Low-temperature lead-free solder alloy

A lead-free solder alloy, low-temperature technology, applied in the direction of welding/cutting media/materials, welding media, welding equipment, etc., can solve the problems of reducing the brittleness of solder solder joints, low strength of solder joints, and reducing joint brittleness, etc., to achieve improved Welding performance, preventing the generation of Bi-rich phase, and improving the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

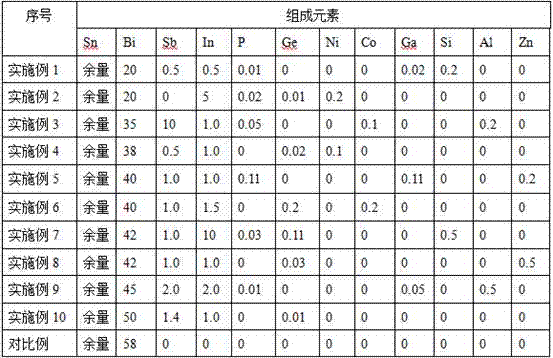

Examples

Embodiment 8

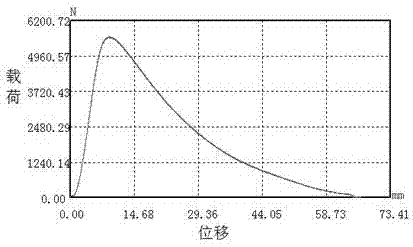

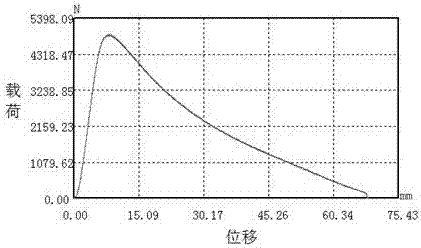

[0047] The load-displacement curve obtained after the low-temperature lead-free solder alloy SnBi42Sb1.0In1.0 sample tensile test of embodiment 8 is as follows figure 1 Shown, the load-displacement curve of comparative example SnBi58 alloy is as figure 2 shown, from figure 1 and figure 2 It can be seen from the curve that the low-temperature lead-free solder alloy SnBi42Sb1.0In1.0 of Example 8 not only has a higher tensile strength, but also has relatively uniform deformation during the deformation stage of the alloy and has good formability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com