Conductive polymer hydrogel as well as preparation method and application thereof

A conductive polymer and hydrogel technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of inability to guarantee the electrical properties of polyaniline gel, and achieve improved cycle stability, simple preparation method, The effect of improving self-discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Electrode preparation: The positive electrode sheet was prepared on the surface of the aluminum foil by using water as a solvent coating method. The polyacrylic acid / polyaniline gel active material: conductive acetylene black is dispersed in a mixed solvent of water and alcohol, and ground evenly to form a viscous coating on a clean aluminum foil, and then dried in a vacuum oven.

[0032] Further, the mass composition of the electrode material is: active material polymer gel:conductive agent acetylene black=2~8:2~5, preferably 5~7:3~4.

[0033] Battery assembly: adopt conventional battery assembly process. Specifically, the CR2032 battery device system was used to test the electrochemical performance and charge and discharge performance of the battery. Lithium is used as the negative electrode and reference electrode, and the electrolyte is 1 M LiPF 6 EC:DMC =1:1 (v / v) solution, the diaphragm is a polypropylene microporous membrane (Celgard 2300) used in industrializa...

Embodiment 1

[0036] Preparation of polyacrylic acid / polyaniline conductive polymer gel

[0037] At room temperature, dissolve 15 g of acrylic acid monomer, 0.4656 g of aniline monomer, and 0.0308 g of cross-linking agent in 50 ml of distilled water to form aniline acrylate (such as figure 1 ) mixed solution. The mixture was stirred evenly and placed at 50 o Heat and stir in a C water bath, add dropwise 10 ml of a solution containing 0.5705 g of initiator ammonium persulfate, and react with stirring for 1 h under the protection of inert argon. The reaction polymer gel is precipitated with a large amount of acetone, filtered, washed and dried to obtain a polyacrylic acid / polyaniline hydrogel product.

Embodiment 2

[0039] Electrode preparation and battery assembly

[0040] (1) Preparation of electrodes. Electrode sheets were prepared on the surface of aluminum foil by coating method. Dissolve active material polymer powder: conductive agent acetylene black = mass ratio 7:3 in water to form a viscous liquid. Then the liquid was coated on a clean aluminum foil with a 90 nm spatula, and then at 60 o C and dried under vacuum until the quality of the film remained unchanged.

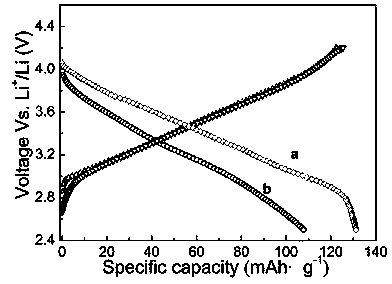

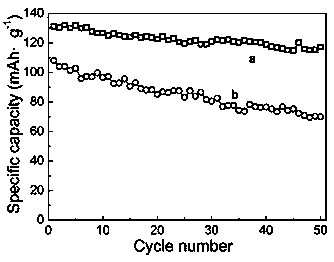

[0041] (2) Assembly of the battery. In this paper, the CR2032 battery device system is mainly used to test the electrochemical performance and charge and discharge performance of the battery. Lithium is used as the negative electrode and reference electrode, the electrolyte is 1 M LiPF6 EC:DMC =1:1 (v / v) solution, the diaphragm is industrially used polypropylene microporous membrane (Celgard 2300), the electrode prepared before As the positive electrode, a CR2032 simulated half-cell was assembled in an argon atmosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com