Efficient gasket pressing device for bottle cap inner gasket

A bottle cap and lining technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, cumbersome operation steps, low automation, etc. The effect of increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

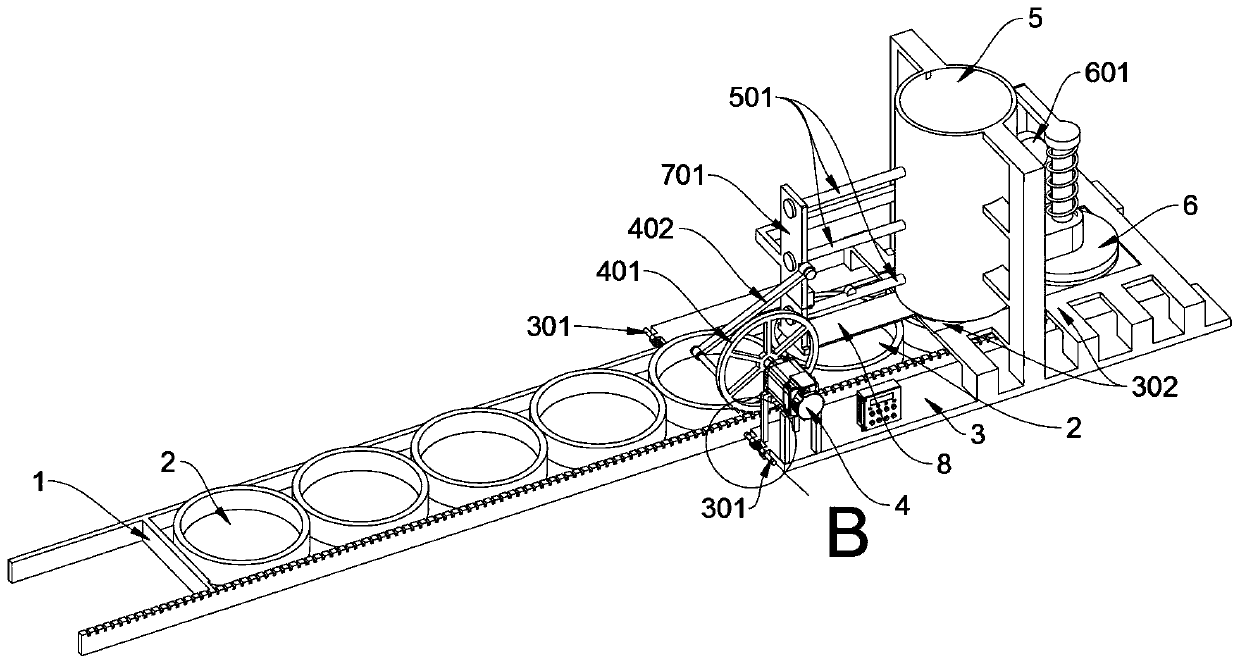

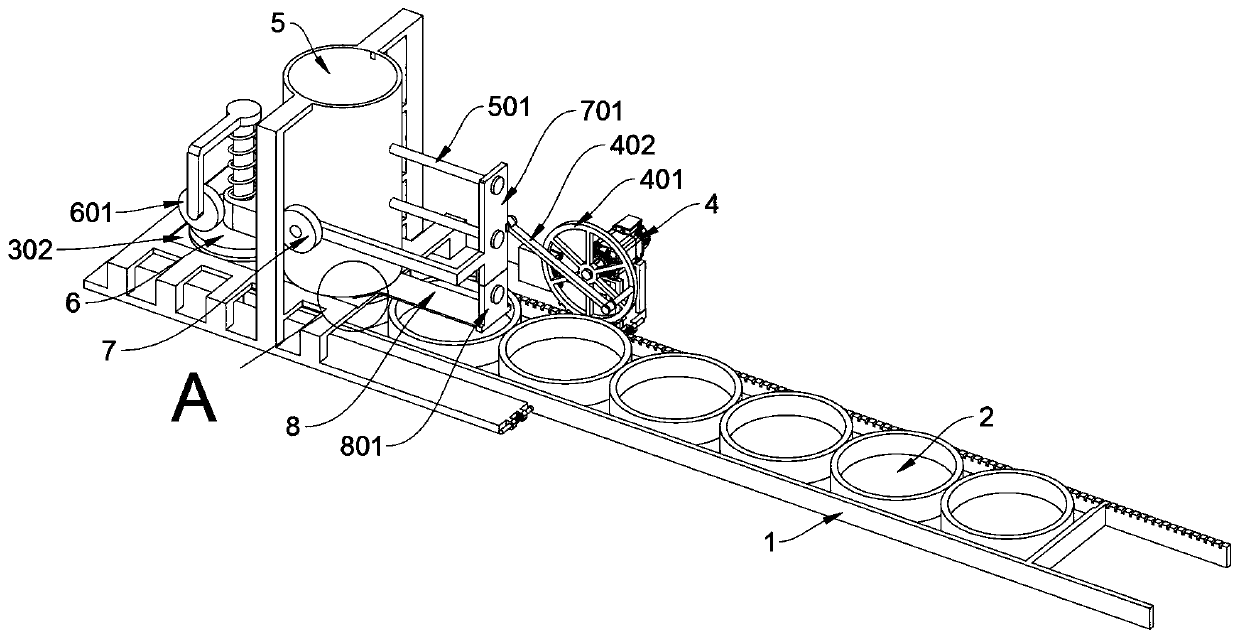

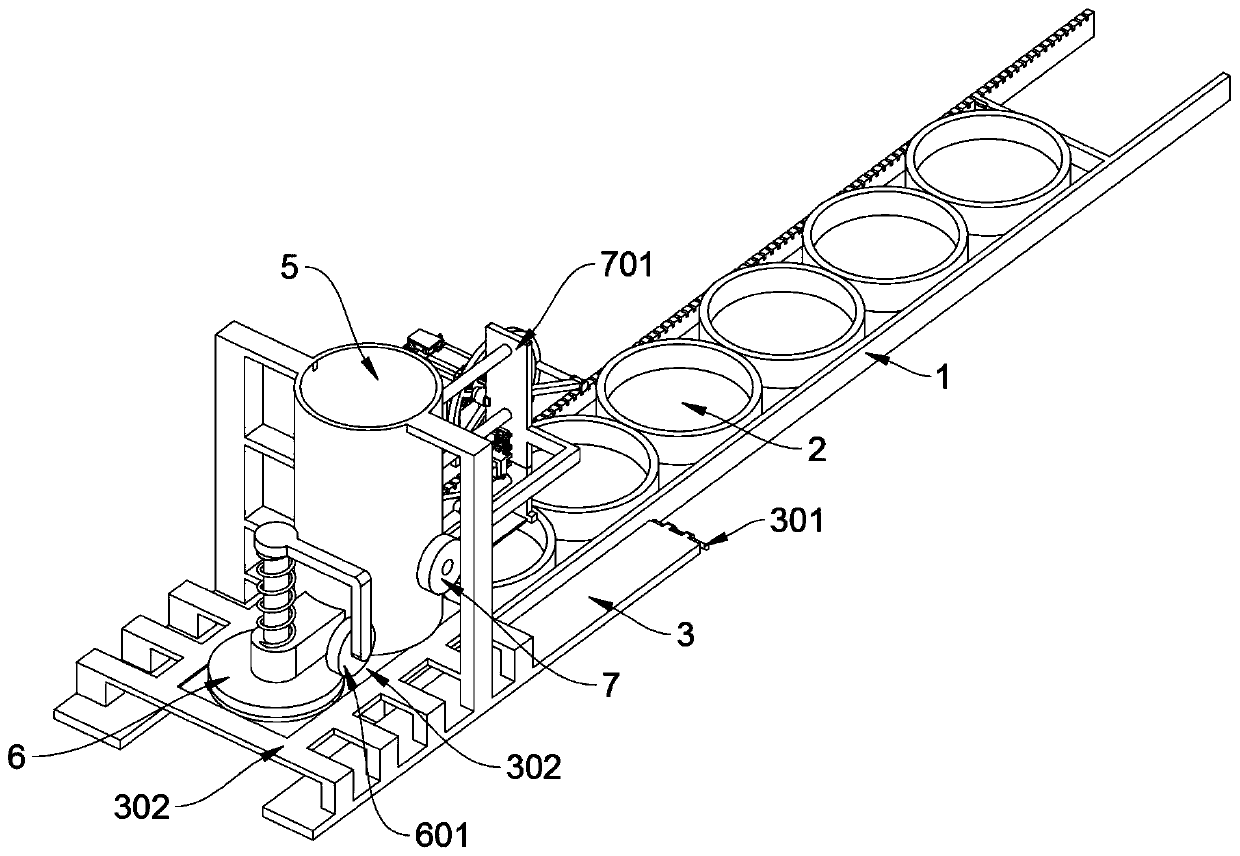

[0030] see Figure 1 to Figure 10, an embodiment provided by the present invention: a high-efficiency gasket pressing device for the inner liner of a bottle cap, including a long strip storage box 1, a base plate 3, a push wheel 7 and a sliding plate 8, and the left and right sides of the long strip storage box 1 Lateral extension support setting, the top right side of the strip storage box 1 is protruded with a row of tooth pieces, the bottle caps 2 are evenly spaced in the strip storage box 1, the base plate 3 includes a positioning insert rod 301, a supporting plate 302 and A circular pressure opening 303, a chute is opened in the middle of the base plate 3, and the strip storage box 1 is located in the chute, and the left and right sides of the rear side of the base plate 3 are pushed through by a spring to insert a positioning insert rod 301, two positioning The ball head at the top of the insertion rod 301 can be inserted into the reference grooves on the left and right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com