Automatic rotating medicine tablet press

A technology of automatic rotation and tablet press, used in punching machines, presses, material forming presses, etc., can solve the problems of infiltration into the ground, endanger human health, waste of medicinal powder, etc., achieve precise tableting specifications, improve tableting Efficiency, pollution and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

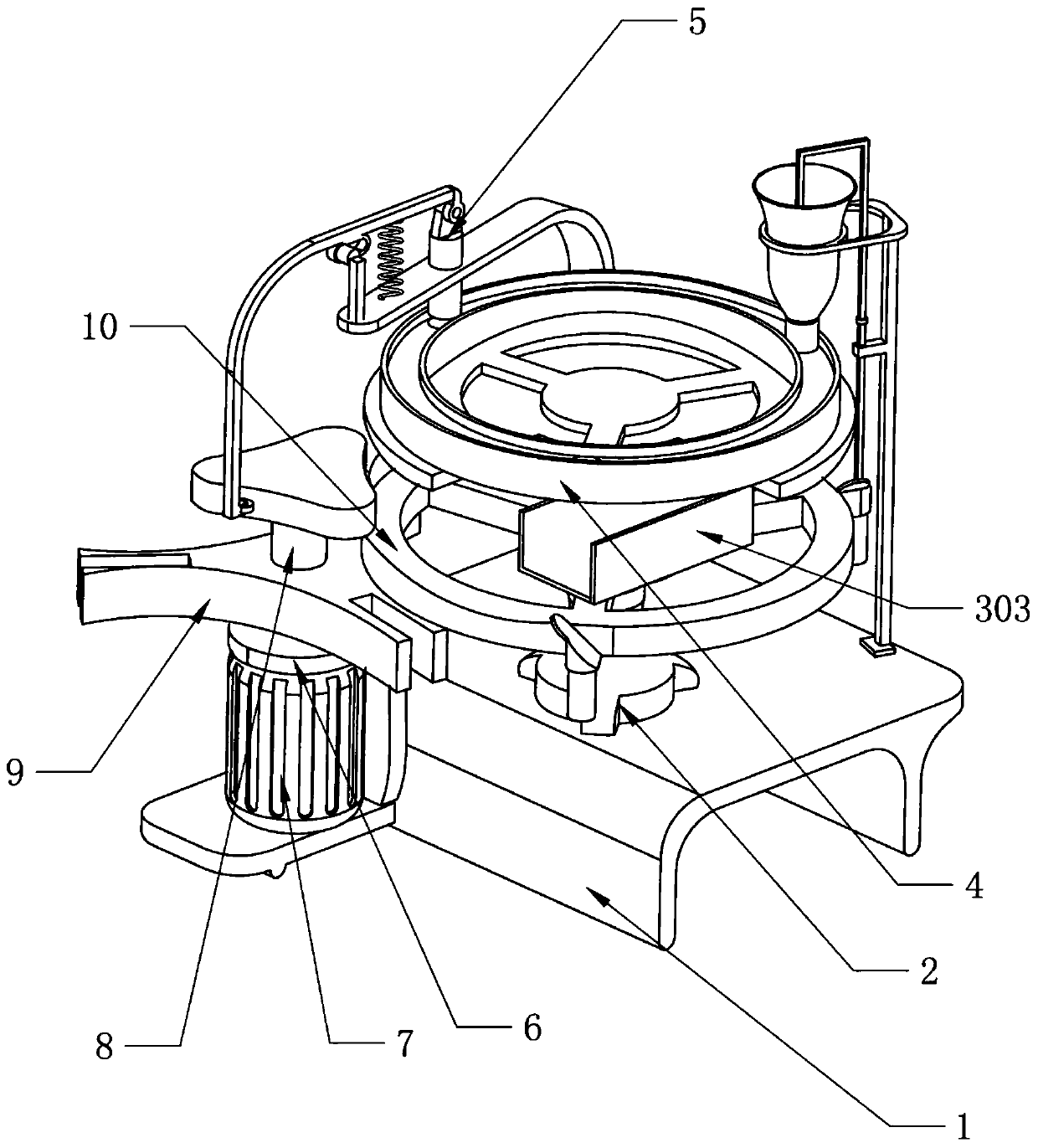

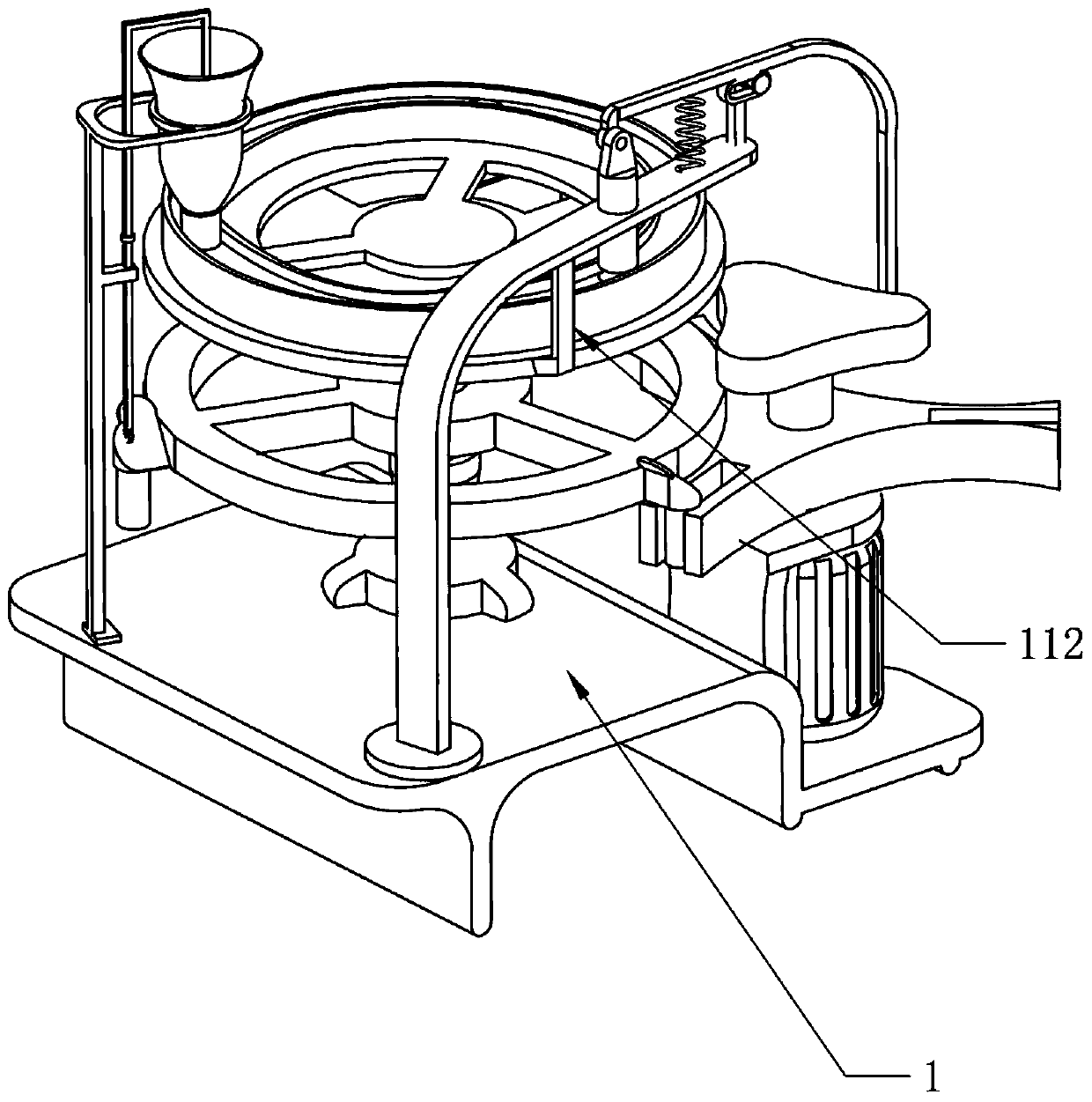

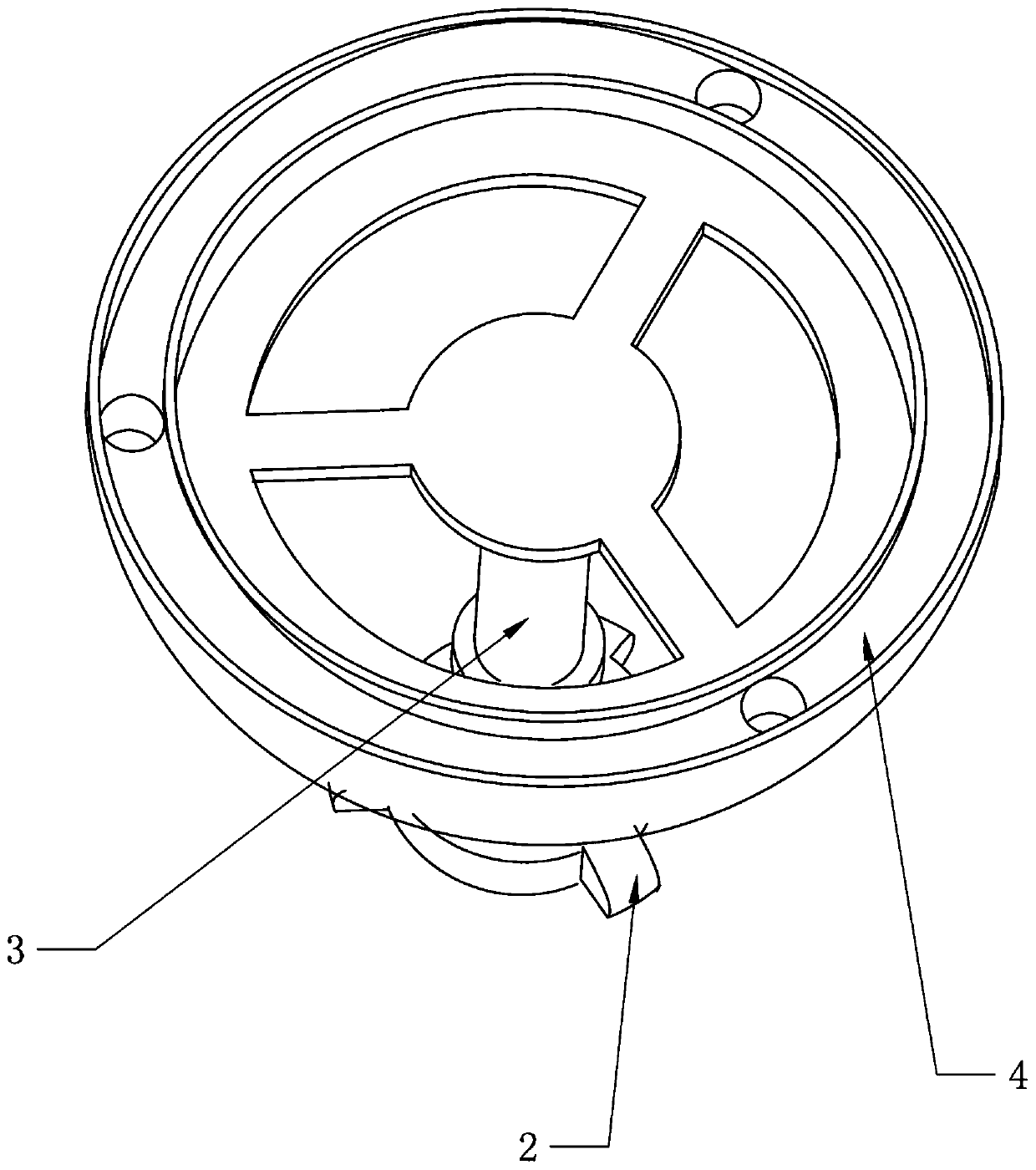

[0023] An automatic rotary pharmaceutical tablet press, such as Figure 1-3 As shown, it includes a bottom plate 1, a rotating seat 2, a conversion shaft 3, a rotating disk 4, a tablet pressing rod 5, a rotating fixed seat 301, a stamping plate 302, a tablet box 303, a mounting plate 11 and a stop rod 112. The top of the bottom plate 1 is equipped with The rotating base 2, the conversion shaft 3 is embedded in the inner circle of the bearing in the rotating base 2, and the upper part of the conversion shaft 3 is fixed with a turntable 4, and three forming holes are uniformly opened on the rotating disc 4, and a tablet pressing rod 5 matching the forming holes is arranged on the rotating disc 4 , the tableting rod 5 cooperates with the forming hole of the turntable 4 to press the medicine powder into tablets, and a rotating fixed seat 301 is installed on the conversion shaft 3, and a stamping plate 302 is welded on the top of the rotating stationary seat 301, and the stamping pl...

Embodiment 2

[0028] On the basis of Example 1, such as Image 6 As shown, it also includes a spring 111, a fixed rod 12, a curved rod structure 13, a first roller 14 and a cam 15, and a fixed rod 12 is fixedly connected to the top of the mounting plate 11 near the first intermittent wheel 9. On the fixed rod 12 A curved rod structure 13 is movably connected, and a spring 111 is connected to one side near the first intermittent wheel 9 on the mounting plate 11. Cam 15 is housed on connecting shaft 8, and cam 15 is positioned at the top of first intermittent wheel 9, and first roller 14 contacts with cam 15.

[0029] When the operator needs to use the tablet pressing rod 5 to press the medicine powder in the turntable 4, he only needs to turn on the servo motor 7. Due to the rotation of the servo motor 7, the cam 15 on the top of the connecting shaft 8 will rotate. When the cam 15 is recessed When in contact with the first roller 14, the curved rod structure 13 will move towards the side cl...

Embodiment 3

[0031] On the basis of Example 2, such as Figure 8 As shown, the curved rod structure 13 is composed of an arc rod 131, a telescopic rod 132 and a locking screw 133. The end of the telescopic rod 132 has a chute. The inner chute, the arc rod 131 can move in the chute in the telescopic rod 132, and the arc rod 131 can be fixed by the locking screw 133 in the telescopic rod 132.

[0032] When the operator needs to adjust the tablet density according to different requirements, the relationship between the telescopic rod 132 and the arc rod 131 can be adjusted. The smaller the connecting part of the rod 131, the higher the density of the tablet. When the contact part between the telescopic rod 132 and the arc rod 131 is adjusted to a proper position, then use the locking screw 133 to lock it, and then different densities can be pressed according to different needs. tablet.

[0033] Such as Figure 7As shown, it also includes a medicine powder fixing frame 16, a sliding rod 17,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com