Spring steel wire rod excellent in pickling performance

A technology of spring steel and wire rods, applied in the field of spring steel wire rods, can solve the problems of increased pickling process cost, degradation of surface properties, failure to improve yield stress, etc., and achieve the effect of excellent pickling performance and excellent surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

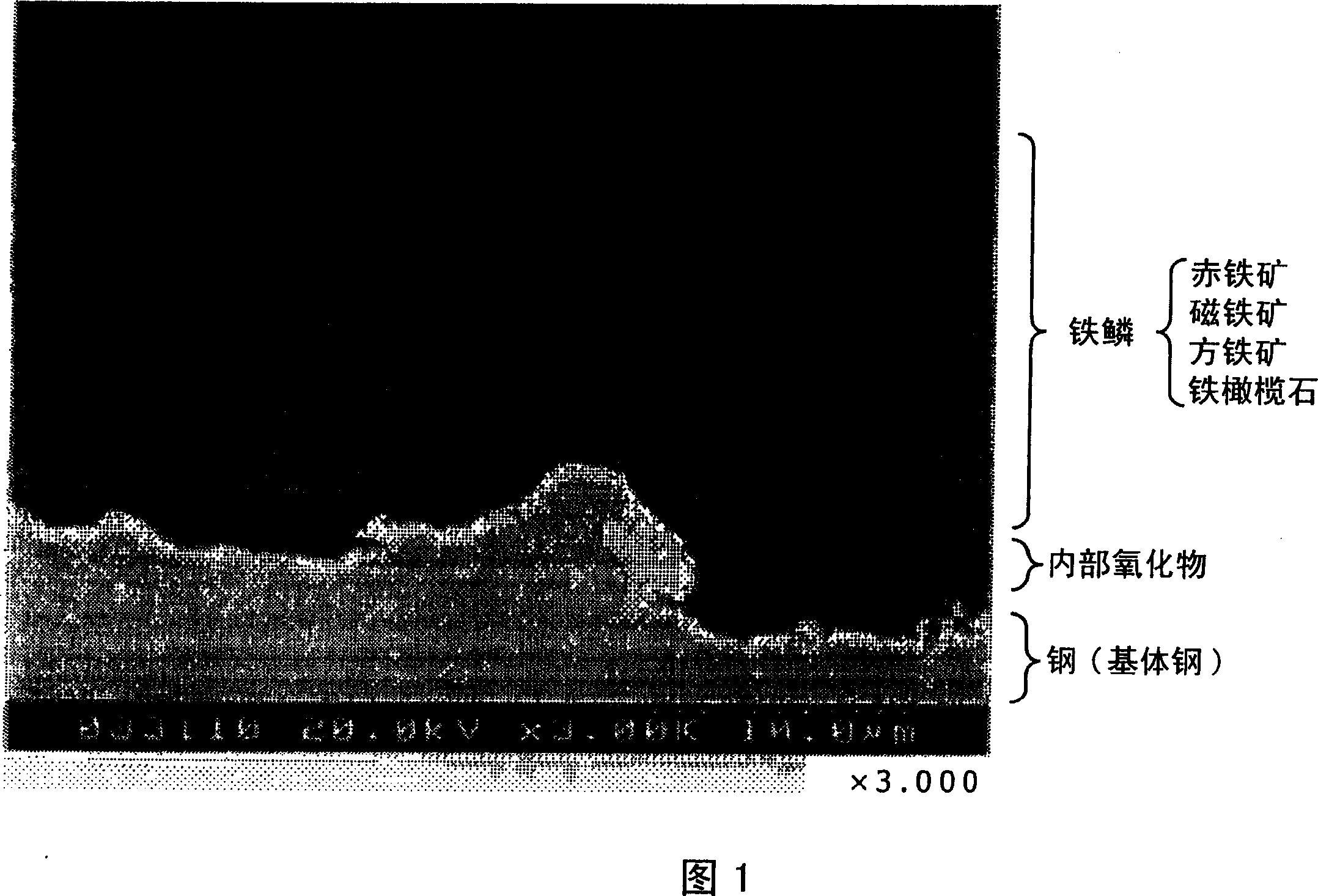

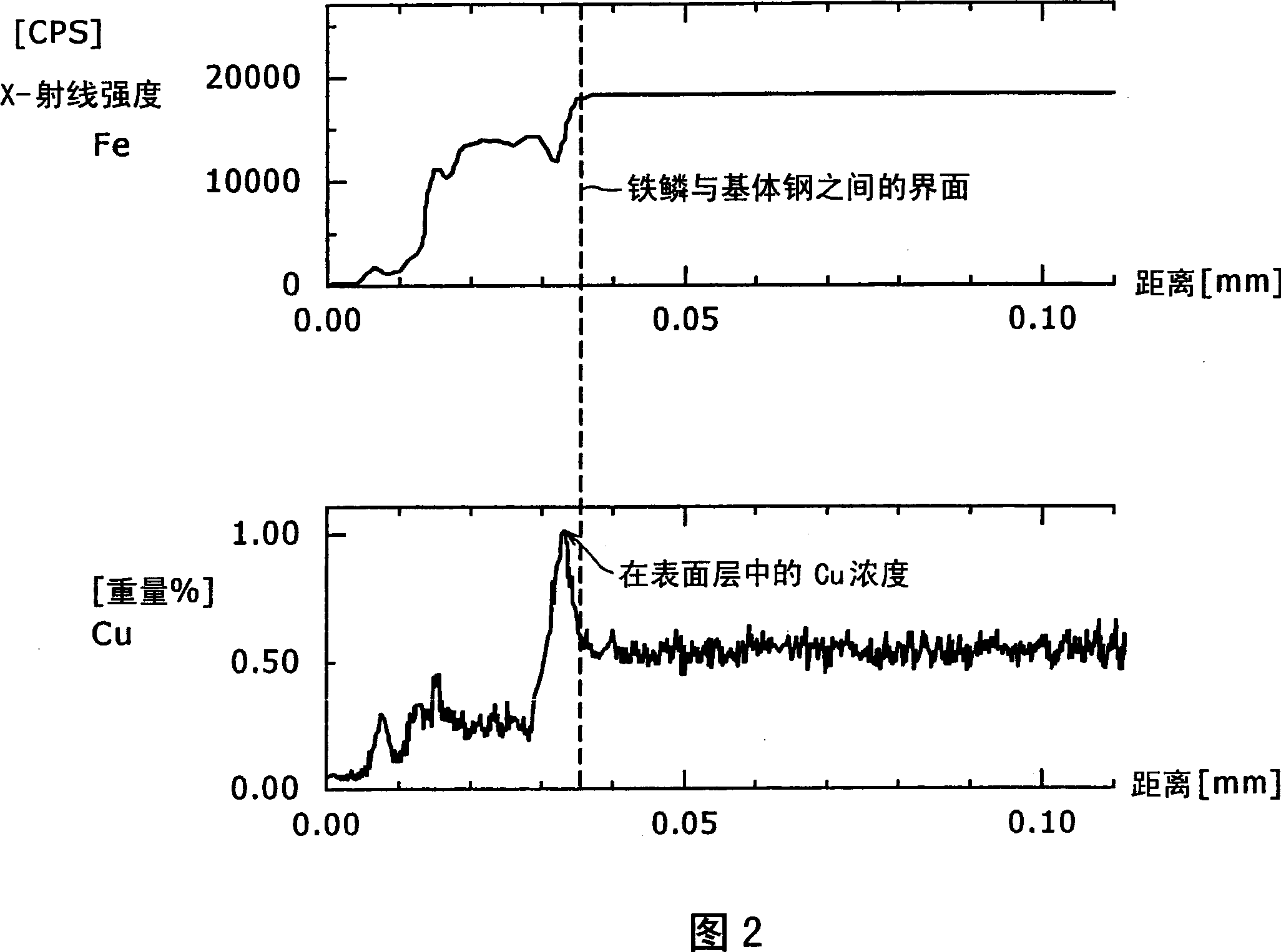

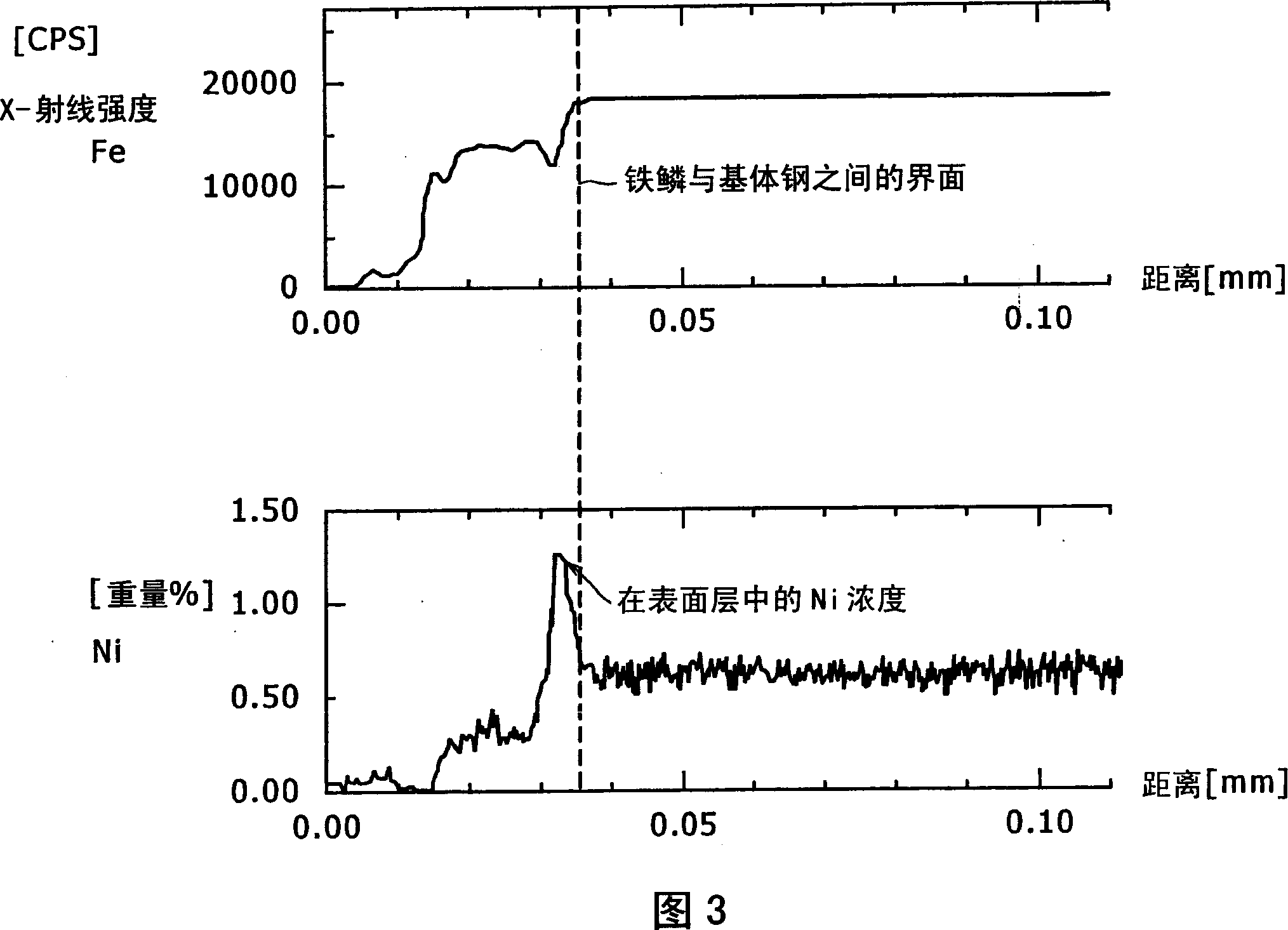

Image

Examples

Embodiment

[0096] Next, the present invention is explained in detail based on examples. However, the following examples do not limit the present invention, and all arbitrary changes within the scope not departing from the foregoing and hereinafter-described gist of the present invention are included in the technical scope of the present invention.

[0097] By melting and refining in a small vacuum furnace, 150 kg of each of the various steels shown in Table 1 (steel types A to K, the balance consisting of Fe and unavoidable impurities) was produced. Each of these steels was hot forged, and a 155 cm square billet was prepared. Subsequently, a steel wire rod having a diameter of 13.5 mm was produced under the heating, soaking and hot rolling conditions described in the wire rod forming processes 1 to 6 shown below. Among the wire forming processes 1 to 6, the wire forming processes 1 and 2 satisfy all the production conditions specified in the present invention and represent examples of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com