Method for separating high-purity phenazine from chemical product production waste

A technology for the production of waste and chemical products, applied in the purification/separation of amino compounds, can solve the problems of waste incineration, complex synthesis process, environmental pollution, etc., and achieve the goal of reducing the temperature of the tower and kettle, high separation efficiency, and guaranteed performance indicators Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

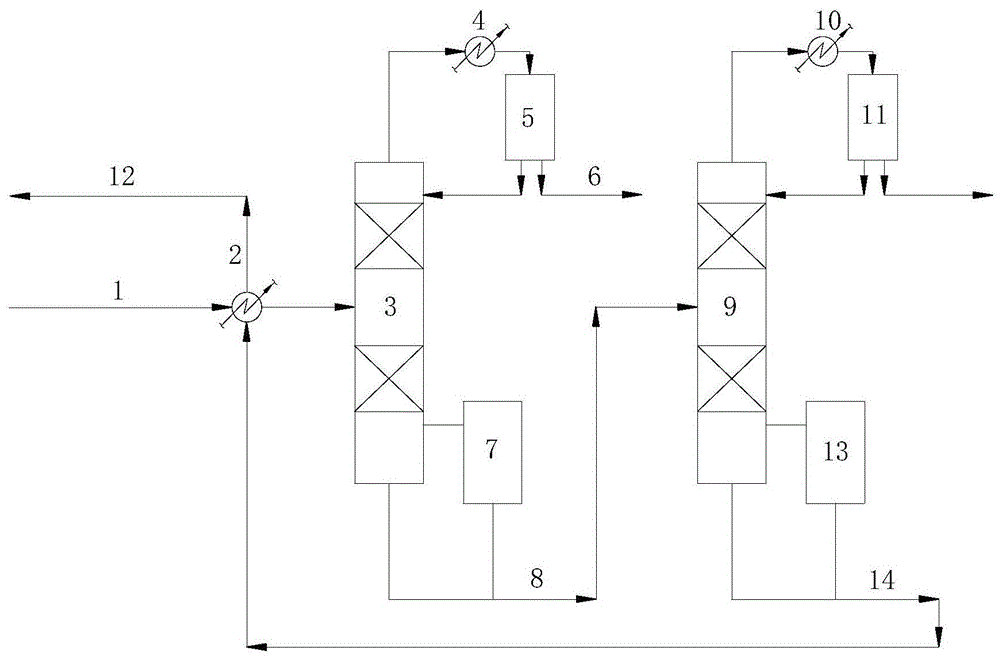

Image

Examples

Embodiment 1

[0024] Purification of raw materials containing phenazine at a rate of 6000 kg per hour, the feed composition is as follows: 55% aniline, 6% phenazine, 1.5% azobenzene, and 37.5% 4-aminodiphenylamine.

[0025] Operating conditions of each tower in the process flow

[0026] light tower Weight removal tower tower type packed tower packed tower Tower diameter(mm) 2600 1200 packing type Stainless steel wire mesh structured packing Stainless steel wire mesh structured packing Theoretical progression 20 30 Operating pressure at the top of the tower (absolute pressure) / Kpa 1 1 Bottom operating temperature / °C 214 217 Reflux ratio 2 8

[0027] Note: The temperature of the raw material entering the tower after heat exchange is 105°C

[0028] The main indicators of the phenazine product produced under the above-mentioned process conditions are as follows:

[0029] main indicators Product purity 99.5...

Embodiment 2

[0031] Purification of raw materials containing phenazine at a rate of 6000 kg per hour, the feed composition is as follows: 50% aniline, 8% phenazine, 1% azobenzene, and 41% 4-aminodiphenylamine.

[0032] Operating conditions of each tower in the process flow

[0033] light tower Weight removal tower tower type packed tower packed tower Tower diameter(mm) 2600 1200 packing type Stainless steel plate corrugated structured packing Stainless steel plate corrugated structured packing Theoretical progression 30 40 Operating pressure at the top of the tower (absolute pressure) / Kpa 3 3 Bottom operating temperature / °C 232 236 Reflux ratio 4 9

[0034] Note: After the heat exchange of raw materials, the temperature of entering the tower is 115°C

[0035] The main indicators of the phenazine product produced under the above-mentioned process conditions are as follows:

[0036] main indicators Produ...

Embodiment 3

[0038] Purification of raw materials containing phenazine with a processing capacity of 6000 kg per hour, the feed composition is as follows: 47.4% of aniline, 10% of phenazine, 0.6% of azobenzene, and 42% of 4-aminodiphenylamine.

[0039] Operating conditions of each tower in the process flow

[0040] light tower Weight removal tower tower type packed tower packed tower Tower diameter(mm) 2600 1200 packing type Stainless steel wire mesh structured packing Stainless steel wire mesh structured packing Theoretical progression 40 50 Operating pressure at the top of the tower (absolute pressure) / Kpa 10 6 Bottom operating temperature / °C 262 253 Reflux ratio 6 10

[0041] Note: After the heat exchange of raw materials, the temperature of entering the tower is 125°C

[0042] The main indicators of the phenazine product produced under the above-mentioned process conditions are as follows:

[0043] main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com