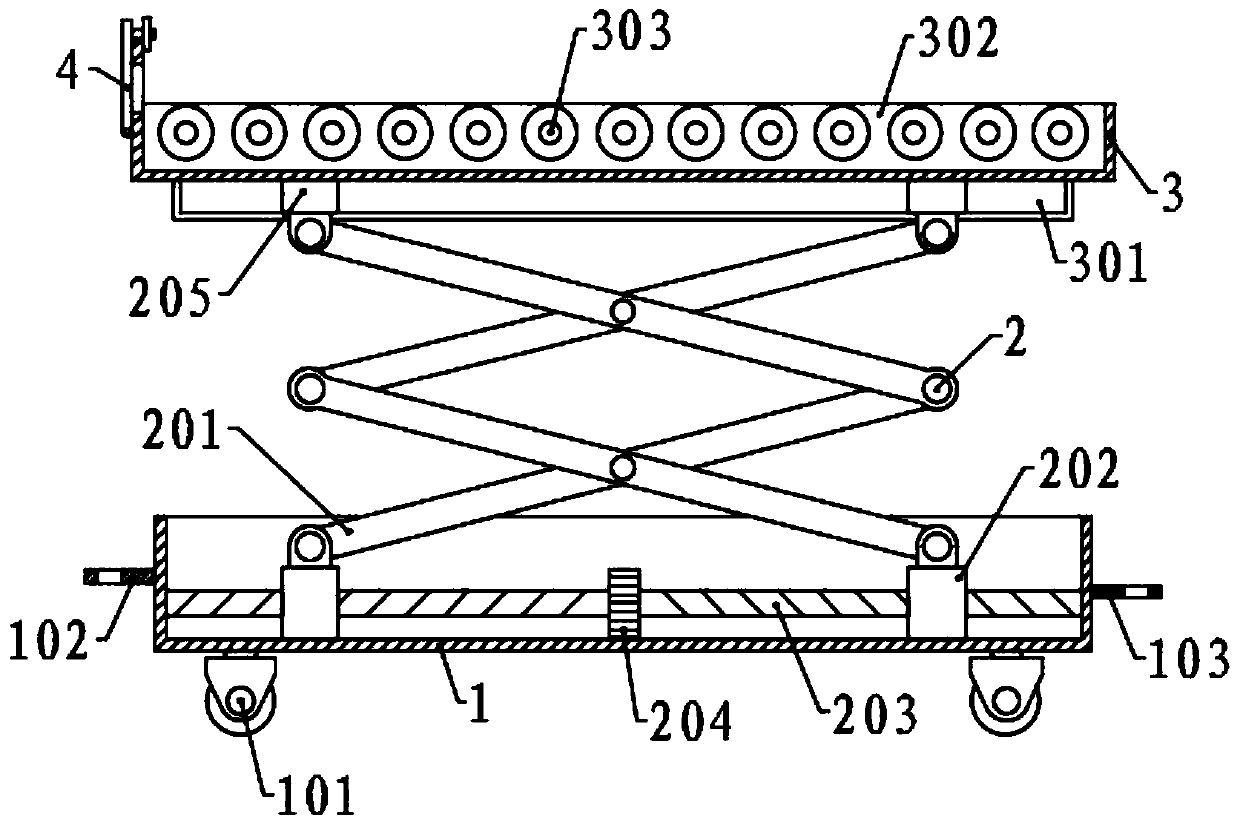

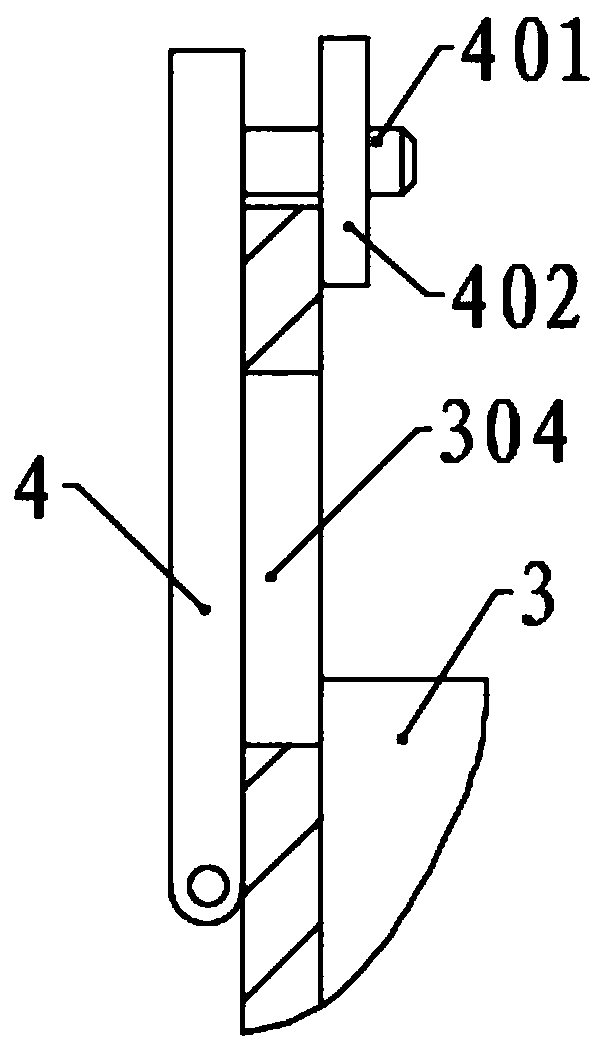

Assembly equipment used for airplane long rod parts and application method of assembly equipment

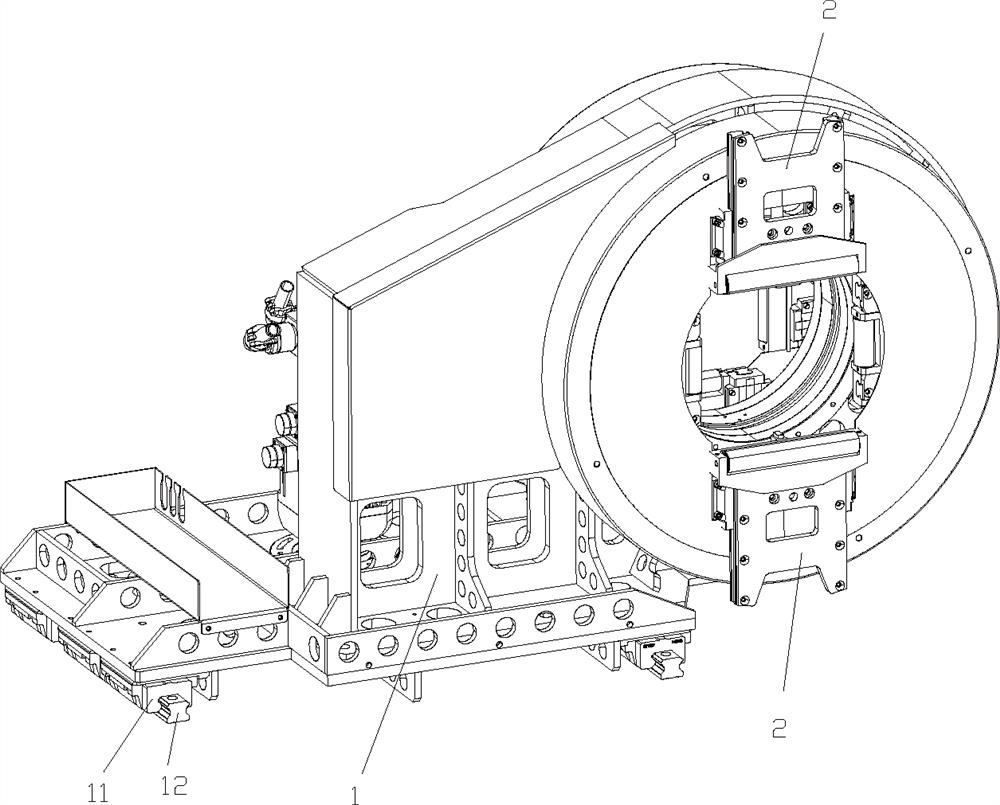

InactiveCN111251242AFeeding is simple and convenientAvoid manual lifting and movingAircraft assemblyWork benchesStructural engineeringEquipment use

The invention discloses assembly equipment used for airplane long rod parts and an application method of the assembly equipment in the technical field of airplane part assembly marching. The assemblyequipment comprises a base, lifting assemblies and a lifting table, limiting assemblies and rolling wheels are arranged on the lifting table, the left side of the lifting table extends upwards, and amoving hole, a sealing plate and a limiting plate are arranged. According to the assembly equipment, multiple long rod parts are placed on the lifting table, the lifting table moves upwards through the lifting assemblies, and the positions of the parts are adjusted; the limiting plate is taken down, the sealing plate is rotated, so that the moving hole is exposed, the parts on the rolling wheels are pushed forwards, and therefore the parts are moved to the corresponding assembly structure to be assembled; and electromagnets are powered on to attract each other, limiting blocks move downwards,the parts are moved to the rolling wheels, operation of feeding the parts onto the rolling wheels is simple and convenient, and therefore multiple parts are assembled in sequence, and manual carrying,moving and the like are avoided.

Owner:荆门怡盛源环保科技有限公司

Manufacturing device based on broken bridge aluminum doors and windows

ActiveCN113369092AScientific and reasonable structureEasy to useLiquid surface applicatorsCleaning using gasesSlide plateScrew thread

The invention discloses a manufacturing device based on broken bridge aluminum doors and windows. A gluing assembly is arranged on one side of a back plate, a mounting plate is connected to the middle of a lead screw through threads, an electric glue gun is mounted in the middle of the mounting plate, an auxiliary sealing assembly is mounted at one end of the mounting plate, a sealing plate is bonded to one end of a connecting spring, and a triangular soft plate is mounted at the end, close to a storage groove, of a smoothing plate; a supporting adjusting assembly is mounted on one side of the back plate, a sliding plate is slidably mounted in the back plate, and a feeding cleaning assembly is arranged at one end of the back plate. Manual gluing is changed into automatic gluing through the gluing assembly, so that the labor intensity is relieved while the gluing effect is better; the auxiliary sealing assembly assists the gluing assembly in use, so that the gluing effect at the smoothing plate is further improved, and the gluing efficiency is improved. The filling effect is better, and a supporting and adjusting assembly adapts to the space size to be adjusted, so that normal use of the device is guaranteed; the feeding and cleaning assembly cleans sundries at a gluing position while facilitating feeding, and the multiple assemblies work together to guarantee the gluing efficiency.

Owner:安徽住方智能制造有限公司

Cold rolling device for steel processing

InactiveCN112404134AWork orderlyReasonable distribution of workRollsMetal rolling arrangementsEngineeringMechanical engineering

The invention provides a cold rolling device for steel processing, and relates to the field of steel processing. The cold rolling device based on steel processing comprises a base, wherein two first supporting plates are symmetrically and fixedly connected to the top of the base; a feeding plate is fixedly connected to the tops of the two first supporting plates; the top of the feeding plate is obliquely arranged; a baffle is fixedly connected to the side wall of the feeding plate; a plurality of pieces of steel are evenly arranged at the top of the feeding plate; a material distributing device is arranged at the bottom of the feeding plate; a second supporting plate is arranged at the bottom end of a slope of the feeding plate in a matched mode and is fixedly connected with the base; anda limiting plate is fixedly connected to the top of the second supporting plate. The cold rolling device for steel processing provided by the invention is provided with a roller set, a supporting layer and a heating pipe are arranged in the roller set, the heating pipe is started to heat the supporting layer during rolling, heat energy is transmitted to a forming layer along strip-shaped holes, and when the forming layer rolls steel, the stress on the surface of the steel is eliminated.

Owner:苏州市太迈达金属科技有限公司

Brand-new-form special welding machine

InactiveCN110814603AFeeding is simple and convenientEasy for workers to operateWelding/cutting auxillary devicesAuxillary welding devicesCounter rotationGear drive

The invention discloses a brand-new-form special welding machine. The brand-new-form special welding machine comprises a main body frame, a rotating mechanism, a gear driving assembly, a workpiece positioning and clamping mechanism and a feeding mechanism, wherein the two sides of the top of the main body frame are movably connected with the bottom of the rotating mechanism, and the top of the main body frame is positioned right behind the rotating mechanism and is fixedly connected with the bottom of the feeding mechanism. The invention relates to the technical field of special welding machines. According to the brand-new-form special welding machine, the rotating mechanism comprises a bottom plate, on the premise that the center distance is 178mm, the height of two welding guns can be adjusted, so that the height adjustment of the welding guns during lifting and welding is realized, the operation is simpler and faster, and the machining efficiency is improved; and four gears in the gear driving assembly are used in a matched mode, so that the reverse rotating welding of the rotating assembly is realized, the two sets of rotating assemblies can rotate without interference on the premise that the center distance is 178mm, and therefore the two welding guns can be welded at the same time.

Owner:TANGSHAN YINGLAI SCI & TECH

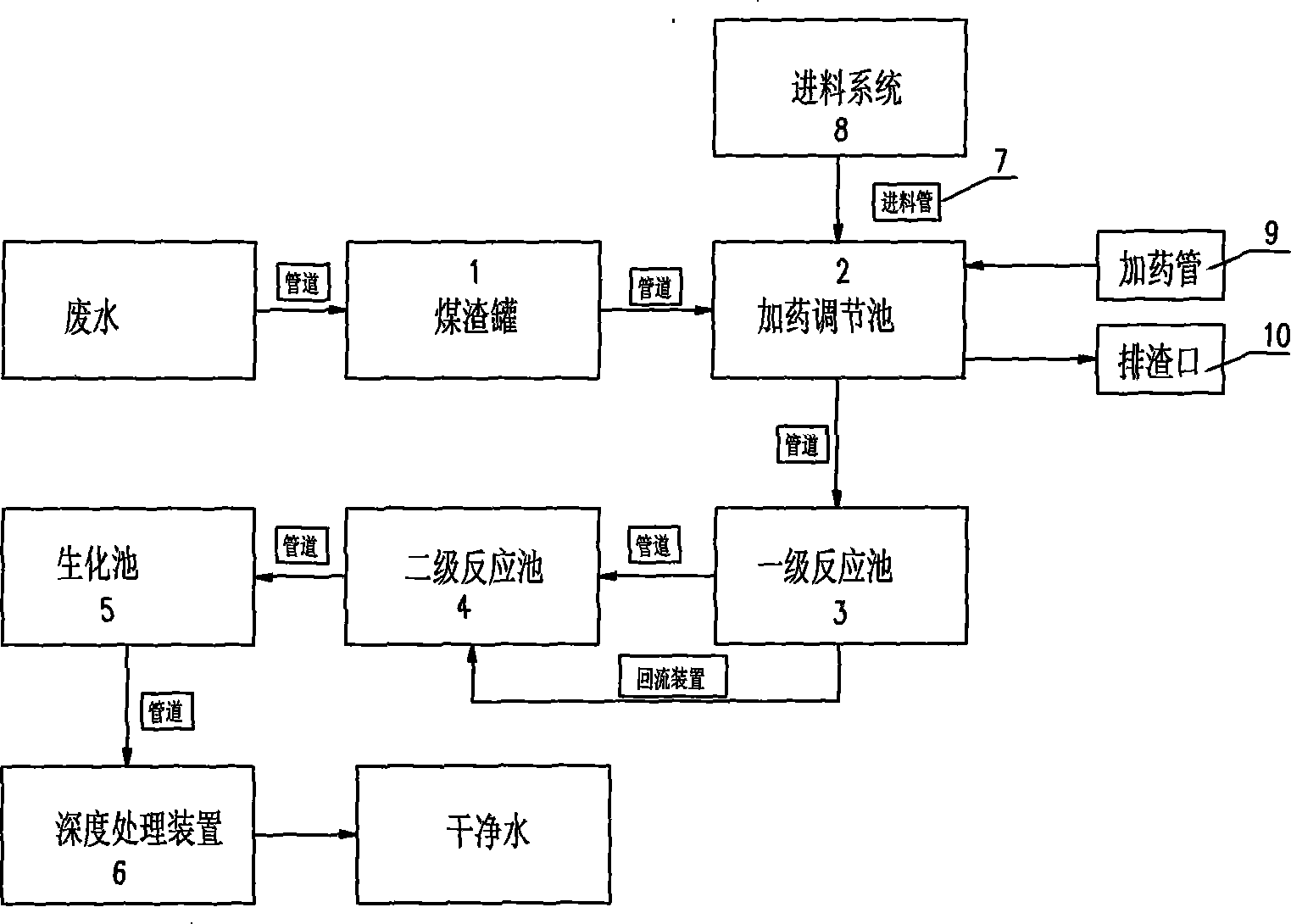

Method and device for processing ceramic phenolic waste water

InactiveCN101250015AAchieve the purpose of reusingEfficient removalFatty/oily/floating substances removal devicesMultistage water/sewage treatmentRefluxElectrolysis

The invention discloses a processing method for ceramic phenol wastewater and devices, which are characterized in that the method comprises steps of a, preliminarily processing the wastewater, charging the ceramic phenol wastewater in a cinder tank for adsorbing and filtering the wastewater, then charging in a drug-adding regulating reaction tank, injecting drug for reaction, regulating to enable the wastewater and medicaments to be uniformly mixed and deoiled, b, sequentially delivering the wastewater preliminarily processed into an iron-carbon first order reaction tank and an iron-carbon second order reaction tank for performing aeration micro-electrolysis reaction, retaining for a while, simultaneously performing circulating reflux between the two reaction tanks, c, delivering the wastewater treated via reaction step of the process b into a biochemical pond for further dephenolization and COD pollutant removal and d, performing advanced treatment. The processing method for ceramic phenol wastewater and the devices have the advantages of safe and reliable process, simple operation, low cost, low operation cost, good and stable processing effect and the like, and have perfect popularization value.

Owner:FOSHAN WEILIQING WATER TREATMENT

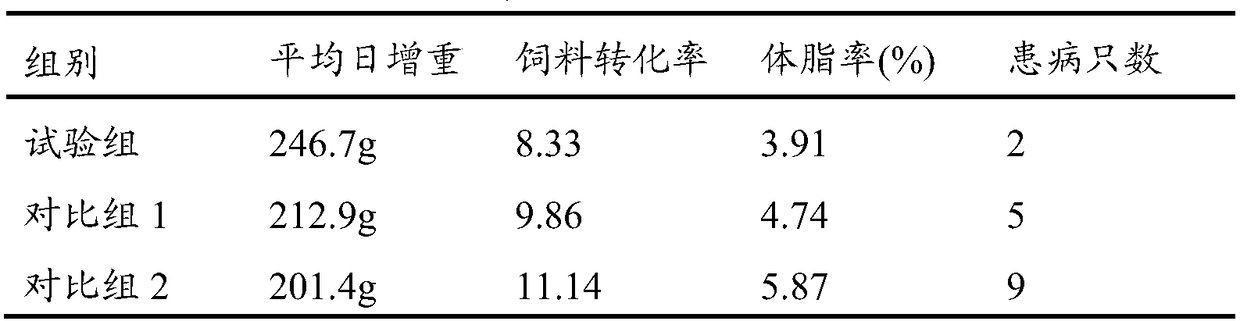

Glycine betaine type drinking water additive for weaning mutton lamb and preparation of glycine betaine type drinking water additive

InactiveCN109123126AAvoid Decomposition DefectsFast absorptionAccessory food factorsBetaineAntioxidative stress

The invention relates to a glycine betaine type drinking water additive preparation for a weaning mutton lamb. The glycine betaine type drinking water additive preparation is compounded from a component A, a component B and a component C, wherein the component A comprises compounds of glycine betaine and choline chloride processed through a rumen envelope; the component B comprises coated procyanidine, taurine, gamma-aminobutyric acid, sodium di-acetate and vitamin P containing water soluble multi-vitamins; and the component C comprises sodium chloride and a lamb milk powder. The preparation has the effects of resisting oxidative stress, improving immunity and benefiting digestion and absorption of a feed, the additive is higher in stability, is longer in storage life, does not absorb moisture easily, is convenient to add, and is more favorable for the rapid absorption of the lamb when being compared with a solid feed additive, the growth and development of the lamb is effectively promoted, the protein ratio of the mutton is increased, and the body fat is reduced.

Owner:山东祥维斯生物科技股份有限公司

Beehive facilitating temperature regulation and feeding

The invention discloses a beehive facilitating temperature regulation and feeding. The beehive comprises a box body which is of a cylinder structure with an opening in the top, a temperature regulation device, a cover body installed at the top of the box body, a feeding box installed on the upper surface of the cover body and communicated with the box body, and a storage box installed at the top of the feeding box, wherein a temperature regulation channel enclosing the inner cavity of the box body is formed in a side wall of the box body, an inlet and an outlet of the temperature regulation device are connected with an inlet and an outlet of the temperature regulation channel, a feeding groove is formed in the feeding box, the storage box is connected with the inner cavity of the feeding groove through a delivery pipe, and the delivery pipe is provided with a valve. The temperature regulation device can introduce cold or hot fluid to the temperature regulation channel so as to refrigerate or heat the inner cavity of the box body, maintain the temperature in the box within a temperature range suitable for swarm survival, improve bee yield and quality and supplement foods in the storage box for the feeding box through the delivery pipe and make feeding simple and convenient.

Owner:天峨县全盛蜂业科技有限公司

A rubber wear resistance testing device and testing method thereof

ActiveCN112362519BHigh precisionMaintain frictional pressureInvestigating abrasion/wear resistanceElectric machineStructural engineering

The invention belongs to the technical field of rubber detection, in particular to a rubber wear resistance detection device and a detection method thereof, aiming at the phenomenon that the sample is often easily worn through during the friction process, so that the wear of the detection equipment affects the detection efficiency. Secondly, during the detection process When the sample is subjected to friction, it is prone to uneven force and offset phenomenon. The following scheme is proposed, including the shell, the top of the shell is hinged with a cover, and the inside of the shell is installed with multiple bearings. The transmission roller is fixedly installed with a stepping motor connected to the transmission roller in the inside of the housing, and a moving belt is sleeved on the outside of the rotating roller. In the feeding stage of the present invention, the assembly for fixing the rubber sample can be lifted by the electric push rod to separate it from the abrasive cloth belt, which can effectively avoid the influence on the abrasive cloth belt during the feeding process, and when the rotational speed of the abrasive cloth belt is constant during the detection process , and then lower the assembly with the rubber sample fixed, so that the sample is in contact with the abrasive cloth belt, and the detection accuracy is improved.

Owner:JIANGXI JINLILONG RUBBER TRACK

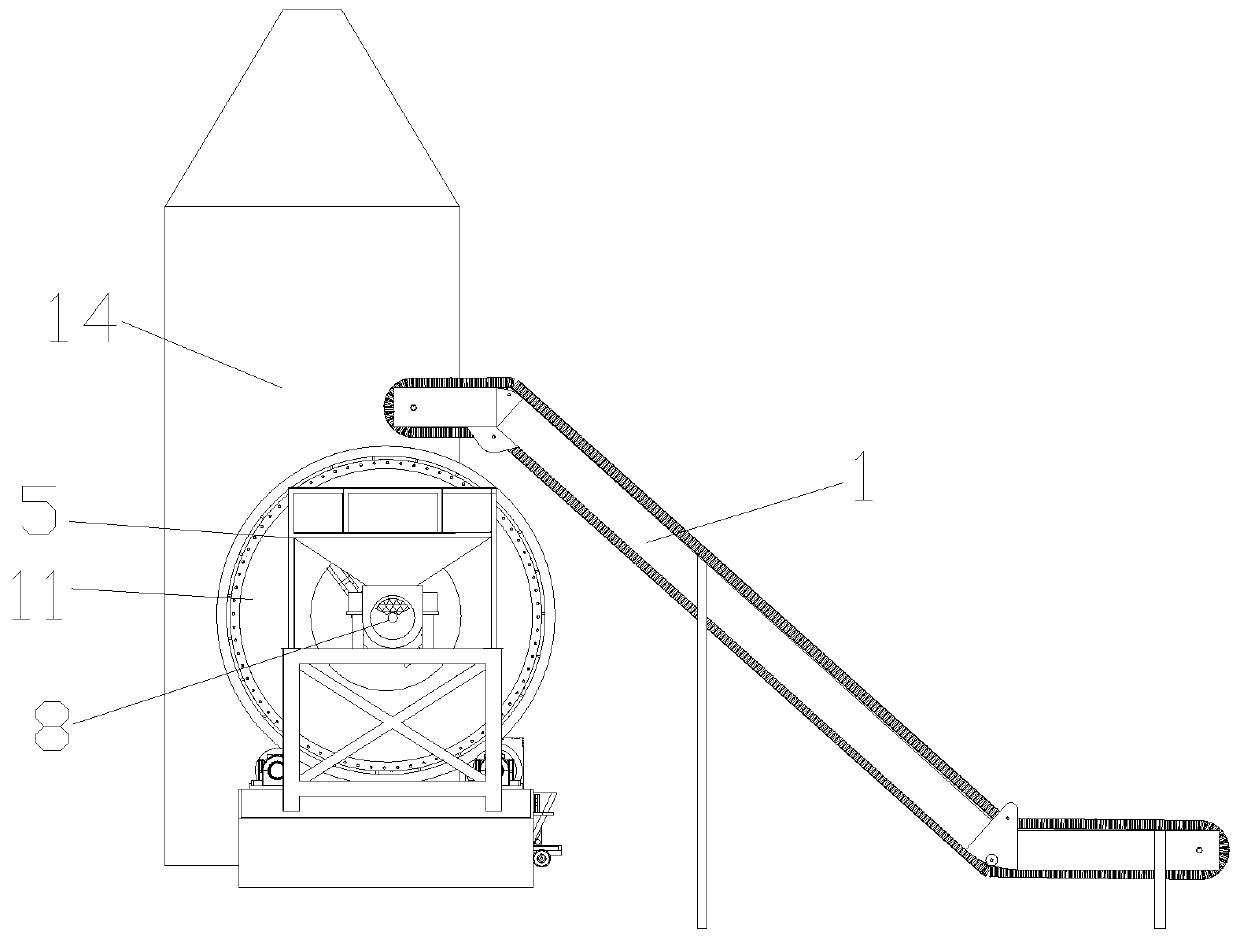

Waste disposal device with environmental protection function for animal husbandry

ActiveCN108940532AFeeding is simple and convenientReduce laborDrying gas arrangementsGrain treatmentsHigh probabilityEngineering

The invention belongs to the technical field of animal husbandry and particularly relates to a waste disposal device with an environmental protection function for animal husbandry. To solve the problems that a conventional organic waste disposal device for animal husbandry is low in use efficiency and has high probability of blockage, the following solution is put forward: the waste disposal device provided by the invention comprises a base, wherein four support pillars in annular array distribution are connected to the top middle of the base through bolts, a box body is connected to the topsof the four support pillars through bolts, and a stirring rack of a rectangular structure is arranged in the box body. The waste disposal device can remove moisture in organic waste, eliminate peculiar smell in the organic waste and facilitate reclamation of the organic waste, and therefore, has favorable economical benefits. The whole disposal process is performed in a closed manner, so that thepeculiar smell can be prevented from diffusion. Meanwhile, the waste disposal device can be effectively prevented from blockage through twice crushing. The waste disposal device protects the environment, and therefore, has a favorable environment-friendly effect.

Owner:INNER MONGOLIA HUAMENG KECHUANG ENVIRONMENTAL PROTECTION TECH ENG CO LTD

Pet PBM probiotic feeding box and method for making pet food by applying feeding box

PendingCN114304399AFeeding is simple and convenientGuaranteed normal feedingFeeding-stuffRotary stirring mixersBiotechnologyFood material

The invention discloses a pet PBM probiotic feeding box and a method for manufacturing pet food through the pet PBM probiotic feeding box, and the pet PBM probiotic feeding box comprises a box body. The box body is provided with a stirring device for stirring pet food, and a first feeding device, a second feeding device, a third feeding device, a water adding device and a food basin which are communicated with the stirring device; according to the pet PBM probiotic feeding box provided by the technical scheme, live bacterium powder, inactivated bacterium liquid, purified water and freeze-dried pet food can be instantly combined according to needs, the food blending time is shortened, and the practical problems that food materials are not accurately weighed, the food is prone to decay, and tableware ingestion is not sanitary are solved. Meanwhile, it can be guaranteed that the pets obtain fresh, convenient and scientific-proportion food, beneficial bacteria in the intestinal tracts of the pets can be remarkably enhanced, harmful bacteria are inhibited, bowel relaxing is achieved, excrement odor is reduced, and the immune function of the intestinal tracts is improved.

Owner:鑫岸生物科技(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com