Fin-tube type heat exchanger

A technology of heat exchangers and pipelines, applied in heat exchange equipment, heat exchangers, water heaters, etc., can solve the problems of reducing heat exchanger efficiency, heat exchange efficiency, and thermal efficiency, etc., and achieve miniaturized manufacturing , Improve heat exchange efficiency and prevent local overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Hereinafter, configurations and functions of preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

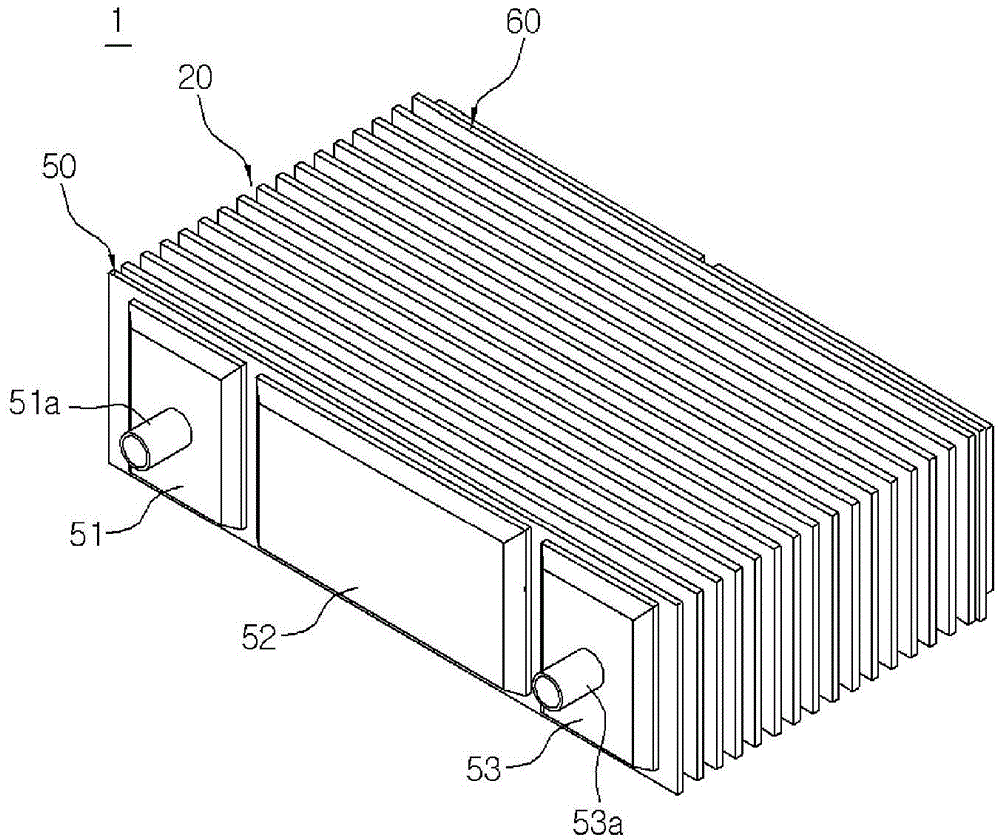

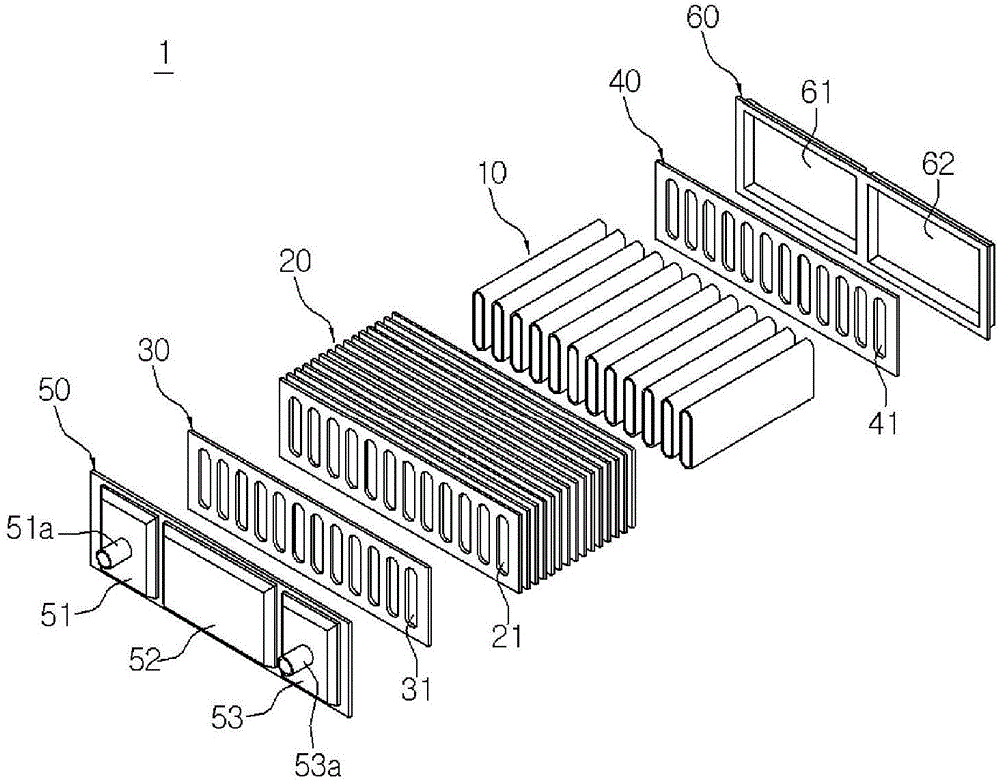

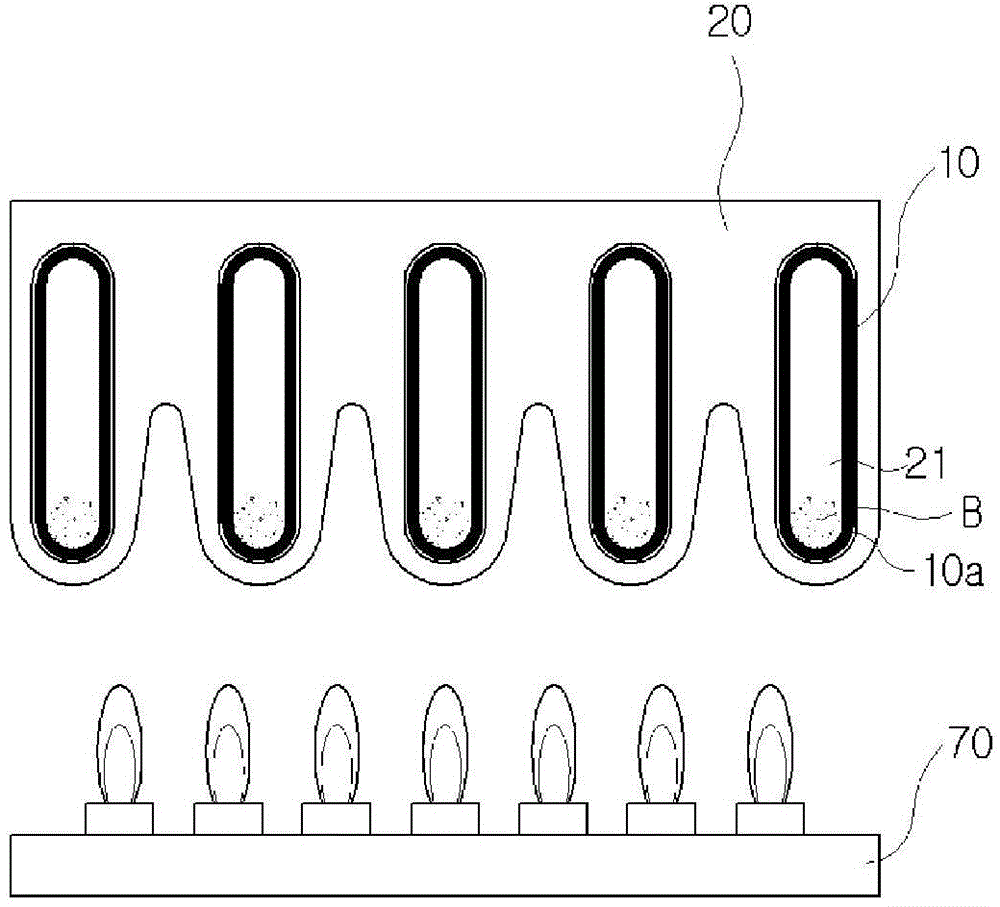

[0063] Figure 6 and Figure 7 is a perspective view of the fin-pipe heat exchanger according to the present invention observed from different angles, Figure 8 for Figure 6 The exploded perspective view of Figure 9 for Figure 6 The A-A line profile.

[0064] The fin-pipe heat exchanger 100 according to the present invention is characterized in that the heat that flows through the inside of the heat medium inflow tube 120a, the tube 110, and the heat medium outflow tube 120b provided so as to pass through the inside of the heat exchanger 100 is The flow of the medium generates turbulence, so as to prevent the boiling of the heat medium and the solidification of foreign matter caused by local overheating, and make the flow of the combustion product passing between the heat transfer fins 150 generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com