Glycine betaine type drinking water additive for weaning mutton lamb and preparation of glycine betaine type drinking water additive

A betaine and additive technology, applied in the field of betaine-containing drinking water additives and its preparation, can solve unrealistic problems and achieve the effects of improving resistance, improving gastrointestinal tract stress, and promoting growth and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

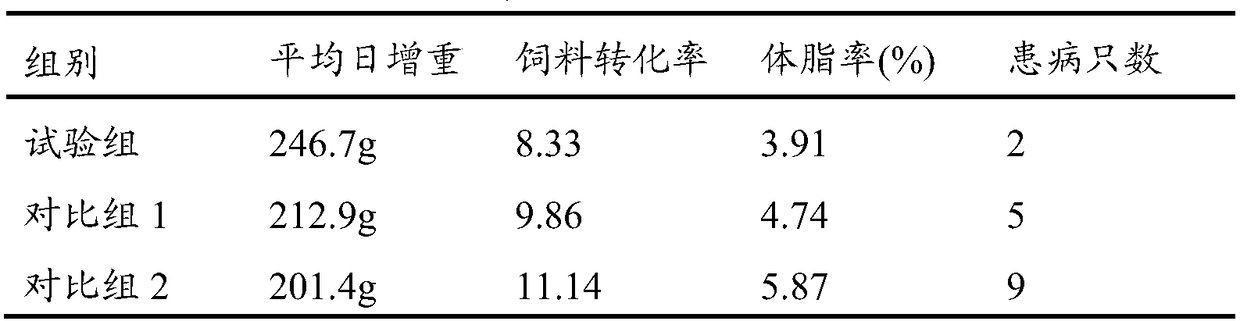

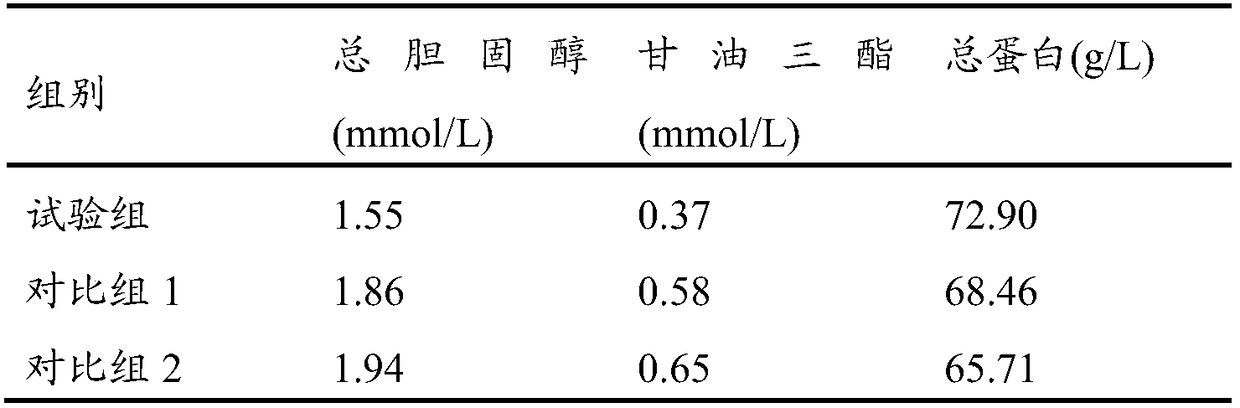

Examples

Embodiment 1

[0060] (S1) Prepare the betaine and choline chloride complex (component A) processed by the rumen envelope:

[0061] (1) Feed grade betaine and choline chloride are mixed by mass ratio 10:2 to obtain about 300g mixture, and ethyl cellulose and dehydrated alcohol are prepared ethyl cellulose coating solution with mass ratio of 1:20, Use a high-pressure spray gun in a coating machine at 60°C to evenly spray 20 g of the coating solution onto the surface of the mixed particles of betaine and choline chloride, and dry them.

[0062] (2) after the chitosan of deacetylation 85% is dissolved at 50 ℃ with 3% acetic acid solution, add deionized water and be mixed with the chitosan solution of 3wt%, as wall material solution; In the coating dryer, the above-mentioned pretreated betaine, choline chloride mixture and the above-mentioned wall material solution are coated in batches twice at intervals according to the mass ratio of 1:0.5, and the obtained coated particles are dried and crush...

Embodiment 2

[0072] (S1) Preparation of component A:

[0073] (1) Feed-grade betaine and choline chloride are mixed in a mass ratio of 10:3 to obtain a 0.52kg mixture, and the ethyl cellulose coating solution prepared by ethyl cellulose and absolute ethanol with a mass ratio of 1:20 , spray 0.12 kg of coating solution evenly onto the surface of betaine and choline chloride mixed particles with a high-pressure spray gun in the coating machine at 60°C, and dry it.

[0074](2) After dissolving chitosan with 85% deacetylation rate with 3% acetic acid solution at 50°C, add deionized water to be mixed with 3wt% chitosan solution as wall material solution; In the coating dryer, the above-mentioned pretreated betaine, choline chloride mixture and the above-mentioned wall material solution are coated according to the mass ratio of 1:0.5, wherein the wall material solution is coated at intervals for 3 times, and the resulting coated The membrane particles were dried and crushed through a 100-mesh s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com