Thermal overload relay base injection mold

A technology of thermal overload relay and injection mold, which is applied in the field of mold equipment, can solve the problems of inconvenient demoulding, low quality of mold products, and low heating temperature of materials, and achieve the effect of maintaining high quality, maintaining precision, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

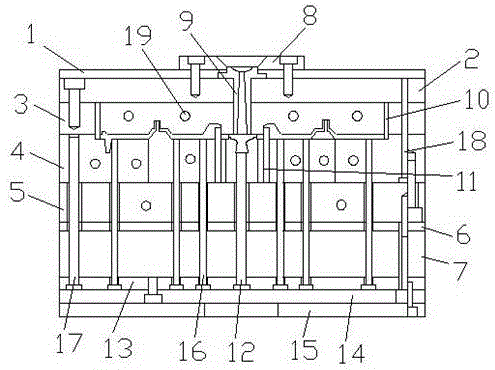

[0023] refer to figure 1 As shown, a thermal overload relay base injection mold includes a fixed mold heat insulation board 1, a fixed mold bottom plate 2, a fixed mold plate 3, a movable mold plate 4, a movable mold bottom plate 5, a movable mold heat insulation plate 6 and a mold foot bar 7, The fixed mold heat insulation board 1, the fixed mold bottom plate 2, the fixed mold plate 3, the movable mold plate 4, the movable mold bottom plate 5, the movable mold heat insulation plate 6 and the mold leg strips 7 are arranged sequentially from top to bottom, and the fixed mold bottom plate 2 is fixedly connected with the fixed formwork 3, and the middle part of the fixed mold heat insulation board 1 is provided with a positioning ring 8. , the two ends of the fixed template 3 are provided with a molding insert 10, the bottom of the sprue sleeve 9 is provided with a molding insert 11, and the molding insert 2 11 is provided with an ejector rod 12, and the mold foot Below the bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com