Two -way complementary electronic device substrate substrate anti -failure heat tube average temperature and heat dissipation device and method

A technology of electronic devices and cooling devices, which is applied in the field of two-way complementary electronic device substrate failure prevention heat pipe uniform temperature cooling device, to achieve the effect of ensuring temperature uniformity, convenient processing, and uniform temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

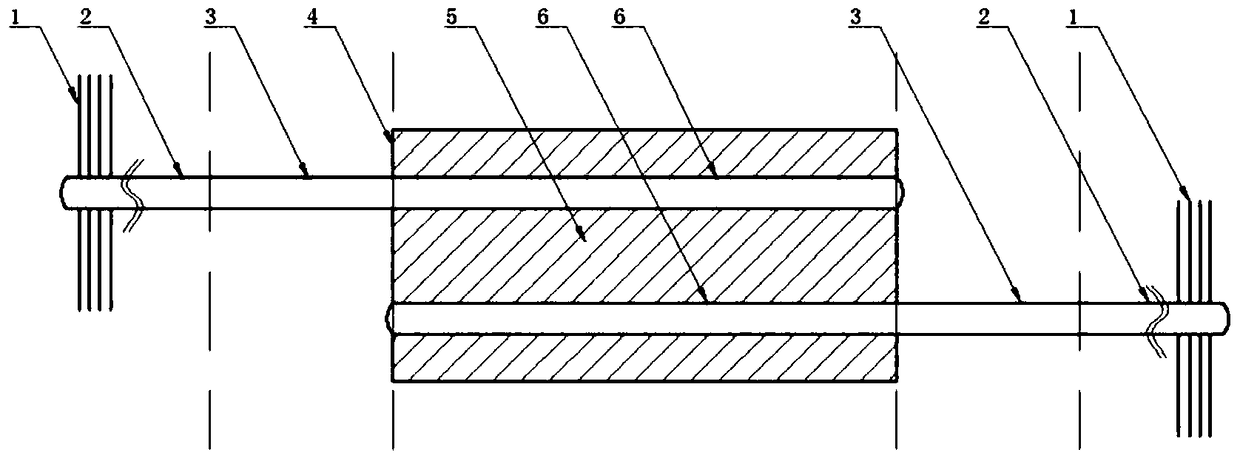

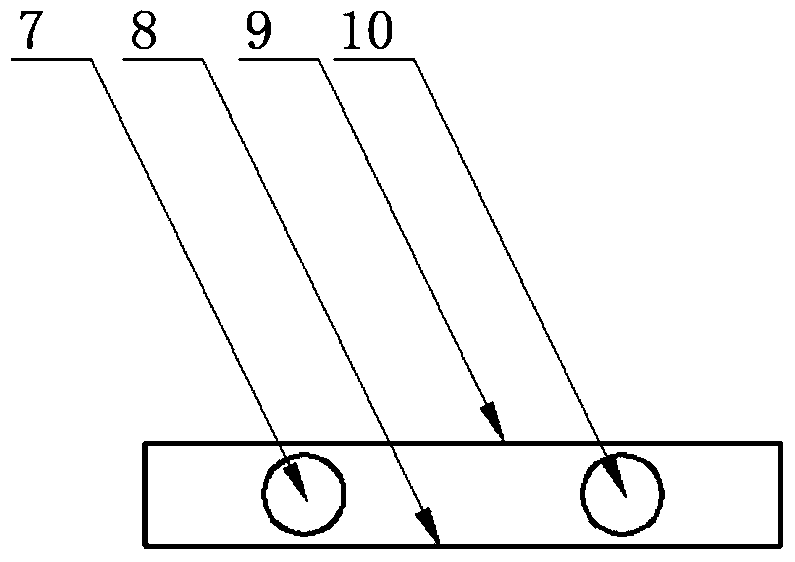

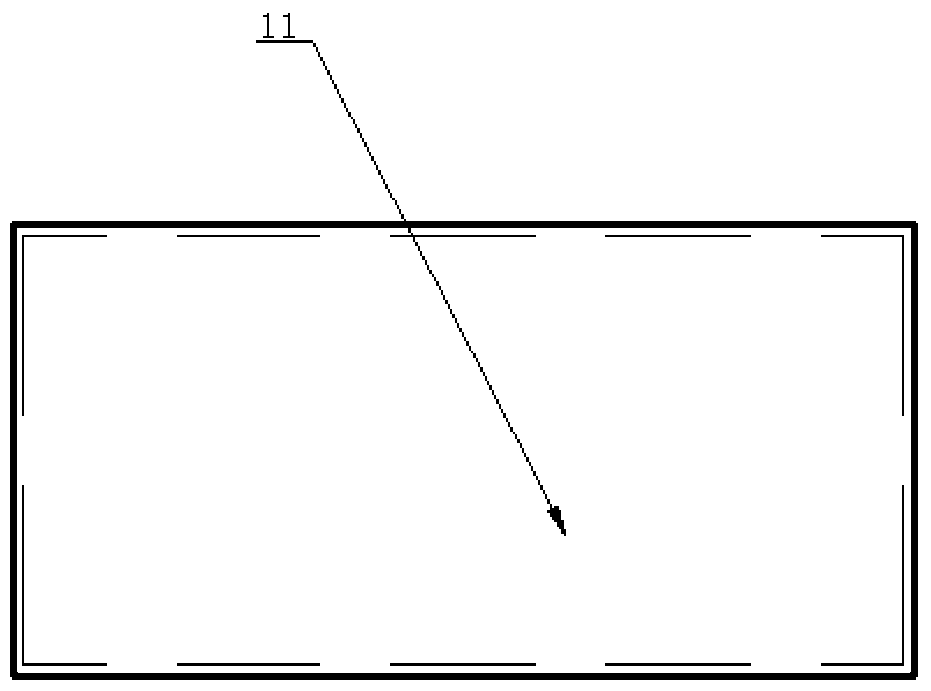

[0019] Such as figure 1 , 2 As shown in . Part of the heat pipe group 10 is inserted into the heat dissipation substrate entity 5. The No. 1 heat pipe group 7 and the No. 2 heat pipe group 10 both include a condensation section 2, an adiabatic section 3 and an evaporation section 6, wherein the evaporation section 6 is inserted into the heat dissipation substrate entity 5 The heat insulating section 3 is provided with an insulating coating, the heat dissipation fins 1 of the condensation section are welded on the condensation section 2, the side surface 4 of the heat dissipation substrate entity 5 is subjected to heat insulation treatment, and the lower surface 8 and the upper surface 9 of the heat dissipation substrate carry a surface heat source , the surface heat source is attached to the heat source arrangement area 11 on the surface of the heat dissipation substrate.

[0020] Both the lower surface 8 and the upper surface 9 of the heat dissipation substrate can carry a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com