Method of continous annealing/hot-dipping of steel sheet containing silicon and apparatus for continuous annealing/hot-dipping

A technology of hot-dip plating and steel plate, which is applied in the direction of hot-dip plating process, heat treatment furnace, heat treatment equipment, etc., can solve problems such as hindering plating performance, alloying speed reduction, and roller defects in the furnace, so as to achieve excellent coating adhesion, The effect of inhibiting enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

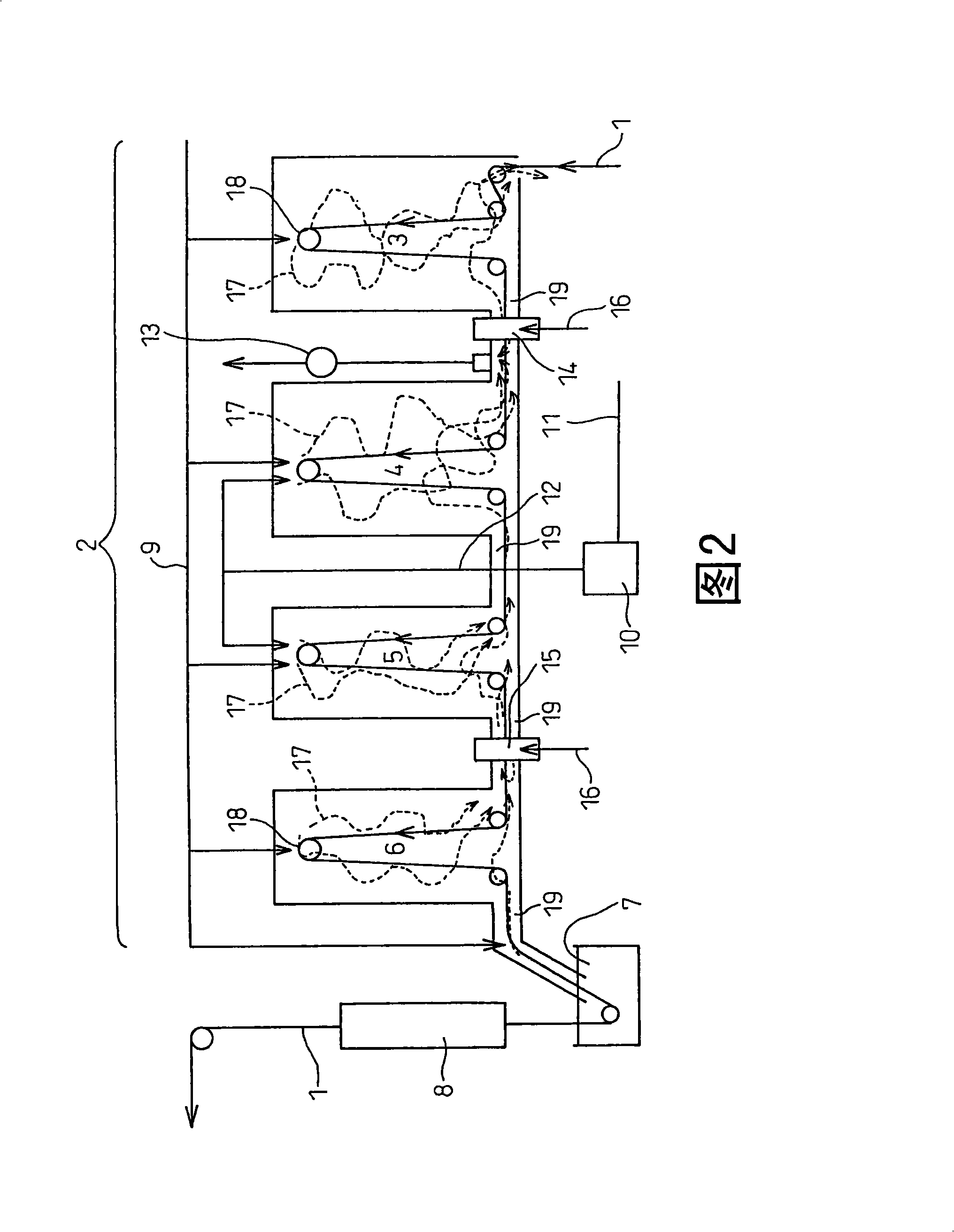

[0039] Fig. 2 shows the outline of one embodiment of the hot-dipping apparatus of the present invention. In this embodiment, the hot-dip coating device is composed of an annealing furnace 2, a hot-dip coating tank 7, and a heating belt front section 3, a heating belt rear section 4, a heat preservation belt 5, and a cooling belt 6 in the conveying direction of the steel plate 1. And alloying device 8. Each belt section 3, 4, 5, 6 of the annealing furnace is equipped with a roller 18 for continuously conveying the steel plate, and an opening 19 is arranged between each belt section, and the steel plate can pass through each belt section in the furnace. Each zone of the annealing furnace 2 is connected to a pipe 9 for introducing an atmospheric gas composed of hydrogen and nitrogen. The humidified nitrogen is obtained by blowing nitrogen gas from the nitrogen gas pipe 11 to the nitrogen humidifier 10 , and is introduced into the heating belt rear stage 4 and the heat preservati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com