Ethanolamine distilling process added with gas purification topping section

A technology of ethanolamine and head stage, which is applied in the field of distillation technology, can solve the problems of large number of plates, high temperature of tower kettle, discoloration of TEA, etc., and achieve the effect of improving processing capacity, reducing temperature of tower kettle and improving quality

Active Publication Date: 2010-05-26

吴兆立 +1

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

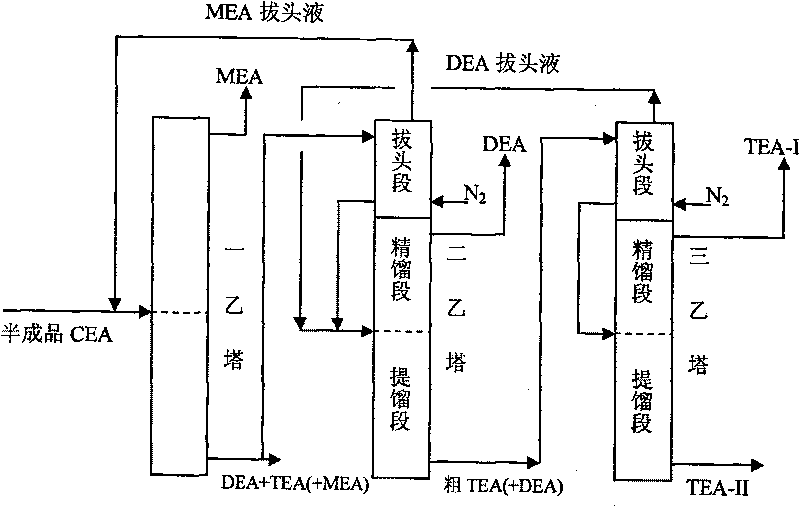

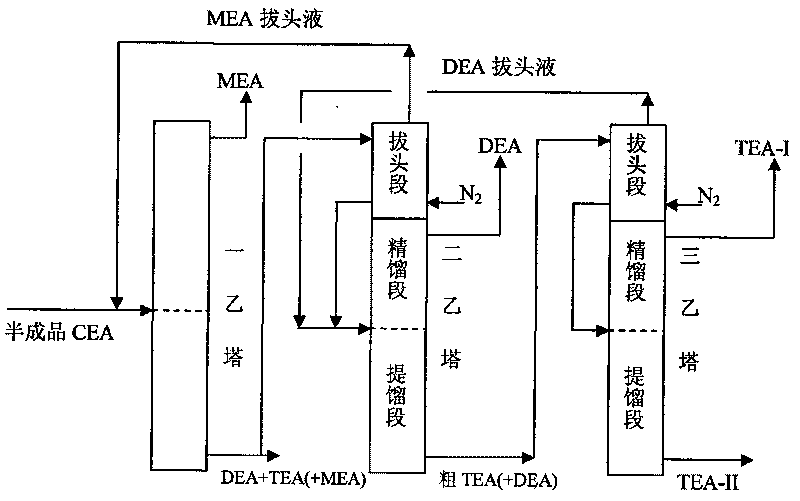

[0007] 1. All MEA must be evaporated from the top of the tower as a product in the first tower, so that the bottom liquid of the first tower (as the feed of the second tower) does not contain MEA at all, otherwise MEA will enter the second tower and Affect the quality of diethyl tower DEA products

However, it is required that the bottom liquid of the first tower does not contain MEA at all, and the number of plates of the first tower must be more, and the temperature of the bottom of the tower is higher, which is unfavorable for improving the efficiency and product quality of the second tower.

[0008] 2. The diethyl tower must distill all the DEA products from the top of the tower, otherwise it will affect the quality of the top product TEA-I of the triethyl tower

In addition, the temperature of the diethyl tower is too high, which will discolor TEA, reduce the quality of TEA-I, and increase the proportion of low-priced TEA-II, which is not expected to happen.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment a

[0032] Example a: Using nitrogen (N2) as the gas for stripping;

Embodiment b

[0033] Example b: Argon (Ar) is used as the gas for stripping;

Embodiment c

[0034] Example c: Using hydrogen (H2) as the gas for gas stripping;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to a vacuum forming technology for the distillation of the chemical materials in the medium and low vacuum, aiming to provide a technology for the vacuum distillation anddehydration of the reaction products in the triethanolamine production. The distillate jetting vacuum distillation technology of the present invention uses the distillate of the vacuum distillation tower as the jetting medium; the jetting medium passes through the vacuum pump and becomes the vacuum source of the vacuum distillation tower. The beneficial effects of the present invention are: the distillate and the jetting medium are the same material; the problem caused by the entering of the distillate into the jetting medium is not needed to be considered; particularly when the water with asmall amount of the ammonia vacuum distilled from the reaction products of the triethanolamine is used as the jetting medium, the present invention is more suitable. The dilute ammonia liquid of the distillate can enter the jetting medium and can return into the reaction system to maintain the water balance.

Description

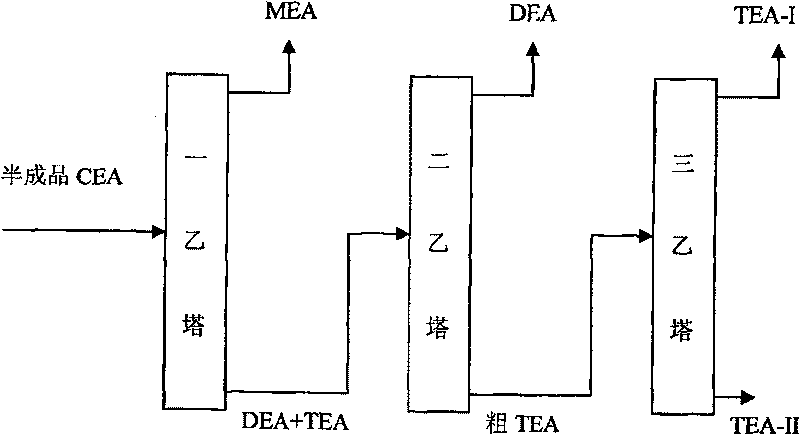

Technical field [0001] The invention relates to the distillation and separation of semi-finished product mixed ethanolamine (CEA) into monoethanolamine (MEA), diethanolamine (DEA), triethanolamine first-class product (TEA-I) and triethanolamine second-class product (TEA-II) in the production of ethanolamine Distillation process. More specifically, the present invention relates to a method of ethanolamine distillation with additional gas-lifting heads. Background technique [0002] In the production of ethanolamine, the semi-finished product mixed with ethanolamine (CEA) that has been deaminated and dehydrated must undergo a few steps of vacuum distillation to convert monoethanolamine (MEA), diethanolamine (DEA), first grade triethanolamine (TEA-I) and triethanolamine Purification and separation of four products of secondary product (TEA-II). The current production process uses three vacuum distillation towers, namely a B tower, a B tower and a B tower, to achieve the purpose of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C07C215/12C07C213/10

Inventor 吴兆立

Owner 吴兆立

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com