Tabletting forming machine

A forming machine and tableting technology, which is applied to punching machines, presses, and material forming presses, etc., can solve the problems of affecting the quality of tablet forming products, unstable pressure holding process, and high production costs, achieving simple structure, Ingenious structure and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

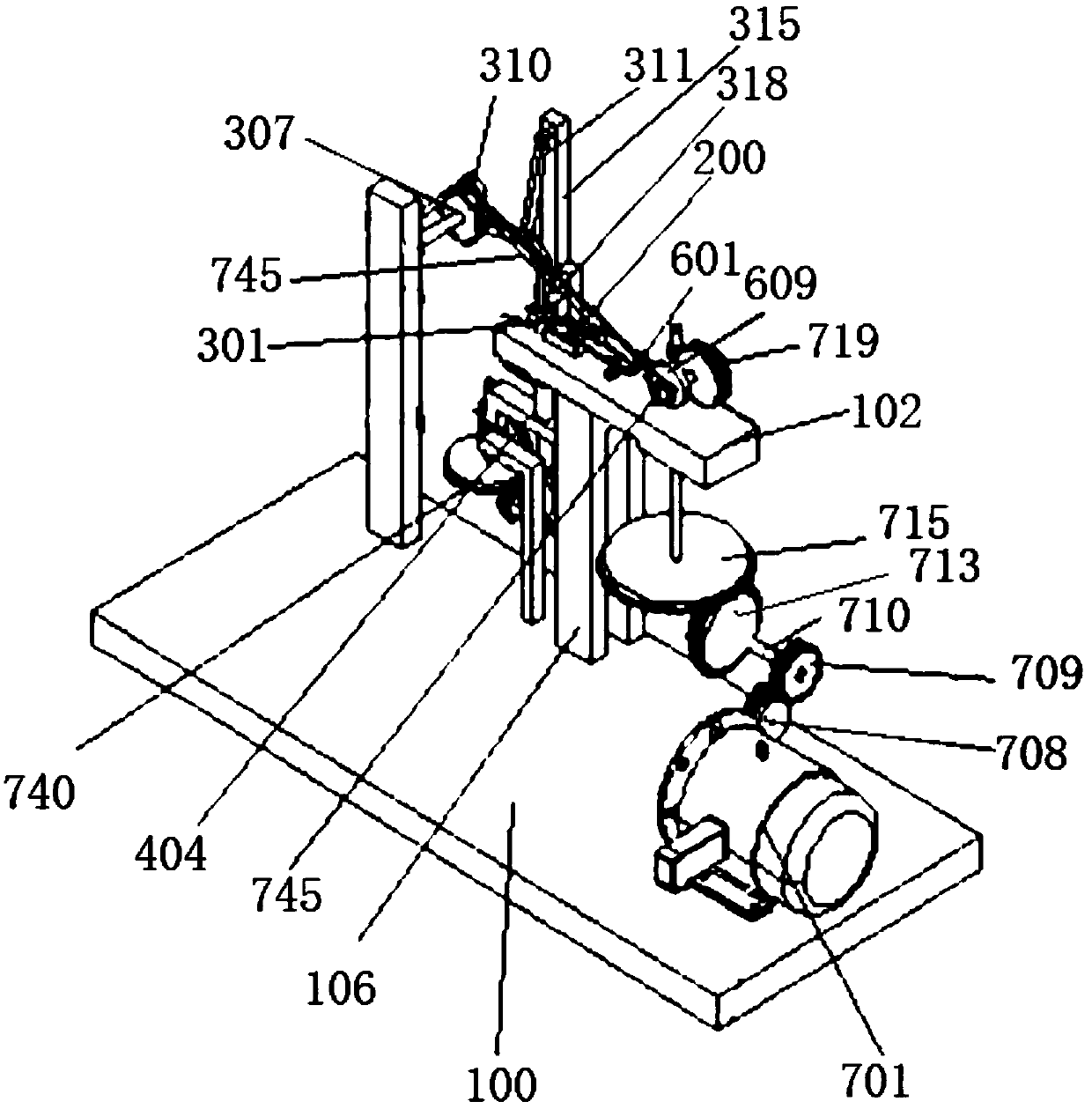

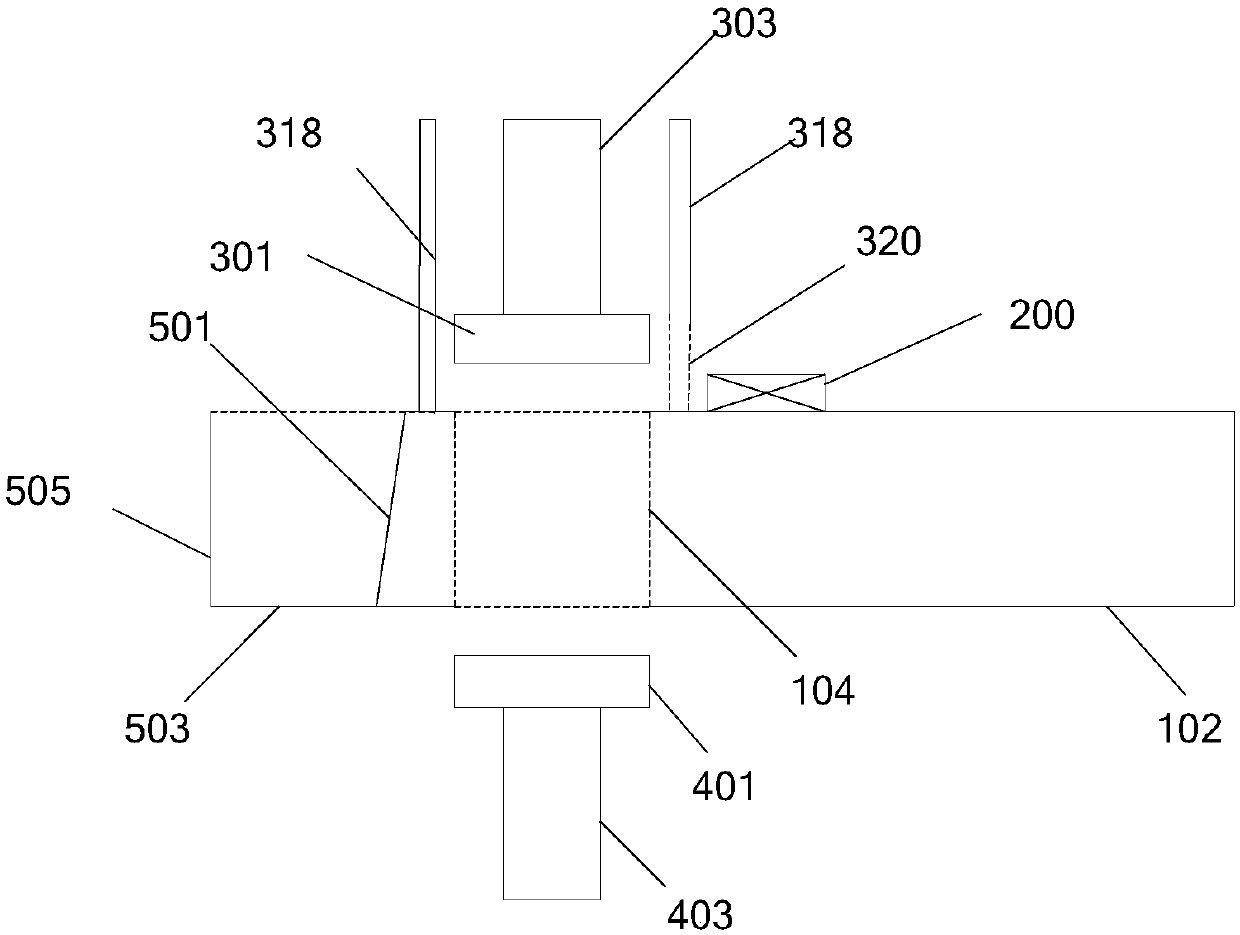

[0066] Such as figure 1 and figure 2 As shown, the present invention provides a tablet forming machine, which includes a base 100, a punch mechanism, a screening material and a feeding mechanism arranged on the base 100.

[0067] The base 100 is provided with a tabletting table 102 on the base 100 ; the tabletting table 102 is provided with a tabletting cavity 104 passing through the top surface and the bottom surface of the tabletting table 102 . The tabletting workbench 102 is set on the base 100 through the support frame 106 .

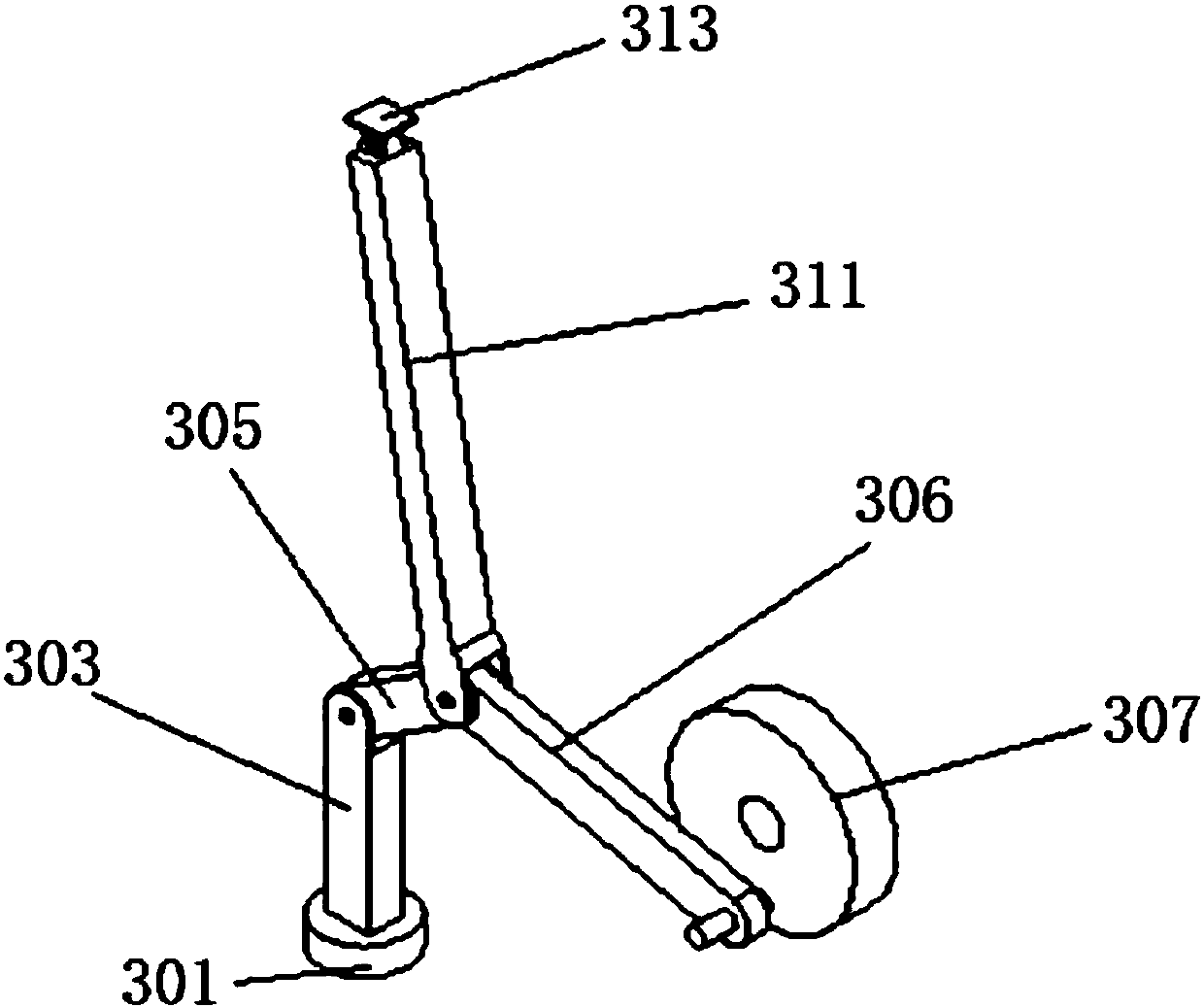

[0068] The punch mechanism includes an upper punch assembly arranged above the tabletting table 102 and a lower punch assembly arranged below the tabletting table 102, the upper punch assembly and the lower punch assembly are suitable for pressing the tablet cavity 104 The raw material inside is stamped to shape; the lower punch assembly is also suitable for pushing the tablet formed in the tableting cavity 104 out of the tableting cavity 104 . ...

Embodiment 2

[0082] see Figure 6 As shown, on the basis of the tablet forming machine in Embodiment 1, the tablet forming machine in this embodiment also includes a transmission mechanism suitable for driving the punch mechanism and the feeding mechanism. Adopting a set of transmission mechanism to simultaneously drive the punch mechanism and the feeding mechanism not only simplifies the overall structure of the tablet forming machine, reduces the production cost, but also improves the tablet compression efficiency.

[0083] The transmission mechanism includes a driving motor 701 arranged on the tablet pressing table 102, a first pulley transmission assembly 703 that is in transmission connection with the driving motor 701, a spur gear assembly that is in transmission connection with the first pulley transmission assembly 703, and a spur gear The final gear stage of the assembly is connected to the drive shaft 710 . The spur gear assembly includes a first spur gear 708 and a second spur ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com