Injection mold of water meter shell

An injection mold and shell technology, applied in the field of water meter shell injection molds, can solve problems such as inability to meet requirements, general processing accuracy, and inconvenient operation, and achieve the effects of good processing effect, convenient operation, and improved processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

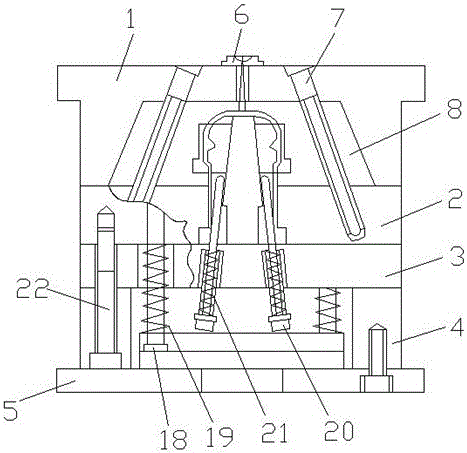

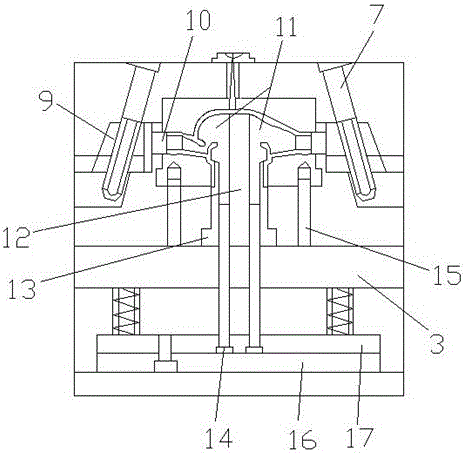

[0020] refer to figure 1 Shown, a kind of injection mold of water meter housing comprises fixed formwork 1, movable formwork 2, movable formwork bottom plate 3, mold foot bar 4 and mold footplate 5, described fixed formwork 1, movable formwork 2, movable formwork bottom plate 3, mold Leg strips 4 and formwork foot plates 5 are arranged sequentially from top to bottom, sprue sleeves 6 and inclined guide posts 7 are arranged on the fixed formwork 1, half sliders 8 are arranged inside the fixed formwork 1, and half The slider 8 is movably connected with the oblique guide post 7, and the middle part of the oblique guide post 7 is provided with a slider 9, a forming core 10 and an insert 11, and the slider 9, the forming core 10 and the insert 11 are fixedly connected in turn, so that The insert 11 is provided with more than one piece, the insert 11 is provided with a main core 12, and the outside of the main core 12 is provided with a main core sleeve 13 and a push rod 14, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com