High-speed bottle cap two-dimensional code chip adding machine

A technology of two-dimensional codes and bottle caps, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low efficiency, achieve the effect of improving tablet compression efficiency and solving low tablet compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

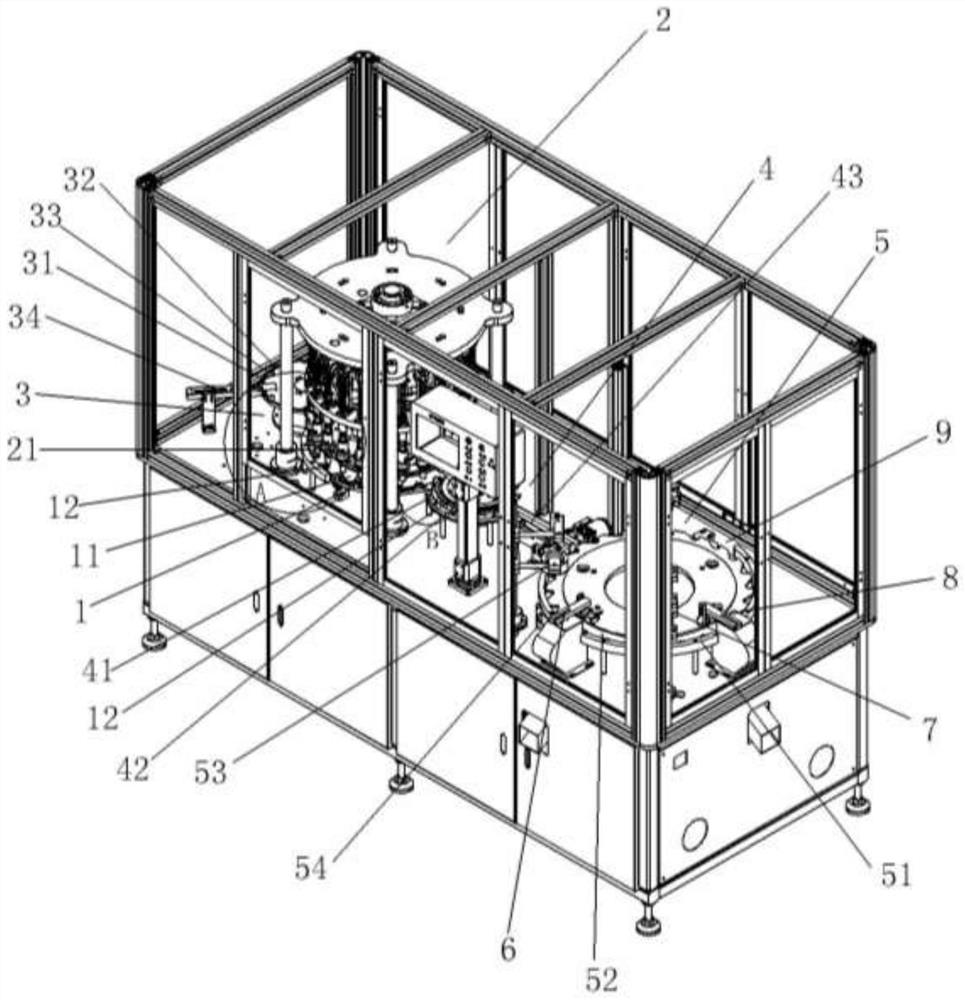

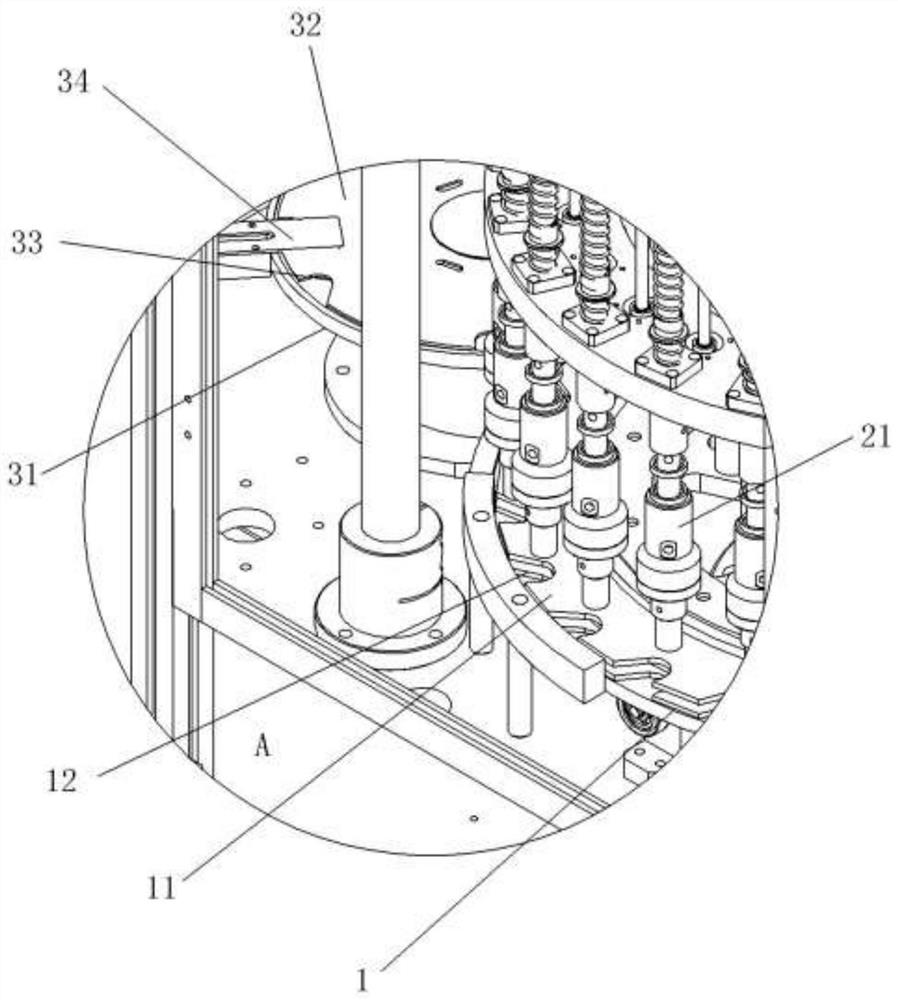

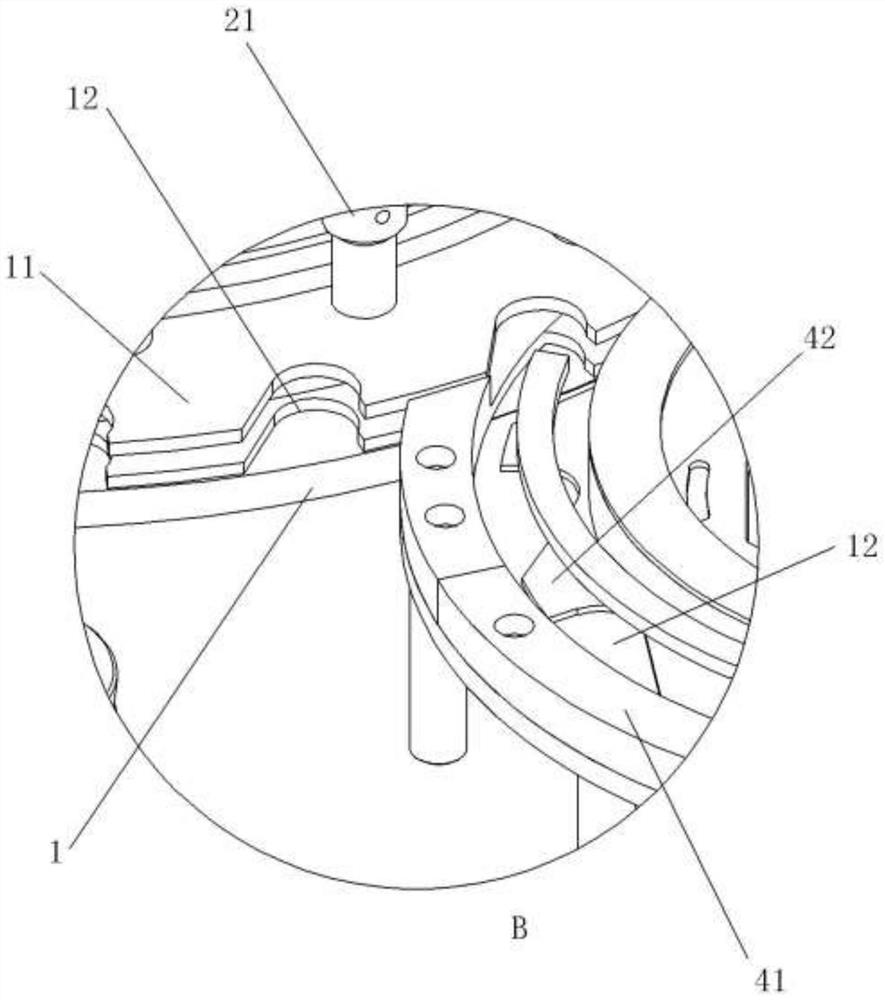

[0025] Such as Figure 1-3 As shown, a high-speed bottle cap adding two-dimensional chip machine according to the present invention includes a first fixed plate 1, and a first bottle cap turntable 11 is arranged on the top of the first fixed plate 1, and the first bottle cap turntable The outer edge of 11 is evenly provided with a bottle cap placement groove 12 in the circumferential direction; There is an adsorption pressing assembly 21 that can move up and down; the outside of the first bottle cap turntable 11 is provided with a two-dimensional code chip feeding mechanism 3, and the feeding level of the two-dimensional code chip feeding mechanism 3 is located in one of the Between the above-mentioned adsorption pressing assembly 21 and the bottle cap placement groove 12.

[0026] Place the bottle cap in the bottle cap placement gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com