Regenerant for regenerated rubber and preparation method of regenerant

A technology of reclaimed rubber and rejuvenating agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Heat 30 parts by weight of gutter oil, 20 parts by weight of naphthenic oil and 20 parts by weight of soybean oil to 70°C with a rotation speed of 100 rpm; after stirring evenly, add 30 parts by weight of coal tar, stir for 9 minutes, and rotate at a speed of 80 rpm / min, the temperature reaches 70°C; then add 3 parts by weight of activator 450, 15 parts by weight of Coumaron resin, 10 parts by weight of phenolic resin and 10 parts by weight of pottery clay, heat and stir for 8min to make the phases compatible; stir After uniformity, cool and stand for 1.5 hours to obtain a regenerant for regenerated rubber (named Z-1).

Embodiment 2

[0034] Heat 50 parts by weight of soybean oil and 10 parts by weight of linseed oil to 100°C at a speed of 120 rpm; after stirring evenly, add 40 parts by weight of aromatic oil, stir and heat to 80°C at a speed of 180 rpm, and stir for 8 minutes Then add activator 450 of 2 mass parts, the R1 resin of 8 mass parts, the epoxy resin of 2 mass parts, the carbon black of 10 mass parts, the high styrene resin of 5 mass parts, heat and stir 7min, make each phase content; after stirring evenly, cool and stand for 1 hour to obtain a regenerant for reclaimed rubber (named Z-2).

Embodiment 3

[0036] Heat 50 parts by weight of oleic acid, 30 parts by weight of naphthenic oil, and 5 parts by weight of natural powdered phenol to 60°C at a speed of 160 rpm; after stirring evenly, add 15 parts by weight of petroleum sludge, stir and heat to 80°C, Rotating speed 180 revs / min, stir 5min; Then add the R1 resin of the activator 480 of 1 mass part, 14 mass parts, the epoxy resin of 4 mass parts, the carbon black of 5 mass parts, the high styrene resin of 6 mass parts, Heat and stir for 8 minutes to make the phases compatible; after stirring evenly, cool and stand for 1.2 hours to prepare a regenerant for regenerated rubber (named Z-3).

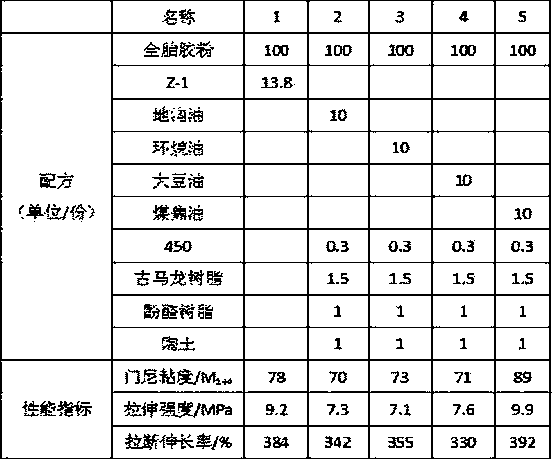

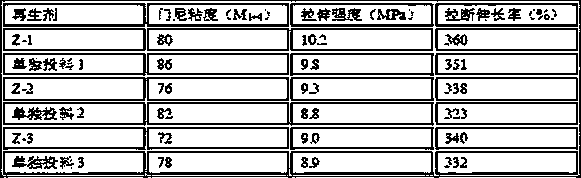

[0037] In the actual regenerated rubber production, various auxiliary agents and regenerants in the present invention have rotational viscosities as shown in the table below:

[0038] Table 1 Comparison of rotational viscosities of additives

[0039]

[0040] It can be seen from Table 1 that the rejuvenating agent prepared by the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com