Method for preparing lanthanum-doped bismuth titanate nano powder by sol-gel hydrothermal method

A sol-gel, nano-powder technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve the effects of reducing production costs, simple equipment and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

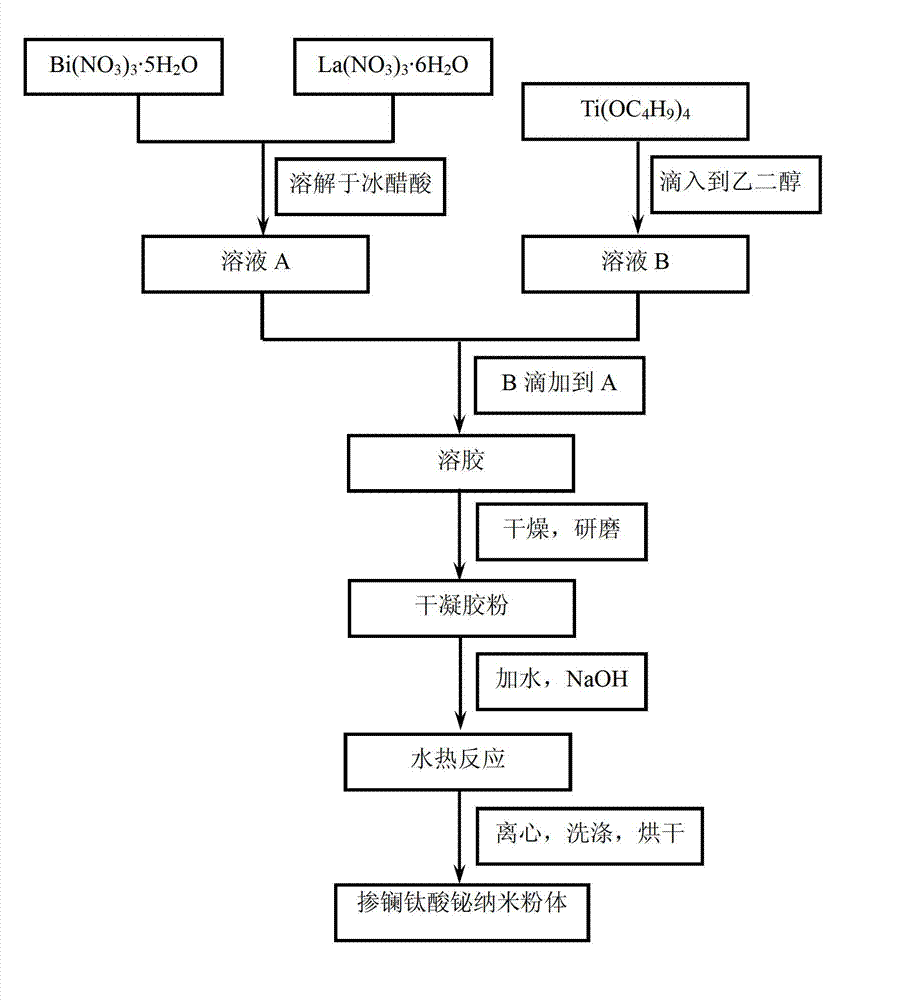

[0033] Such as figure 1 As shown, the Bi of this embodiment 3.25 La 0.75 Ti 3 o 12 The preparation process includes the following steps:

[0034] According to Bi 3.25 La 0.75 Ti 3 o 12 Chemical formula, weigh analytically pure Bi(NO 3 ) 3 ·5H 2 O, La(NO 3 ) 3 ·6H 2 O and Ti(OC 4 h 9 ) 4 . First, the weighed Bi(NO 3 ) 3 ·5H 2 O and La(NO 3 ) 3 ·6H 2 O was dissolved in 20ml of glacial acetic acid solution, stirred by magnetic force for 10min, to obtain uniform solution A, the molar concentration of metal ions in solution A was 1mol / L; 4 h 9 ) 4 Add the solution dropwise to 20ml of ethylene glycol solution at a titration rate of 15mL / min, and stir it magnetically for 5min to obtain a uniform solution B; then add solution B dropwise to solution A at a titration rate of 3mL / min, and pass Stir magnetically for 2 hours to prepare a uniform sol; then dry the sol in an oven at 85° C. to obtain a xerogel, and grind to obtain a xerogel powder, that is, a hydroth...

Embodiment 2

[0039] According to Bi 3.25 La 0.75 Ti 3 o 12 Chemical formula, weigh analytically pure Bi(NO 3 ) 3 ·5H 2 O, La(NO 3 ) 3 ·6H 2 O and Ti(OC 4 h 9 ) 4 . First, the weighed Bi(NO 3 ) 3 ·5H 2 O and La(NO 3 ) 3 ·6H 2 O was dissolved in 20ml of glacial acetic acid solution, stirred by magnetic force for 10min to obtain uniform solution A, the molar concentration of metal ions in solution A was 2mol / L; 4 h 9 ) 4 The solution was added dropwise to a mixture of 20ml ethylene glycol methyl ether and acetylacetone (15ml ethylene glycol methyl ether and 5ml acetylacetone), the titration rate was 20mL / min, and stirred by magnetic force for 5min to obtain a uniform solution B; Solution B was added dropwise to solution A at a titration rate of 4mL / min, and stirred by magnetic force for 2 hours to form a uniform sol; then the sol was dried in an oven at 90°C to obtain a xerogel, which was ground to obtain a xerogel Rubber powder, namely the precursor of hydrothermal react...

Embodiment 3

[0041] According to Bi 3.5 La 0.5 Ti 3 o 12 , weigh the analytically pure Bi(NO 3 ) 3 ·5H 2 O, La(NO 3 ) 3 ·6H 2 O and Ti(OC 4 h 9 ) 4 . First, the weighed Bi(NO 3 ) 3 ·5H 2 O and La(NO 3 ) 3 ·6H 2 O is dissolved in the glacial acetic acid solution of 25ml, by magnetic stirring 10min, obtains uniform solution A, the molar concentration of metal ion in the solution A is 1.5mol / L; 4 h 9 ) 4 Add the solution dropwise into 25ml of ethylene glycol solution at a titration rate of 15mL / min, and stir it magnetically for 5 minutes to obtain a uniform solution B; then add solution B dropwise to solution A, and stir it magnetically for 2 hours to form a uniform The sol; then the sol was dried in an oven at 85°C to obtain a xerogel, which was ground to obtain a xerogel powder, that is, a hydrothermal reaction precursor. Put the hydrothermal reaction precursor into a hydrothermal kettle, add pure water as a solvent, and 6mol / L NaOH as a mineralizer, and the filling deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com