Polyimide composite film with electromagnetic shielding function and preparation method thereof

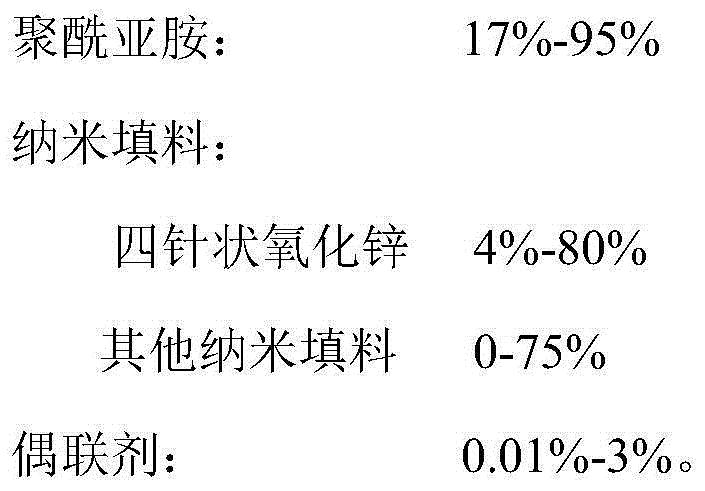

A technology of polyimide and composite film, which is applied in the field of electromagnetic shielding film and its preparation through composite modification of polyimide by nano-filling, can solve the problems of large coating thickness and restricted application fields, and achieve uniform performance, The effect of implementing mild conditions and increasing the fill factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] First, 41.647 g of tetraacicular zinc oxide (T-ZnOw) was weighed and placed in a vacuum oven at a constant temperature of 105° C. for 8 hours. Then put it into 89.0213g of DMAc, add 1.5617g of coupling agent KH550 at the same time, ultrasonically stir at 10°C for 10min, and the ultrasonic frequency is 20KHz. Add 4.2359g ODA, continue to stir ultrasonically, the ultrasonic frequency is 20KHz, the temperature is controlled at 10°C, after it is completely dissolved, add 4.6141g of dianhydride monomer PMDA in an equimolar amount to ODA in 3 batches, and the ultrasonic frequency is 20KHz, the temperature is controlled Stir continuously at 10° C. for 4 h to form a homogeneous phase, and prepare 141.08 g of a PAA / T-ZnOw-ZnO composite solution with a solid content of 37%.

[0037] Coat the composite solution on a glass plate, put it into a vacuum oven and raise the temperature step by step at a rate of 2.5°C / min (100°C×40min, 220°C×30min, 320°C×30min), dehydration and cyclizati...

Embodiment 2

[0039] First, 0.774 g of tetraacicular zinc oxide (T-ZnOw) and 0.1915 g of silver oxide (AgO) were weighed and placed in a vacuum oven at a constant temperature of 100° C. for 6 hours. Then put it into 77.4g DMAc, add 0.002g coupling agent KH560 at the same time, stir ultrasonically at 15°C for 15min, and ultrasonic frequency is 40KHz. Add 8.8016g of BAPB, continue to stir ultrasonically, the ultrasonic frequency is 40KHz, and the temperature is controlled at 15°C. After it is completely dissolved, add a total of 9.5787g of dianhydride monomer BPDA with a molar ratio of 1.05:1 to BAPB in 5 batches. 40KHz, temperature controlled at 15°C, continuous stirring for 3h to form a homogeneous phase, and 96.739g of a PAA / T-ZnOw-AgO composite solution with a solid content of 20% was obtained.

[0040] Coat the composite solution on a glass plate, put it into a vacuum oven to raise the temperature step by step, the heating rate is 2°C / min (120°C×40min, 180°C×40min, 280°C×40min), dehydrat...

Embodiment 3

[0042] First, 55.2 g of tetraacicular zinc oxide (T-ZnOw), 6.9 g of granular zinc oxide (ZnO) and 6.9 g of nickel oxide (NiO) were weighed and placed in a vacuum oven at a constant temperature of 105° C. for 6 h. Then put it into 134.7714g DMF, add 0.6g coupling agent KH560 at the same time, stir ultrasonically at 20°C for 18min, ultrasonic frequency 60KHz. Add 7.618g of MDA, continue to stir ultrasonically, the ultrasonic frequency is 60KHz, and the temperature is controlled at 20°C. After it is completely dissolved, add 12.6296g of dianhydride monomer BTDA with a molar mass ratio of 1.02:1 to MDA in 7 batches. The frequency was 60KHz, the temperature was controlled at 20°C, and the mixture was continuously stirred for 3.5h to form a homogeneous phase, and 224.619g of a PAA / T-ZnOw-ZnO-NiO composite solution with a solid content of 40% was prepared.

[0043] Coat the composite solution on a stainless steel casting plate, put it into a vacuum oven to raise the temperature step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com