Method for thermally evaporating and preparing organic material nanometer cluster

A technology of organic materials and nano-clusters, applied in the field of organic light-emitting display devices, can solve the problems of reducing the life of organic light-emitting devices, low vacuum degree, complex process, etc., and achieve the effects of maintaining luminescent properties, accelerating aging, and high aggregation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

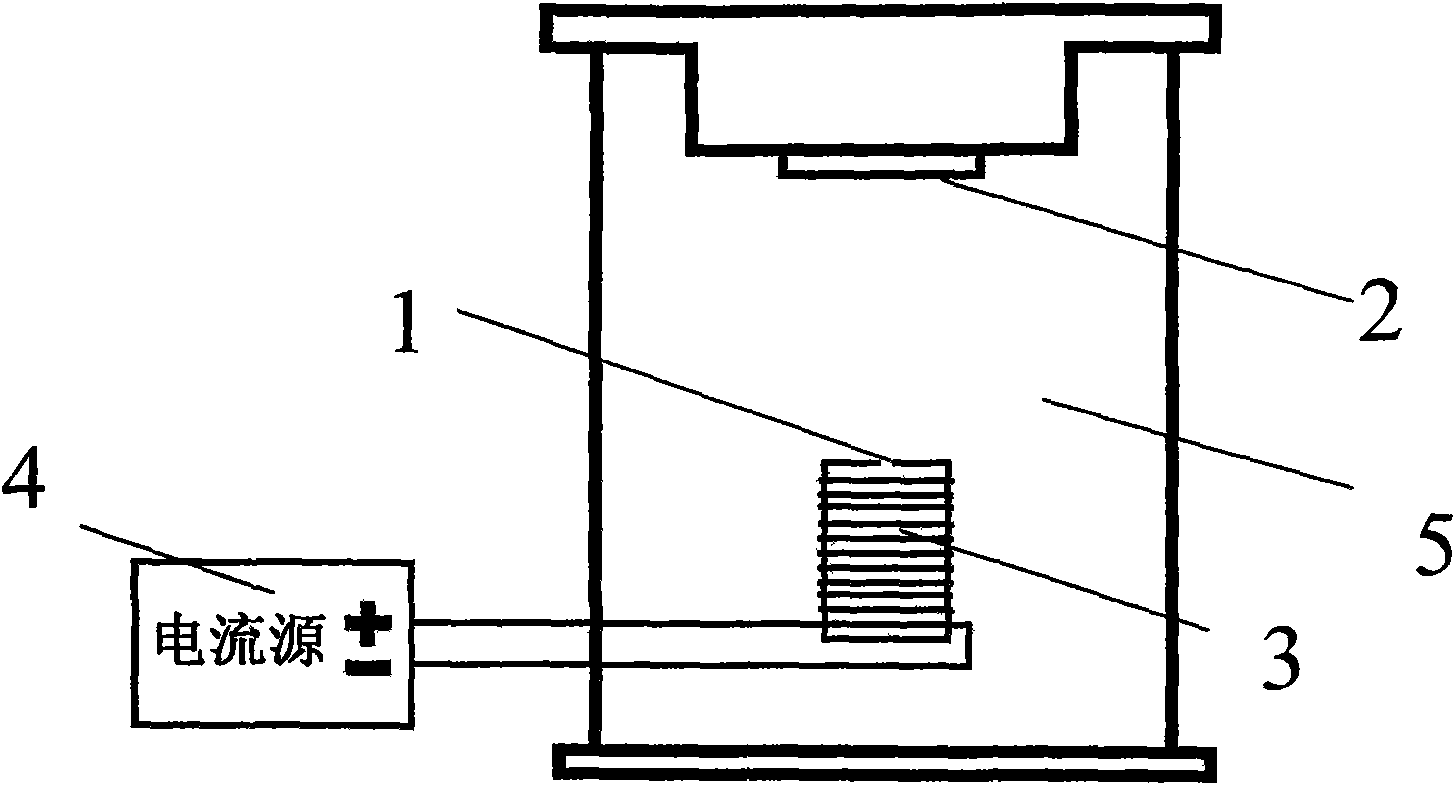

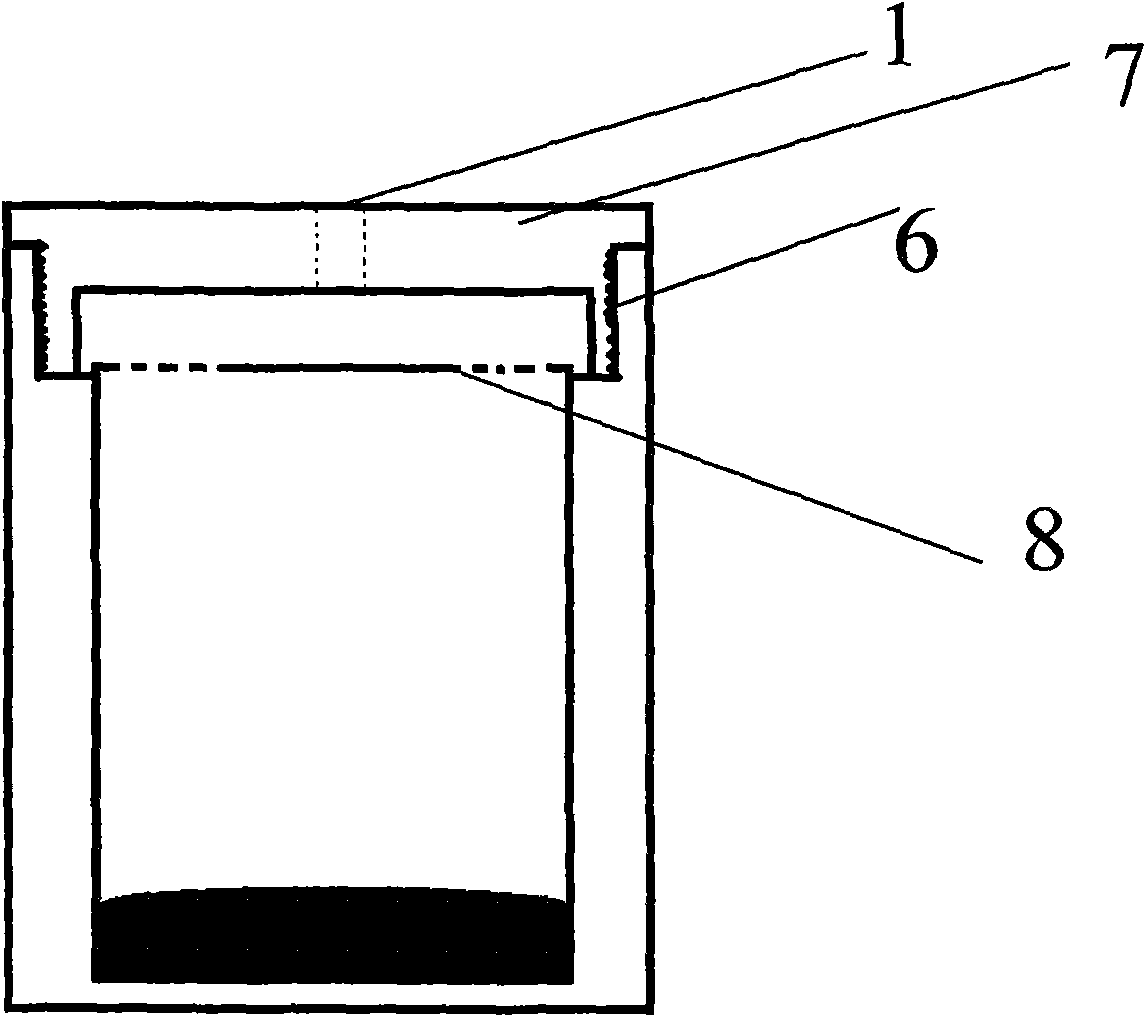

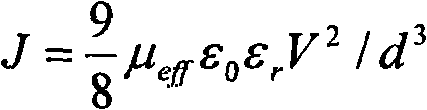

[0015] The method for preparing an organic light-emitting device by the cluster evaporation method proposed in the present invention adopts a boron nitride crucible 3 in the vacuum chamber 5 as a nanocluster film preparation device, and the boron nitride crucible 3 has a cylindrical appearance and is divided into an upper cover. 7 and the two parts of the lower cavity, the upper and lower parts are tightly connected together by the thread 6, and the metal sheet 8 is located between the cover 7 and the lower cavity, so that the entire crucible has good airtightness, and the steam cannot leak from the gap, nitrogen A small hole 1 is opened on the top of the boron crucible 3, and the top of the small hole 1 is facing the substrate 2 on the vacuum chamber 5; using ITO and Al as electrodes, electrons and holes recombine to emit light under the actio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com