P-zn1-xmgxo crystal film and method for making same

A technology of p-zn1-xmgxo and thin film, which is applied in the field of p-type doped Zn1-xMgxO crystal thin film and its preparation, can solve the problems affecting the application of ZnO-based crystal thin film, and achieve easy control of deposition parameters, low growth temperature, good film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

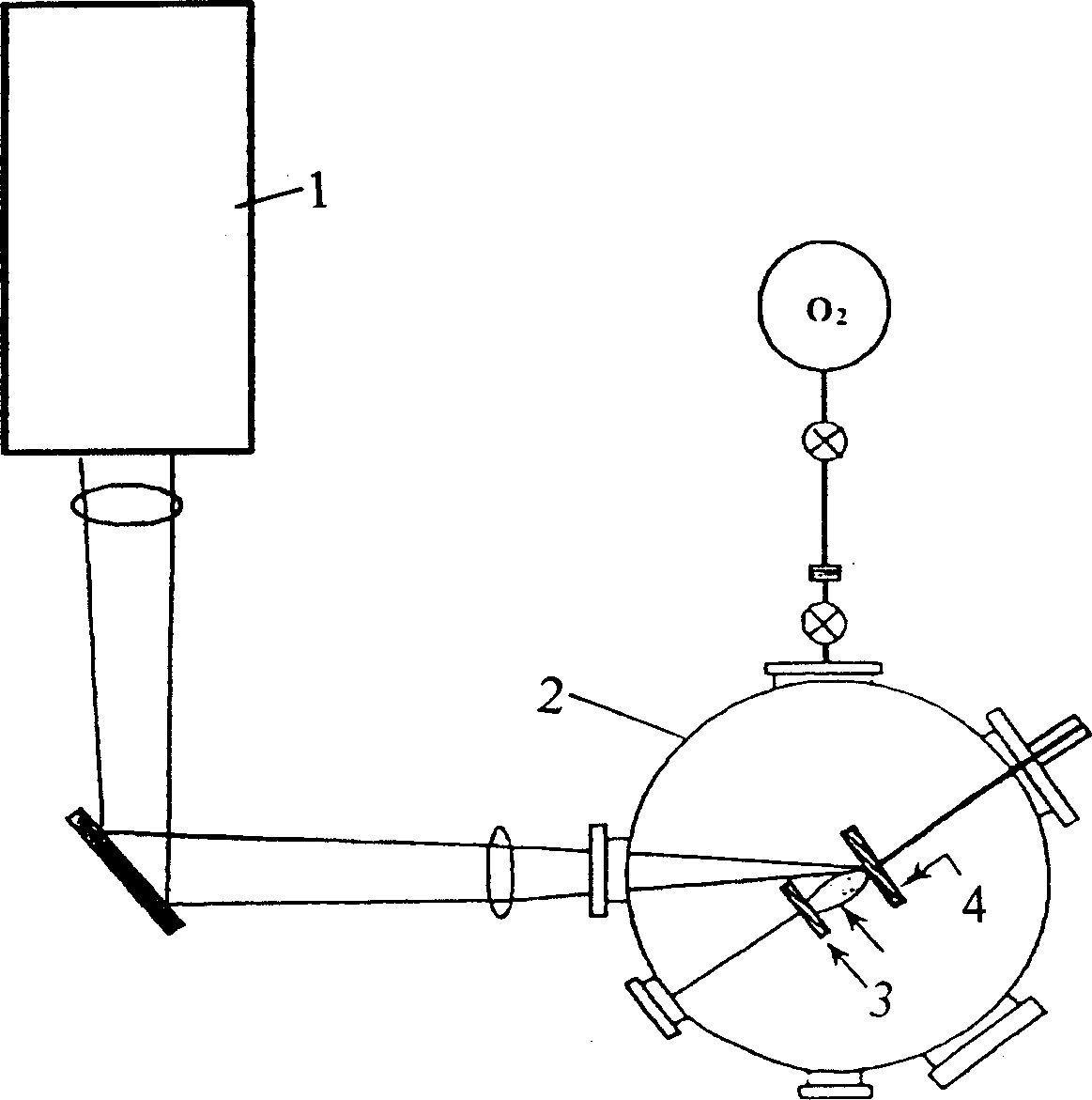

Method used

Image

Examples

Embodiment

[0019] Example: with Al 2 o 3 is the donor dopant, N 2 O is the acceptor doping source, and p-Zn is grown on the silicon wafer as the substrate 1-x Mg x O film. Specific steps are as follows:

[0020] 1) Sintering of ceramic targets: Weigh high-purity ZnO, MgO and Al with a purity >99.99% 2 o 3 powder, so that the molar ratio of MgO to ZnO is 1:4, Al 2 o 3 The molar content is 0.5%. The weighed ZnO, MgO and Al 2 o 3 The powder is mixed and poured into a ball mill jar equipped with agate balls, and milled on a ball mill for 20 hours. The purpose is to mix the raw materials evenly and refine them to a certain extent, so as to facilitate the forming and sintering of ceramic targets. Then the raw materials are separated and dried, added with a binder for grinding, and pressed into shape. Finally, put the formed embryo into the sintering furnace, discharge elements at low temperature (200-400°C) to volatilize the binder, and then heat up to 800-1200°C for 3 hours to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com