Method for improving self discharge of super capacitor

A supercapacitor and self-discharge technology, which is applied in the field of electrochemistry, can solve problems such as hindering the promotion of supercapacitors, complex processes, and poor stability of supercapacitors, and achieve the effect of improving self-discharge performance and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

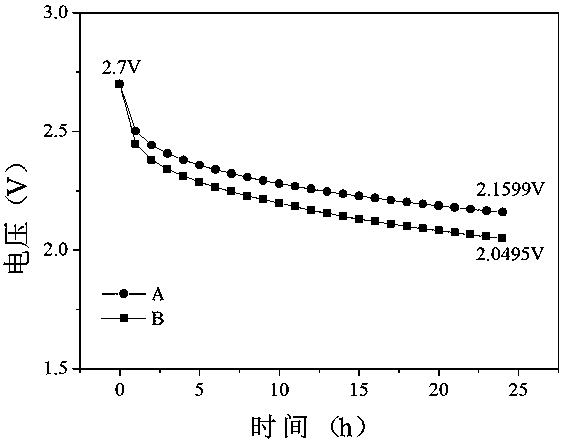

[0058] The first embodiment of the present invention provides a method for improving self-discharge of a supercapacitor. The method includes the following steps:

[0059] 1) Put the activated carbon electrode as the substrate into the vacuum reaction chamber of the atomic layer deposition equipment;

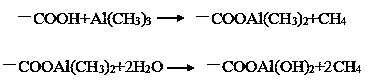

[0060] 2) Pass trimethyl aluminum vapor into the vacuum reaction chamber, and the trimethyl aluminum vapor reacts with the surface functional groups of the activated carbon electrode; the surface functional groups of the activated carbon electrode include carboxyl groups, carboxylic anhydrides, lactone groups, phenol groups, Quinone, ether and carbonyl; taking -COOH as an example, the reaction involved can be divided into the following two steps:

[0061]

[0062] 3) Use high-purity argon to flush the trimethylaluminum vapor that has not participated in the reaction and the byproducts produced by the reaction;

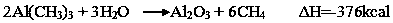

[0063] 4) Use trimethyl aluminum as aluminum source and use H 2 O is the oxy...

Embodiment 2

[0073] The second embodiment of the present invention provides a method for improving self-discharge of a supercapacitor. The method includes the following steps:

[0074] 1) Put the activated carbon electrode as the substrate into the vacuum reaction chamber of the atomic layer deposition equipment;

[0075] 2) Pour TiCl into the vacuum reaction chamber 4 Steam, TiCl 4 The steam reacts with the surface functional groups of the activated carbon electrode;

[0076] 3) Use high-purity argon to flush TiCl that has not participated in the reaction 4 Steam and by-products from the reaction;

[0077] 4) Take TiCl 4 As the titanium source, with H 2 O is the oxygen source, and the cyclic reaction is carried out as follows: pass TiCl 4 Vapor, atomic layer deposition; flush the unreacted TiCl with high-purity Ar gas 4 And by-products produced by the reaction; pass water vapor, water vapor and TiCl 4 The molecules of the vapor react to form TiO 2 Membrane; Use high-purity Ar gas to flush the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com