Method and device for preparing battery pole piece

A technology for battery pole pieces and preparation devices, which is applied in electrode manufacturing, devices for coating liquid on the surface, special surfaces, etc., and can solve the problems of low micro-short circuit rate of self-discharge performance, poor self-discharge performance of batteries, and high micro-short circuit rate , achieve low micro-short circuit rate, good self-discharge performance, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

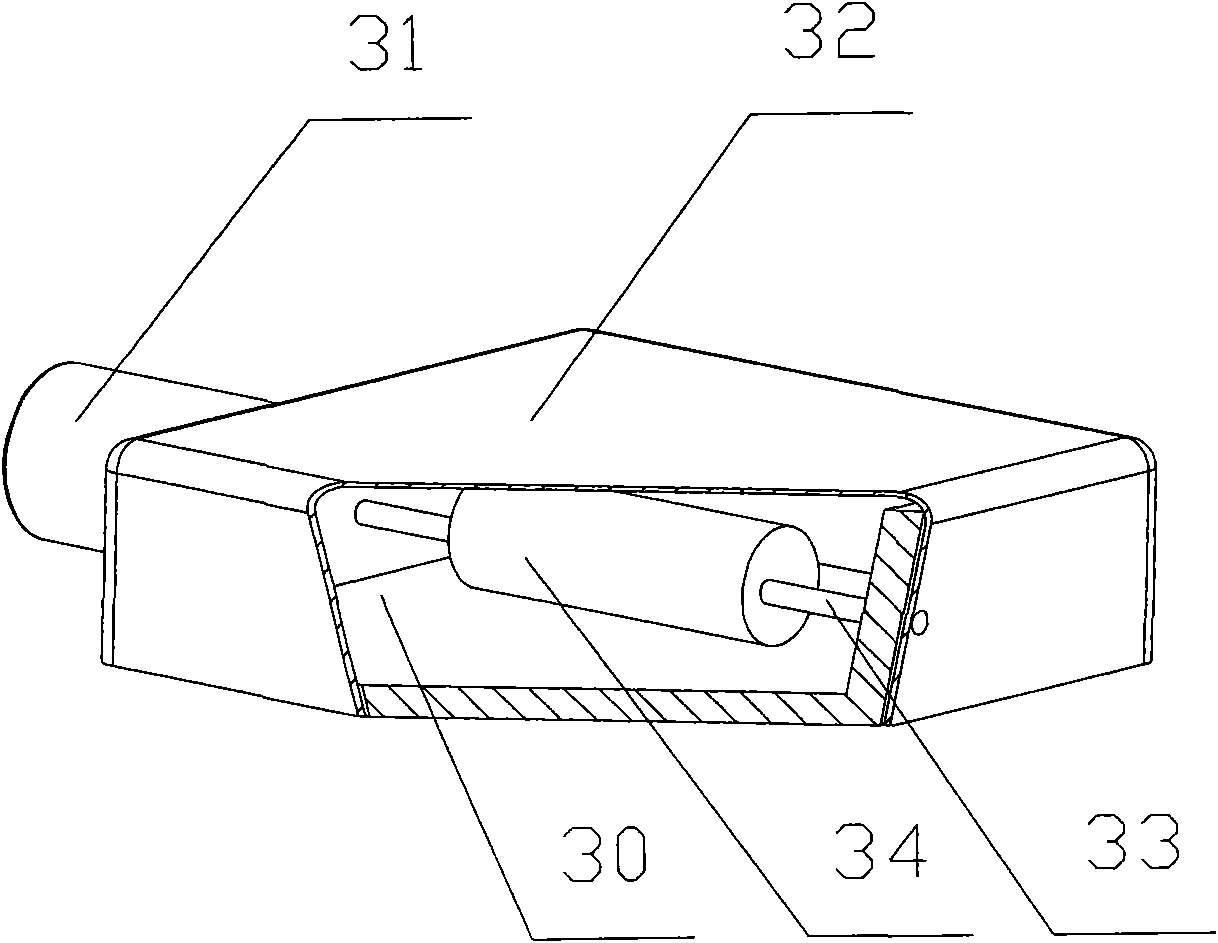

[0029] According to another embodiment, the vibration generating device in the vibration device 3 is externally connected with the vibration box 30, that is, the vibration device 3 includes a motor 31, an eccentric wheel 34 and a vibration input shaft (not shown in the figure). ), preferably, the motor 31 and the eccentric wheel 34 can be integrated and connected to the vibration box 30 through a vibration input shaft. Therefore, the motor 31 is energized to drive the eccentric wheel 34 to vibrate, and the vibration is transmitted to the vibration input shaft through the vibration input shaft. The vibration box 30 transmits the vibration to the coating part 21 through the cover body 32. More preferably, the vibration input shaft can be connected with the cover body 32 of the vibration box 30 to directly transmit the vibration generated by the eccentric wheel 34. The vibration is transmitted to the cover body 32 , and then drives the coating part 21 on the cover body 32 to vibra...

Embodiment 1

[0051] This example is used to illustrate the device and method for preparing battery pole pieces provided by the present invention.

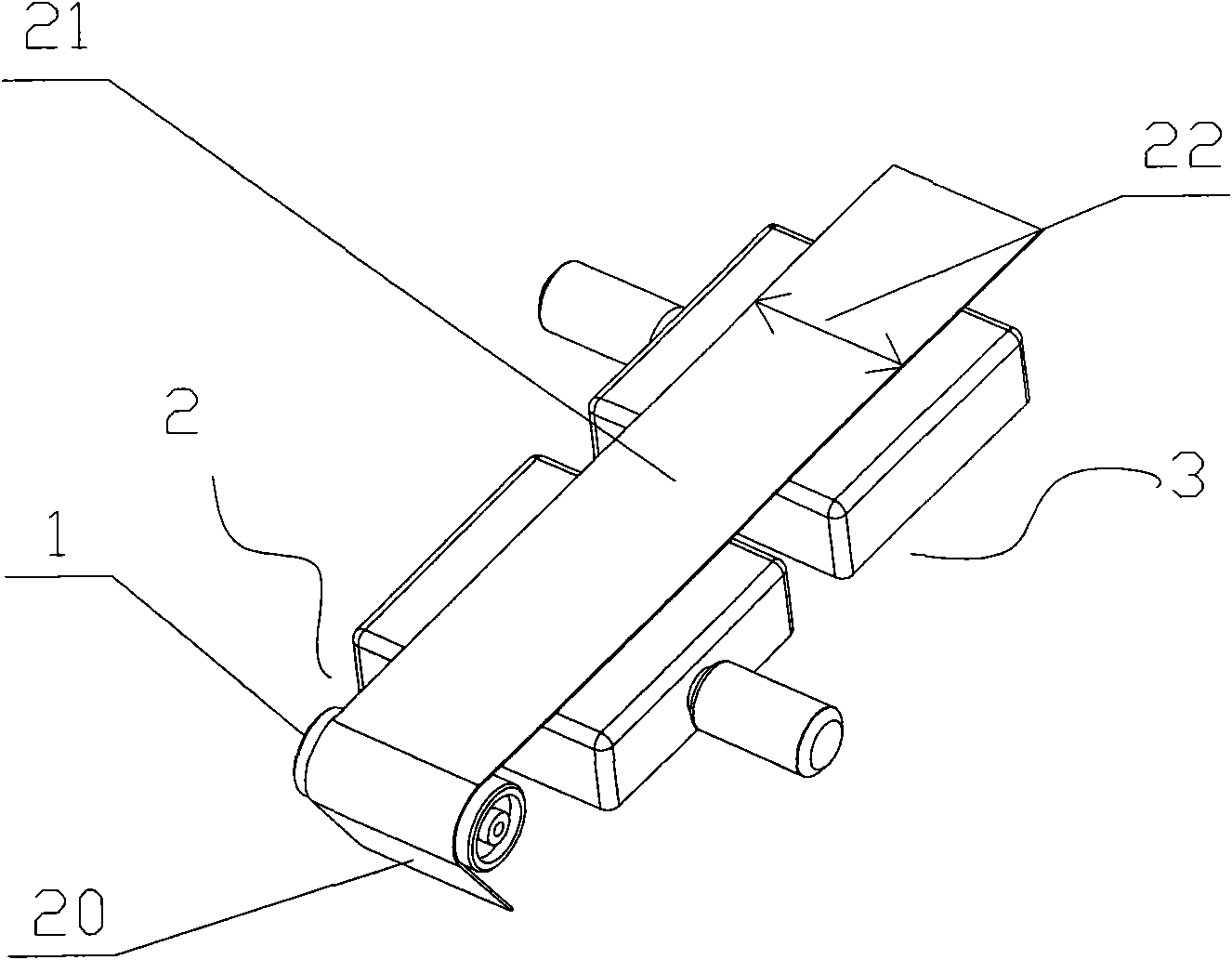

[0052] Apparatus for preparing battery pole pieces such as figure 1 and figure 2 shown. The vibrating device 3 includes five identical vibrating boxes 30 (produced by BYD: model LB-2008A vibrating device) arranged in sequence, wherein the distance between adjacent vibrating boxes 30 is 15 cm. The vibration box 30 includes a cover body 32, which is made of stainless steel and has a size of 100 cm (length)×50 cm (width)×17 cm (height).

[0053] The coating device includes a base wheel 1 and a coating wheel (not shown in the figure). The radius of the base wheel 1 is 100-200 mm, and the axial width is 400-600 mm. The shortest horizontal distance between the axial edge of the base wheel 1 and the outer edge of the vibration device 3 is 30 centimeters, and the center line of the vibration box 30 on the width passes through the midpoint of the b...

Embodiment 2

[0062] This example is used to illustrate the device and method for preparing battery pole pieces provided by the present invention.

[0063] According to the device and method described in Example 1 to prepare battery pole pieces, the difference is,

[0064] The number of the vibrating boxes 30 is three.

[0065] The above-mentioned electrode slurry was applied to one surface of the aluminum foil as the current collector 2 by a coating wheel at a linear speed of 2000 mm / min. The conveying speed of the current collector 2 is 2000 mm / min, and the coating part 21 also passes through the vibrating device 3 at a speed of 2000 mm / min, that is, the total time for the vibration of the coating part 21 is 1.5 minutes , the time interval between two adjacent vibrations is 0.075 minutes. Also, the frequencies of the vibrations to which the application portion 21 was subjected were 800 Hz, 700 Hz, and 600 Hz in order, and the amplitudes were 0.3 mm, 0.25 mm, and 0.20 mm in order.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com