Catalyst as well as preparation method and application thereof

A catalyst and binder technology, applied in the field of syngas to low-carbon alcohol, can solve the problems of catalyst CO conversion rate and total alcohol selectivity, etc., to improve physical strength and stability, inhibit enrichment, and increase yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] In order to achieve the above object, the present invention also provides a preparation method of the above-mentioned catalyst, the preparation method comprising: carrying out a precipitation reaction on a mixture of copper-containing soluble salt, iron-containing soluble salt and manganese-containing soluble salt and a precipitating agent, and after filtering, to obtain A filter cake; and a slurry formed by mixing the filter cake with water, and mixing the slurry with a binder, drying and roasting to obtain a catalyst; wherein the binder is selected from silica sol and silicon-containing soluble salts.

[0029] Due to Fe 3 o 4 is the active phase of the water-gas shift, leading to CO 2 In this catalyst, the ratio of copper and iron is limited to a specific ratio range, so that the two can more synergistically generate alcohol, and there is no excess iron to generate ferric oxide, which inhibits CO to a certain extent 2 production, while increasing the yield of total ...

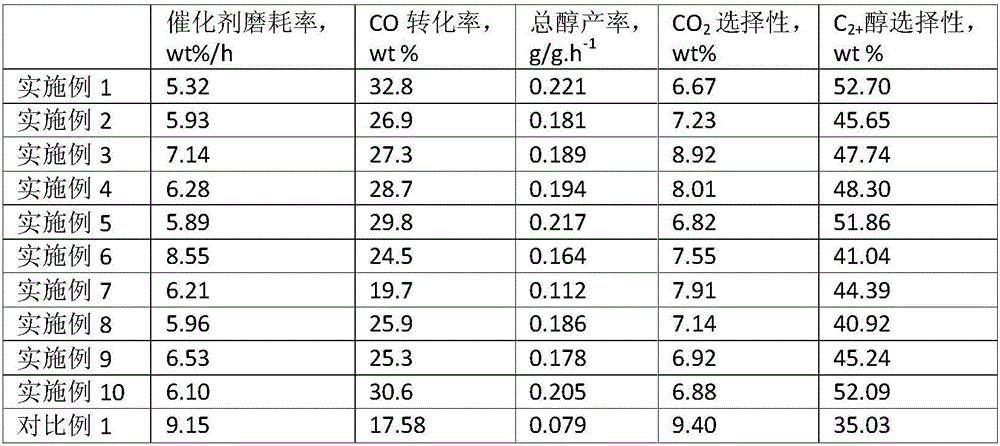

Embodiment 1

[0044] Weigh 362.4g Cu (NO 3 ) 2 ·3H 2 O, 424.2gFe(NO 3 ) 3 9H 2 O hydrate, 42.95g50%Mn(NO 3 ) 2 Aqueous solution, add 500mL deionized water and mix well; precipitant is potassium carbonate solution, precipitation reaction is carried out at a precipitation temperature of 70°C and a pH of 7.2, and aging is carried out at 60°C for 4 hours after the reaction is completed; the precipitate is fully filtered and washed, Until the conductivity of the washing liquid is detected to be below 100 μm / cm; the obtained filter cake is beaten again, and the temperature of the slurry is controlled at 70°C, and 252.08 g of commercially available silica sol with a concentration of 25% is added dropwise to it until it is evenly stirred. Slurry spray-drying was carried out, and the average particle diameter D50 of the obtained catalyst was 56 μm, and then the catalyst was calcined at 400° C. for 8 hours to obtain finished catalyst particles. The catalyst wear rate results are shown in Table...

Embodiment 2

[0047] Weigh 362.4g Cu (NO 3 ) 2 ·3H 2 O, 121.2gFe(NO 3 ) 3 9H 2 O hydrate, 10.74g50%Mn(NO 3 ) 2For the aqueous solution, add 500mL deionized water and mix well; the precipitation agent is sodium carbonate solution, and the precipitation reaction is carried out at a precipitation temperature of 70°C and a pH of 7.2. After the reaction is completed, aging is carried out at 60°C for 4 hours; Until the conductivity of the washing liquid is detected to be below 100 μm / cm; the obtained filter cake is beaten again, and the temperature of the slurry is controlled at 70°C, and 252.08 g of commercially available silica sol with a concentration of 25% is added dropwise to it until it is evenly stirred. Slurry spray-drying was carried out, and the average particle diameter D50 of the obtained catalyst was 48 μm, and then the catalyst was calcined at 400° C. for 8 hours to obtain finished catalyst particles. The catalyst wear rate results are shown in Table 1.

[0048] The catalyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com