Nickel-hydrogen battery negative electrode hydrogen storage material capable of being used at low temperature and matched electrolytic solution thereof

A technology of hydrogen storage material and nickel-hydrogen battery, which is applied in the direction of nickel storage battery, alkaline storage battery electrode, alkaline storage battery, etc. Improve the effect of wide application temperature range and high low temperature electrochemical capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

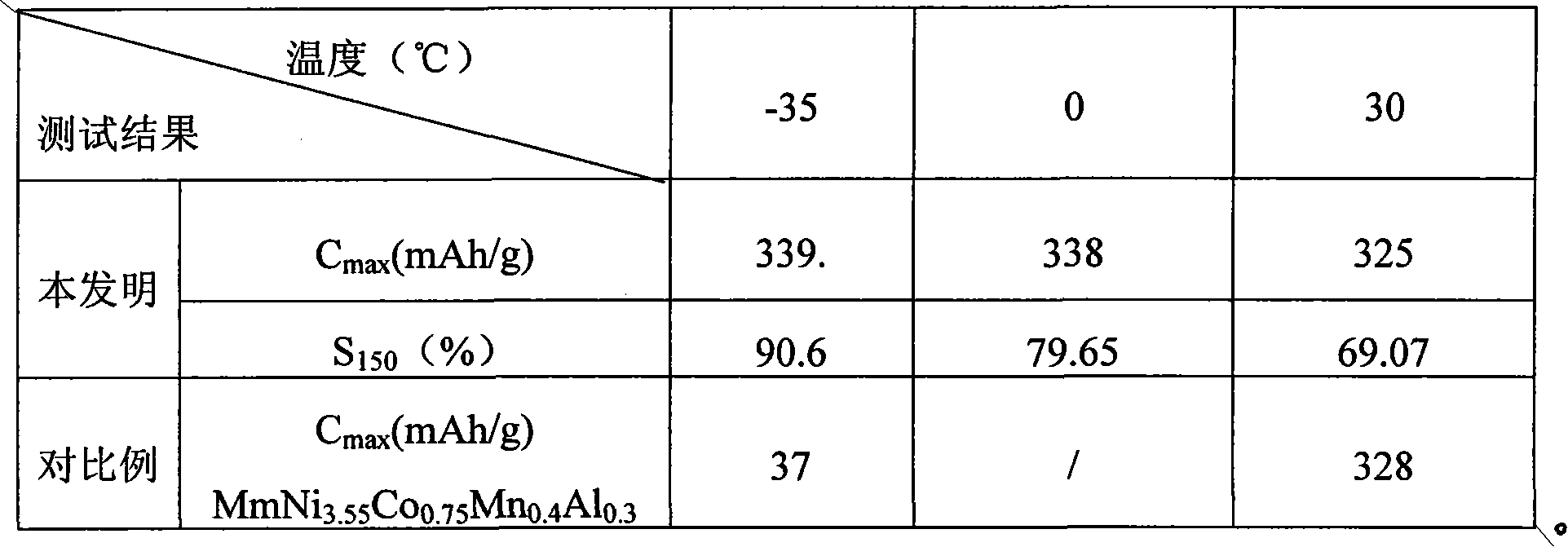

Embodiment 1

[0016] The anode hydrogen storage material that can be used for low-temperature nickel-hydrogen batteries described in this embodiment has a general chemical formula of RE x Mg 1-x Ni yx m z , wherein, RE=La, M=Co, Mn, x=1, y=3.785, z=1.213, according to the chemical formula LaNi 3.785 co 1.07 mn 0.143 Calculate the composition weight ratio, the raw materials La, Ni, Co, Mn have a purity of 99%, and then melt them in an argon-protected induction melting furnace to obtain alloy samples, grind them into alloy powders of less than 200 mesh at room temperature (ie 25°C), and implement as above Methods The negative electrode sheet was prepared for the electrode activation test at room temperature. After the activation process was completed, it was lowered to the test temperature, and the hydrogen storage alloy was charged for 6 hours at a charging current density of 60mA / g in the environment of -35°C, 0°C, and 30°C. , after standing for 5 minutes, then discharge to the cut-off...

Embodiment 2

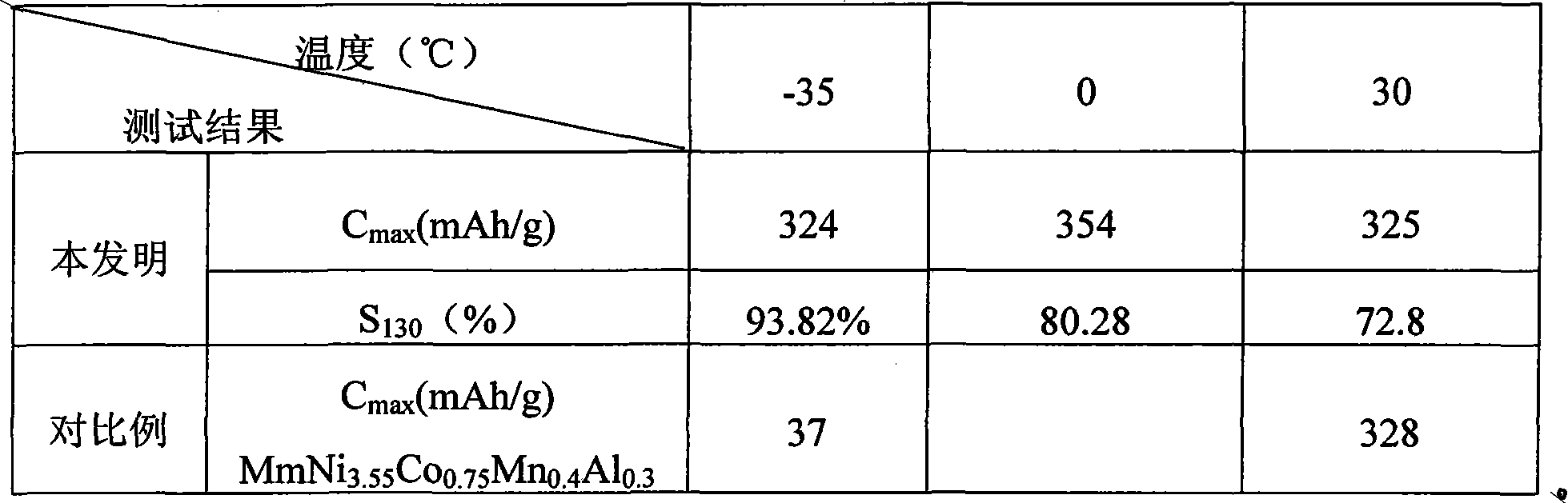

[0021] The negative electrode hydrogen storage material for the nickel-hydrogen battery described in this embodiment has a general chemical formula of RE x Mg 1-x Ni yx m z , RE=Ml (wherein Ml each part rare earth weight ratio is 80%La; 10%Ce; 10%Nd), M=Co, Mn; x=0.7, y=3.785, z=1.213, raw material is Ml, MgNi2 , Ni, Co, Mn, the master alloy Ml is first prepared by induction melting according to the atomic ratio 0.7 Ni 2.05 co 0.75 mn 0.1 , and then in an argon-protected induction melting furnace with Ml 0.7 Ni 2.05 co 0.75 mn 0.1 with MgNi 2 According to chemical formula Ml 0.7 Mg 0.3 Ni 2.65 co 0.75 mn 0.1 Calculate the composition weight ratio and smelt the alloy sample, grind it into alloy powder less than 200 mesh at room temperature (ie 25°C), prepare the negative electrode sheet according to the above implementation method, and conduct the electrode activation test at room temperature. After the activation process is completed, lower it to the test temper...

Embodiment 3

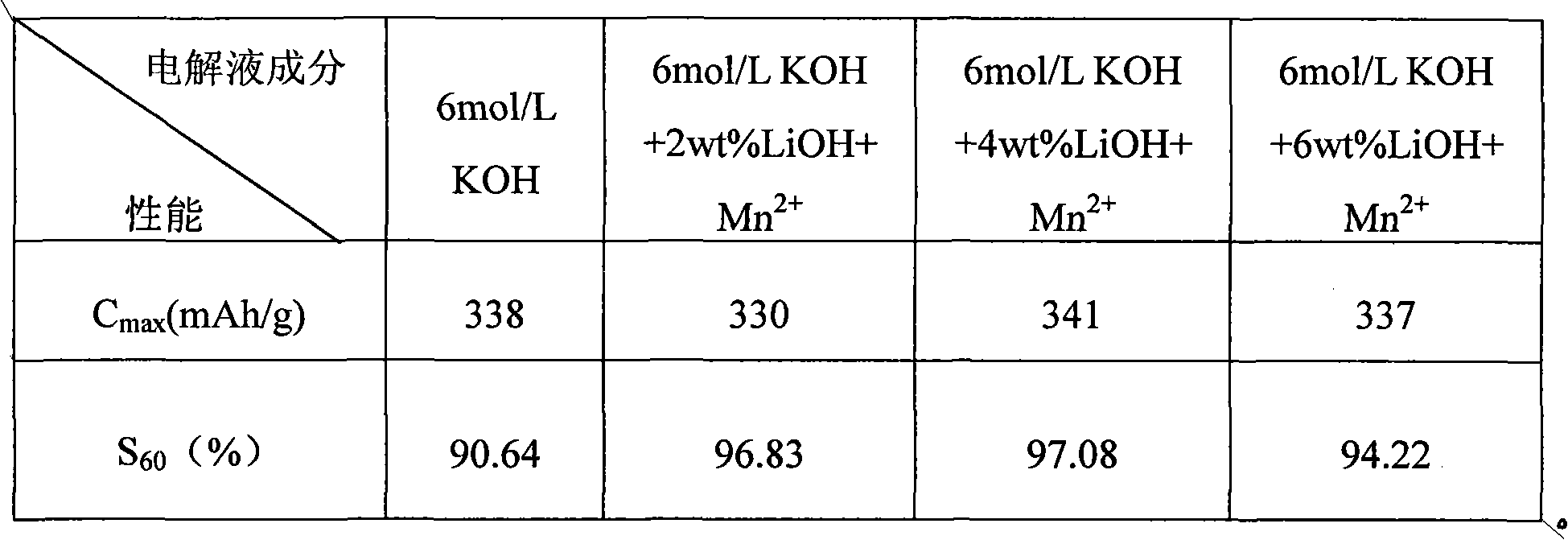

[0026] The electrolyte suitable for the negative electrode hydrogen storage material of the present invention is to add 0-6wt% LiOH and an appropriate amount of MnSO into a 6 mol / liter KOH solution 4 Make Mn 2+ Reaching saturation in the electrolyte, the role of LiOH is that Li can be adsorbed on Ni(OH) 2 The surface of the particles prevents the particles from growing and agglomerating, and improves the utilization rate of the electrode active material. At the same time, Li + It can also prevent electrode expansion, improve the reversibility of electrode reaction, strengthen the oxygen evolution polarization during electrode charging, prolong the service life of electrodes, etc.; saturate Mn 2+ The function is to inhibit the dissolution of the corresponding metal manganese in the negative electrode alloy, improve the utilization rate of the active material, and reduce the capacity loss. Place the electrode sheet prepared in Example 1 in the electrolyte of this example at ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com