Assembly equipment used for airplane long rod parts and application method of assembly equipment

A part assembly and long rod technology, which is applied to the field of aircraft long rod parts assembly equipment, can solve the problems of safety impact of installation workers, inconvenient operation, parts falling, etc., to avoid manual lifting and movement, and easy and convenient feeding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

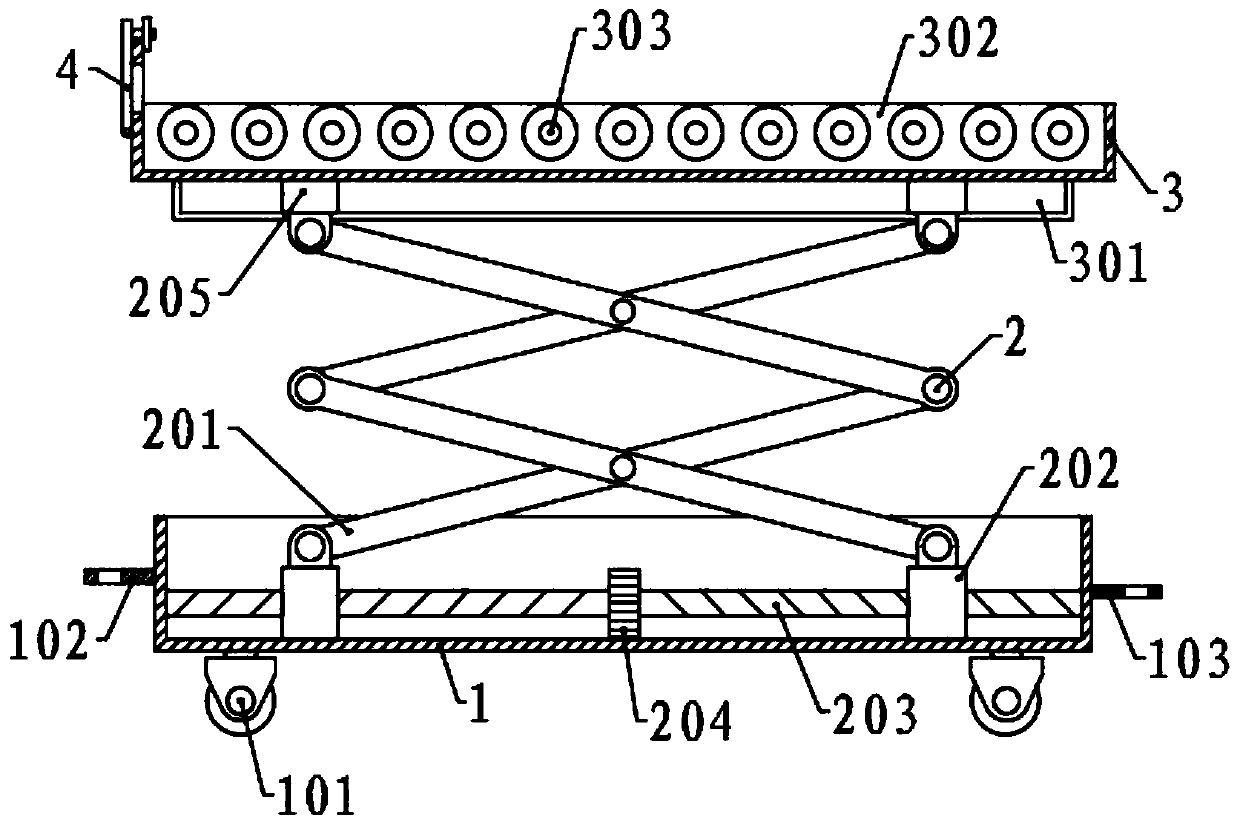

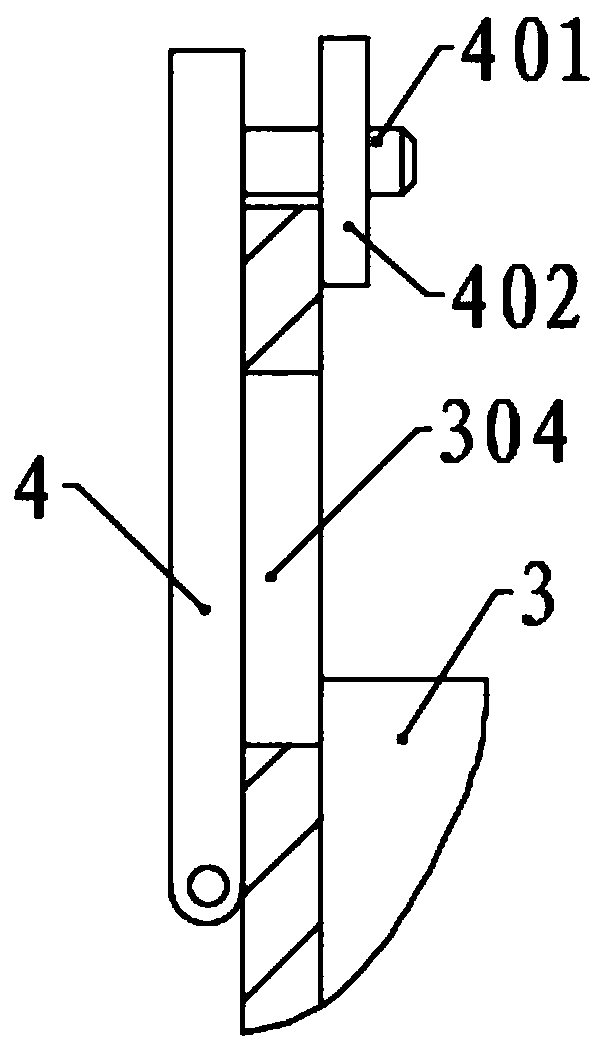

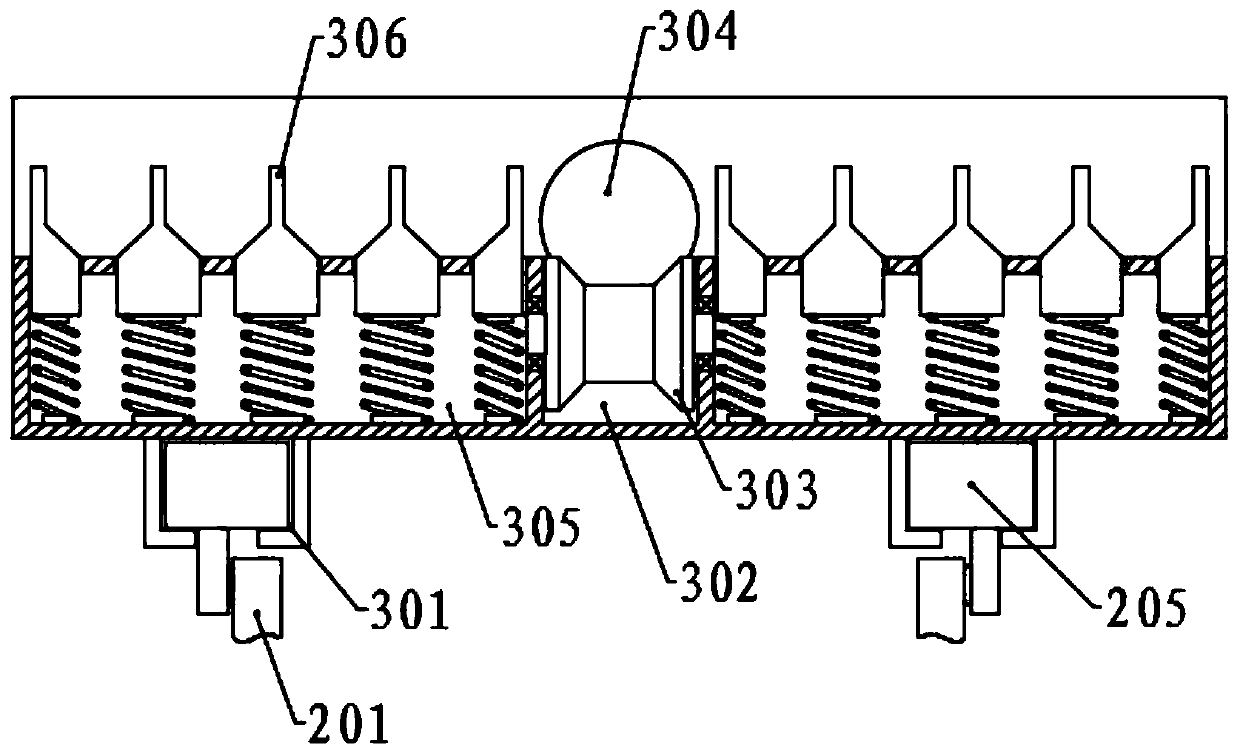

[0030] Please refer to the accompanying drawings, the present invention provides a technical solution: an assembly equipment for aircraft long rod parts and its use method, including a base 1, the four corners of the bottom surface of the base 1 are provided with moving wheels 101, and the base 1 is symmetrical There are two lifting components 2, and the lifting platform 3 is connected with the lifting component 2. Two sliding grooves 302 are arranged symmetrically on both sides of the bottom surface of the lifting platform 3, and the two lifting components 2 are respectively connected with the corresponding sliding grooves 302. There is a moving groove 301 in the middle of the top surface of the lifting platform 3, and a spring chamber 305 is arranged on both sides, and a plurality of rollers 303 are evenly and rotatably connected in the moving groove 301, and a plurality of limit positions are evenly arranged in the spring chamber 305 along the length direction. Assemblies, t...

Embodiment 2

[0041] The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that a positioning assembly is provided at the position corresponding to the moving wheel 101 in the base 1. The positioning assembly includes a second screw 5 that is rotatably connected to the bottom surface of the base 1. The second screw 5 The upper thread is connected with a mobile plate 501, and the bottom surface of the mobile plate 501 is symmetrically fixed with a vertical slide plate on both sides.

[0042] After the equipment moves to the corresponding position, the lifting platform 3 moves up, and breaks away from the base 1, and turns the second screw rod 5, so that the moving plate 501 drives the slide plate and the positioning plate 502 to move down, so that the positioning plate 502 is pressed against the bottom surface, thereby limiting The location of the equipment, to avoid its random movement, can fix structures such as rubber pads on the bottom surface o...

Embodiment 3

[0044] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that a first fixing plate 102 is fixed on one side of the base 1, a second fixing plate 103 is fixed on the other side, and the first fixing plate 102 and the second Connection holes are provided on the fixing plates 103 , through the first fixing plate 102 and the second fixing plate 103 , multiple assembly devices can be fixedly connected sequentially, so as to be suitable for longer rod parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com