High-toughness antimony system compound flame retardant nylon material and preparation method thereof

A technology of flame-retardant nylon and high toughness, which is applied in the field of high-toughness antimony-based compound flame-retardant nylon materials and its preparation, which can solve the problems of reducing the mechanical properties of nylon, improve compatibility, improve dispersion, and improve flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

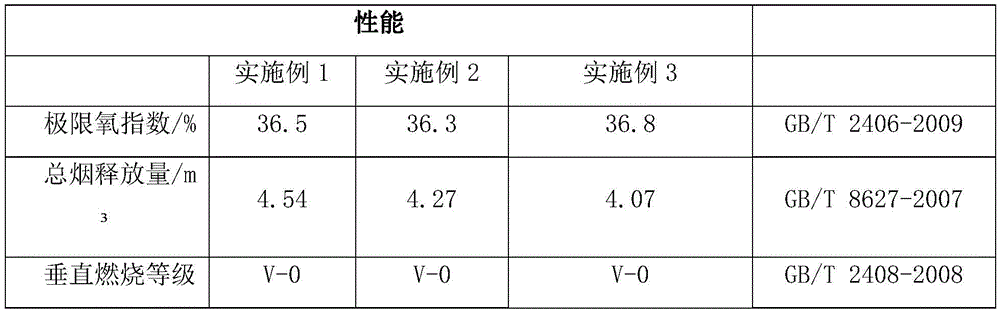

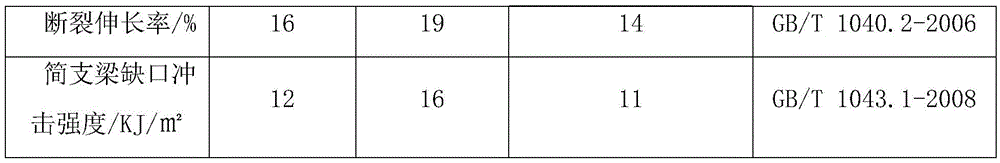

Examples

Embodiment 1

[0042] A high-toughness antimony-based composite flame-retardant nylon material, comprising the following raw materials in parts by weight: 15 kg of nylon 66 resin, 15 kg of nylon 6 resin, 2.4 kg of antimony trioxide (main content of more than 99.6%, particle size of 0.5 μm), boric acid Zinc 1.2kg, Magnesium Hydroxide 3.6kg, Brominated Polystyrene 3kg, Resorcinol Bis(diphenyl) Phosphate 1.5kg, POE-g-MAH Elastomer 5.1kg, Zinc Stearate 1.2kg, Aluminum Ester 1.5kg, main antioxidant 1010, 0.3kg.

[0043] The preparation method of the above-mentioned high-toughness antimony compound flame-retardant nylon material comprises the following steps:

[0044] S1. Drying: Nylon 66 and Nylon 6 are dried with hot air circulation at a temperature of 110°C and a drying time of 15 hours.

[0045] S2. Surface modification: Weigh antimony trioxide, magnesium hydroxide, zinc borate and aluminate according to the above amount and put them into a high-speed mixer for modification. The modification ...

Embodiment 2

[0049] A high-toughness antimony-based composite flame-retardant nylon material, comprising the following raw materials in parts by weight: 18 kg of nylon 66 resin, 12 kg of nylon 6 resin, 1.5 kg of antimony trioxide (the main content is more than 99.6%, and the particle size is 0.5 μm), boric acid Zinc 1.2kg, aluminum hydroxide 3kg, chlorinated polystyrene 4.4kg, tricresyl phosphate 1.5kg, EVA grafted maleic anhydride elastomer 5.4kg, tin stearate 1.2kg, silane coupling agent 1.5kg, main Antioxidant 1076, 0.3kg.

[0050] The preparation method of the above-mentioned high-toughness antimony compound flame-retardant nylon material comprises the following steps:

[0051] S1. Drying: Nylon 66 and Nylon 6 are dried with hot air circulation at a temperature of 100°C and a drying time of 15 hours.

[0052] S2. Surface modification: Weigh antimony trioxide, aluminum hydroxide, zinc borate and silane coupling agent according to the above amount and put them into a high-speed mixer fo...

Embodiment 3

[0056] A high-toughness antimony compound flame-retardant nylon material, comprising the following raw materials in parts by weight: 21 kg of nylon 66 resin, 9 kg of nylon 6 resin, 0.9 kg of antimony trioxide (main content of more than 99.6%, particle size of 0.5 μm), boric acid Zinc 0.9kg, Magnesium Hydroxide 1.5kg, Brominated Polystyrene 6kg, Resorcinol Bis(diphenyl) Phosphate 1.6kg, Butadiene Rubber 7kg, Zinc Stearate 1.2kg, Aluminate 1.5kg, Antioxidant 1010, 0.3kg.

[0057] The preparation method of the above-mentioned high-toughness antimony compound flame-retardant nylon material comprises the following steps:

[0058] S1. Drying: Nylon 66 and Nylon 6 are dried by hot air circulation at a temperature of 130°C and a drying time of 15 hours.

[0059] S2. Surface modification: Weigh antimony trioxide, magnesium hydroxide, zinc borate and aluminate according to the above amount and put them into a high-speed mixer for modification. The modification temperature is 140°C, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com