Method for preparing water-based super-nano lithium iron phosphate battery

A lithium iron phosphate battery, lithium iron phosphate technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of no improvement in low temperature resistance, and achieve the effects of improved bonding fastness, excellent low temperature, and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

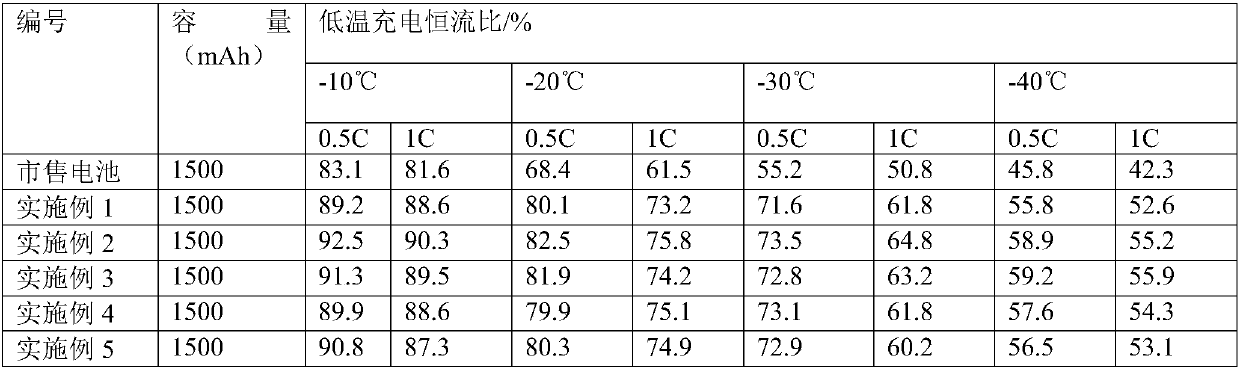

Examples

Embodiment 1

[0039] A method for preparing a water-based super nanometer lithium iron phosphate battery, said preparation method comprising the following steps:

[0040] (1) Preparation of positive and negative electrode slurry:

[0041] (1.1) Preparation of positive electrode slurry: sand-grind the lithium iron phosphate material to obtain lithium iron phosphate powder particles with D50≤4 μm, and then prepare it according to the formula: 90% of lithium iron phosphate powder particles, 5% of acetylene black and 5% styrene-butadiene emulsion was mixed and homogenized to obtain positive electrode slurry;

[0042] (1.2) Negative electrode slurry preparation: According to the formula: 89% of artificial graphite, 3% of carboxymethyl cellulose, 3% of styrene-butadiene emulsion and 5% of acetylene black were mixed and homogenized to obtain negative electrode slurry.

[0043]The preparation method of artificial graphite described therein is as follows:

[0044] (S.1) Preparation of polymer emul...

Embodiment 2

[0054] A method for preparing a water-based super nanometer lithium iron phosphate battery, said preparation method comprising the following steps:

[0055] (1) Preparation of positive and negative electrode slurry:

[0056] (1.1) Preparation of positive electrode slurry: Sand mill the lithium iron phosphate material to obtain lithium iron phosphate powder particles with D50≤4 μm, and then prepare it according to the formula: 94% of lithium iron phosphate powder particles, 5% of Ketjen black and 1% polytetrafluoroethylene emulsion is mixed and homogenized to obtain positive electrode slurry;

[0057] (1.2) Negative electrode slurry preparation: According to the formula: 95% artificial graphite, 1% carboxymethyl cellulose, 1% polytetrafluoroethylene emulsion and 3% Ketjen black were mixed and homogenized to obtain negative electrode slurry.

[0058] The preparation method of artificial graphite described therein is as follows:

[0059] (S.1) Preparation of polymer emulsion: a...

Embodiment 3

[0069] A method for preparing a water-based super nanometer lithium iron phosphate battery, said preparation method comprising the following steps:

[0070] (1) Preparation of positive and negative electrode slurry:

[0071] (1.1) Preparation of positive electrode slurry: Sand mill the lithium iron phosphate material to obtain lithium iron phosphate powder particles with D50≤4 μm, and then prepare it according to the formula: 92% of lithium iron phosphate powder particles, 4% of vapor phase growth carbon fiber and polyvinyl alcohol 4% to obtain positive electrode slurry after mixing and homogenizing;

[0072] (1.2) Negative electrode slurry preparation: According to the formula: 92% artificial graphite, 2% carboxymethyl cellulose, 2% polyvinyl alcohol and 4% vapor-phase grown carbon fiber were mixed and homogenized to obtain the negative electrode slurry.

[0073] The preparation method of artificial graphite described therein is as follows:

[0074] (S.1) Preparation of pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com