Glass lamination machine for producing insulating glass

A technology of laminating machine and glass, which is applied to conveyor objects, furnaces, furnace components, etc., can solve the problems of inconvenient use and operation, increased cost and energy consumption, operator injury, etc., and achieves easy installation and placement, and simplifies installation steps. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

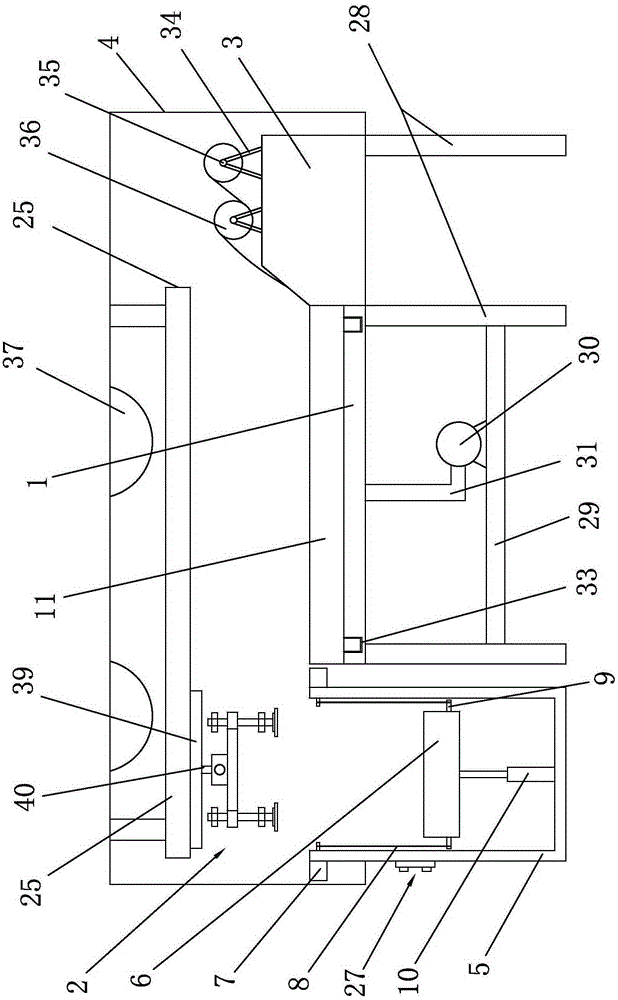

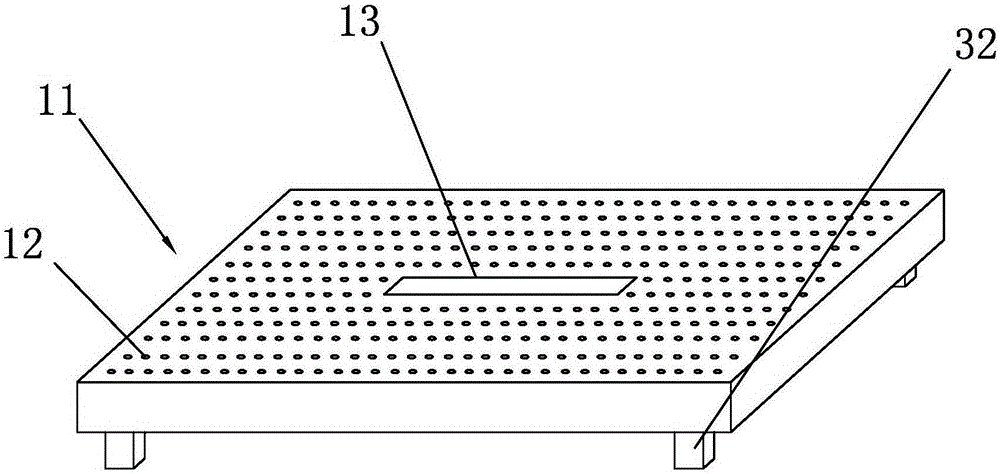

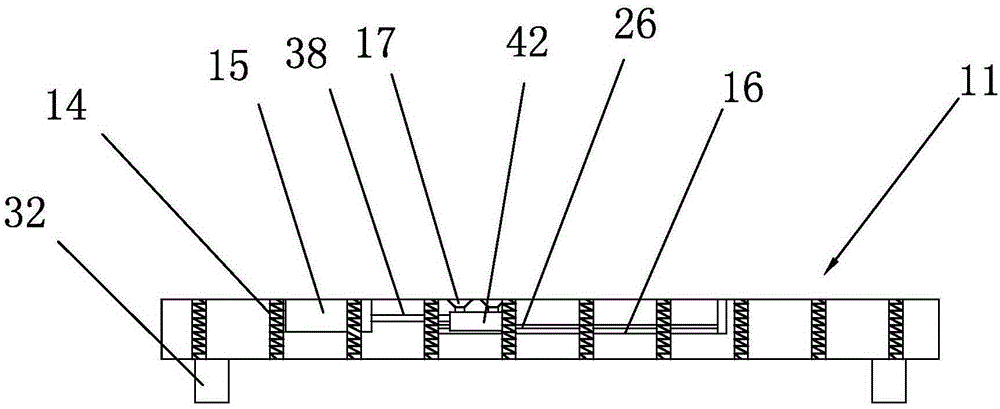

[0030] Such as Figure 1 to Figure 5 As shown, it is a glass combining machine for producing insulating glass according to the present invention, which includes a feeding device, a combining workbench 1, a suction cup device 2, a film holder 3 and a protective cover 4, and the discharging device includes a feeding frame 5 and the discharge tray 6, the left end of the discharge frame 5 is provided with a controller 27, the controller 27 is provided with a control button, the control button includes a first control button and a second control button, and the discharge device is controlled by the controller 27. To operate, press the first control button and the discharge tray 6 moves downward, which is convenient for the operator to place the glass on the discharge tray 6, and press the second control button, the discharge tray 6 moves upward, which is convenient for the suction cup device 2 to pair the glass The suction of the glass makes the work of the glass laminator continue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com