Method for inspecting droplet discharge head, device for inspecting droplet discharge head, and droplet discharge device

An inspection method and inspection device technology, applied to printing devices, printing, etc., can solve problems such as inability to obtain sufficient contrast, disappearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

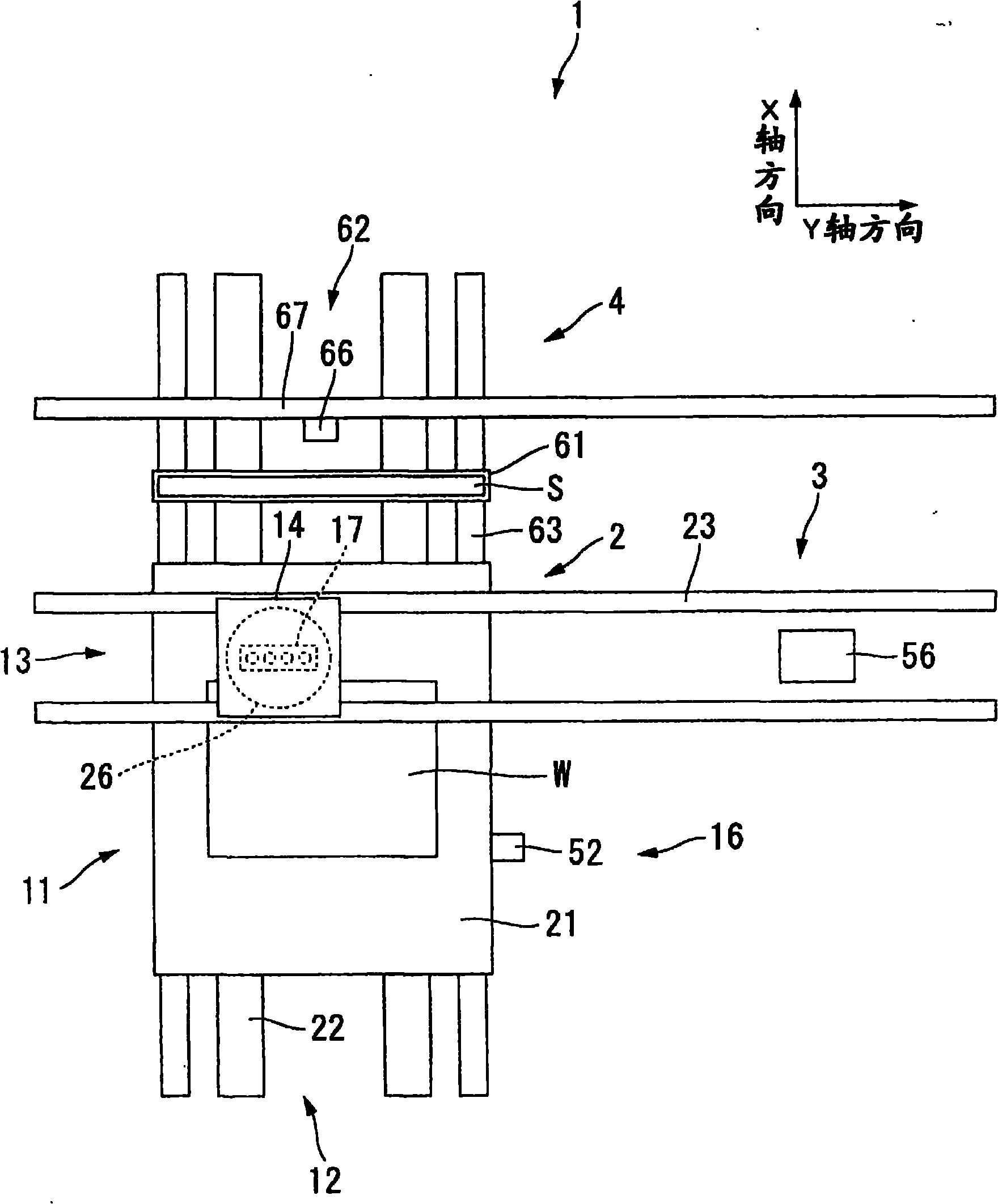

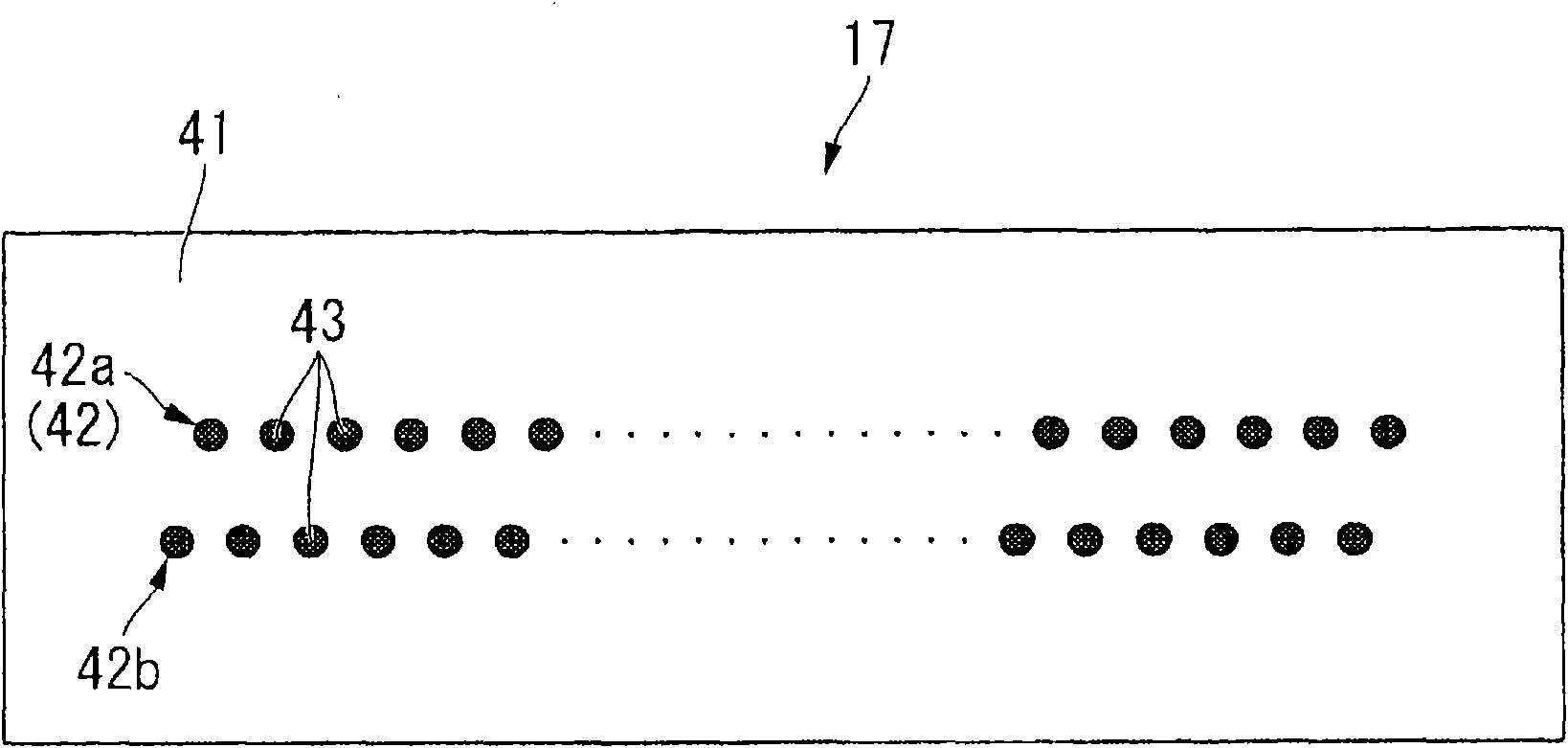

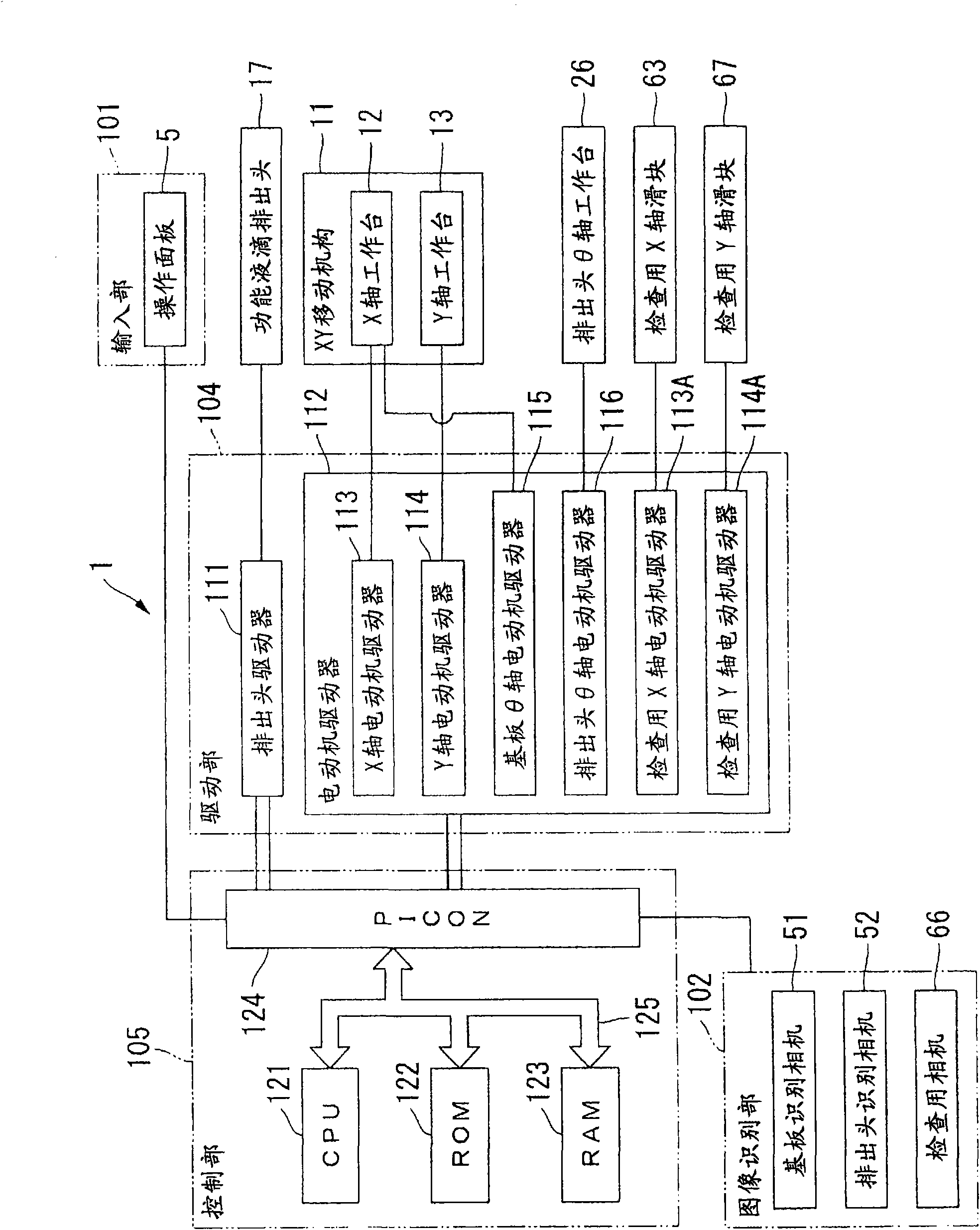

[0029] Hereinafter, an embodiment of an inspection method and inspection device for a droplet discharge head, and a liquid droplet discharge device including the same according to the present invention will be described with reference to the accompanying drawings. The droplet discharge device of this embodiment is installed in a drawing system incorporated in a manufacturing line of an electro-optical device, and a functional liquid such as a special ink or a luminescent resin liquid is introduced into a droplet discharge head to form a film formation portion on a substrate.

[0030] figure 1 It is a top schematic view of the droplet ejection device in the embodiment of the present invention. figure 2 It is a schematic diagram of the functional droplet discharge head seen from the nozzle surface side. image 3 is a block diagram showing a control system of the droplet discharge device. Figure 4 It is a schematic plan view showing the inspection area of the inspection cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com