Refining method of isopropenyl acetate

A technology of propylene acetate and a refining method, applied in the field of rectification, can solve problems such as inability to meet large-scale continuous production, inability to achieve high product purity, poor product quality repeatability, etc., and to overcome low production capacity and reduced energy consumption. , The effect of large operation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

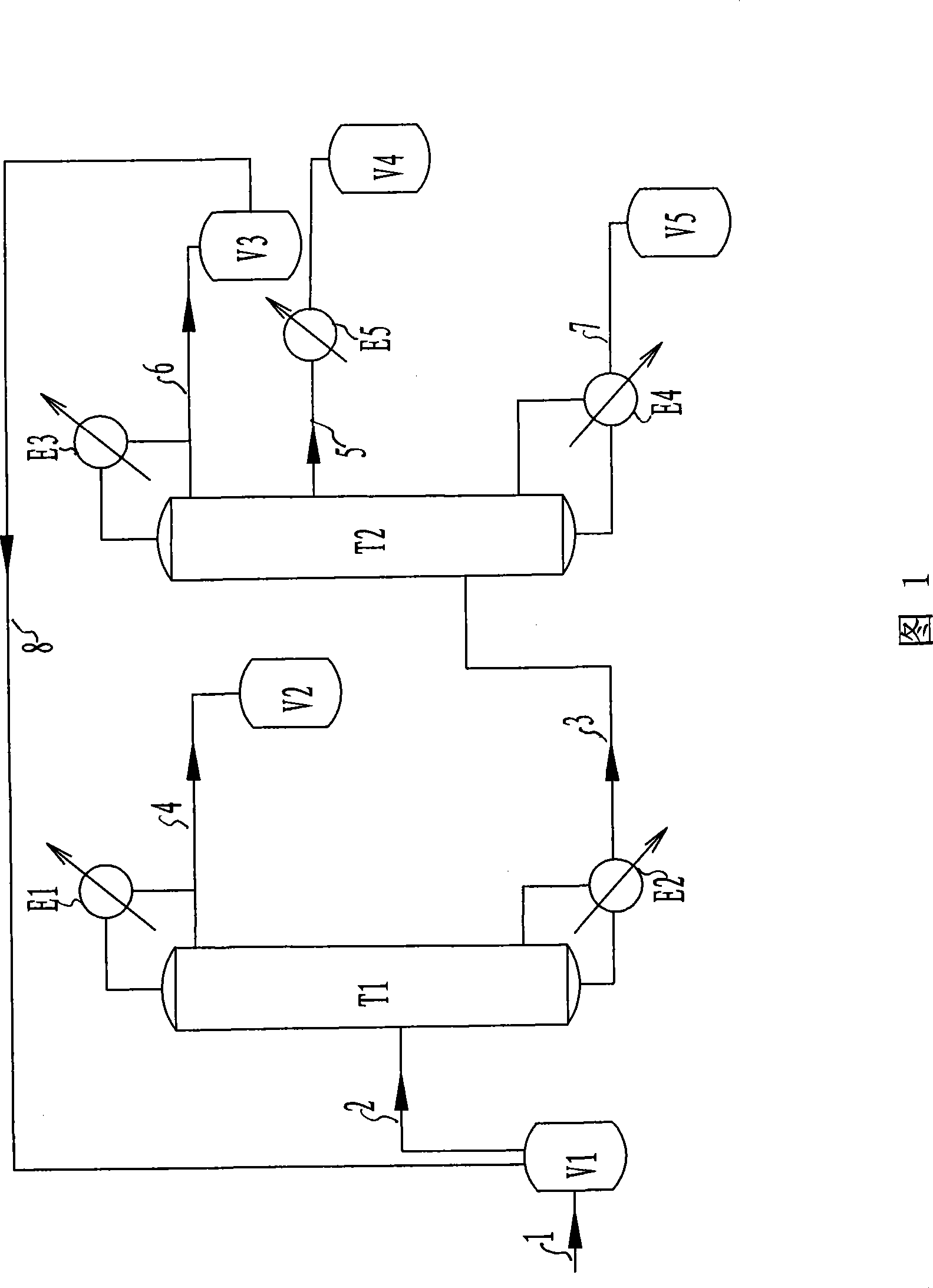

Image

Examples

Embodiment 1

[0031] The composition of crude isopropenyl acetate is: 70wt% isopropenyl acetate, 20wt% acetone, 5wt% acetic acid and 5wt% acetic anhydride. The operating conditions are:

[0032] (1) The first distillation tower, 55 theoretical plates, reflux ratio 4, tower top 10kPa (atmospheric pressure), tower bottom temperature 104℃, tower top temperature 60℃, tower bottom control acetone content 0.1%, feed position It is the 25th plate from the top of the tower;

[0033](2) The second distillation tower, 55 theoretical plates, reflux ratio 4, tower top pressure is -60kPa gauge pressure, tower bottom temperature is 101℃, tower top temperature is 70℃, and the feed position is calculated from the top of the tower On the 35th tray, the position where isopropylene acetate is extracted from the liquid phase side line of the rectifying section of the rectification tower is the 10th tray, and the temperature of the side line for extracting isopropylene acetate is 75°C.

[0034] After analysis, the ...

Embodiment 2

[0036] The composition of crude isopropenyl acetate is 70wt% isopropenyl acetate, 20wt% acetone, 5wt% acetic acid and 5wt% acetic anhydride, and the operating conditions are:

[0037] (1) The first distillation tower, 55 theoretical plates, reflux ratio 4, tower top 10kPa (atmospheric pressure), tower bottom temperature 96℃, tower top temperature 56℃, tower bottom control acetone content 1%, feed position It is the 25th plate from the top of the tower;

[0038] (2) The second distillation tower, 55 theoretical plates, reflux ratio 4, tower top pressure is -60kPa gauge pressure, tower bottom temperature is 101℃, tower top temperature is 70℃, and the feed position is calculated from the top of the tower On the 35th tray, the position where isopropylene acetate is extracted from the liquid phase side line of the rectifying section of the rectification tower is the 10th tray, and the temperature at which the isopropylene acetate is extracted from the side line is 75°C.

[0039] After ...

Embodiment 3

[0041] The composition of crude isopropenyl acetate is 70wt% isopropenyl acetate, 20wt% acetone, 5wt% acetic acid and 5wt% acetic anhydride, and the operating conditions are:

[0042] (1) The first rectification tower, 55 theoretical plates, reflux ratio of 4, tower top 10kPa (atmospheric pressure), tower bottom temperature of 92℃, tower top temperature of 56℃, tower bottom control acetone content of 4% , The feed position is the 25th tray from the top of the tower;

[0043] (2) The second rectification tower, 55 theoretical plates, reflux ratio of 5, top pressure of gauge pressure -60kPa, bottom temperature of 101℃, top temperature of 69℃, the feed position is from the top of the tower Counting from the 35th tray, the position where isopropenyl acetate is extracted from the liquid phase side line of the rectification tower is the 10th tray, and the temperature of the side line to extract isopropenyl acetate is 75 ℃.

[0044] After analysis, the acetone content obtained from the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com