Coating slurry, preparation method thereof, and composite porous diaphragm and lithium ion battery prepared by applying coating slurry

A porous and slurry technology, applied in the field of lithium ion batteries and composite porous diaphragms, can solve the problem of flame retardant and explosion-proof safety performance affecting the capacity, charge and discharge cycle life of lithium batteries, lack of mechanical strength of organic coatings, and reduced lithium ion conductivity. and other problems, to achieve the effect of improving high temperature thermal stability, good thermal shrinkage resistance, and ensuring mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

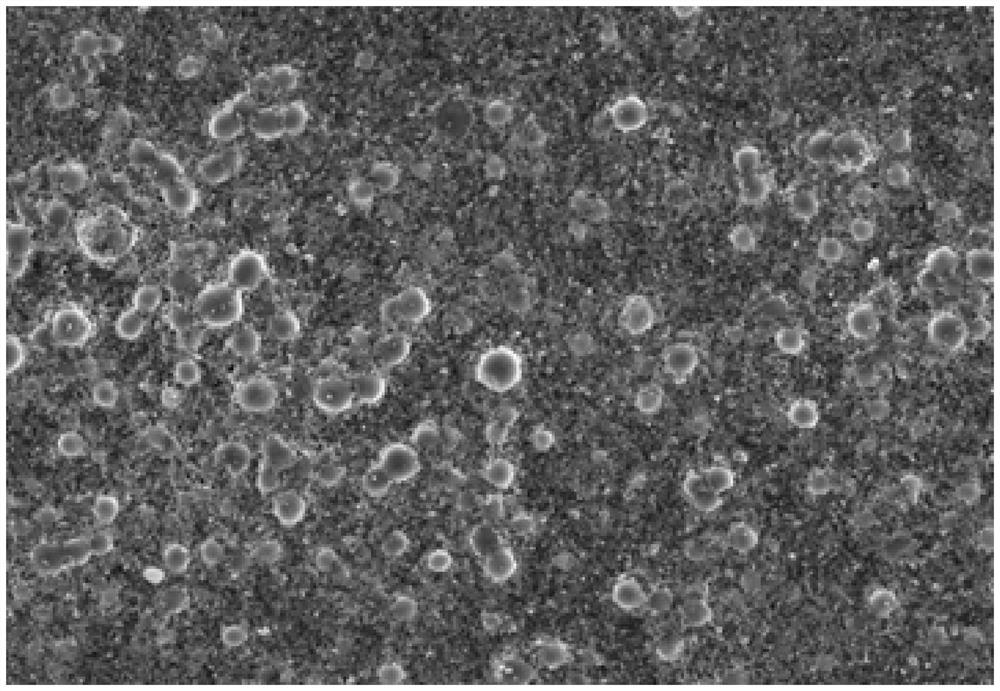

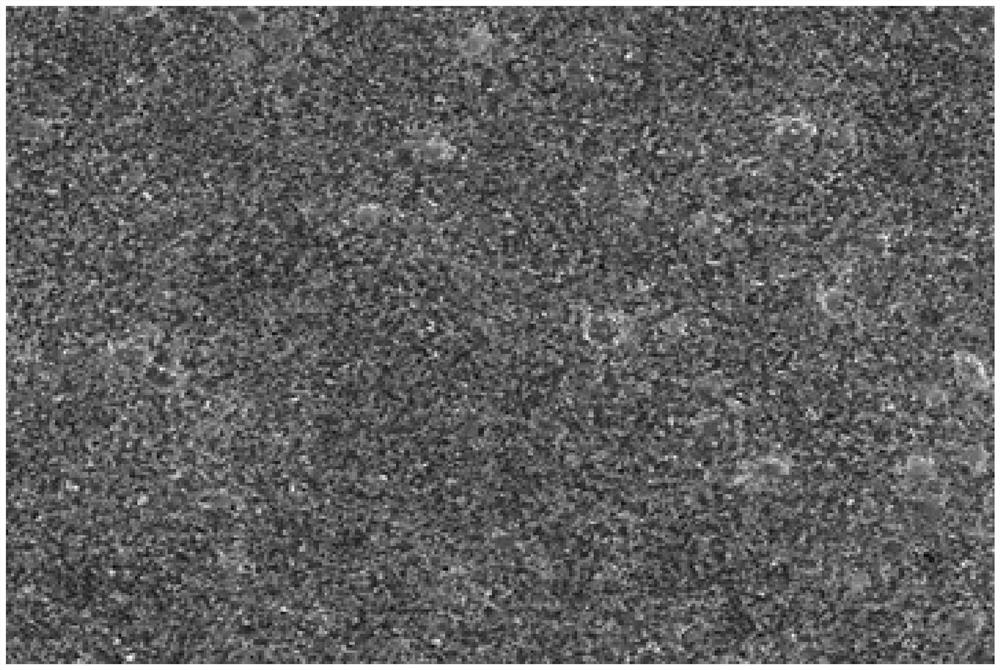

Image

Examples

Embodiment 1

[0049] Preparation of coating slurry:

[0050] Preparation of preparatory materials: In this application, Al2O3 is represented, other inorganic ceramic materials, such as SiO 2 , γ-AlOOH, BaSO 4 , CaO, TiO 2 , ZnO 2 , MgO, ZrO 2 , SnO 2 The same applies to this application. Weigh 100g of aluminum oxide particles with a particle size D50 of 0.4um and 50g of polyvinylidene fluoride powder polymerized from hexafluoropropylene and vinylidene fluoride, with a degree of polymerization of 4% and a melting temperature of 130°C, and mix until uniform , then add 100g of deionized water, put it into a blender and stir at a low speed, the stirring rate is 100r / min, stir and knead until viscous to get the preparation;

[0051] Thickening solution preparation: Weigh 60g of sodium carboxymethyl cellulose, add 700g of deionized water, stir for 15 minutes to fully dissolve it, and obtain a thickening solution;

[0052] The first step is to mix the preparatory material with the thickenin...

Embodiment 2

[0059] Preparation of coating slurry

[0060] Preparatory material preparation: Weigh 160g of aluminum oxide particles with a particle size D50 of 0.4um and polyvinylidene fluoride powder polymerized from hexafluoropropylene and vinylidene fluoride with a polymerization degree of 4% and a melting temperature of 150°C 90g, mix until uniform, then add 200g of deionized water, put it into a mixer for low-speed stirring, the stirring rate is 80r / min, stir and knead until viscous to get the preparation;

[0061] Thickening solution preparation: Weigh 95g of sodium carboxymethyl cellulose, add 600g of deionized water, stir for 20min to fully dissolve it, and obtain a thickening solution;

[0062] The first step is to mix the preparatory material with the thickening solution, stir, and control the rotation speed at 1000r / min, and stir for 1.5h to obtain the premixed material;

[0063] In the second step, add 33g of polyacrylate to the premixed material obtained in the first step, co...

Embodiment 3

[0068] Preparation of coating slurry:

[0069] Preparatory material preparation: Weigh 200g of aluminum oxide particles with a particle size D50 of 0.4um and polyvinylidene fluoride powder polymerized from hexafluoropropylene and vinylidene fluoride with a degree of polymerization of 4% and a melting temperature of 150°C 120g, mix until uniform, then add 300g of deionized water, put it into a mixer for low-speed stirring, the stirring rate is 50r / min, stir and knead until viscous to get the preparation;

[0070] Thickening solution preparation: weigh 120g of sodium carboxymethyl cellulose, add 300g of deionized water, stir for 30min to fully dissolve it, and obtain a thickening solution;

[0071] The first step is to mix the preparatory material with the thickening solution, stir, and control the rotation speed at 1000r / min, and stir for 2 hours to obtain the premixed material;

[0072] In the second step, add 60g of polyacrylate to the premixed material obtained in the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com