Disposing method and device of papermaking waste water

A technology for papermaking wastewater and a treatment method, applied in the field of water treatment, can solve problems such as large consumption of chemical agents, and achieve the effects of reducing membrane pollution and avoiding environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

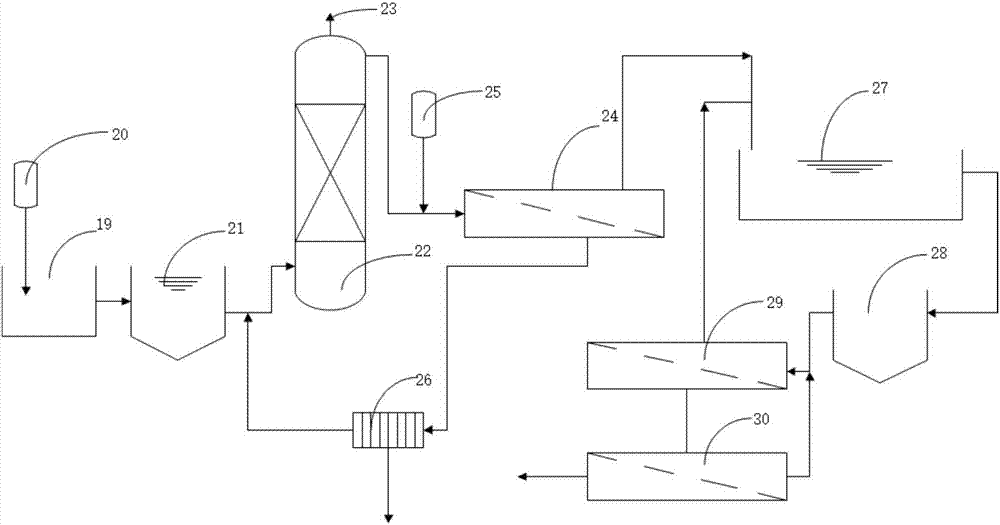

[0084] In the first step, after primary sedimentation, 0.05wt% biodegradable flocculant chitosan is added to the wastewater for pulping and papermaking, and after the flocculation reaction, the flocs are precipitated;

[0085] In the second step, the wastewater treated in the first step is sent to the anaerobic reaction tower for reaction. The dissolved oxygen (DO) content in the anaerobic reaction tower is below 0.15mg / L, the pH is 6.5-7.5, and the sludge concentration is 5 ~12gVSS / L, mud age 60 days, temperature 20℃;

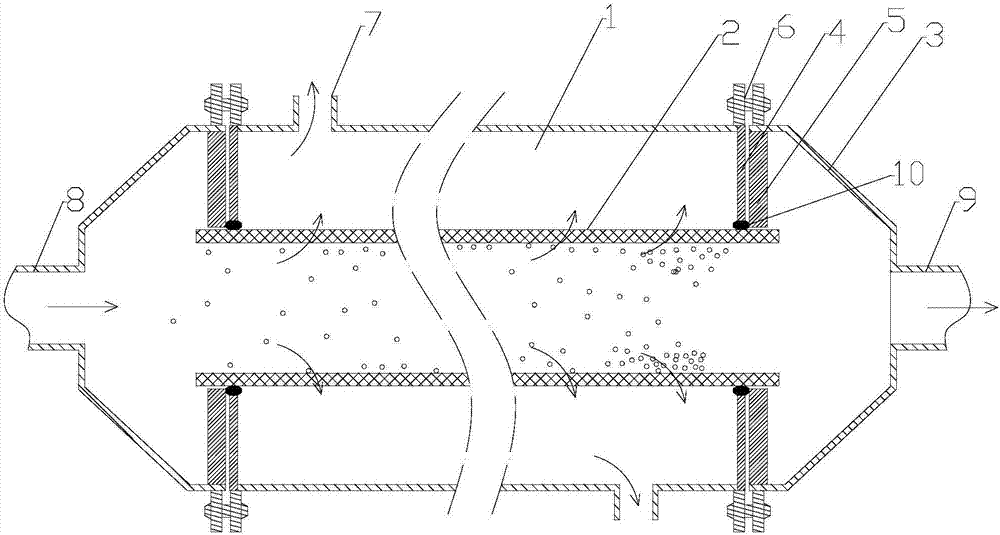

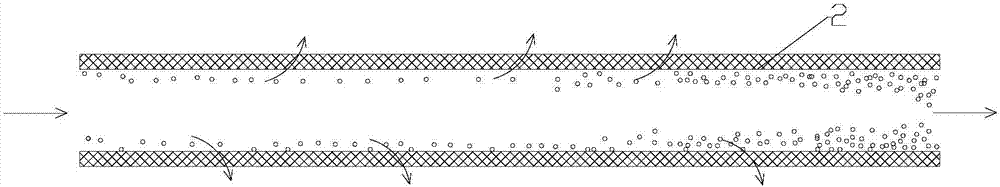

[0086] In the third step, after adding sodium carbonate precipitant to the product water in the upper part of the anaerobic reaction tower, it is sent to a tubular ceramic microfiltration membrane filter for filtration. The amount of sodium carbonate added is 0.1g more than that required for the complete precipitation of calcium ions. / L, the average pore size range of the microfiltration membrane in the tubular ceramic microfiltration membrane filter is 800nm...

Embodiment 2

[0091] In the first step, after primary sedimentation, 0.2wt% biodegradable flocculant chitosan is added to the wastewater for pulping and papermaking, and after the flocculation reaction, the flocs are precipitated;

[0092] In the second step, the wastewater treated in the first step is sent to the anaerobic reaction tower for reaction. The dissolved oxygen (DO) content in the anaerobic reaction tower is below 0.15mg / L, the pH is 6.5-7.5, and the sludge concentration is 5 ~12gVSS / L, mud age 100 days, temperature 32℃;

[0093] In the third step, after adding sodium carbonate precipitant to the product water in the upper part of the anaerobic reaction tower, it is sent to a tubular ceramic microfiltration membrane filter for filtration. The amount of sodium carbonate added is 0.1g more than that required for the complete precipitation of calcium ions. / L, the average pore size range of the microfiltration membrane in the tubular ceramic microfiltration membrane filter is 2000n...

Embodiment 3

[0098] In the first step, after primary sedimentation, 0.1t% biodegradable flocculant chitosan is added to the wastewater for pulping and papermaking, and after the flocculation reaction, the flocs are precipitated;

[0099] In the second step, the wastewater treated in the first step is sent to the anaerobic reaction tower for reaction. The dissolved oxygen (DO) content in the anaerobic reaction tower is below 0.15mg / L, the pH is 6.5-7.5, and the sludge concentration is 5 ~12gVSS / L, mud age 80, temperature 28℃;

[0100] In the third step, after adding sodium carbonate precipitant to the product water in the upper part of the anaerobic reaction tower, it is sent to a tubular ceramic microfiltration membrane filter for filtration. The amount of sodium carbonate added is 0.1g more than that required for the complete precipitation of calcium ions. / L, the average pore size range of the microfiltration membrane in the tubular ceramic microfiltration membrane filter is 1000nm, the cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com